engine coolant LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 9 of 1007

CONTENTS

6CONTENTS

EMISSION CONTROL ............................................................................. 17-1-1

ADJUSTMENTS

Evaporative loss control system (EVAPS) - leak test - NAS........................................................... 17-1-1

REPAIRS

Valve - depression limiter - Td4 ..................................................................................................... 17-1-3

Solenoid - canister purge - KV6 ...................................................................................................... 17-1-4

Charcoal canister - petrol - Non NAS ............................................................................................. 17-1-4

Charcoal canister - NAS ................................................................................................................. 17-1-5

Valve - canister purge - K1.8 .......................................................................................................... 17-1-6

Valve - EGR - Td4 .......................................................................................................................... 17-1-7

Solenoid/modulator valve - EGR - Td4 ........................................................................................... 17-1-8

Thermal valve - exhaust gas recirculation (EGR) -

Td4 Automatic transmission (hot climates) - from 03 MY ............................................................... 17-1-9

Cooler - EGR - Td4 ......................................................................................................................... 17-1-9

Module - tank leakage diagnostic (DMTL) ...................................................................................... 17-1-11

Filter - fuel leak detection pump - KV6 - NAS ................................................................................ 17-1-12

Catalytic converter - RH - KV6 - NAS ............................................................................................ 17-1-12

ENGINE MANAGEMENT SYSTEM - SIEMENS....................................... 18-3-1

REPAIRS

Spark plugs - up to 03MY ............................................................................................................... 18-3-1

Spark plugs - from 03MY ................................................................................................................ 18-3-2

Coil - each - LH bank - up to 03MY ................................................................................................ 18-3-3

Coil - each - LH bank - from 03MY ................................................................................................. 18-3-3

Coil - each - RH bank - up to 03MY ................................................................................................ 18-3-4

Coil - each - RH bank - from 03MY................................................................................................. 18-3-4

Engine control module (ECM) - Non NAS ..................................................................................... 18-3-5

Engine control module (ECM) - fuel - NAS .................................................................................... 18-3-6

Idle Air Control Valve (IACV) ......................................................................................................... 18-3-7

Sensor - intake air temperature (IAT) - NAS .................................................................................. 18-3-8

Sensor - engine coolant temperature (ECT) .................................................................................. 18-3-8

Sensor - crankshaft position (CKP) ............................................................................................... 18-3-9

Sensor - throttle position (TP) ......................................................................................................... 18-3-10

Sensor - thermostat monitoring (TM) - KV6 - NAS ........................................................................ 18-3-11

Sensor - camshaft position (CMP) ................................................................................................. 18-3-12

Sensor - knock (KS) ....................................................................................................................... 18-3-13

Switch - throttle pedal - Non NAS ................................................................................................... 18-3-13

Sensor - combined - manifold absolute pressure/Intake air temperature (MAP/IAT) ..................... 18-3-14

Sensor - throttle position (TP) - NAS - up to 03MY......................................................................... 18-3-15

Sensor - throttle position (TP) - NAS - from 03MY ......................................................................... 18-3-16

Page 28 of 1007

INTRODUCTION

01-3

Abbreviations and Symbols

A Amperes

AAP Ambient Air Pressure

AAT Ambient Air Temperature

ABDC After Bottom Dead Centre

ABS Anti-Lock Brake System

ABS / TC Anti-lock Brake System / Traction

Control

ac Alternating current

A/C Air Conditioning

ACE Active Cornering Enhancement

ACEA Association of Constructors of

European Automobiles

AFR Air Fuel Ratio

AP Ambient Pressure

ASC Anti-shunt Control

ATC Air Temperature Control

ATDC After Top Dead Centre

AUX Auxiliary

AVC Automatic Volume Control

BBDC Before Bottom Dead Centre

BBUS Battery Backed Up Sounder

BCU Body Control Unit

BDC Bottom Dead Centre

bhp Brake Horse Power

BP Boost Pressure

BPP Brake Pedal Position

BS British Standard

BTDC Before Top Dead Centre

BWD Backward

C Celsius

CAN Controller Area Network

CD Compact Disc

CDC Centre Differential Control

CDL Central Door Locking

CD - ROM Compact Disc - Read Only

Memory

CFC Chlorofluorocarbon

CHMSL Centre High Mounted Stop Lamp

CKP Crankshaft Position

CLV Calculated Load Value

cm Centimetre

cm

2Square centimetre

cm3Cubic centimetre

CMP Camshaft Position

CPP Clutch Pedal Position

CO Carbon Monoxide

CO

2Carbon Dioxide

COB Clear Over Base

CR Common Rail

CVS Canister Vent Solenoid

dB Decibels

DDM Driver's Door Module

deg. Degree, angle or temperature

DI Direct Injection

dia. DiameterDIN Deutsche Industrie Normen

(German Industrial Standards)

dc Direct current

DCV Directional Control Valve

DOHC Double Overhead Camshaft

DSP Digital Signal Processing

DTI Dial Test Indicator

DMF Dual Mass Flywheel

DVD Digital Versatile Disc

EACV Electronic Air Control Valve

EAT Electronic Automatic

Transmission

EBD Electronic Brake pressure

Distribution

ECD European Community Directive

ECM Engine Control Module

ECT Engine Coolant Temperature

ECU Electronic Control Unit

EDC Electronic Diesel Control

EEPROM Electronic Erasable

Programmable Read Only

Memory

EGR Exhaust Gas Recirculation

EKA Emergency Key Access

ELR Emergency Locking Retractor

EN European Norm

EOBD European On Board Diagnostics

EON Enhanced Other Network

ERL Electrical Reference Library

ETC Electronic Traction Control

EUI Electronic Unit Injector

EVAP Evaporative Emission

EVR Electronic Vacuum Regulator

F Fahrenheit

ft. Feet

FBH Fuel Burning Heater

FET Field Effect Transistor

FIP Fuel Injection Pump

FTC Fast Throttle Control

FWD Forward

> Greater than

g Gramme or Gravity

gal. Gallons

GMT Greenwich Mean Time

GPS Global Positioning System

hHour

hc High compression

HC Hydro Carbons

HDC Hill Descent Control

HDOP Height Dilation Of Precision

HDPE High Density Polyethylene

HFS Heated Front Screen

Hg Mercury

HO

2S Heated Oxygen Sensor

HMW High Molecular Weight

Page 32 of 1007

GENERAL INFORMATION

03-1

GENERAL INFORMATION

General precautions

Dangerous substances

Modern vehicles contain many materials and liquids

which if not handled with care can be hazardous to

both personal health and the environment.

WARNING: Many liquids and other substances

used in motor vehicles are poisonous and should

under no circumstances be consumed and

should, as far as possible, be kept from contact

with the skin. These liquids and substances

include acid, anti-freeze, asbestos, brake fluid,

fuel, windscreen washer additives, lubricants,

refrigerants and various adhesives.

Always read carefully the instructions printed on

labels or stamped on components and obey them

implicitly. Such instructions are included for

reasons of your health and personal safety.

Never disregard them.

WARNING: Many of the fluids used in motor

vehicles, such as coolant, brake fluid and power

steering fluid, are inflammable. Take care not to

spill fluids when topping-up, a fire may result. If

spillage does occur, ensure the area is

thoroughly cleaned before starting the engine.

Synthetic rubber

Many 'O' rings, seals, hoses, flexible pipes and other

similar items which appear to be natural rubber, are

in fact, made of synthetic materials called

Fluoroelastomers.

Under normal operating conditions this material is

safe and does not present a health hazard. However,

if the material is damaged by fire or excessive

heating, it can break down and produce highly

corrosive Hydrofluoric acid which can cause serious

burns on contact with skin.

If skin contact does occur:

lRemove any contaminated clothing

immediately.

lIrrigate effected area of skin with a copious

amount of cold water or limewater for 15 to 60

minutes.

lObtain medical assistance immediately.

Should any material be in a burnt or over-heated

condition, handle with extreme caution and wear

protective clothing (seamless industrial gloves,

protective apron etc.). Decontaminate and dispose of

gloves immediately after use.Lubricating oils

WARNING: Avoid excessive skin contact with used

engine oil. Used engine oil contains potentially

harmful contaminants which may cause skin cancer

or other serious skin disorders.

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats from

the skin, leading to dryness, irritation and dermatitis.

Health protection precautions

The following precautions should be observed at all

times:

lAvoid prolonged and repeated contact with oils,

particularly used engine oils.

lWear protective clothing, including impervious

gloves where practicable.

lDo not put oily rags in pockets.

lAvoid contaminating clothes (particularly those

next to the skin) with oil.

lOveralls must be cleaned regularly. Discard

heavily soiled clothing and oil impregnated

footwear.

lFirst aid treatment should be obtained

immediately for open cuts and wounds.

lUse barrier creams: apply before each work

period to help prevent lubricating oil from

contaminating the skin.

lWash with soap and water to ensure all oil is

removed (propriety skin cleansers and nail

brushes will help).

lUse moisturisers after cleaning; preparations

containing lanolin help replace the skin's natural

oils which have been removed.

lDo not use petrol, kerosene, diesel fuel, gas, oil,

thinners or solvents for cleaning skin.

lIf skin disorders develop, obtain medical advice

without delay.

lWhere practicable, degrease components prior

to handling.

lWear eye protection (e.g. goggles or face

shield) if there is a risk of eye contamination.

Eye wash facilities should be provided in the

close vicinity of the work area.

Page 34 of 1007

GENERAL INFORMATION

03-3

Brake hydraulics

Observe the following recommendations when

working on the brake system:

lAlways use two spanners when loosening or

tightening brake pipe or hose connections.

lEnsure that hoses run in a natural curve and are

not kinked or twisted.

lFit brake pipes securely in their retaining clips

and ensure that the pipe run cannot contact a

potential chafing point.

lContainers used for hydraulic brake fluid must

be kept absolutely clean.

lDo not store hydraulic brake fluid in an unsealed

container, it will absorb water and in this

condition would be dangerous to use due to a

lowering of its boiling point.

lDo not allow hydraulic brake fluid to be

contaminated with mineral oil, or put new

hydraulic brake fluid in a container which has

previously contained mineral oil.

lDo not re-use hydraulic brake fluid previously

removed from the system.

lAlways use clean brake fluid or a recommended

alternative to clean hydraulic components.

lFit a blanking cap to a hydraulic union and a

plug to its socket, immediately after

disconnection of pipes and hoses to prevent the

ingress of dirt.

lAbsolute cleanliness must be observed when

working with hydraulic components.

lIt is imperative that the correct brake fittings are

used and that threads of components are

compatible.

Cooling system caps and plugs

Extreme care is necessary when removing engine

cooling system expansion tank caps and coolant

drain or bleed screws when the engine is hot, and

especially if it is overheated.

To avoid the possibility of scalding allow the engine

to cool before attempting coolant cap or plug

removal.

Environmental Precautions

General

This section provides general information which can

help to reduce adverse environmental impacts

incurred through the activities carried out in

workshops.

Emissions to air

Many of the activities that are carried out in

workshops emit gases and fumes which contribute to

global warming, depletion of the ozone layer and/or

the formation of photo-chemical smog at ground

level. By considering and controlling how the

workshop activities are carried out, these gases and

fumes can be minimised, thus reducing the damage

to the environment.

Exhaust fumes

Running car engines is an essential part of workshop

activities and exhaust fumes need to be ventilated to

atmosphere. However, the amount of time engines

are running and the position of the vehicle should be

carefully considered at all times, to reduce the

release of poisonous gases and minimise the

inconvenience to people living nearby.

Solvents

Some of the cleaning agents used are solvent based

and will evaporate to atmosphere if used carelessly,

or if cans are left unsealed. All solvent containers

should be firmly closed when not needed and solvent

should be used sparingly. Suitable alternative

materials may be available to replace some of the

commonly used solvents. Similarly, many paints are

solvent based and the spray should be minimised to

reduce solvent emissions.

Refrigerant

It is illegal to release any refrigerants into the

atmosphere. Discharge and replacement of these

materials from air conditioning units should only be

carried out using the correct equipment.

Checklist

Always adhere to the following:

Engines –

ldon't leave engines running unnecessarily;

lminimise testing times and check where the

exhaust fumes are being blown.

Page 50 of 1007

GENERAL INFORMATION

03-19

Electrical precautions

General

The following guidelines are intended to ensure the

safety of the operator and ensure the prevention of

damage to the electrical and electronic components

fitted to the vehicle. Where necessary, specific

precautions are detailed in the individual procedures

of this manual.

Equipment

Prior to commencing any test procedure on the

vehicle, ensure that the relevant test equipment is

working correctly and any harness or connectors are

in good condition. It is particularly important to check

the condition of the lead and plugs of mains operated

equipment.

Polarity

Never reverse connect the vehicle battery and

always ensure the correct polarity when connecting

test equipment.

High Voltage Circuits

Whenever disconnecting live ht circuits, always use

insulated pliers and never allow the open end of the

ht lead to contact other components, particularly

ECU's.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Connectors and harnesses

The engine compartment of a vehicle is a particularly

hostile environment for electrical components and

connectors:

lAlways ensure electrically related items are dry

and oil free before disconnecting and

connecting test equipment.

lEnsure disconnected multiplugs and sensors

are protected from being contaminated with oil,

coolant or other solutions. Contamination could

impair performance or result in catastrophic

failure.

lNever force connectors apart using tools to

prise apart or by pulling on the wiring harness.

lAlways ensure locking tabs are disengaged

before disconnection, and match orientation to

enable correct reconnection.

lEnsure that any protection (covers, insulation

etc.) is replaced if disturbed.Having confirmed a component to be faulty:

lSwitch off the ignition and disconnect the

battery.

lRemove the component and support the

disconnected harness.

lWhen replacing the component, keep oily hands

away from electrical connection areas and push

connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, disable the alarm

system and switch off all electrical equipment. If the

radio is to be serviced, ensure the security code has

been deactivated.

CAUTION: To prevent damage to electrical

components, always disconnect the battery

when working on the vehicle's electrical system.

The ground lead must be disconnected first and

reconnected last.

CAUTION: Always ensure that battery leads are

routed correctly and are not close to any

potential chafing points.

Battery charging

Only recharge the battery with it removed from the

vehicle. Always ensure any battery charging area is

well ventilated and that every precaution is taken to

avoid naked flames and sparks.

Ignition system safety precautions

The vehicle's ignition system produces high voltages

and the following precautions should be observed

before carrying out any work on the system:

WARNING: Before commencing work on an

ignition system, ensure all high tension

terminals, adapters and diagnostic equipment

are adequately insulated and shielded to prevent

accidental personal contacts and minimise the

risk of shock. Wearers of surgically implanted

pacemaker devices should not be in close

proximity of ignition circuits or diagnostic

equipment.

Page 105 of 1007

TORQUE WRENCH SETTINGS

06-2

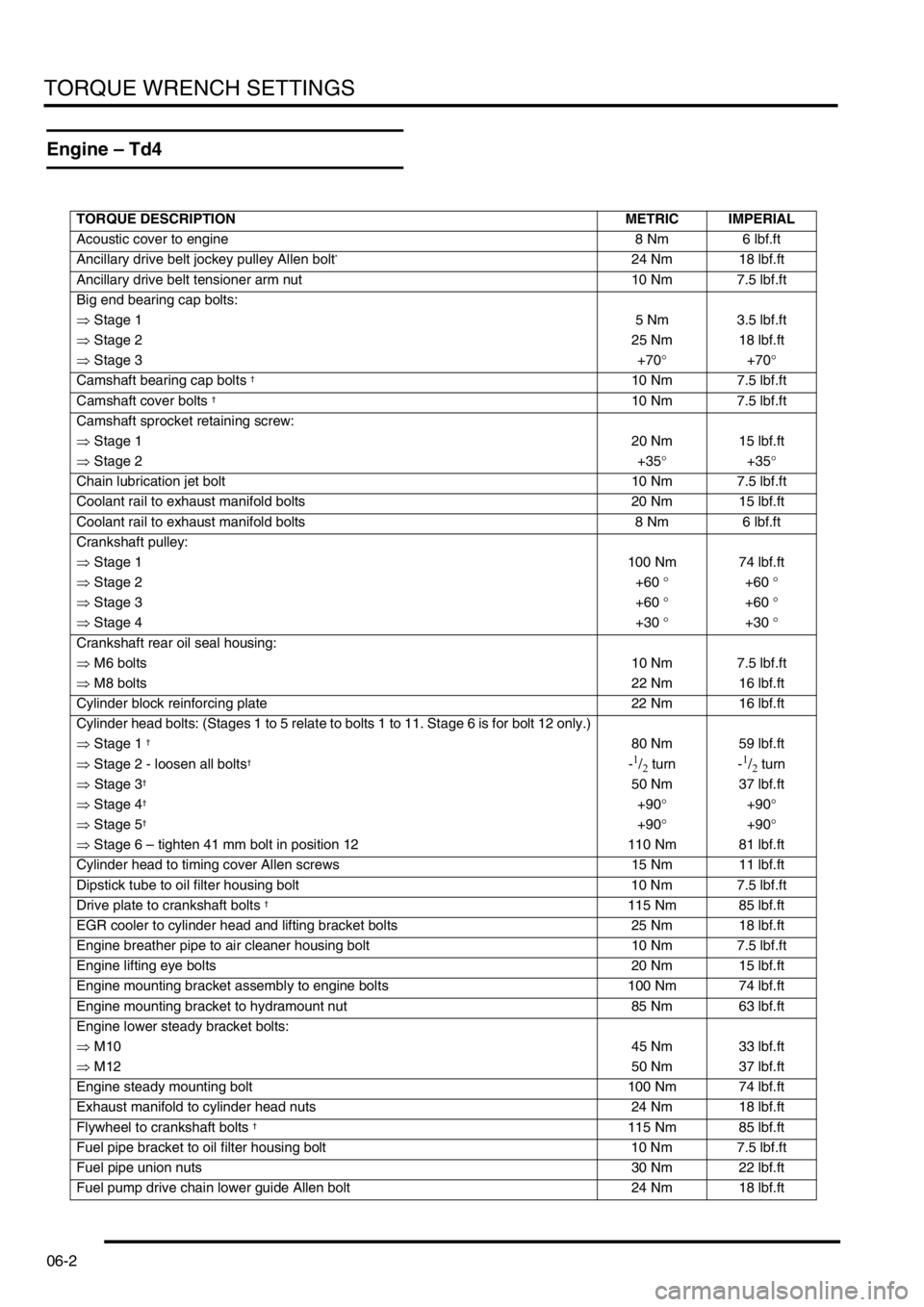

Engine – Td4

TORQUE DESCRIPTION METRIC IMPERIAL

Acoustic cover to engine 8 Nm 6 lbf.ft

Ancillary drive belt jockey pulley Allen bolt

*24 Nm 18 lbf.ft

Ancillary drive belt tensioner arm nut 10 Nm 7.5 lbf.ft

Big end bearing cap bolts:

⇒ Stage 15 Nm 3.5 lbf.ft

⇒ Stage 225 Nm 18 lbf.ft

⇒ Stage 3+70°+70°

Camshaft bearing cap bolts

† 10 Nm 7.5 lbf.ft

Camshaft cover bolts

† 10 Nm 7.5 lbf.ft

Camshaft sprocket retaining screw:

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+35°+35°

Chain lubrication jet bolt 10 Nm 7.5 lbf.ft

Coolant rail to exhaust manifold bolts 20 Nm 15 lbf.ft

Coolant rail to exhaust manifold bolts 8 Nm 6 lbf.ft

Crankshaft pulley:

⇒ Stage 1100 Nm 74 lbf.ft

⇒ Stage 2+60 °+60 °

⇒ Stage 3+60 °+60 °

⇒ Stage 4+30 °+30 °

Crankshaft rear oil seal housing:

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts22 Nm 16 lbf.ft

Cylinder block reinforcing plate 22 Nm 16 lbf.ft

Cylinder head bolts: (Stages 1 to 5 relate to bolts 1 to 11. Stage 6 is for bolt 12 only.)

⇒ Stage 1

†80 Nm 59 lbf.ft

⇒ Stage 2 - loosen all bolts

†-1/2 turn -1/2 turn

⇒ Stage 3

†50 Nm 37 lbf.ft

⇒ Stage 4

†+90°+90°

⇒ Stage 5

†+90°+90°

⇒ Stage 6 – tighten 41 mm bolt in position 12 110 Nm 81 lbf.ft

Cylinder head to timing cover Allen screws 15 Nm 11 lbf.ft

Dipstick tube to oil filter housing bolt 10 Nm 7.5 lbf.ft

Drive plate to crankshaft bolts

† 115 Nm 85 lbf.ft

EGR cooler to cylinder head and lifting bracket bolts 25 Nm 18 lbf.ft

Engine breather pipe to air cleaner housing bolt 10 Nm 7.5 lbf.ft

Engine lifting eye bolts 20 Nm 15 lbf.ft

Engine mounting bracket assembly to engine bolts 100 Nm 74 lbf.ft

Engine mounting bracket to hydramount nut 85 Nm 63 lbf.ft

Engine lower steady bracket bolts:

⇒ M1045 Nm 33 lbf.ft

⇒ M1250 Nm 37 lbf.ft

Engine steady mounting bolt 100 Nm 74 lbf.ft

Exhaust manifold to cylinder head nuts 24 Nm 18 lbf.ft

Flywheel to crankshaft bolts

† 115 Nm 85 lbf.ft

Fuel pipe bracket to oil filter housing bolt 10 Nm 7.5 lbf.ft

Fuel pipe union nuts 30 Nm 22 lbf.ft

Fuel pump drive chain lower guide Allen bolt 24 Nm 18 lbf.ft

Page 106 of 1007

TORQUE WRENCH SETTINGS

06-3

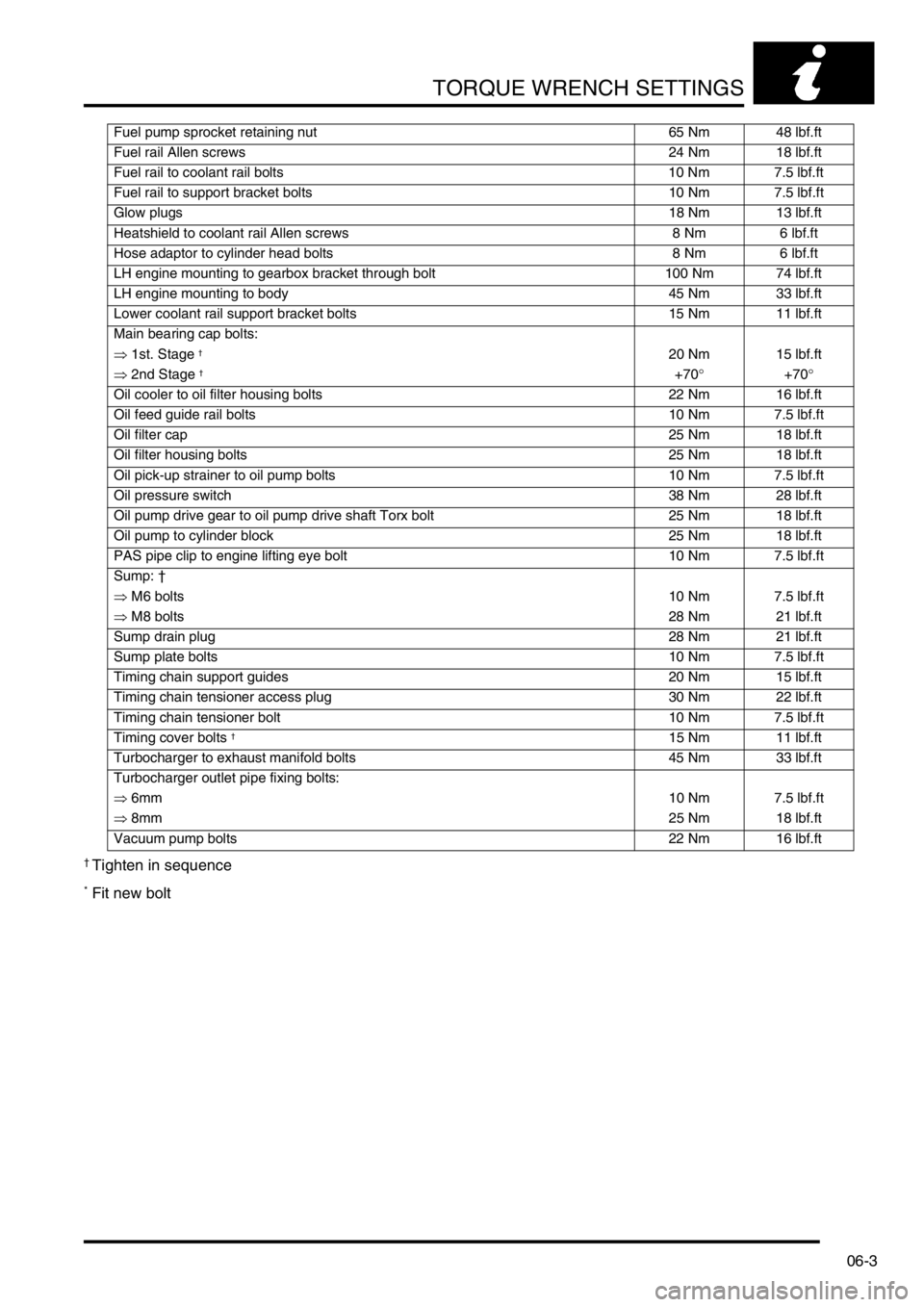

† Tighten in sequence

* Fit new bolt

Fuel pump sprocket retaining nut 65 Nm 48 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel rail to coolant rail bolts 10 Nm 7.5 lbf.ft

Fuel rail to support bracket bolts 10 Nm 7.5 lbf.ft

Glow plugs18 Nm 13 lbf.ft

Heatshield to coolant rail Allen screws 8 Nm 6 lbf.ft

Hose adaptor to cylinder head bolts 8 Nm 6 lbf.ft

LH engine mounting to gearbox bracket through bolt 100 Nm 74 lbf.ft

LH engine mounting to body 45 Nm 33 lbf.ft

Lower coolant rail support bracket bolts 15 Nm 11 lbf.ft

Main bearing cap bolts:

⇒ 1st. Stage

† 20 Nm 15 lbf.ft

⇒ 2nd Stage

† +70°+70°

Oil cooler to oil filter housing bolts 22 Nm 16 lbf.ft

Oil feed guide rail bolts 10 Nm 7.5 lbf.ft

Oil filter cap25 Nm 18 lbf.ft

Oil filter housing bolts 25 Nm 18 lbf.ft

Oil pick-up strainer to oil pump bolts 10 Nm 7.5 lbf.ft

Oil pressure switch 38 Nm 28 lbf.ft

Oil pump drive gear to oil pump drive shaft Torx bolt 25 Nm 18 lbf.ft

Oil pump to cylinder block 25 Nm 18 lbf.ft

PAS pipe clip to engine lifting eye bolt 10 Nm 7.5 lbf.ft

Sump: †

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts28 Nm 21 lbf.ft

Sump drain plug28 Nm 21 lbf.ft

Sump plate bolts10 Nm 7.5 lbf.ft

Timing chain support guides 20 Nm 15 lbf.ft

Timing chain tensioner access plug 30 Nm 22 lbf.ft

Timing chain tensioner bolt 10 Nm 7.5 lbf.ft

Timing cover bolts

† 15 Nm 11 lbf.ft

Turbocharger to exhaust manifold bolts 45 Nm 33 lbf.ft

Turbocharger outlet pipe fixing bolts:

⇒ 6mm10 Nm 7.5 lbf.ft

⇒ 8mm25 Nm 18 lbf.ft

Vacuum pump bolts 22 Nm 16 lbf.ft

Page 107 of 1007

TORQUE WRENCH SETTINGS

06-4

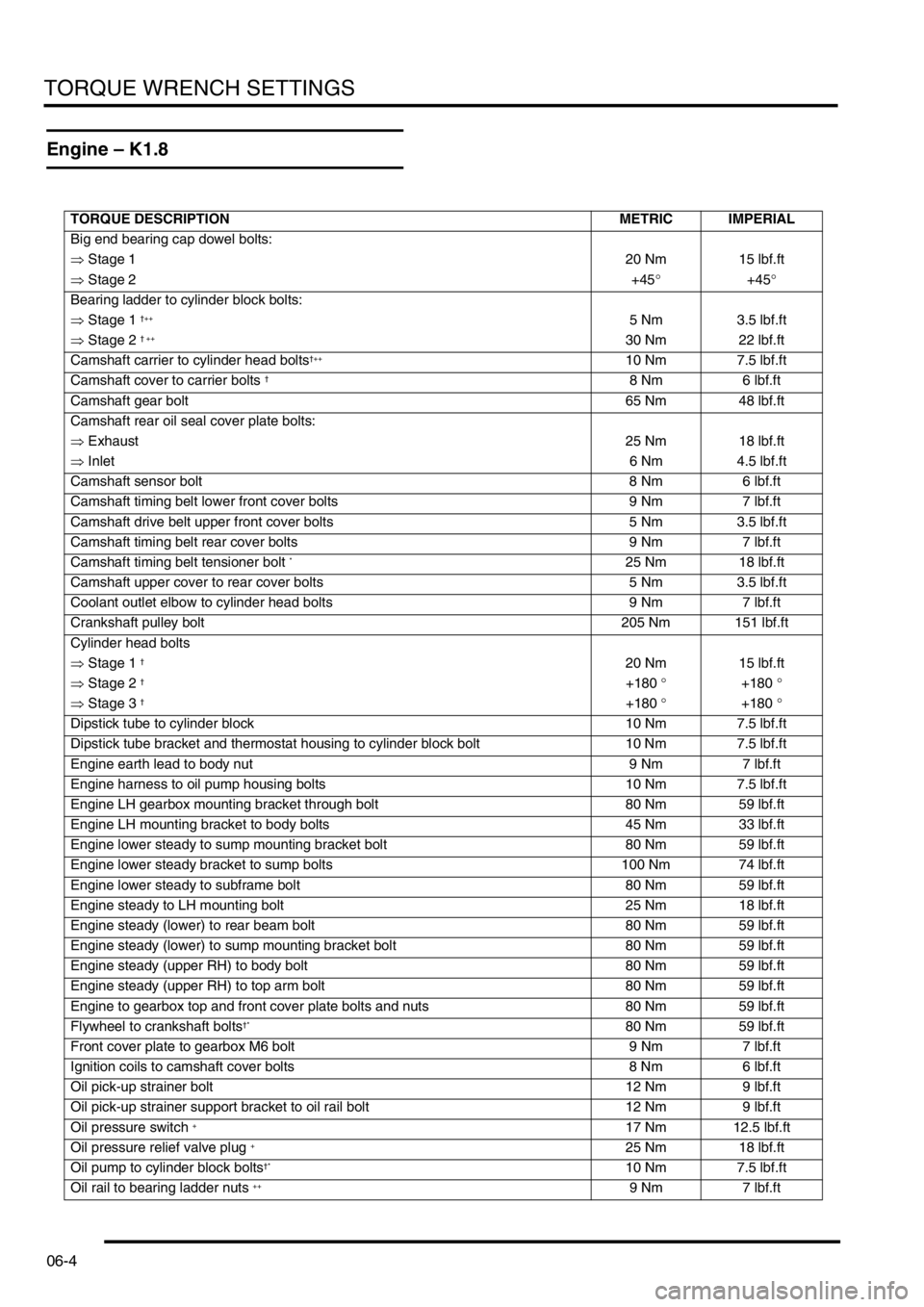

Engine – K1.8

TORQUE DESCRIPTION METRIC IMPERIAL

Big end bearing cap dowel bolts:

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+45°+45°

Bearing ladder to cylinder block bolts:

⇒ Stage 1

†++5 Nm 3.5 lbf.ft

⇒ Stage 2

† ++30 Nm 22 lbf.ft

Camshaft carrier to cylinder head bolts

†++10 Nm 7.5 lbf.ft

Camshaft cover to carrier bolts

†8 Nm 6 lbf.ft

Camshaft gear bolt 65 Nm 48 lbf.ft

Camshaft rear oil seal cover plate bolts:

⇒ Exhaust25 Nm 18 lbf.ft

⇒ Inlet6 Nm 4.5 lbf.ft

Camshaft sensor bolt 8 Nm 6 lbf.ft

Camshaft timing belt lower front cover bolts 9 Nm 7 lbf.ft

Camshaft drive belt upper front cover bolts 5 Nm 3.5 lbf.ft

Camshaft timing belt rear cover bolts 9 Nm 7 lbf.ft

Camshaft timing belt tensioner bolt

* 25 Nm 18 lbf.ft

Camshaft upper cover to rear cover bolts 5 Nm 3.5 lbf.ft

Coolant outlet elbow to cylinder head bolts 9 Nm 7 lbf.ft

Crankshaft pulley bolt 205 Nm 151 lbf.ft

Cylinder head bolts

⇒ Stage 1

†20 Nm 15 lbf.ft

⇒ Stage 2

†+180 °+180 °

⇒ Stage 3

†+180 °+180 °

Dipstick tube to cylinder block 10 Nm 7.5 lbf.ft

Dipstick tube bracket and thermostat housing to cylinder block bolt 10 Nm 7.5 lbf.ft

Engine earth lead to body nut 9 Nm 7 lbf.ft

Engine harness to oil pump housing bolts 10 Nm 7.5 lbf.ft

Engine LH gearbox mounting bracket through bolt 80 Nm 59 lbf.ft

Engine LH mounting bracket to body bolts 45 Nm 33 lbf.ft

Engine lower steady to sump mounting bracket bolt 80 Nm 59 lbf.ft

Engine lower steady bracket to sump bolts 100 Nm 74 lbf.ft

Engine lower steady to subframe bolt 80 Nm 59 lbf.ft

Engine steady to LH mounting bolt 25 Nm 18 lbf.ft

Engine steady (lower) to rear beam bolt 80 Nm 59 lbf.ft

Engine steady (lower) to sump mounting bracket bolt 80 Nm 59 lbf.ft

Engine steady (upper RH) to body bolt 80 Nm 59 lbf.ft

Engine steady (upper RH) to top arm bolt 80 Nm 59 lbf.ft

Engine to gearbox top and front cover plate bolts and nuts 80 Nm 59 lbf.ft

Flywheel to crankshaft bolts

†*80 Nm 59 lbf.ft

Front cover plate to gearbox M6 bolt 9 Nm 7 lbf.ft

Ignition coils to camshaft cover bolts 8 Nm 6 lbf.ft

Oil pick-up strainer bolt 12 Nm 9 lbf.ft

Oil pick-up strainer support bracket to oil rail bolt 12 Nm 9 lbf.ft

Oil pressure switch

+17 Nm 12.5 lbf.ft

Oil pressure relief valve plug

+25 Nm 18 lbf.ft

Oil pump to cylinder block bolts

†*10 Nm 7.5 lbf.ft

Oil rail to bearing ladder nuts

++9 Nm 7 lbf.ft

Page 112 of 1007

TORQUE WRENCH SETTINGS

06-9

Engine Management System – EDC

TORQUE DESCRIPTION METRIC IMPERIAL

Camshaft position (CMP) sensor Torx screw 8 Nm 6 lbf.ft

Crankshaft position (CKP) sensor Allen screw 8 Nm 6 lbf.ft

'E' box cover Allen screws 2 Nm 1.5 lbf.ft

Engine coolant temperature sensor (ECT) 15 Nm 11 lbf.ft

Engine breather pipe to air cleaner housing bolt 6 Nm 4.4 lbf.ft

Mass air flow / inlet air temperature MAF/IAT sensor to air cleaner housing 6 Nm 4.4 lbf.ft

Throttle pedal to stud nuts 25 Nm 18 lbf.ft

Throttle Position (TP) sensor nuts and bolts 10 Nm 7 lbf.ft

TP sensor release lever nut 10 Nm 7 lbf.ft

Page 113 of 1007

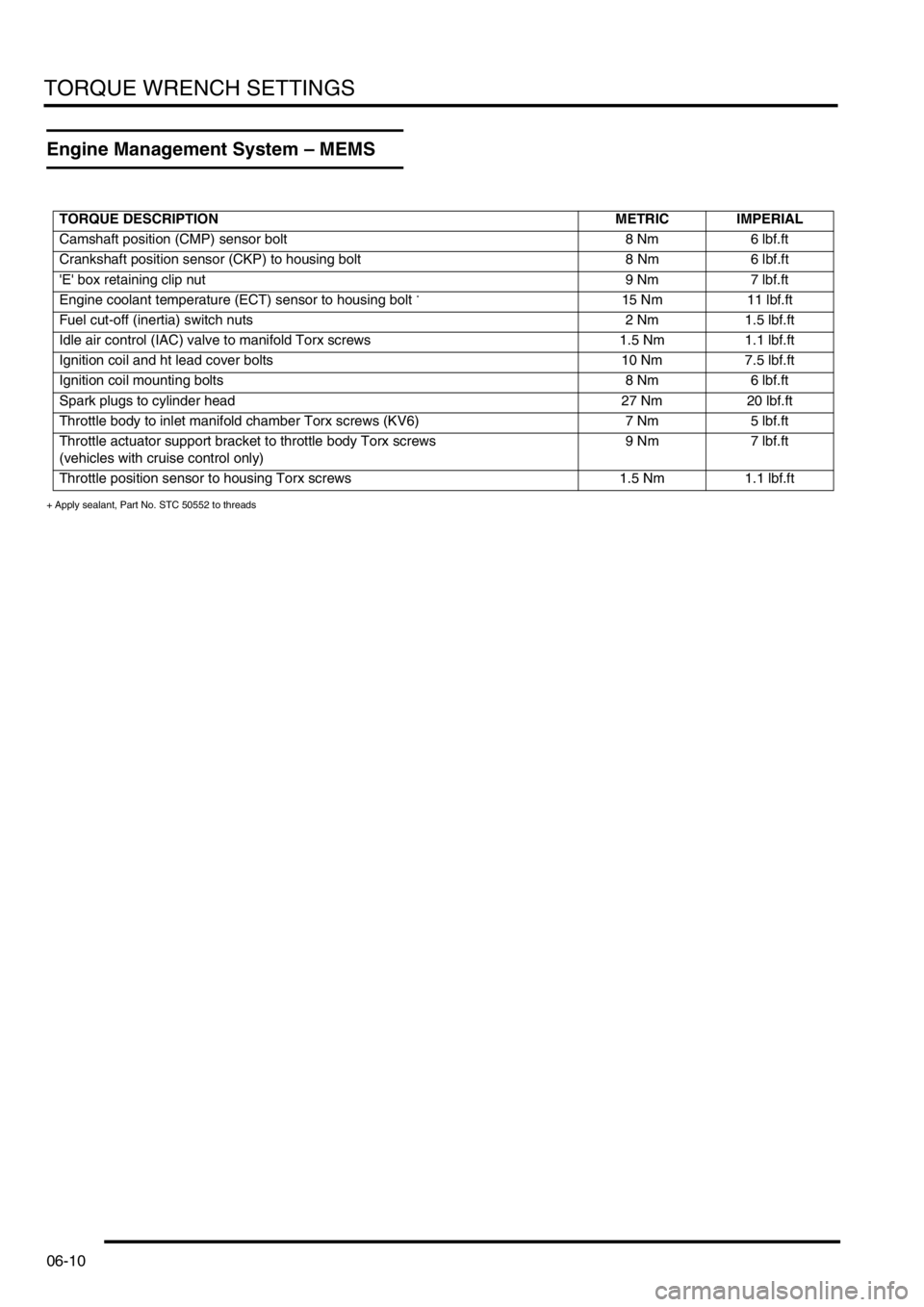

TORQUE WRENCH SETTINGS

06-10

Engine Management System – MEMS

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Camshaft position (CMP) sensor bolt 8 Nm 6 lbf.ft

Crankshaft position sensor (CKP) to housing bolt 8 Nm 6 lbf.ft

'E' box retaining clip nut 9 Nm 7 lbf.ft

Engine coolant temperature (ECT) sensor to housing bolt

*15 Nm 11 lbf.ft

Fuel cut-off (inertia) switch nuts 2 Nm 1.5 lbf.ft

Idle air control (IAC) valve to manifold Torx screws 1.5 Nm 1.1 lbf.ft

Ignition coil and ht lead cover bolts 10 Nm 7.5 lbf.ft

Ignition coil mounting bolts 8 Nm 6 lbf.ft

Spark plugs to cylinder head 27 Nm 20 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 7 Nm 5 lbf.ft

Throttle actuator support bracket to throttle body Torx screws

(vehicles with cruise control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft