oil type LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 96 of 1007

GENERAL DATA

04-33

Heating and Ventilation

Air Conditioning

PTC heater - Td4 engine - if fitted

⇒ Make/Type Catem, 900 Watt output, 12 volt supply, located in Hevac unit

FBH - Td4 engine - if fitted

⇒ Make/Type Webasto Thermotop C, self-regulating, 5 kW output

System CFC free, sealed, closed-loop system

Refrigerant HFC - R134a

Refrigerant charge quantity:

All models except LHD KV6

LHD KV6 models540 ± 25 grammes

430 ± 25 grammes

Compressor, up to 04MY (some very early 04MY

vehicles may be fitted with this type of compressor):

⇒ Type Denso - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 5%

⇒ Displacement (Max.) 95%

Compressor, 04MY onwards

⇒ Type Sanden PXV16 - variable displacement, 7-cylinder swash plate unit

⇒ High Pressure Blow-off valve 35.3 bar (3.53 MPa, 512 lbf/in

2)

⇒ Displacement (Min.) 3%

⇒ Displacement (Max.) 100%

Lubricating oil Nippon Denso ND-8

Evaporator thermostat:

⇒ Opens

⇒ Closes+2 °C (+36 °F)

-4 °C (+25 °F)

Condenser fan control PWM signal from ECM to cooling fan control unit

Refrigerant Pressure Sensor

Low pressure limit:

⇒ A/C on (pressure rising) 2.25 ± 0.2 bar (32.6 ± 2.9 lbf/in

2)

⇒ A/C off (pressure falling) 1.96 ± 0.2 bar (28.4 ± 2.9 lbf/in

2)

High pressure limit:

⇒ A/C off (pressure rising) 31.4 ± 2.0 bar (455.3 ± 29 lbf/in

2)

⇒ A/C on (pressure falling) 25.5 ± 2.0 bar (369.8 ± 29 lbf/in

2)

Page 145 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

Fluids

Fuel

Always use the following recommended fuels:

Petrol engines

Use unleaded petrol with a minimum octane rating of

95 RON to ENN 228 specification.

In an emergency (and only if the correct fuel is

unavailable), lower octane rated fuel can be used for

very limited periods of moderate, low speed

motoring, provided engine 'knocking' does not occur.

Fuels of 90 RON is used in certain markets; 90 RON

fuel can be used regularly ONLY if the engine has

been tuned specifically to suit low octane fuel.

Certain markets use fuel containing a 23% Ethanol

additive.

K1.8 and KV6 engines are also available for use with

a low octane leaded fuel specification in some

markets.

Diesel engines

Use a good quality diesel fuel or automotive gas oil

(AGO) conforming to EN 590 specification.

It is important that the sulphur content of diesel fuel

does not exceed 0.3%.

Ensure the fuel filter element is changed at the

recommended intervals.

+ MAINTENANCE, MAINTENANCE, Fuel

Filter - Diesel.

Brake Fluid

Use only DOT 4 brake fluid. DO NOT use brake fluid

of a different specification.

PAS fluid

Use Texaco 9226 fluid.Anti-freeze solutions

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system.

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze

solution at the intervals given on the Service

Maintenance Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

The following recommended quantities of anti-freeze

will provide frost protection to -36 °C (-33 °F):

Engine – Td4

Engine – K1.8

Engine – KV6

Concentration 50%

Amount of anti-freeze 3.75 litres

(6.625 imp. pts)

Concentration 50%

Amount of anti-freeze 2.9 litres

(5.125 imp. pts)

Concentration 50%

Amount of anti-freeze 3.9 litres

(6.875 imp. pts, )

Page 888 of 1007

AIR CONDITIONING

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING 82-1

AIR CONDITIONING REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

Refrigerant recovery - recycling and

recharge

$% 82.30.02

Refrigerant recovery

WARNING: Servicing must only be carried

out by personnel familiar with both the

vehicle system and the charging and testing

equipment. All operations must be carried

out in a well ventilated area away from open

flame and heat sources.

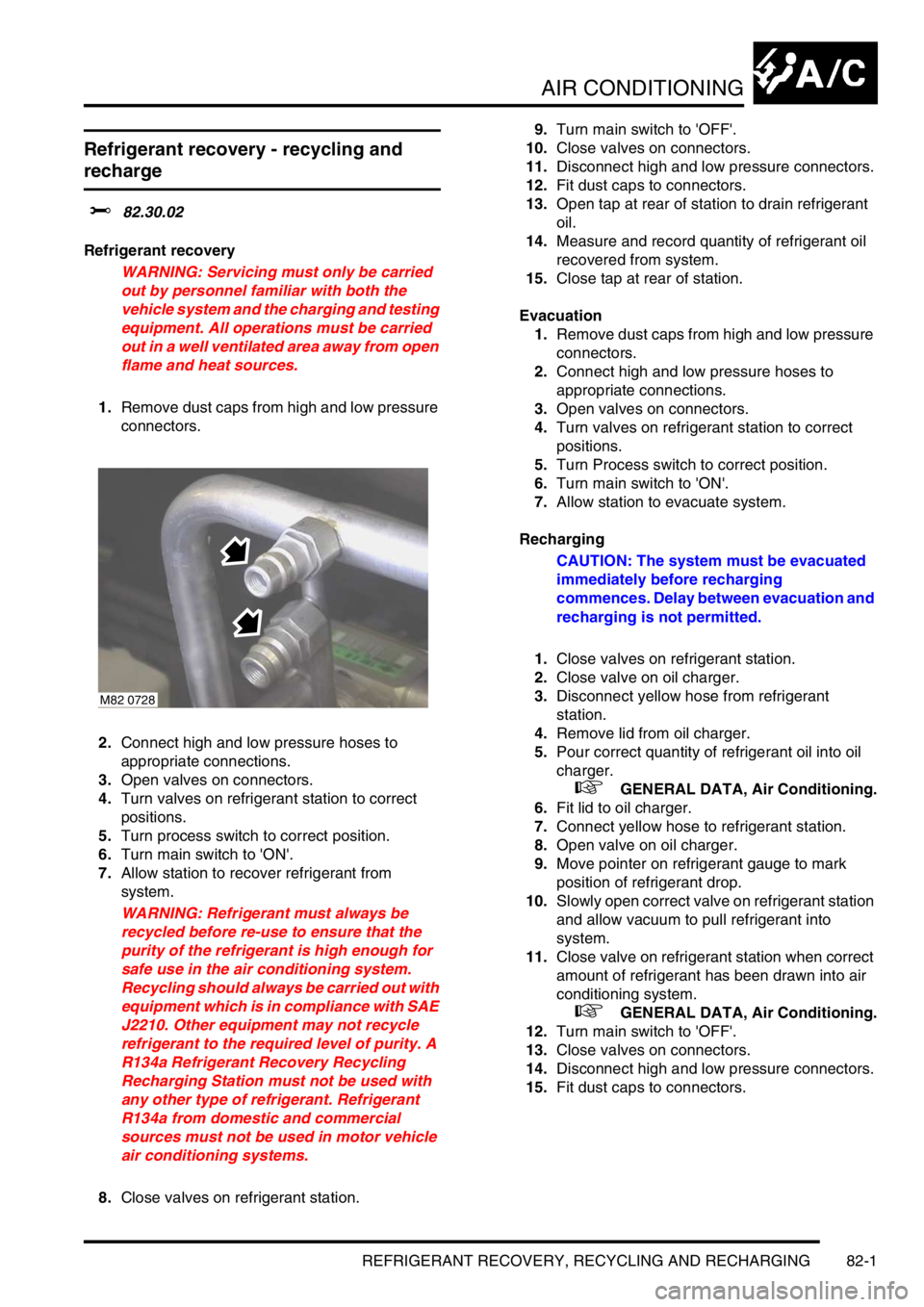

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to recover refrigerant from

system.

WARNING: Refrigerant must always be

recycled before re-use to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system.

Recycling should always be carried out with

equipment which is in compliance with SAE

J2210. Other equipment may not recycle

refrigerant to the required level of purity. A

R134a Refrigerant Recovery Recycling

Recharging Station must not be used with

any other type of refrigerant. Refrigerant

R134a from domestic and commercial

sources must not be used in motor vehicle

air conditioning systems.

8.Close valves on refrigerant station.9.Turn main switch to 'OFF'.

10.Close valves on connectors.

11.Disconnect high and low pressure connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant

oil.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to evacuate system.

Recharging

CAUTION: The system must be evacuated

immediately before recharging

commences. Delay between evacuation and

recharging is not permitted.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant

station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

+ GENERAL DATA, Air Conditioning.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into

system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

+ GENERAL DATA, Air Conditioning.

12.Turn main switch to 'OFF'.

13.Close valves on connectors.

14.Disconnect high and low pressure connectors.

15.Fit dust caps to connectors.

M82 0728