steering LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 149 of 1007

MAINTENANCE

10-2 MAINTENANCE

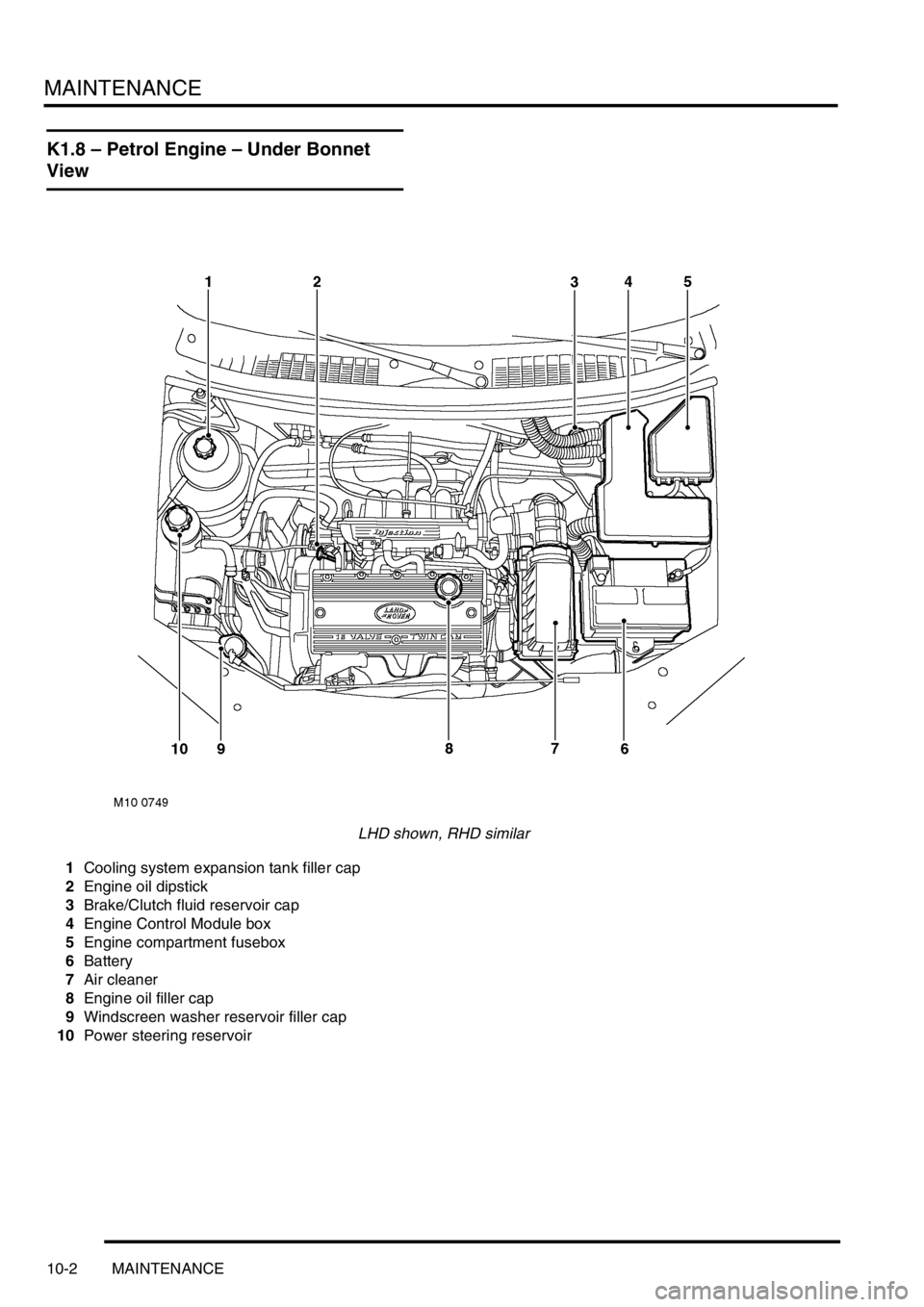

K1.8 – Petrol Engine – Under Bonnet

View

LHD shown, RHD similar

1Cooling system expansion tank filler cap

2Engine oil dipstick

3Brake/Clutch fluid reservoir cap

4Engine Control Module box

5Engine compartment fusebox

6Battery

7Air cleaner

8Engine oil filler cap

9Windscreen washer reservoir filler cap

10Power steering reservoir

Page 150 of 1007

MAINTENANCE

MAINTENANCE 10-3

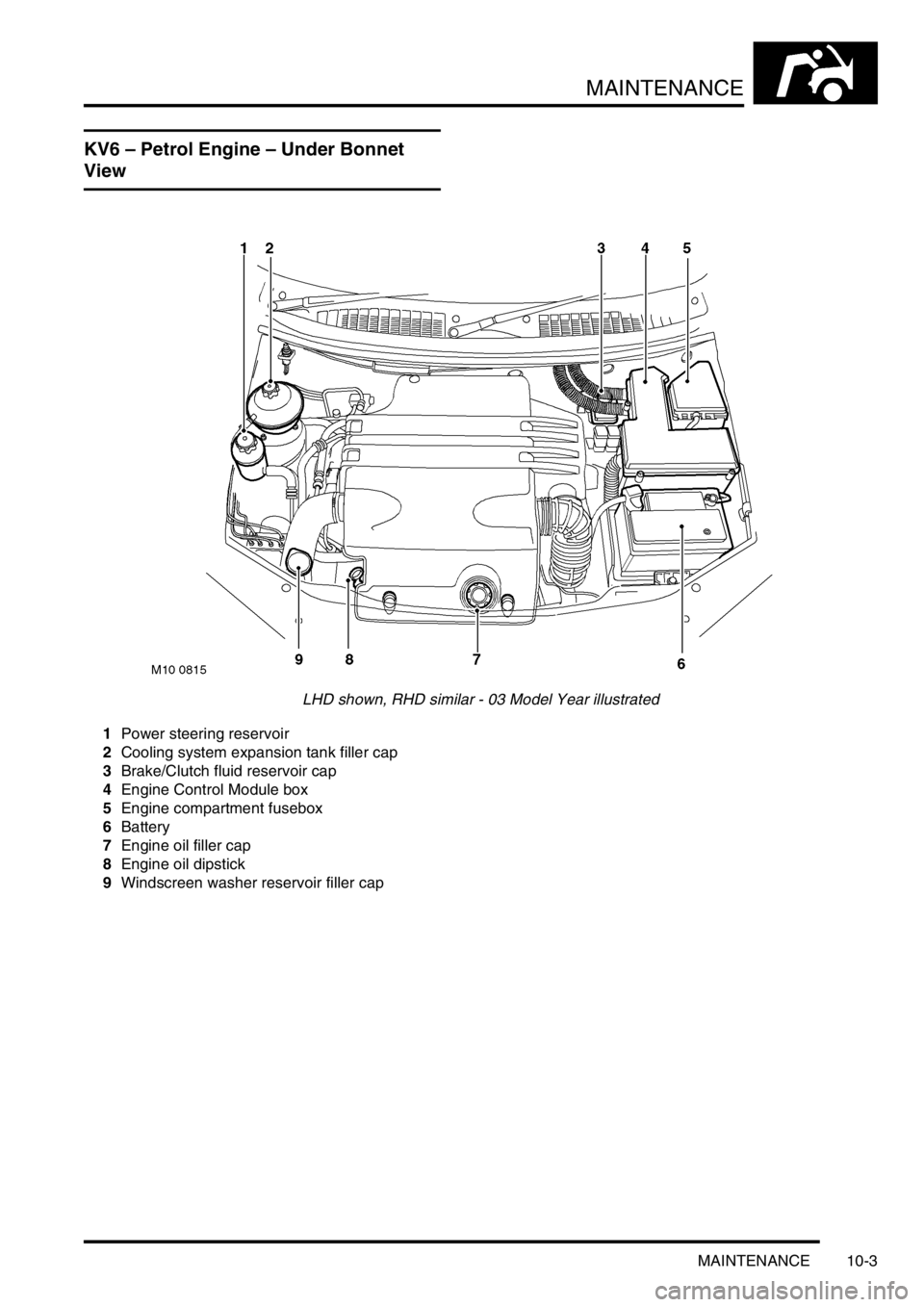

KV6 – Petrol Engine – Under Bonnet

View

LHD shown, RHD similar - 03 Model Year illustrated

1Power steering reservoir

2Cooling system expansion tank filler cap

3Brake/Clutch fluid reservoir cap

4Engine Control Module box

5Engine compartment fusebox

6Battery

7Engine oil filler cap

8Engine oil dipstick

9Windscreen washer reservoir filler cap

Page 154 of 1007

MAINTENANCE

MAINTENANCE 10-7

Tyres

Check

1.Check for any apparent damage to tyres,

paying particular attention to side walls.

2.Look at tyre treads and check for any unusual

wear patterns which may indicate out of

specification adjustment of steering or

suspension.

NOTE: Any adjustments to steering or

suspension will be subject to additional labour

and/or material cost and should not be carried

out without the authorisation of the customer.

3.Measure the tread depth across the width of the

tyre and around the circumference. Annotate

the maintenance check sheet with the lowest

figure obtained from each tyre.

NOTE: Any requirement to replace tyres should

be advised to the customer before any remedial

work is carried out. This will be subject to

additional labour and/or material cost and

should not be carried out without the

authorisation of the customer.

CAUTION: If new tyres are to be fitted,

ensure that they are fitted to the rear axle

only or to both front and rear axles. DO NOT

fit new tyres to front axle only.

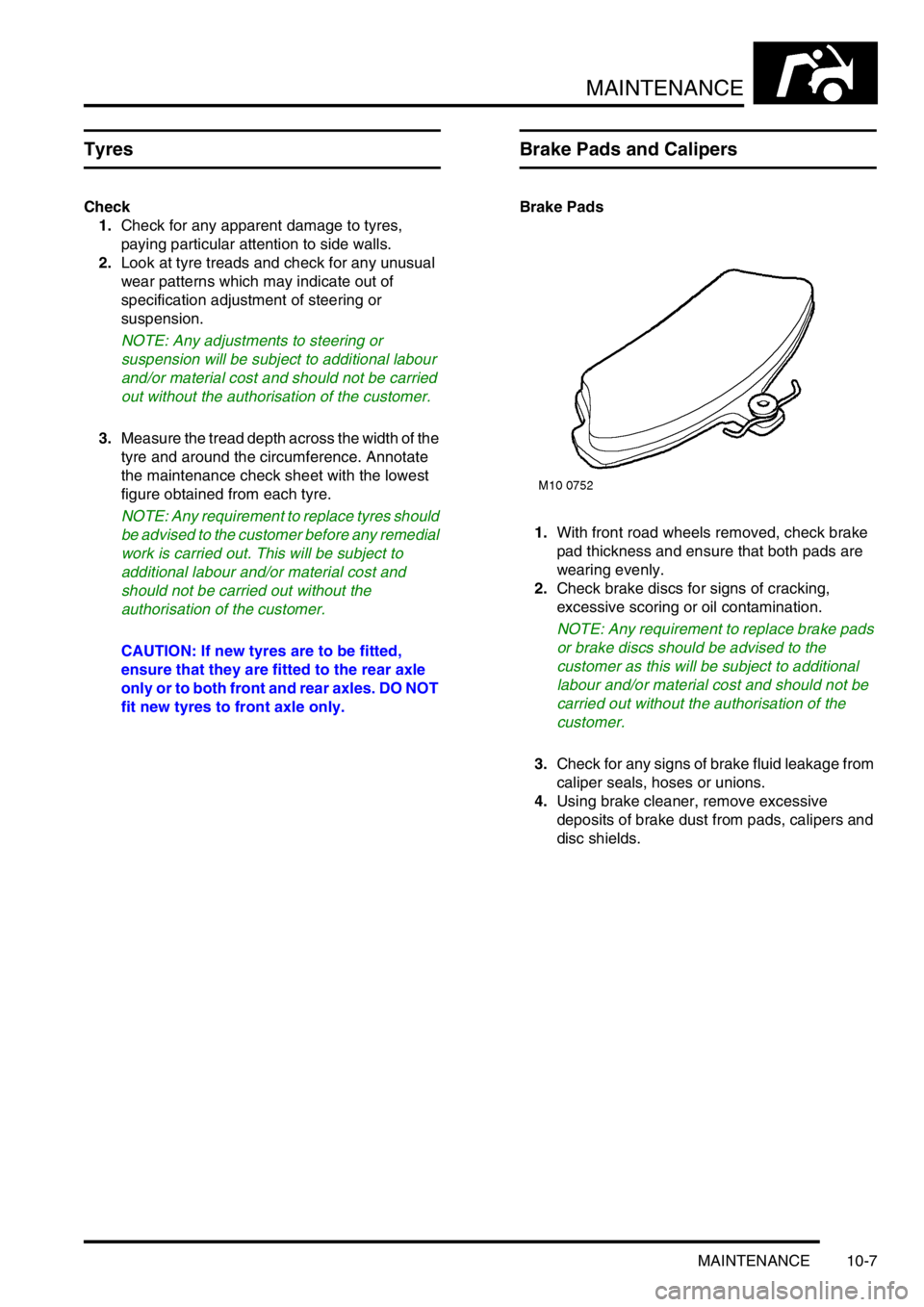

Brake Pads and Calipers

Brake Pads

1.With front road wheels removed, check brake

pad thickness and ensure that both pads are

wearing evenly.

2.Check brake discs for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirement to replace brake pads

or brake discs should be advised to the

customer as this will be subject to additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

3.Check for any signs of brake fluid leakage from

caliper seals, hoses or unions.

4.Using brake cleaner, remove excessive

deposits of brake dust from pads, calipers and

disc shields.

Page 164 of 1007

MAINTENANCE

MAINTENANCE 10-17

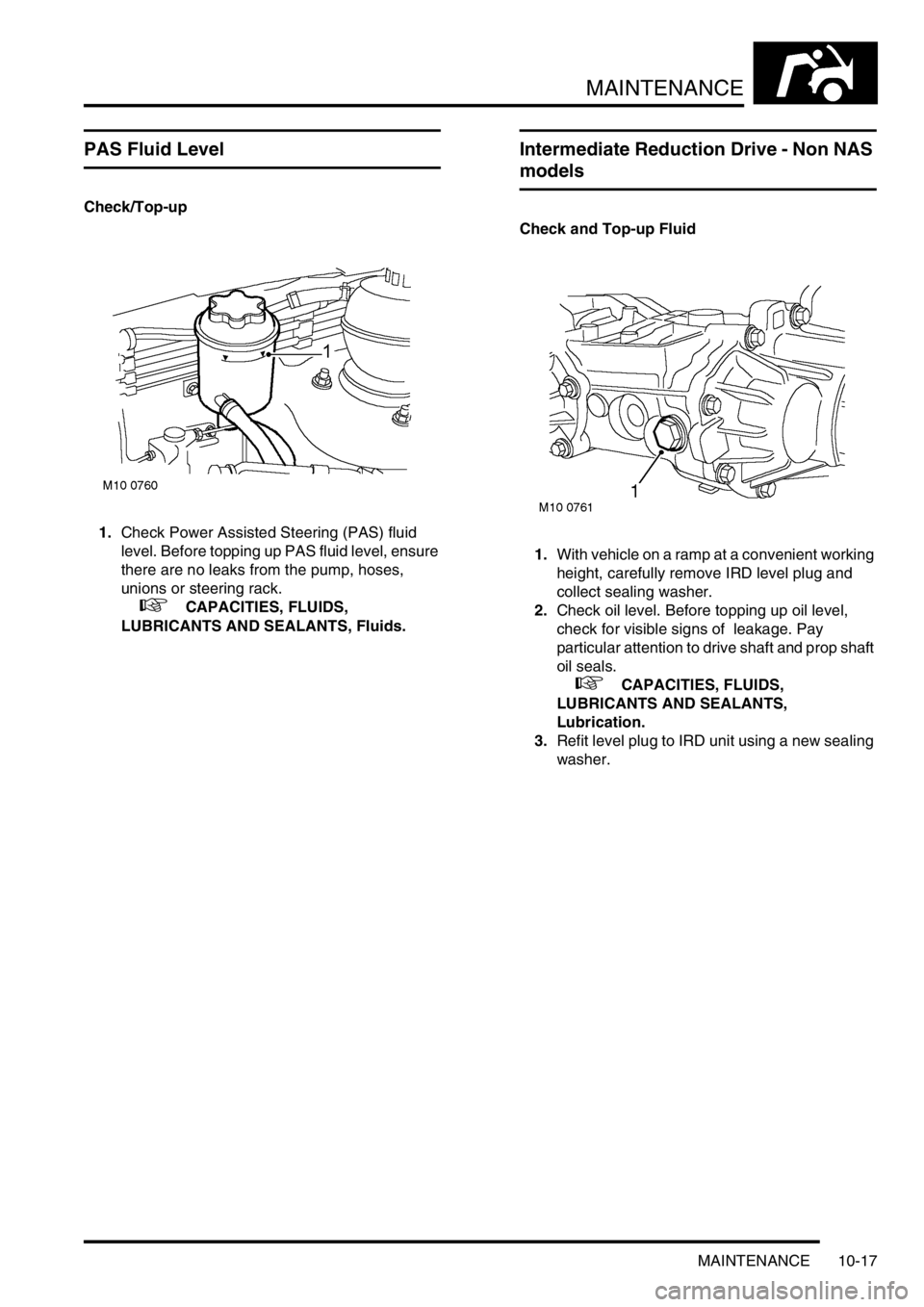

PAS Fluid Level

Check/Top-up

1.Check Power Assisted Steering (PAS) fluid

level. Before topping up PAS fluid level, ensure

there are no leaks from the pump, hoses,

unions or steering rack.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

Intermediate Reduction Drive - Non NAS

models

Check and Top-up Fluid

1.With vehicle on a ramp at a convenient working

height, carefully remove IRD level plug and

collect sealing washer.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft and prop shaft

oil seals.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Refit level plug to IRD unit using a new sealing

washer.

Page 175 of 1007

MAINTENANCE

10-28 MAINTENANCE

Steering

Check

1.Check/tighten steering unit and steering rod

ball joint fixings.

2.Check condition of ball joints and dust covers.

3.Check steering rack bellows for any signs of

leakage.

Road Test

There are two purposes for conducting a road test.

Firstly, to ensure the work completed within the

dealership meets the standards required as laid

down by dealership processes. Secondly, for a

skilled technician to assess the general condition of

the vehicle and report any conditions that the

customer should be made aware of.

CAUTION: Two wheel dynamometer tests must

not be carried out. Four wheel dynamometer

tests must be restricted to 3 mph (5 kph).

Engine Start

1.Check for correct operation of starter switch.

Ensure the engine starts in a correct manner.

Leave the engine running.

Starter Inhibitor Switch – (Automatic only)

1.Select 'D' gear lever position.

2.Check that engine will not start.

3.Select 'R' gear lever position and repeat start

check.

4.Check that engine will start in 'P' and 'N'

positions.

Selector Cable – (Automatic only)

1.Check for correct setting of gear selector cable.

Engine Performance and Throttle Operation

1.Start engine and check that it starts easily.

2.Check that 'oil pressure' and 'no charge'

warning lamps extinguish.

3.Check that throttle pedal movement is free and

unrestricted.

4.Check that engine is responsive to throttle

movement.

Clutch and Gear Selection –

(Manual only, normal driving conditions)

1.Check that clutch engages smoothly without

judder, slipping or noise.

2.Check for abnormal transmission noise.

3.Check for smooth quiet gear changes and that

gear selected engages easily.

Page 176 of 1007

MAINTENANCE

MAINTENANCE 10-29

Gear Change and Parking Pawl Engagement –

(Automatic only, normal driving conditions)

1.Select 'R' and check for smooth take up.

2.Select 'D' and check for smooth up-changes of

ratio from rest.

3.Slow down vehicle and check for smooth down-

changes of ratio.

4.Stop vehicle on a slope.

5.Select 'P' and release handbrake.

6.Check that vehicle does not move and that

selector does not slip out of 'P'.

7.Carry out a similar check with vehicle facing in

the opposite direction.

Steering

1.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

Suspension

1.Check for noise, irregularity in ride (e.g.

dampers) and wheel imbalance.

Foot brake

1.Check for pedal effort, travel, braking

efficiency, pulling and binding.

Handbrake

1.Apply handbrake firmly, check travel and

ratchet hold and release.

Instruments

1.Check for correct operation of all instruments

and warning devices where practical.

Body

1.Check for abnormal body noise.

Seat Belts

1.Check for operation of inertia reels.Road Test

1.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

lEngine noise

lGearbox noise

lSuspension noise

lBody noise

lBraking system operation

lGear selection

lEngine performance

2.Where possible, check for correct operation of

Hill Descent Control (HDC) system. This should

not be carried out if excessive journey time is

required.

3.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

4.Check all underbonnet fluid levels and top-up if

necessary.

Page 207 of 1007

ENGINE - K SERIES KV6

12-3-30 REPAIRS

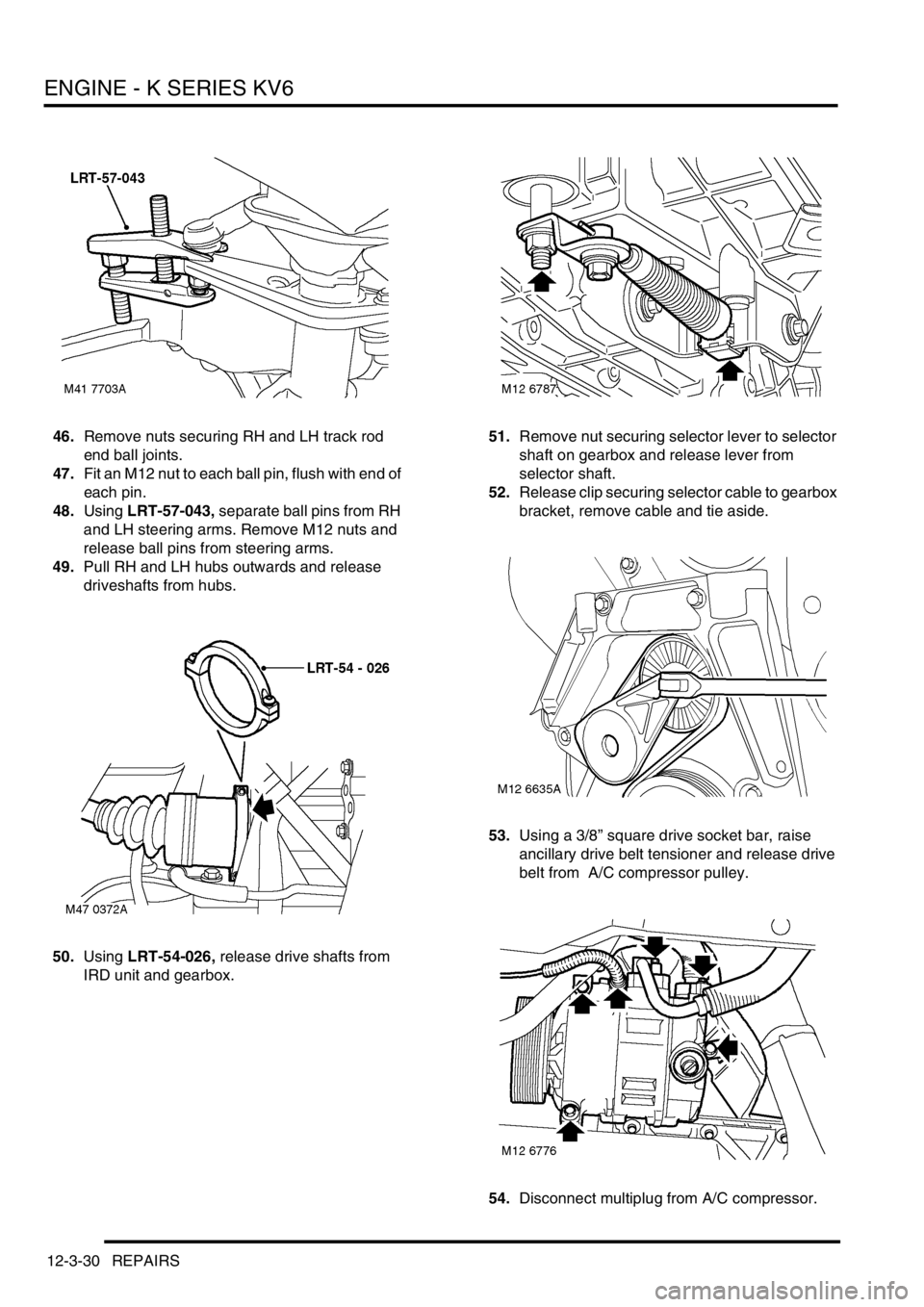

46.Remove nuts securing RH and LH track rod

end ball joints.

47.Fit an M12 nut to each ball pin, flush with end of

each pin.

48.Using LRT-57-043, separate ball pins from RH

and LH steering arms. Remove M12 nuts and

release ball pins from steering arms.

49.Pull RH and LH hubs outwards and release

driveshafts from hubs.

50.Using LRT-54-026, release drive shafts from

IRD unit and gearbox.51.Remove nut securing selector lever to selector

shaft on gearbox and release lever from

selector shaft.

52.Release clip securing selector cable to gearbox

bracket, remove cable and tie aside.

53.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and release drive

belt from A/C compressor pulley.

54.Disconnect multiplug from A/C compressor.

Page 210 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-33

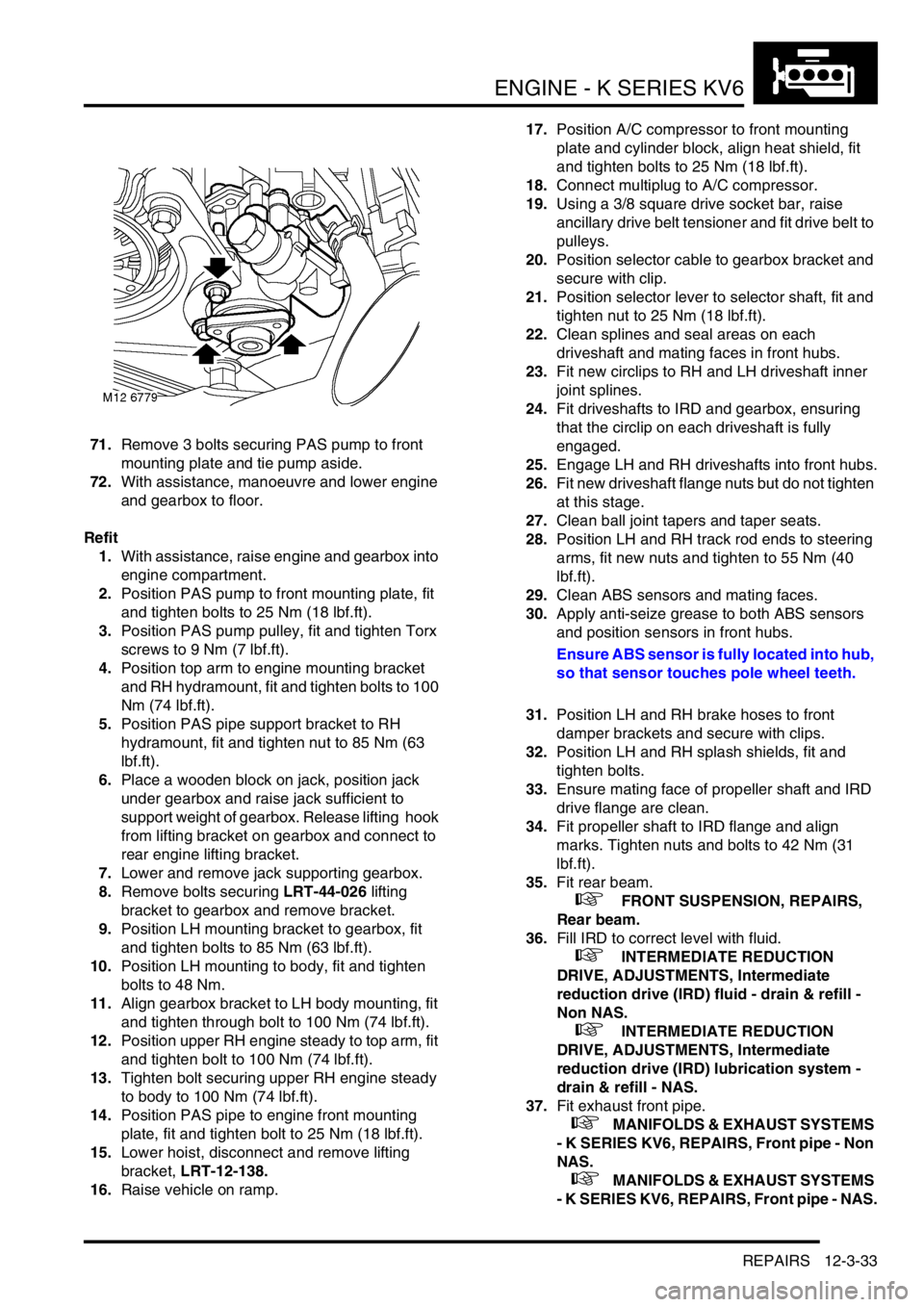

71.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

72.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm (18 lbf.ft).

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm (74 lbf.ft).

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm (63

lbf.ft).

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.

8.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm (18 lbf.ft).

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on ramp.17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

18.Connect multiplug to A/C compressor.

19.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm (18 lbf.ft).

22.Clean splines and seal areas on each

driveshaft and mating faces in front hubs.

23.Fit new circlips to RH and LH driveshaft inner

joint splines.

24.Fit driveshafts to IRD and gearbox, ensuring

that the circlip on each driveshaft is fully

engaged.

25.Engage LH and RH driveshafts into front hubs.

26.Fit new driveshaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm (40

lbf.ft).

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

Ensure ABS sensor is fully located into hub,

so that sensor touches pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

Page 217 of 1007

ENGINE - K SERIES KV6

12-3-40 REPAIRS

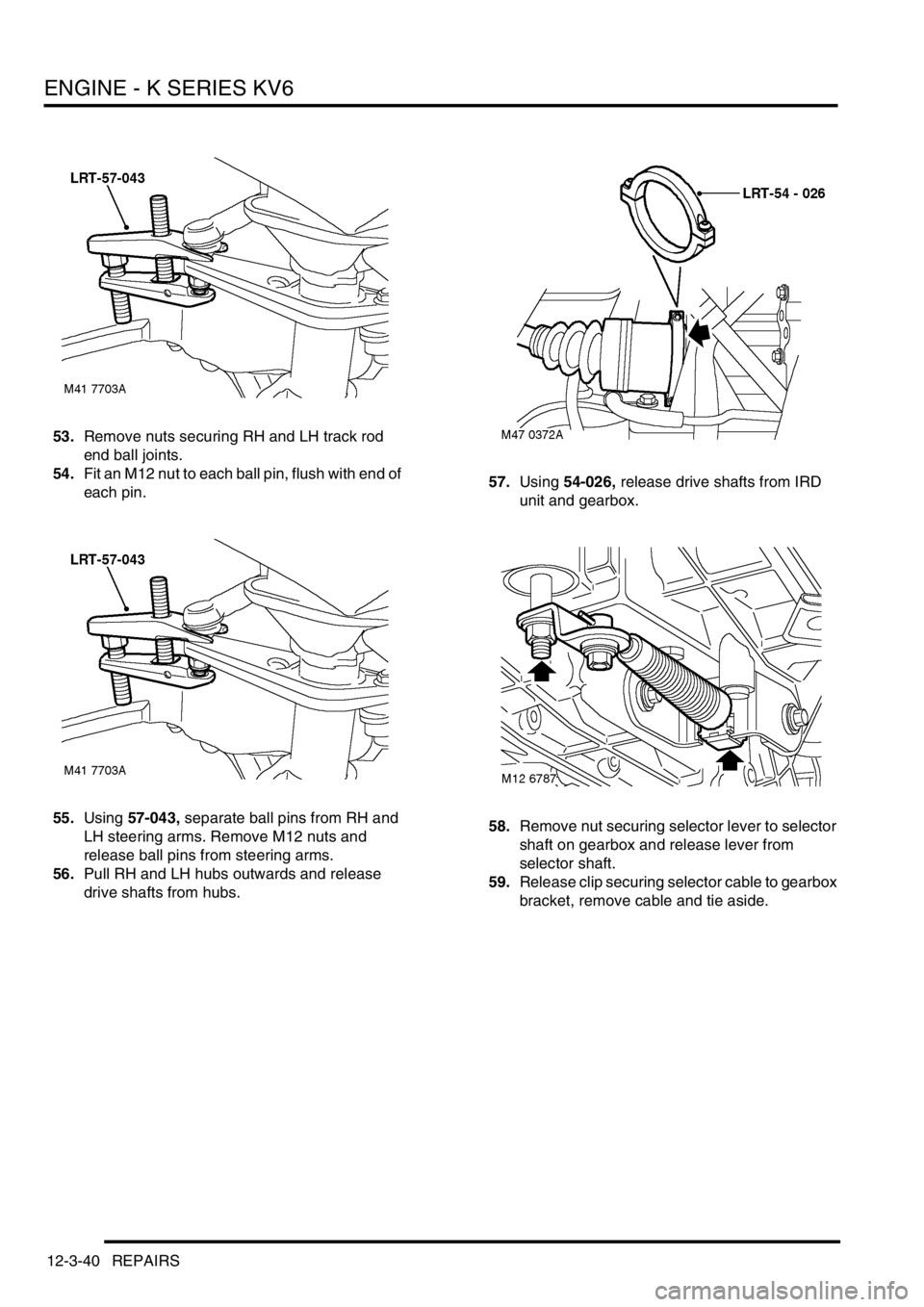

53.Remove nuts securing RH and LH track rod

end ball joints.

54.Fit an M12 nut to each ball pin, flush with end of

each pin.

55.Using 57-043, separate ball pins from RH and

LH steering arms. Remove M12 nuts and

release ball pins from steering arms.

56.Pull RH and LH hubs outwards and release

drive shafts from hubs.57.Using 54-026, release drive shafts from IRD

unit and gearbox.

58.Remove nut securing selector lever to selector

shaft on gearbox and release lever from

selector shaft.

59.Release clip securing selector cable to gearbox

bracket, remove cable and tie aside.

Page 220 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-43

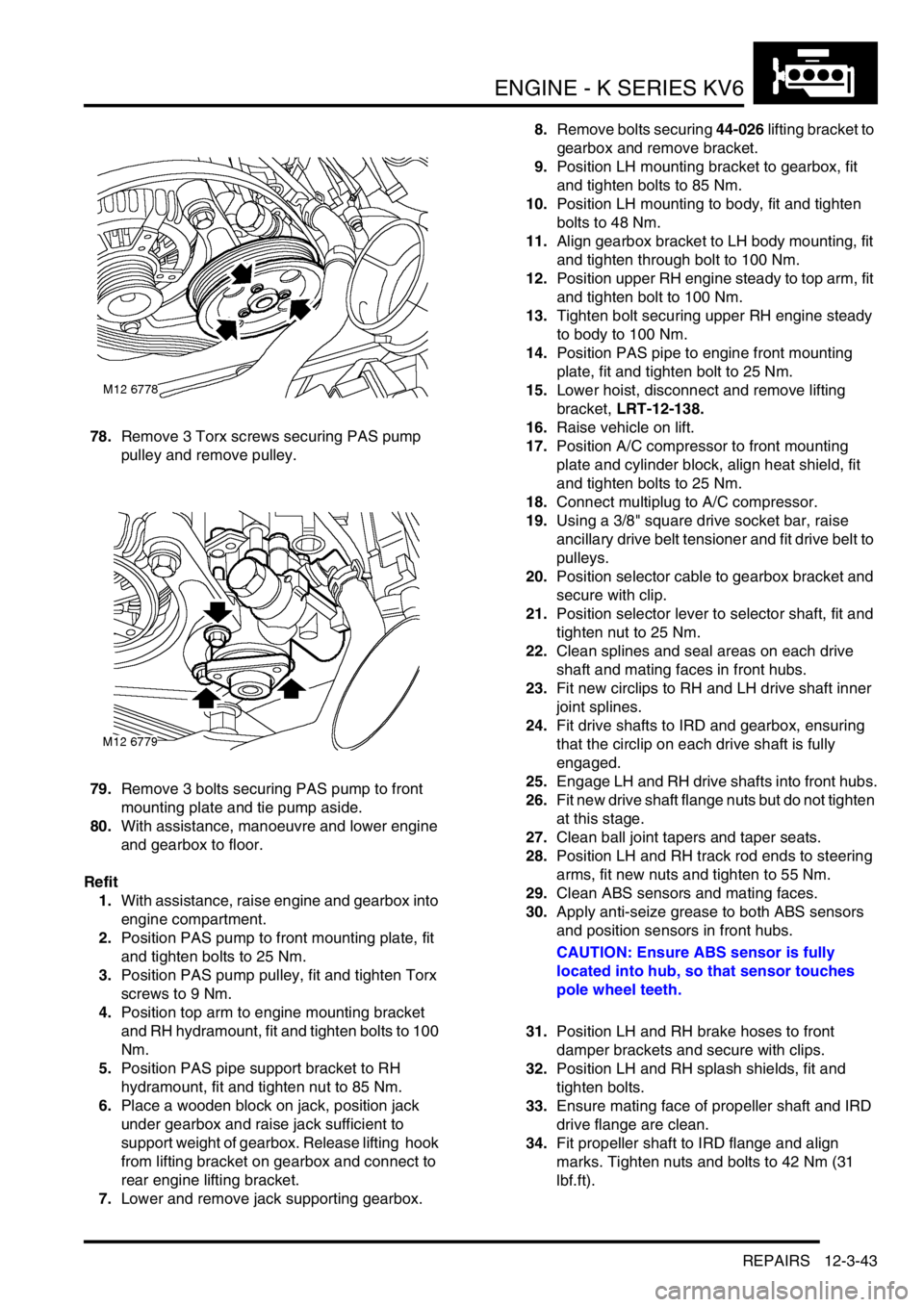

78.Remove 3 Torx screws securing PAS pump

pulley and remove pulley.

79.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

80.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm.

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm.

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm.

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm.

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.8.Remove bolts securing 44-026 lifting bracket to

gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm.

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm.

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm.

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm.

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm.

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on lift.

17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm.

18.Connect multiplug to A/C compressor.

19.Using a 3/8" square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm.

22.Clean splines and seal areas on each drive

shaft and mating faces in front hubs.

23.Fit new circlips to RH and LH drive shaft inner

joint splines.

24.Fit drive shafts to IRD and gearbox, ensuring

that the circlip on each drive shaft is fully

engaged.

25.Engage LH and RH drive shafts into front hubs.

26.Fit new drive shaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm.

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).