service indicator LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 7 of 1007

CONTENTS

4CONTENTS

MAINTENANCE ........................................................................................ 10-1

MAINTENANCE

Td4 - Diesel Engine - Under Bonnet View ...................................................................................... 10-1

K1.8 – Petrol Engine – Under Bonnet View .................................................................................... 10-2

KV6 – Petrol Engine – Under Bonnet View .................................................................................... 10-3

Seats and Seat Belts ...................................................................................................................... 10-4

Lamps, Horns and Warning Indicators ........................................................................................... 10-4

Wipers and Washers ...................................................................................................................... 10-5

Handbrake ...................................................................................................................................... 10-5

Alarm Handset Battery.................................................................................................................... 10-6

Road Wheels .................................................................................................................................. 10-6

Tyres ............................................................................................................................................... 10-7

Brake Pads and Calipers ................................................................................................................ 10-7

Brake Fluid...................................................................................................................................... 10-9

Road Wheel Speed Sensors .......................................................................................................... 10-9

Fuel Filter - Petrol ........................................................................................................................... 10-10

Fuel Filter - Diesel........................................................................................................................... 10-10

Fuel Pump and Filter assembly - Diesel - 03 Model Year onwards ................................................ 10-10

Fuel Sedimenter - Diesel - 03 Model Year onwards ....................................................................... 10-10

Door Locks, Hinges, Check Straps and Bonnet Catch ................................................................... 10-11

Anti-freeze ...................................................................................................................................... 10-12

Cooling System and Intercooler...................................................................................................... 10-12

Vent filter - turbocharger boost control solenoid valve - Td4 .......................................................... 10-13

Spark Plugs – K1.8 ......................................................................................................................... 10-13

Spark Plugs – KV6.......................................................................................................................... 10-13

Air Cleaner – Petrol Models ............................................................................................................ 10-13

Ancillary Drive Belt – Td4 ............................................................................................................... 10-14

Ancillary Drive Belt – K1.8 .............................................................................................................. 10-14

Ancillary Drive Belt – KV6 ............................................................................................................... 10-15

Camshaft Timing Belt – K1.8 .......................................................................................................... 10-15

Camshaft Timing Belt – KV6........................................................................................................... 10-16

Brake/Clutch Reservoir ................................................................................................................... 10-16

PAS Fluid Level .............................................................................................................................. 10-17

Intermediate Reduction Drive - Non NAS models .......................................................................... 10-17

Intermediate Reduction Drive - NAS models .................................................................................. 10-18

Manual Gearbox – PG1 .................................................................................................................. 10-18

Manual Gearbox – GETRAG .......................................................................................................... 10-19

Automatic Gearbox – JATCO ......................................................................................................... 10-19

Rear Axle ........................................................................................................................................ 10-20

Clutch Pipes and Unions ................................................................................................................ 10-21

Windscreen and Rear Washer Reservoir ....................................................................................... 10-21

Battery ............................................................................................................................................ 10-21

Engine Oil and Filter – Td4 ............................................................................................................. 10-22

Engine Oil and Filter – K1.8 ............................................................................................................ 10-23

Engine Oil and Filter – KV6 ............................................................................................................ 10-24

Fuel Hoses and Pipes..................................................................................................................... 10-25

Brake Hoses and Pipes ................................................................................................................. 10-26

Check Exhaust System................................................................................................................... 10-26

Suspension ..................................................................................................................................... 10-27

Steering ......................................................................................................................................... 10-28

Road Test ....................................................................................................................................... 10-28

Endorse Service Record ................................................................................................................. 10-30

Report any Unusual Features ......................................................................................................... 10-30

Page 26 of 1007

INTRODUCTION

01-1

INTRODUCTION

How To Use This Manual

General

To assist in the use of this Manual, it is divided into

sections and sub-sections. The section title is given

at the top of each page and the relevant sub-section

is given at the bottom.

There is a single contents section at the front of the

Manual, which is divided by section and sub-section.

Each section is numbered from page 1.

The individual items comprising repair operations are

to be followed in the sequence in which they appear.

Item numbers shown in illustrations are referred to in

the associated text.

Adjustment, Repair and Overhaul operations include

reference to Service tool numbers and the

associated illustration depicts the tool in use.

Adjustment and repair operations also include

reference to wear limits, relevant data, torque

figures, specialist information and useful assembly

details. Each adjustment or repair operation is given

a Service Repair Operation (SRO) number.

WARNINGS, CAUTIONS and NOTES have the

following meanings:

WARNING: Procedures which must be followed

precisely to avoid the possibility of injury.

CAUTION: Calls attention to procedures which

must be followed to avoid damage to

components.

NOTE: Gives helpful information.

References

References to the LH or RH side given in this Manual

are made when viewing the vehicle from the rear.

With the engine and gearbox assembly removed, the

crankshaft pulley end of the engine is referred to as

the front.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and tested after

completion and if necessary a road test of the vehicle

is carried out. This is of particular importance where

safety related items are concerned.

Dimensions

The dimensions quoted are to design engineering

specification. Service limits are included where

applicable.Electrical Reference Library (ERL) and Circuit

Diagrams

The Electrical Reference Library (ERL) and Circuit

Diagrams are separate publications intended for use

by trained Land Rover technicians and should be

referred to when attempting to diagnose electrically

related concerns.

The ERL contains descriptions of how the circuits

operate, fuse details, earth point locations, and a

definitive guide to the attributes and location of every

connector on the vehicle.

The ERL is used in conjunction with the Circuit

Diagrams. Both publications are designed to support

all aspects of electrical fault diagnosis.

TESTBOOK (Fault Diagnostic Equipment)

Freelander is equipped with a number of electronic

control systems to provide optimum performance of

the vehicle's systems.

Diagnostic equipment (TESTBOOK/T4) is available

to assist with the fault diagnostic abilities of the

dealer workshop. In particular, the equipment can be

used to interrogate the Engine Control Module

(ECM) for diagnosis of emissions related faults which

may become evident by the illumination of the

Malfunction Indicator Lamp (MIL) in the instrument

pack. This feature is included in compliance with the

latest emissions legislation pertinent to a particular

market (e.g. EU3 for Europe, OBDII for North

America etc.).

This repair manual is produced as a reference

source to supplement Testbook/T4. When available,

the equipment should be used as the primary means

of fault diagnosis on electronically controlled

systems.

Features of TestbookT4 include:

lFully upgradable support for the technician

lStructured diagnostics to accommodate all skill

levels.

lTouch screen operation - Testbook only.

lDirect print out of screen information and test

results.

Page 29 of 1007

INTRODUCTION

01-4

HRW Heated Rear Window

ht/HT High tension

HSLA High Strength Low Alloy

IACV Idle Air Control Valve

IAT Intake Air Temperature

ICE In-Car Entertainment

i.dia. Internal diameter

IDM Intelligent Driver Module

IF Intermediate Frequency

in Inch

in

2Square inch

in3Cubic inch

ILT Inlet Throttle

ISO International Organisation for

Standardisation

ITS Inflatable Tubular Structure

k Thousand

kg Kilogramme

kg/h Kilogrammes per hour

km Kilometre

km/h Kilometres per hour

kPa KiloPascal

KS Knock Sensor

lb(s) Pounds

lbf Pounds force

lbf.in Pounds force inches

lbf/in

2Pounds per square inch

lbf.ft Pounds force feet

λLambda

lc Low compression

LCD Liquid Crystal Display

LED Light Emitting Diode

LEV Low Emission Vehicle

LH Left-Hand

LHD Left-Hand Drive

LSM Light Switch Module

LVS Liquid Vapour Separator

mMetre

µMicro

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MFU Multi-Function Unit

MFL Multi-Function Logic

max. Maximum

MEMS Modular Engine Management

System

MIG Metal/Inert Gas

MIL Malfunction Indicator Lamp

MPa MegaPascal

MOSFET Metal Oxide Semiconductor Field

Effect Transistor

min. Minimum

- Minus (tolerance)

' Minute (angle)

mm Millimetre

mph Miles per hour MPi Multi-Point injection

MV Motorised Valve

MY Model Year

NAS North American Specification

(-) Negative (electrical)

Nm Newton metre

No. Number

NO

2Nitrogen Dioxide

NO

xOxides of Nitrogen

NTC Negative Temperature

Coefficient

NRV Non Return Valve

OBD On Board Diagnostics

OBM On Board Monitoring

o.dia. Outside diameter

OAT Organic Acid Technology

ORM Off-road Mode

ΩOhm

PAS Power Assisted Steering

PCB Printed Circuit Board

PCV Positive Crankcase Ventilation

PDC Parking Distance Control

PDOP Position Dilation Of Precision

PI Programme Information

PPS Pulse Per Second

PS Programme Service

psi Pounds per square inch

pts. Pints

% Percentage

+ Plus (tolerance) or Positive

(electrical)

±Plus or minus (tolerance)

PTC Positive Temperature Coefficient

PTFE Polytetrafluorethylene

PWM Pulse Width Modulation

RDS Radio Data Service

rRadius

:Ratio

ref Reference

REG Regionalisation

RES Rover Engineering Standards

rev/min Revolutions per minute

RF Radio Frequency

RGB Red / Green / Blue

RH Right-Hand

RHD Right-Hand Drive

ROM Read Only Memory

RON Research Octane Number

ROV Roll Over Valve

ROW Rest Of World

SAE Society of Automotive Engineers

SAI Secondary Air Injection

" Second (angle)

SLABS Self Levelling and Anti-Lock

Brake System

SLS Self Levelling Suspension

SOHC Single Overhead Camshaft

SPE Single Point Entry

Page 177 of 1007

MAINTENANCE

10-30 MAINTENANCE

Endorse Service Record

Check

1.Insert date and mileage of next service.

2.Insert current mileage.

3.Tick one of the boxes on the brake fluid

replacement indicator.

4.Tick one of the boxes on the camshaft drive belt

indicator.

5.Endorse service record with dealer stamp.

6.Sign and date the service record.

7.Sign and date the maintenance check sheet.

Report any Unusual Features

Check

1.Produce a written report detailing additional

work necessary, or items which may require

attention prior to the next service.

Page 292 of 1007

EMISSION CONTROL

ADJUSTMENTS 17-1-1

EMISS ION CONTROL ADJUST ME NTS

Evaporative loss control system

(EVAPS) - leak test - NAS

$% 17.90.02.01

The following procedure allows a fuel leak, indicated

by the Malfunction Indicator Lamp (MIL), to be

accurately located. It must only be carried out once it

has been established that there are no obvious faults

with any of the system components.

Check

1.Check components in fuel and EVAP system

for obvious damage. Ensure all connections

are properly secured.

2.The system must be checked using a EVAPS

Diagnostic Testing Station LRA-19-004.

3.Disconnect vent pipe from purge valve and

connect adapter LRA-19-004/1.

NOTE: The reason for inserting the adapter into

the purge valve is that there is currently no

service port fitted to Freelander.

4.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Release clip and disconnect hose from

charcoal canister.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

6.Block charcoal canister port with bung,

included in LRA-19-004.

7.Connect LRA-19-004 to service port fitted on

purge valve.

8.Carry out procedures given in the operating

instructions, these are supplied with LRA-19-

004.Adjust

1.If a leak has been detected, replace component

as necessary and repeat leak test to validate

repair.

2.Remove bung from charcoal canister.

3.Connect hose to charcoal canister and secure

with clip.

4.Fit rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

5.Disconnect adaptor LRA-19-004/1 from purge

valve.

6.Connect hose to purge valve.

Page 600 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-19

Rotary coupler - (SRS) air bag system

$% 76.74.20

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION,

Supplementary restraint system

precautions.

CAUTION: Before disconnecting any part of

the steering linkage, ensure the road wheels

are positioned straight ahead and the

steering wheel is prevented from turning.

Unrestricted turning of the steering wheel

will damage the SRS rotary coupler.

2.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

CAUTION: Use adhesive tape to prevent

rotation of the rotary coupler once the

steering wheel is removed.

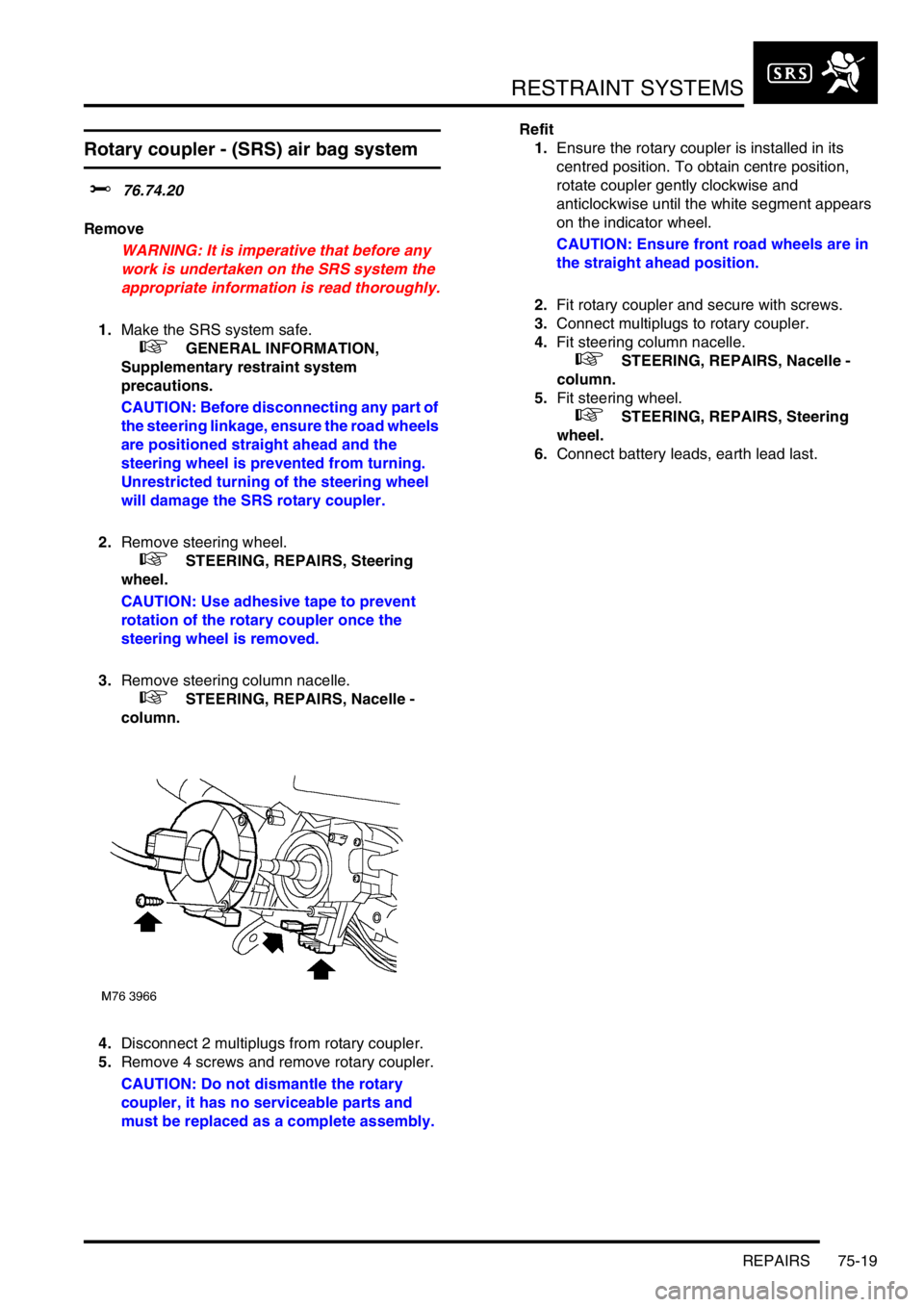

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

4.Disconnect 2 multiplugs from rotary coupler.

5.Remove 4 screws and remove rotary coupler.

CAUTION: Do not dismantle the rotary

coupler, it has no serviceable parts and

must be replaced as a complete assembly.Refit

1.Ensure the rotary coupler is installed in its

centred position. To obtain centre position,

rotate coupler gently clockwise and

anticlockwise until the white segment appears

on the indicator wheel.

CAUTION: Ensure front road wheels are in

the straight ahead position.

2.Fit rotary coupler and secure with screws.

3.Connect multiplugs to rotary coupler.

4.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

5.Fit steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

6.Connect battery leads, earth lead last.