brakes LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 580 of 1007

BRAKES

REPAIRS 70-31

Refit

1.Position modulator to mounting bracket fit bolts

and tighten to 9 Nm (7 lbf.ft).

2.Clean brake pipe unions.

3.Connect brake pipe unions to modulator

ensuring pipes are connected to their correct

ports.

4.Tighten unions to 17 Nm (12 lbf.ft).

5.Connect ABS modulator multiplug and secure

catch.

6. Td4 and KV6 models: Position air intake duct

to body.

7. Td4 and KV6 models: Secure intake duct to

washer bottle filler neck and harness clip.

8. Td4 and KV6 models: Fit air intake hose.

9.Fit PAS reservoir to mounting bracket.

10.Fit bolts securing PAS oil cooler pipes and

tighten to 10 Nm (7.5 lbf.ft).

11. Td4 models: Fit intercooler outlet hose and

tighten clips.

12. Td4 and KV6 models: Fit engine accoustic

cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

13.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

14.To ensure correct operation, the ABS system

MUST be tested using TestBook/T4.

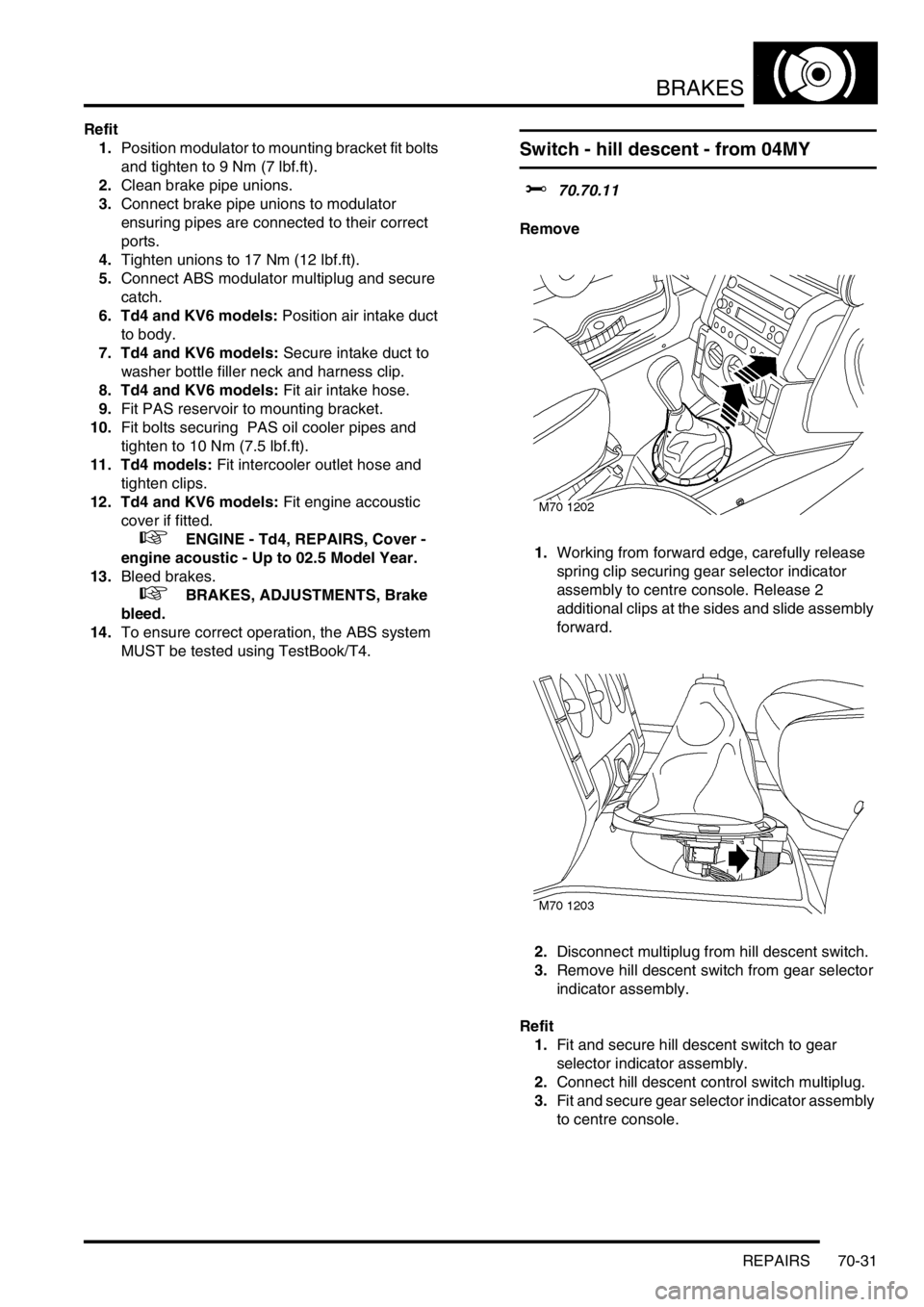

Switch - hill descent - from 04MY

$% 70.70.11

Remove

1.Working from forward edge, carefully release

spring clip securing gear selector indicator

assembly to centre console. Release 2

additional clips at the sides and slide assembly

forward.

2.Disconnect multiplug from hill descent switch.

3.Remove hill descent switch from gear selector

indicator assembly.

Refit

1.Fit and secure hill descent switch to gear

selector indicator assembly.

2.Connect hill descent control switch multiplug.

3.Fit and secure gear selector indicator assembly

to centre console.

Page 581 of 1007

BRAKES

70-32 REPAIRS

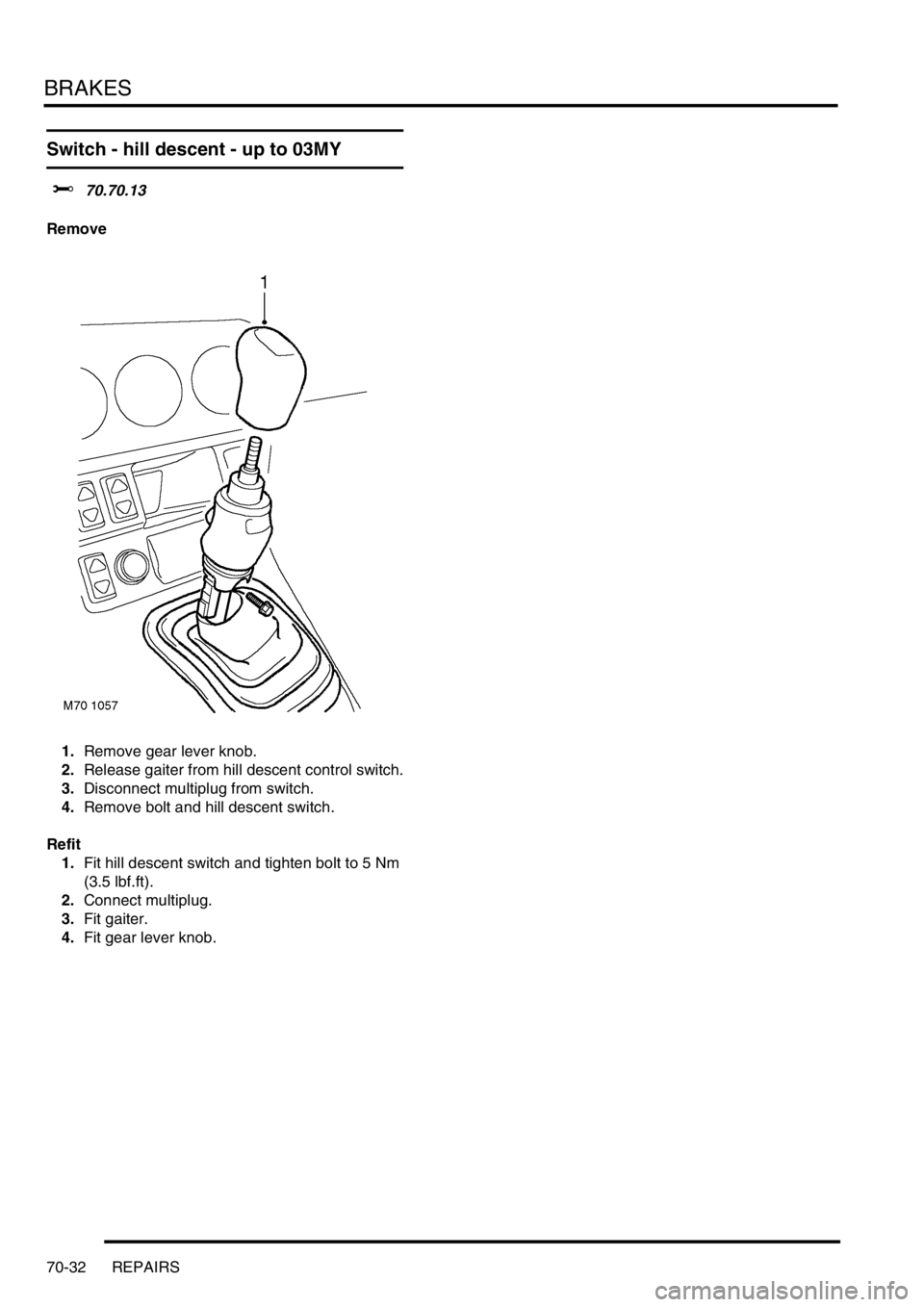

Switch - hill descent - up to 03MY

$% 70.70.13

Remove

1.Remove gear lever knob.

2.Release gaiter from hill descent control switch.

3.Disconnect multiplug from switch.

4.Remove bolt and hill descent switch.

Refit

1.Fit hill descent switch and tighten bolt to 5 Nm

(3.5 lbf.ft).

2.Connect multiplug.

3.Fit gaiter.

4.Fit gear lever knob.

Page 789 of 1007

PANEL REPAIRS

77-2-34 REPAIRS

26. LH side: Remove LH engine mounting from

body.

27. LH side: On models with Diesel engines,

remove fuel filter.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Filter - main - up to 03MY.

28. LH side: Remove LH front brake pipe.

29. RH side: Remove front bumper RH support

bracket.

30. RH side: Remove windscreen washer

reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

31. RH side: Remove coolant expansion tank.

32. RH side: Remove RH engine mounting from

body.

33. RH side: Remove PAS fluid reservoir.

34. RH side: Remove RH front brake pipe.

35. Driver's side: Remove passenger

compartment fuse box.

36.Remove brake pedal box and brake servo.

37.Remove clutch pedal box.

38.Release vehicle harness from valance and

position aside.

39.Remove treadplate from front door aperture.

Release front carpet and position aside.

40.Remove insulation pads from engine bulkhead.

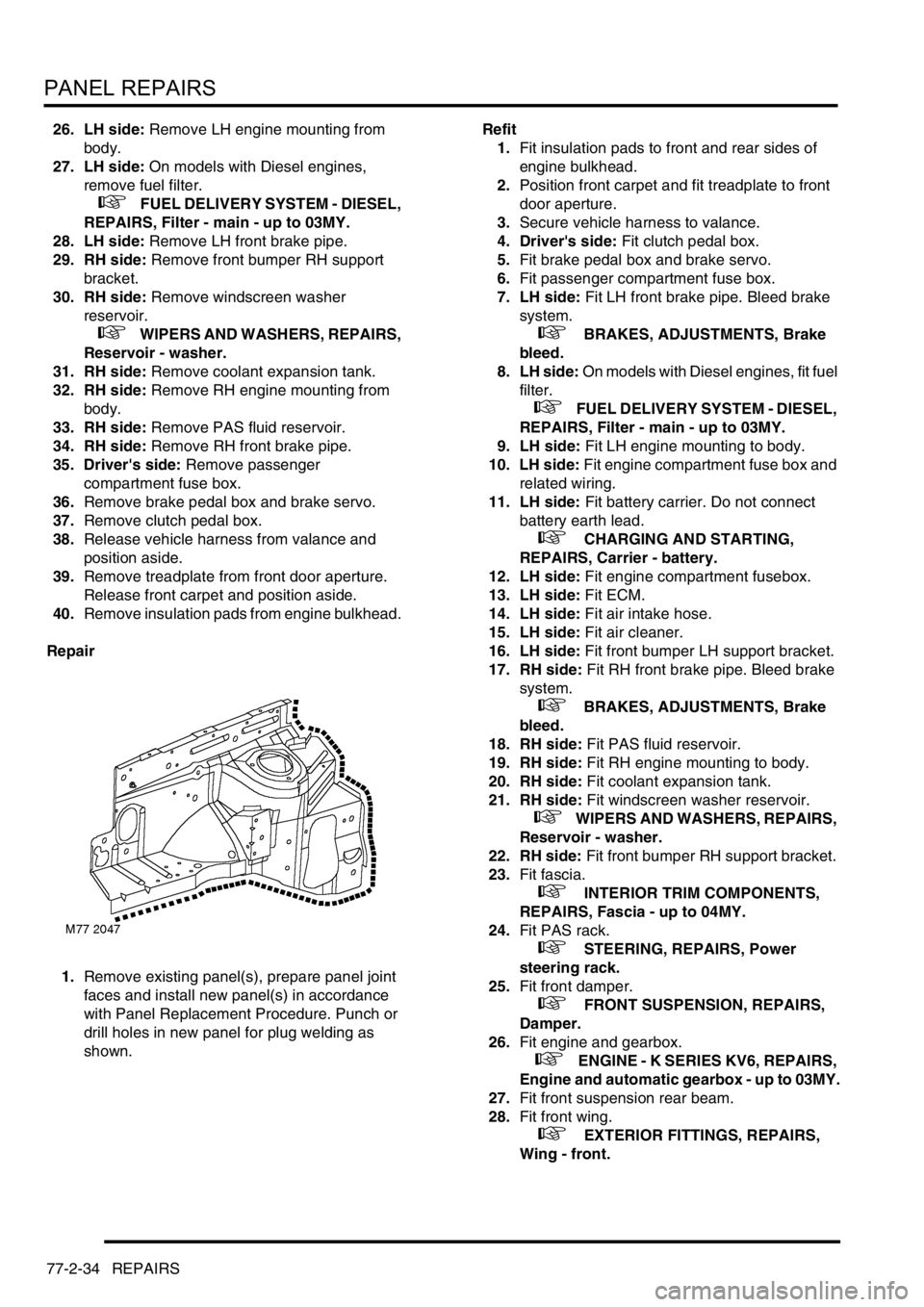

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Refit

1.Fit insulation pads to front and rear sides of

engine bulkhead.

2.Position front carpet and fit treadplate to front

door aperture.

3.Secure vehicle harness to valance.

4. Driver's side: Fit clutch pedal box.

5.Fit brake pedal box and brake servo.

6.Fit passenger compartment fuse box.

7. LH side: Fit LH front brake pipe. Bleed brake

system.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

8. LH side: On models with Diesel engines, fit fuel

filter.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Filter - main - up to 03MY.

9. LH side: Fit LH engine mounting to body.

10. LH side: Fit engine compartment fuse box and

related wiring.

11. LH side: Fit battery carrier. Do not connect

battery earth lead.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

12. LH side: Fit engine compartment fusebox.

13. LH side: Fit ECM.

14. LH side: Fit air intake hose.

15. LH side: Fit air cleaner.

16. LH side: Fit front bumper LH support bracket.

17. RH side: Fit RH front brake pipe. Bleed brake

system.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

18. RH side: Fit PAS fluid reservoir.

19. RH side: Fit RH engine mounting to body.

20. RH side: Fit coolant expansion tank.

21. RH side: Fit windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

22. RH side: Fit front bumper RH support bracket.

23.Fit fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

24.Fit PAS rack.

+ STEERING, REPAIRS, Power

steering rack.

25.Fit front damper.

+ FRONT SUSPENSION, REPAIRS,

Damper.

26.Fit engine and gearbox.

+ ENGINE - K SERIES KV6, REPAIRS,

Engine and automatic gearbox - up to 03MY.

27.Fit front suspension rear beam.

28.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

Page 791 of 1007

PANEL REPAIRS

77-2-36 REPAIRS

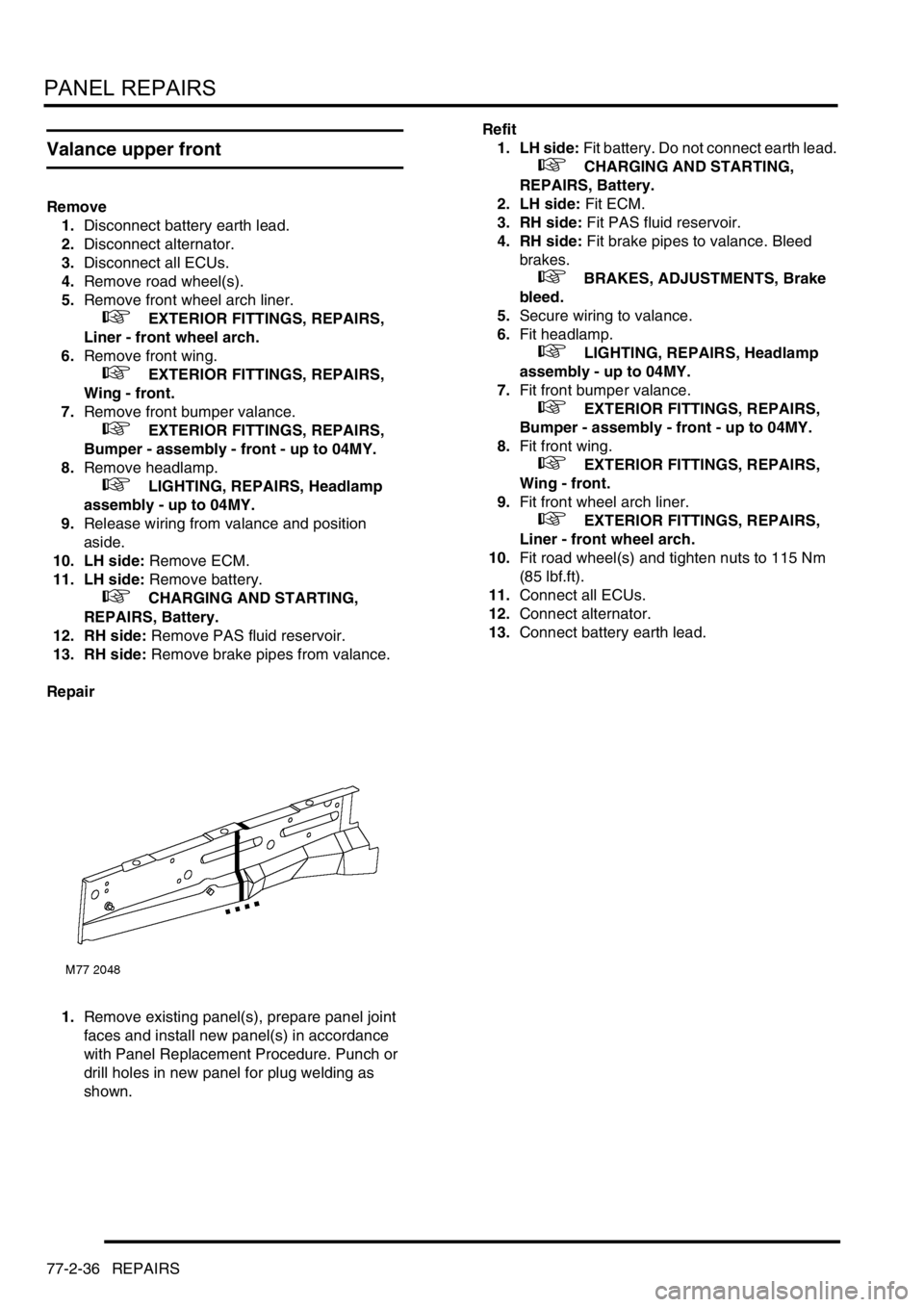

Valance upper front

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

6.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

7.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

8.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

9.Release wiring from valance and position

aside.

10. LH side: Remove ECM.

11. LH side: Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

12. RH side: Remove PAS fluid reservoir.

13. RH side: Remove brake pipes from valance.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Refit

1. LH side: Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

2. LH side: Fit ECM.

3. RH side: Fit PAS fluid reservoir.

4. RH side: Fit brake pipes to valance. Bleed

brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

5.Secure wiring to valance.

6.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

7.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

8.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

9.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

10.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

11.Connect all ECUs.

12.Connect alternator.

13.Connect battery earth lead.

Page 793 of 1007

PANEL REPAIRS

77-2-38 REPAIRS

Refit

1. LH side: Fit LH front brake pipe. Bleed brake

system.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

2. LH side: Fit engine compartment fuse box and

related wiring.

3. LH side: Fit battery carrier. Do not connect

battery earth lead.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

4. LH side: Fit ECM.

5. LH side: Fit air intake hose.

6. LH side: Fit air cleaner.

7. RH side: Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

8. RH side: Fit windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

9. RH side: Fit RH front brake pipe. Bleed brake

system.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

10. RH side: Fit PAS fluid reservoir.

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

12.Secure headlamp wiring.

13.Fit PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

14.Fit radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

15.Fit front bumper support bracket.

16.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

17.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

18.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

19.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

20.Connect all ECUs.

21.Connect alternator.

22.Connect battery earth lead.

Page 794 of 1007

PANEL REPAIRS

REPAIRS 77-2-39

Valance outer reinforcement

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove road wheel(s).

5.Remove front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

6.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

7.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

8.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

9.Release wiring from valance and position

aside.

10. LH side: Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11. LH side: Remove ECM.

12. LH side: Remove relay module.

13. LH side: Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

14. LH side: Remove engine compartment fuse

box and related wiring.

15. RH side: Remove PAS fluid reservoir.

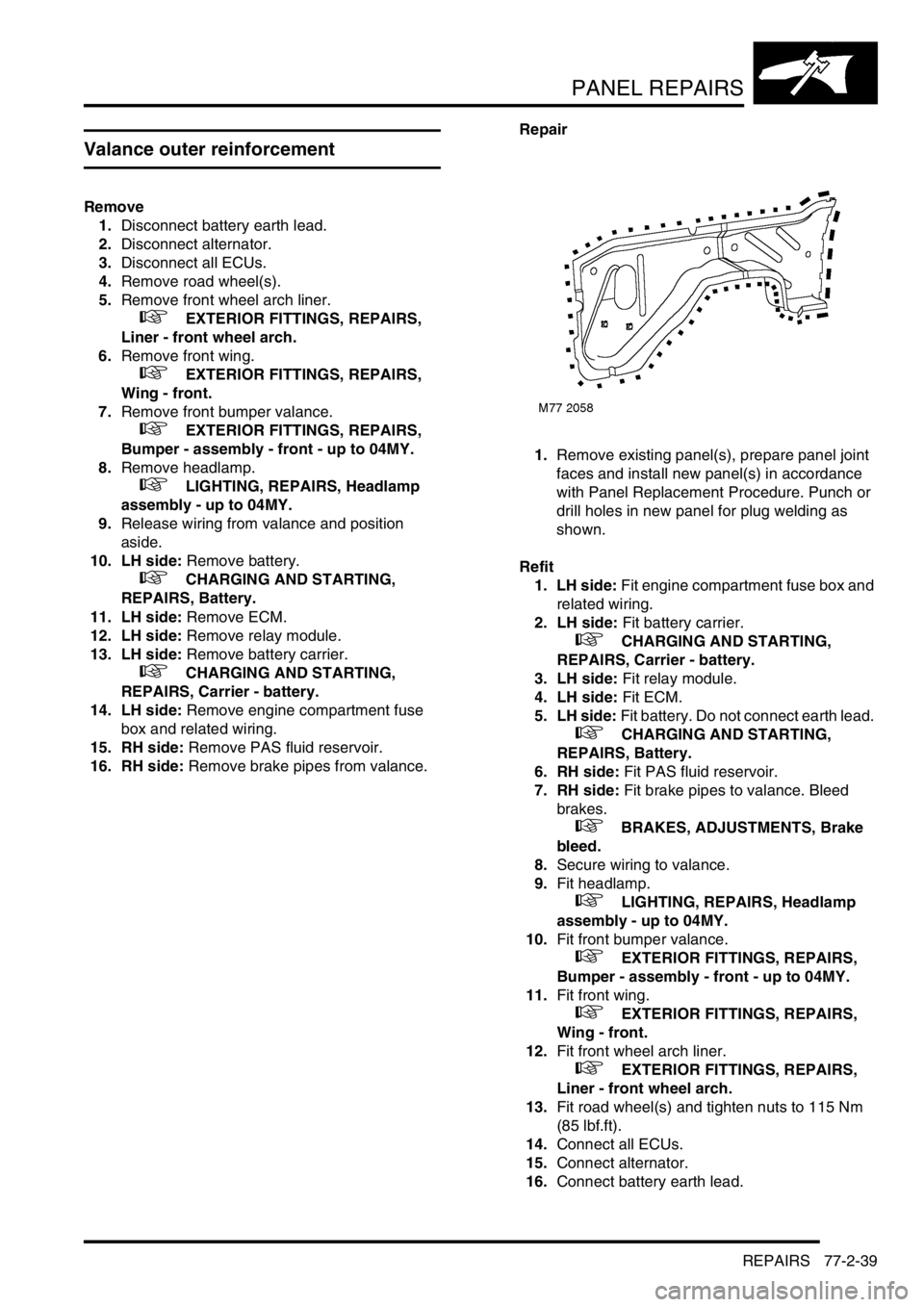

16. RH side: Remove brake pipes from valance. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. LH side: Fit engine compartment fuse box and

related wiring.

2. LH side: Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

3. LH side: Fit relay module.

4. LH side: Fit ECM.

5. LH side: Fit battery. Do not connect earth lead.

+ CHARGING AND STARTING,

REPAIRS, Battery.

6. RH side: Fit PAS fluid reservoir.

7. RH side: Fit brake pipes to valance. Bleed

brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

8.Secure wiring to valance.

9.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

10.Fit front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

11.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front.

12.Fit front wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - front wheel arch.

13.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

14.Connect all ECUs.

15.Connect alternator.

16.Connect battery earth lead.

Page 836 of 1007

CORROSION PREVENTION AND SEALING

CORROSION PREVENTION 77-4-5

Corrosion Prevention

The following information details Corrosion Prevention treatments.

Factory treatments

During production, vehicle bodies are treated with the following anti-corrosion materials:

lAn application of cavity wax which is sprayed into the sill panels and the lower areas of the door panels.

lA PVC-based underbody sealer which is sprayed onto the underside of the main floor and sills, the exterior of

the safe well and the forward face of the lower dash crossmember.

lA coating of underbody wax which is applied to the entire underbody inboard of the sill vertical flanges, and

covers all moving and flexible components EXCEPT for wheels, tyres, brakes and exhaust.

lA coat of protective wax applied to the engine bay area.

Whenever body repairs are carried out, ensure the anti-corrosion materials in the affected area are repaired or

renewed as necessary using the approved materials.

Cavity wax injection

Areas treated with cavity wax are shown in the following Figures. After repairs, always re-treat these areas with an

approved cavity wax. In addition, treat all interior surfaces which have been disturbed during repairs whether they

have been treated in production or not. This includes all box members, cavities and door interiors. It is permissible to

drill extra holes for access where necessary, provided these are not positioned in load-bearing members. Ensure that

such holes are treated with a suitable zinc rich primer, brushed with wax and then sealed with a rubber grommet.

Before wax injection, ensure that the cavity to be treated is free from any contamination or foreign matter. Where

necessary, clear out any debris using compressed air.

Ensure that cavity wax is applied AFTER the final paint process and BEFORE refitting any trim components.

During application, ensure that the wax covers all flange and seam areas and that it is adequately applied to all

repaired areas of both new and existing panels.

It should be noted that new panel assemblies and complete body shells are supplied without wax injection treatment.

Ensure that such treatment is carried out after repairs.

Effective cavity wax protection is vital. Always observe the following points:

lComplete all paint refinish operations before wax application.

lClean body panel areas and blow-clean cavities if necessary, before treatment.

lMaintain a temperature of 18°C during application and drying.

lCheck the spray pattern of injection equipment.

lMask off all areas not to be wax coated and which could be contaminated by wax overspray.

lRemove body fixings, such as seat belt retractors, if contamination is at all likely.

lMove door glasses to fully closed position before treating door interiors.

lTreat body areas normally covered by trim before refitting items.

lCheck that body and door drain holes are clear after the protective wax has dried.

lKeep all equipment clean, especially wax injection nozzles.

Page 839 of 1007

CORROSION PREVENTION AND SEALING

77-4-8 SEALING

Underbody sealer

Underfloor areas and sill outer panels are treated with a Plastisol PVC underbody sealer. This material is not suitable

for re-treatment. When repairing areas of underbody sealer, strip the factory-applied underbody sealer back to a

suitable break point. Ensure that a clean metal surface is exposed and that the edge of the existing sealer adheres

soundly to the panel.

Apply new underbody sealer between primer and surfacer paint operations. Apply seam sealer as necessary before

application of underbody sealer. Ensure that blanking plugs and grommets in the floor pan (except those used for wax

injection) are fitted before underbody sealer application. Refit any heat-fusible plugs which have been disturbed in

repair with the aid of a hot air blower, or replace with rubber grommets.

caut : Ensure that suspension units, wheels, tyres, power unit, driveshafts, exhaust and brakes (including all mounting

points) are shielded prior to application of fresh underbody sealer.

Underbody wax

The underbody wax must be reinstated following all repairs affecting floor panels. The wax is applied over paints and

underbody sealers.

caut : Remove old underbody wax completely from a zone extending at least 200mm beyond the area where new

underbody sealer is to be applied.

Engine bay wax

Reinstate all protective engine bay wax disturbed during repairs using an approved material.

Where repairs have involved replacement of engine bay panels, treat the entire engine compartment including all

components, clips and other fixtures with an approved underbonnet lacquer or wax.

Precautions during body repairs and handling

Take care when handling the vehicle in the workshop. Underbody sealers, seam sealers, underbody wax and body

panels may be damaged if the vehicle is carelessly lifted.

Proprietary anti-corrosion treatments

The application of proprietary anti-corrosion treatments in addition to the factory-applied treatment could invalidate

the Corrosion Warranty and should be discouraged. This does not apply to approved, compatible, preservative waxes

which may be applied on top of existing coatings.

Fitting approved accessories

When fitting accessories ensure that the vehicle's corrosion protection is not affected, either by breaking the protective

coating or by introducing a moisture trap.

Do not screw self-tapping screws directly into body panels. Fit suitable plastic inserts to the panel beforehand. Always

ensure that the edges of holes drilled into panels, chassis members and other body parts are protected with a suitable

zinc rich or acid etch primer, and follow with a protective wax coating brushed onto the surrounding area.

Do not attach painted metal surfaces of any accessory directly to the vehicle's bodywork unless suitably protected.

Where metal faces are bolted together always interpose a suitable interface material such as weldable zinc rich

primer, extruded strip, or zinc tape.

Steam cleaning and dewaxing

Due to the high temperatures generated by steam cleaning equipment, there is a risk that certain trim components

could be damaged and some adhesives and corrosion prevention materials softened or liquified.

Adjust the equipment so that the nozzle temperature does not exceed 90°C (194°F). Take care not to allow the steam

jet to dwell on one area, and keep the nozzle at least 300mm from panel surfaces.

DO NOT remove wax or lacquer from underbody or underbonnet areas during repairs. Should it be necessary to

steam clean these areas, apply a new coating of wax or underbody protection as soon as possible.