brakes LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 5 of 1007

CONTENTS

2CONTENTS

GENERAL DATA ..................................................................................... 04-1

Engine - Td4 Diesel ........................................................................................................................ 04-1

Engine - K1.8 Petrol........................................................................................................................ 04-6

Engine - KV6 Petrol ........................................................................................................................ 04-11

Fuel system - Td4 Diesel ................................................................................................................ 04-16

Fuel system - K1.8 Petrol ............................................................................................................... 04-18

Fuel system - KV6 Petrol ................................................................................................................ 04-18

Cooling system - Td4 Diesel ........................................................................................................... 04-19

Cooling system - K1.8 Petrol .......................................................................................................... 04-19

Cooling system - KV6 Petrol ........................................................................................................... 04-19

Clutch.............................................................................................................................................. 04-20

Manual Gearbox - Getrag ............................................................................................................... 04-21

Manual Gearbox - PG1 ................................................................................................................... 04-22

Intermediate Reduction Drive (IRD)................................................................................................ 04-24

Automatic Gearbox - Jatco ............................................................................................................. 04-25

Rear Axle and Final Drive ............................................................................................................... 04-26

Steering .......................................................................................................................................... 04-27

Front Suspension............................................................................................................................ 04-28

Rear Suspension ............................................................................................................................ 04-30

Brakes............................................................................................................................................. 04-31

Wheels and tyres ............................................................................................................................ 04-32

Tyre pressures ................................................................................................................................ 04-32

Heating and Ventilation................................................................................................................... 04-33

Air Conditioning .............................................................................................................................. 04-33

Electrical - Td4 engine .................................................................................................................... 04-34

Electrical - K1.8 engine ................................................................................................................... 04-34

Electrical - KV6 engine ................................................................................................................... 04-34

Dimensions ..................................................................................................................................... 04-35

Weights ........................................................................................................................................... 04-36

IDENTIFICATION NUMBERS .................................................................. 05-1

Vehicle Identification Number ......................................................................................................... 05-1

Identification Number Locations ..................................................................................................... 05-2

Page 6 of 1007

CONTENTS

CONTENTS 3

TORQUE WRENCH SETTINGS .............................................................. 06-1

Maintenance ................................................................................................................................... 06-1

Engine – Td4................................................................................................................................... 06-2

Engine – K1.8 ................................................................................................................................. 06-4

Engine – KV6 .................................................................................................................................. 06-6

Emission Control ............................................................................................................................. 06-8

Engine Management System – EDC .............................................................................................. 06-9

Engine Management System – MEMS ........................................................................................... 06-10

Engine Management System – Siemens ........................................................................................ 06-11

Fuel Delivery System – Diesel ........................................................................................................ 06-12

Fuel delivery system – Petrol .......................................................................................................... 06-13

Cooling System – Td4..................................................................................................................... 06-14

Cooling System – K1.8 ................................................................................................................... 06-14

Cooling System – KV6 .................................................................................................................... 06-14

Manifolds and Exhaust System – Td4 ............................................................................................ 06-15

Manifolds and Exhaust Systems – K1.8 ......................................................................................... 06-16

Manifolds and Exhaust Systems – KV6 .......................................................................................... 06-17

Clutch .............................................................................................................................................. 06-18

Manual Gearbox – PG1 .................................................................................................................. 06-19

Manual Gearbox – Getrag .............................................................................................................. 06-20

Intermediate Reduction Drive ......................................................................................................... 06-21

Automatic Gearbox – Jatco ............................................................................................................. 06-22

Driveshafts ...................................................................................................................................... 06-23

Rear Axles and Final Drive ............................................................................................................. 06-24

Steering........................................................................................................................................... 06-25

Front Suspension and Subframe .................................................................................................... 06-26

Rear Suspension and Subframe ..................................................................................................... 06-27

Brakes ............................................................................................................................................. 06-28

Supplementary Restraint Systems .................................................................................................. 06-29

Body ................................................................................................................................................ 06-30

Heating and Ventilation ................................................................................................................... 06-32

Air Conditioning............................................................................................................................... 06-33

Wipers and Washers ....................................................................................................................... 06-34

Electrical ......................................................................................................................................... 06-35

LIFTING AND TOWING ........................................................................... 08-1

Jacking ............................................................................................................................................ 08-1

Towing ............................................................................................................................................ 08-2

Emergency starting ......................................................................................................................... 08-4

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS ...................... 09-1

Capacities ....................................................................................................................................... 09-1

Fluids .............................................................................................................................................. 09-2

Lubrication ...................................................................................................................................... 09-3

Sealants .......................................................................................................................................... 09-4

Page 14 of 1007

CONTENTS

CONTENTS 11

REAR SUSPENSION ................................................................................ 64-1

REPAIRS

Bush - trailing link............................................................................................................................ 64-1

Bearing - hub ................................................................................................................................. 64-2

Damper .......................................................................................................................................... 64-5

Trailing arm .................................................................................................................................... 64-8

Bush - trailing arm .......................................................................................................................... 64-9

Link - adjustable - transverse ......................................................................................................... 64-10

Link - transverse fixed .................................................................................................................... 64-11

Bush - link - transverse .................................................................................................................. 64-12

Sub frame ...................................................................................................................................... 64-13

BRAKES ................................................................................................... 70-1

ADJUSTMENTS

Brake bleed ..................................................................................................................................... 70-1

Cable - handbrake - check and adjust ............................................................................................ 70-2

REPAIRS

Drum - rear ...................................................................................................................................... 70-3

Disc - front....................................................................................................................................... 70-5

Hose - front - primary - LH .............................................................................................................. 70-6

Hose - rear ...................................................................................................................................... 70-7

Cylinder - master - tandem - LHD ................................................................................................... 70-8

Cylinder - master - tandem - RHD................................................................................................... 70-9

Lever assembly - handbrake........................................................................................................... 70-10

Cable - handbrake ......................................................................................................................... 70-11

Switch - handbrake warning ............................................................................................................ 70-12

Switch - stop light ............................................................................................................................ 70-13

Sensor - brake pedal position ........................................................................................................ 70-13

Shoes/pads - front - set................................................................................................................... 70-14

Brake Shoes - rear set .................................................................................................................... 70-15

Servo assembly - LHD .................................................................................................................... 70-17

Servo assembly - RHD ................................................................................................................... 70-19

Vacuum pump - Td4 - manual ........................................................................................................ 70-20

Vacuum pump - Td4 - automatic ..................................................................................................... 70-21

Vacuum - enhancer - KV6 .............................................................................................................. 70-22

Carrier assembly - calliper - front ................................................................................................... 70-23

Wheel cylinder - rear ....................................................................................................................... 70-24

Switch - low fluid level ..................................................................................................................... 70-25

Sensor & harness - front wheel - RH .............................................................................................. 70-25

Sensor & harness - front wheel - LH ............................................................................................... 70-27

Sensor & harness - rear wheel ....................................................................................................... 70-29

Modulator unit ................................................................................................................................. 70-30

Switch - hill descent - from 04MY ................................................................................................... 70-31

Switch - hill descent - up to 03MY................................................................................................... 70-32

Page 45 of 1007

GENERAL INFORMATION

03-14

Self-locking nuts

Self-locking nuts, i.e. nylon insert or deferred thread

nuts can be re-used providing resistance can be felt

when the locking portion of the nut passes over the

thread of the bolt or stud.

DO NOT apply heat in an attempt to free deferred

thread nuts or fittings; as well as causing damage to

protective coatings, there is a risk of damage to

electronic equipment and brake linings from stray

heat.

Where self-locking nuts have been removed, it is

advisable to replace them with new ones of the same

type.

Where bearing pre-load is involved, nuts should be

tightened in accordance with special instructions.

Flexible pipes and hoses

General

When removing and installing flexible hydraulic pipes

and hoses, ensure that the following practices are

observed to ensure component serviceability:

lBefore removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

lObtain appropriate plugs or caps before

detaching hose end fittings, so that the ports

can be immediately covered to prevent the

ingress of dirt.

lClean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any faulty hoses.

lWhen refitting a hose, ensure that no

unnecessary bends are introduced, and that

hose is not twisted before or during tightening of

union nuts.

lFit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of

dirt.

lAbsolute cleanliness must be observed with

hydraulic components at all times.

lAfter any work on hydraulic systems, carefully

inspect for leaks underneath the vehicle while a

second operator applies maximum brake

pressure to the brakes (engine running) and

operates the steering.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

Page 48 of 1007

GENERAL INFORMATION

03-17

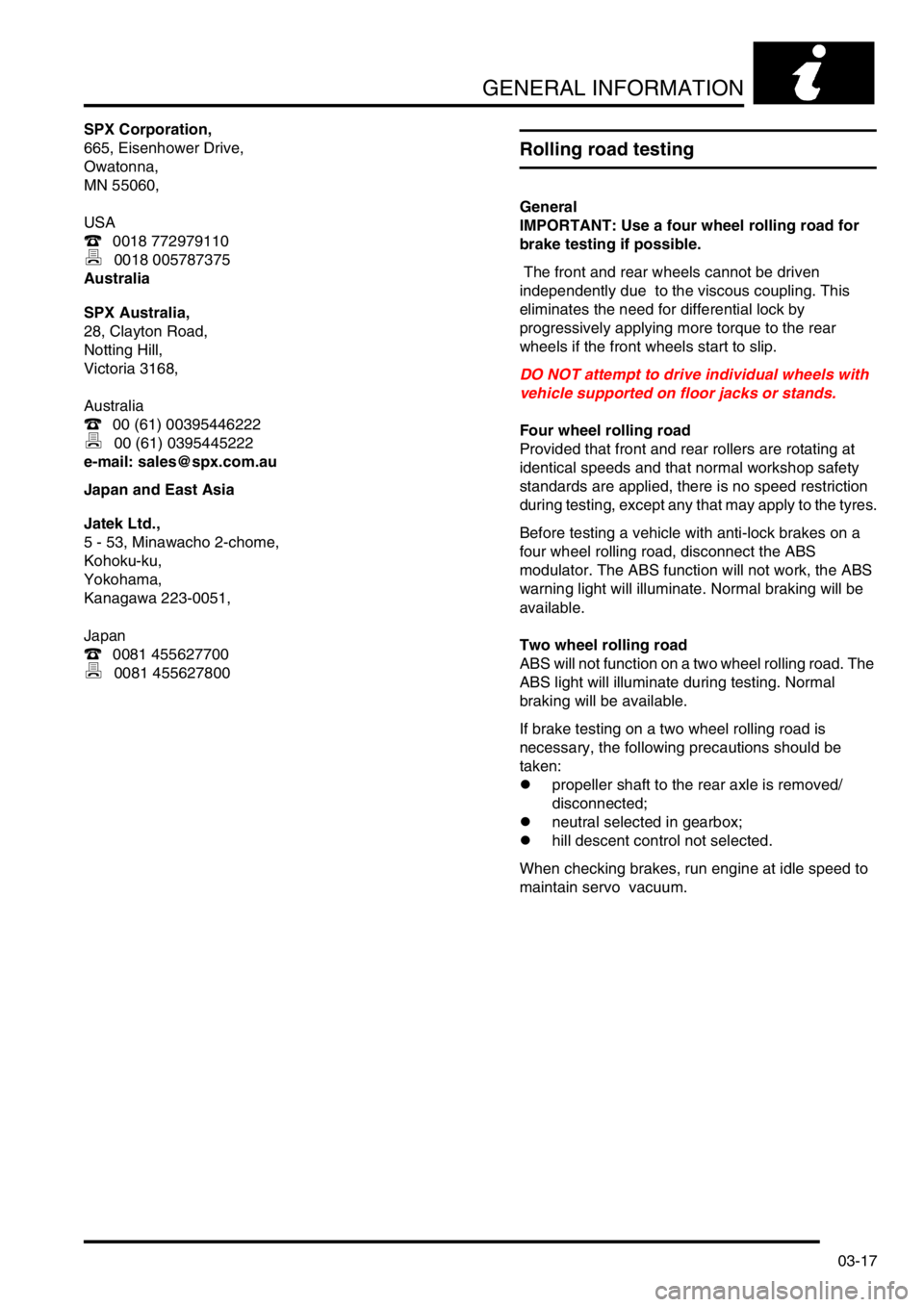

SPX Corporation,

665, Eisenhower Drive,

Owatonna,

MN 55060,

USA

( 0018 772979110

) 0018 005787375

Australia

SPX Australia,

28, Clayton Road,

Notting Hill,

Victoria 3168,

Australia

( 00 (61) 00395446222

) 00 (61) 0395445222

e-mail: [email protected]

Japan and East Asia

Jatek Ltd.,

5 - 53, Minawacho 2-chome,

Kohoku-ku,

Yokohama,

Kanagawa 223-0051,

Japan

( 0081 455627700

) 0081 455627800

Rolling road testing

General

IMPORTANT: Use a four wheel rolling road for

brake testing if possible.

The front and rear wheels cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively applying more torque to the rear

wheels if the front wheels start to slip.

DO NOT attempt to drive individual wheels with

vehicle supported on floor jacks or stands.

Four wheel rolling road

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing, except any that may apply to the tyres.

Before testing a vehicle with anti-lock brakes on a

four wheel rolling road, disconnect the ABS

modulator. The ABS function will not work, the ABS

warning light will illuminate. Normal braking will be

available.

Two wheel rolling road

ABS will not function on a two wheel rolling road. The

ABS light will illuminate during testing. Normal

braking will be available.

If brake testing on a two wheel rolling road is

necessary, the following precautions should be

taken:

lpropeller shaft to the rear axle is removed/

disconnected;

lneutral selected in gearbox;

lhill descent control not selected.

When checking brakes, run engine at idle speed to

maintain servo vacuum.

Page 94 of 1007

GENERAL DATA

04-31

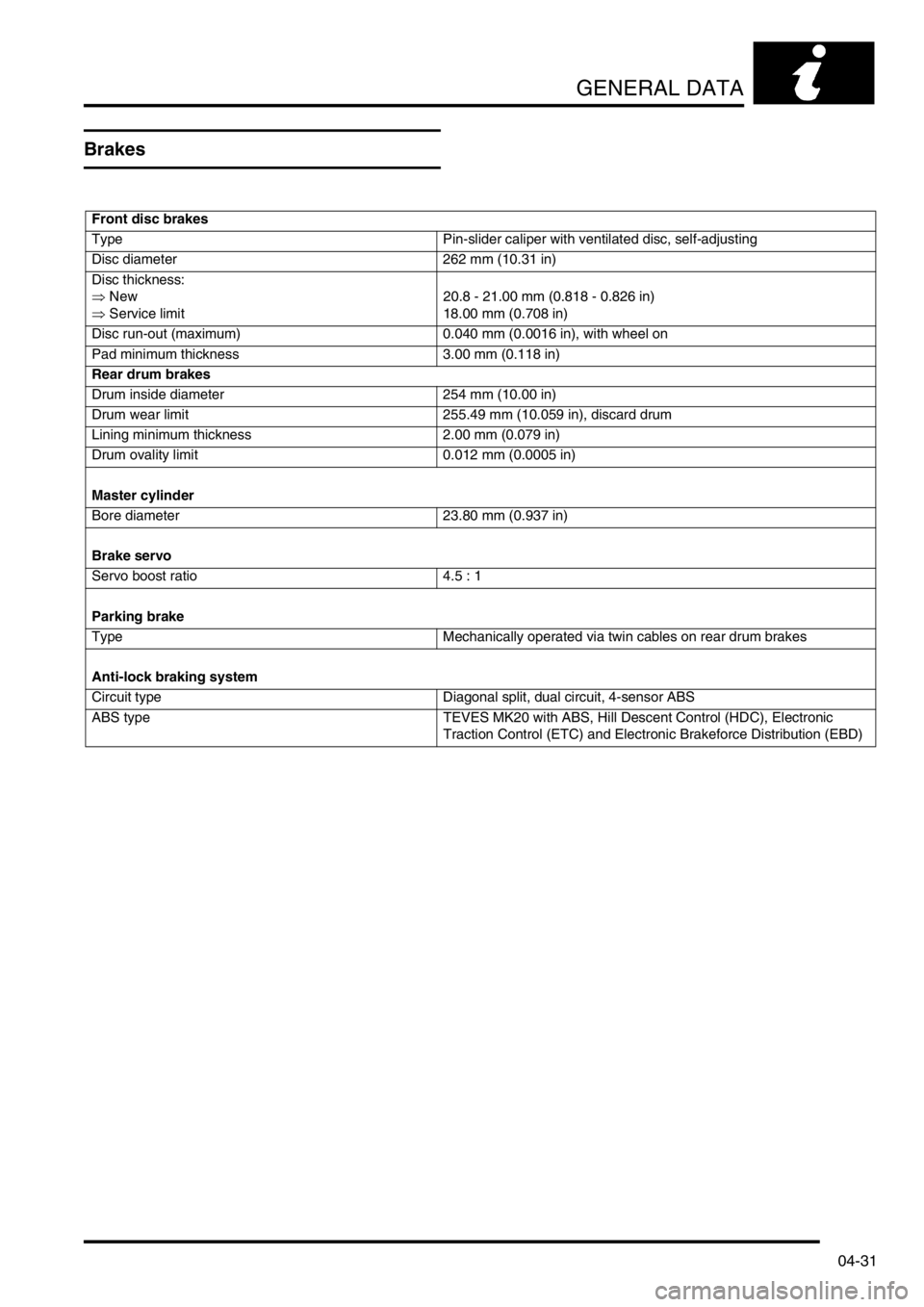

Brakes

Front disc brakes

Type Pin-slider caliper with ventilated disc, self-adjusting

Disc diameter 262 mm (10.31 in)

Disc thickness:

⇒ New

⇒ Service limit20.8 - 21.00 mm (0.818 - 0.826 in)

18.00 mm (0.708 in)

Disc run-out (maximum) 0.040 mm (0.0016 in), with wheel on

Pad minimum thickness 3.00 mm (0.118 in)

Rear drum brakes

Drum inside diameter 254 mm (10.00 in)

Drum wear limit 255.49 mm (10.059 in), discard drum

Lining minimum thickness 2.00 mm (0.079 in)

Drum ovality limit 0.012 mm (0.0005 in)

Master cylinder

Bore diameter 23.80 mm (0.937 in)

Brake servo

Servo boost ratio 4.5 : 1

Parking brake

Type Mechanically operated via twin cables on rear drum brakes

Anti-lock braking system

Circuit type Diagonal split, dual circuit, 4-sensor ABS

ABS type TEVES MK20 with ABS, Hill Descent Control (HDC), Electronic

Traction Control (ETC) and Electronic Brakeforce Distribution (EBD)

Page 131 of 1007

TORQUE WRENCH SETTINGS

06-28

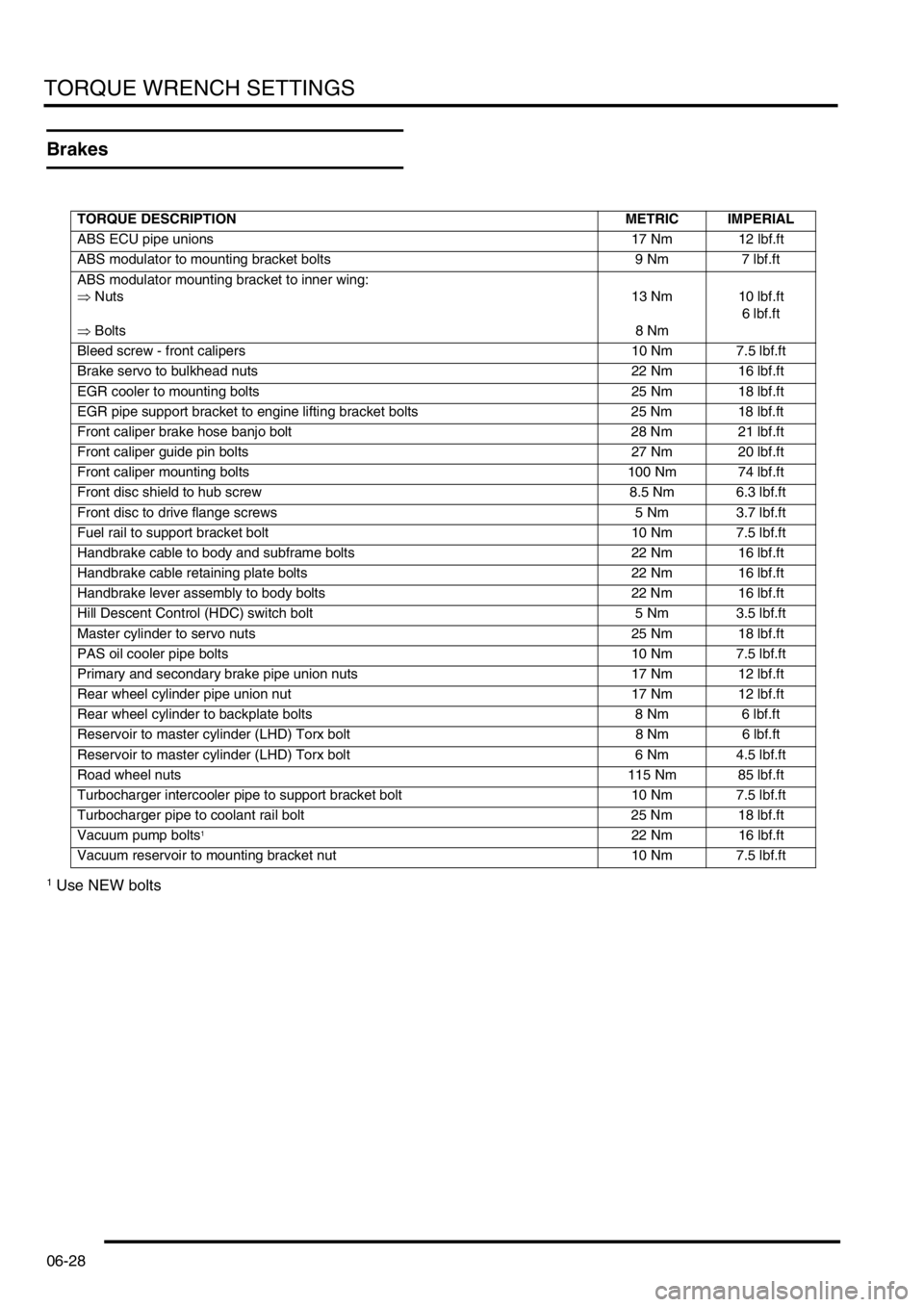

Brakes

1 Use NEW bolts

TORQUE DESCRIPTION METRIC IMPERIAL

ABS ECU pipe unions 17 Nm 12 lbf.ft

ABS modulator to mounting bracket bolts 9 Nm 7 lbf.ft

ABS modulator mounting bracket to inner wing:

⇒ Nuts

⇒ Bolts13 Nm

8 Nm10 lbf.ft

6 lbf.ft

Bleed screw - front calipers 10 Nm 7.5 lbf.ft

Brake servo to bulkhead nuts 22 Nm 16 lbf.ft

EGR cooler to mounting bolts 25 Nm 18 lbf.ft

EGR pipe support bracket to engine lifting bracket bolts 25 Nm 18 lbf.ft

Front caliper brake hose banjo bolt 28 Nm 21 lbf.ft

Front caliper guide pin bolts 27 Nm 20 lbf.ft

Front caliper mounting bolts 100 Nm 74 lbf.ft

Front disc shield to hub screw 8.5 Nm 6.3 lbf.ft

Front disc to drive flange screws 5 Nm 3.7 lbf.ft

Fuel rail to support bracket bolt 10 Nm 7.5 lbf.ft

Handbrake cable to body and subframe bolts 22 Nm 16 lbf.ft

Handbrake cable retaining plate bolts 22 Nm 16 lbf.ft

Handbrake lever assembly to body bolts 22 Nm 16 lbf.ft

Hill Descent Control (HDC) switch bolt 5 Nm 3.5 lbf.ft

Master cylinder to servo nuts 25 Nm 18 lbf.ft

PAS oil cooler pipe bolts 10 Nm 7.5 lbf.ft

Primary and secondary brake pipe union nuts 17 Nm 12 lbf.ft

Rear wheel cylinder pipe union nut 17 Nm 12 lbf.ft

Rear wheel cylinder to backplate bolts 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 6 Nm 4.5 lbf.ft

Road wheel nuts 115 Nm 85 lbf.ft

Turbocharger intercooler pipe to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger pipe to coolant rail bolt 25 Nm 18 lbf.ft

Vacuum pump bolts

122 Nm 16 lbf.ft

Vacuum reservoir to mounting bracket nut 10 Nm 7.5 lbf.ft

Page 141 of 1007

LIFTING AND TOWING

08-2

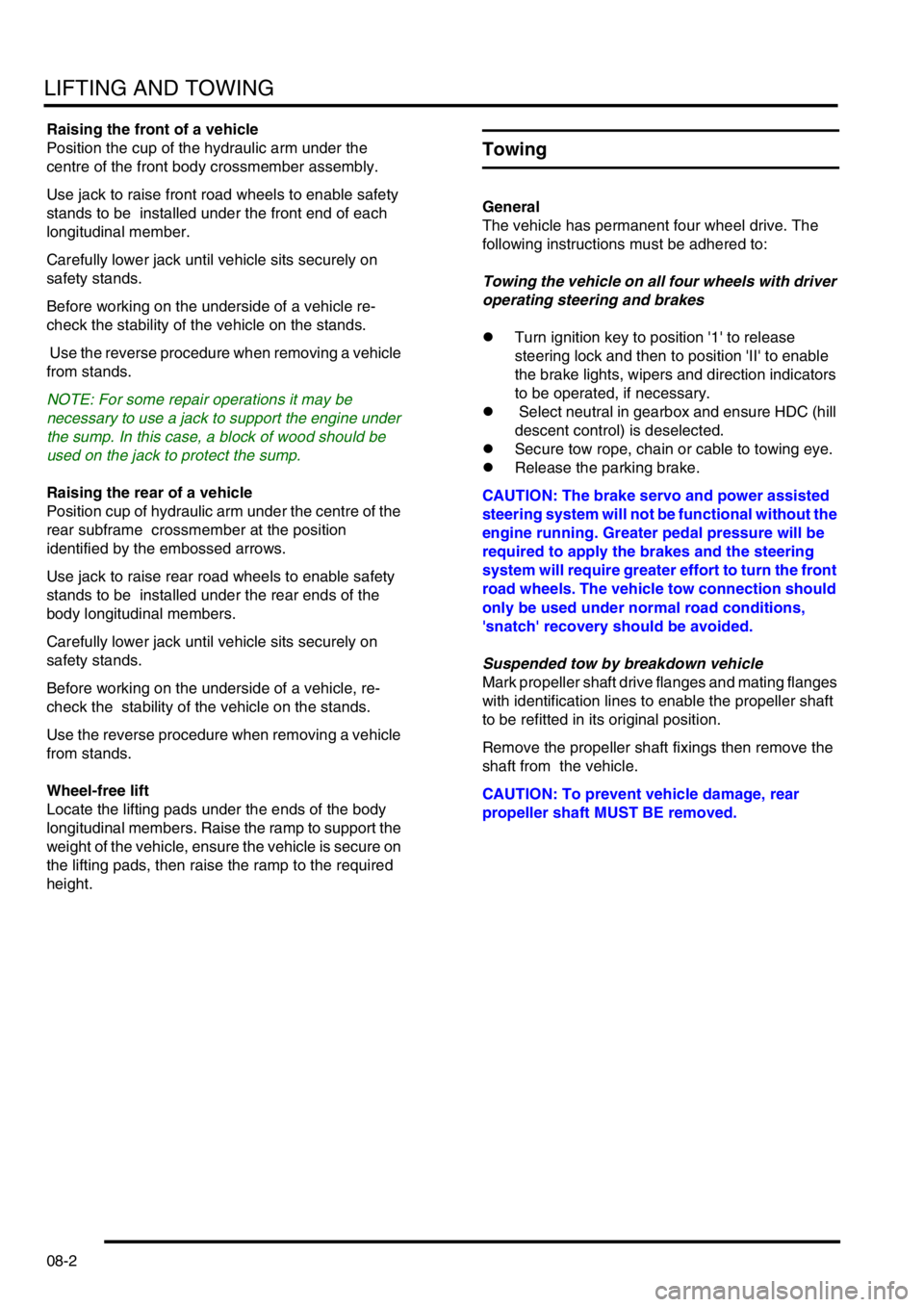

Raising the front of a vehicle

Position the cup of the hydraulic arm under the

centre of the front body crossmember assembly.

Use jack to raise front road wheels to enable safety

stands to be installed under the front end of each

longitudinal member.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

NOTE: For some repair operations it may be

necessary to use a jack to support the engine under

the sump. In this case, a block of wood should be

used on the jack to protect the sump.

Raising the rear of a vehicle

Position cup of hydraulic arm under the centre of the

rear subframe crossmember at the position

identified by the embossed arrows.

Use jack to raise rear road wheels to enable safety

stands to be installed under the rear ends of the

body longitudinal members.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle, re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

Wheel-free lift

Locate the lifting pads under the ends of the body

longitudinal members. Raise the ramp to support the

weight of the vehicle, ensure the vehicle is secure on

the lifting pads, then raise the ramp to the required

height.

Towing

General

The vehicle has permanent four wheel drive. The

following instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes

lTurn ignition key to position '1' to release

steering lock and then to position 'II' to enable

the brake lights, wipers and direction indicators

to be operated, if necessary.

l Select neutral in gearbox and ensure HDC (hill

descent control) is deselected.

lSecure tow rope, chain or cable to towing eye.

lRelease the parking brake.

CAUTION: The brake servo and power assisted

steering system will not be functional without the

engine running. Greater pedal pressure will be

required to apply the brakes and the steering

system will require greater effort to turn the front

road wheels. The vehicle tow connection should

only be used under normal road conditions,

'snatch' recovery should be avoided.

Suspended tow by breakdown vehicle

Mark propeller shaft drive flanges and mating flanges

with identification lines to enable the propeller shaft

to be refitted in its original position.

Remove the propeller shaft fixings then remove the

shaft from the vehicle.

CAUTION: To prevent vehicle damage, rear

propeller shaft MUST BE removed.

Page 152 of 1007

MAINTENANCE

MAINTENANCE 10-5

Wipers and Washers

Check

1.Operate screen washer and switch on wipers.

Check washer jets are correctly aimed and

check for smooth smearless operation across

screen of wiper blades at all speeds, including

intermittent.

2.Repeat operation for rear screen wipers/

washers.

3.Check all wiper blades for condition and signs

of splits or damage.

4.Check security of wiper arms.

Handbrake

Check

1.With the vehicle stationary and on a level

surface, apply and release handbrake and

check for correct operation. If required, adjust

handbrake.

+ BRAKES, ADJUSTMENTS, Cable -

handbrake - check and adjust.

NOTE: Any adjustment required as a result of

the checking process will be subject to

additional labour and/or material cost and

should not be carried out without the

authorisation of the customer.

Adjust Handbrake

(First 12,000 miles/12 months only)

1.Adjust handbrake cable.

+ BRAKES, ADJUSTMENTS, Cable -

handbrake - check and adjust.

NOTE: Additional time is built into the first

12,000/12 months service time to allow for

handbrake cable adjustment.

Page 155 of 1007

MAINTENANCE

10-8 MAINTENANCE

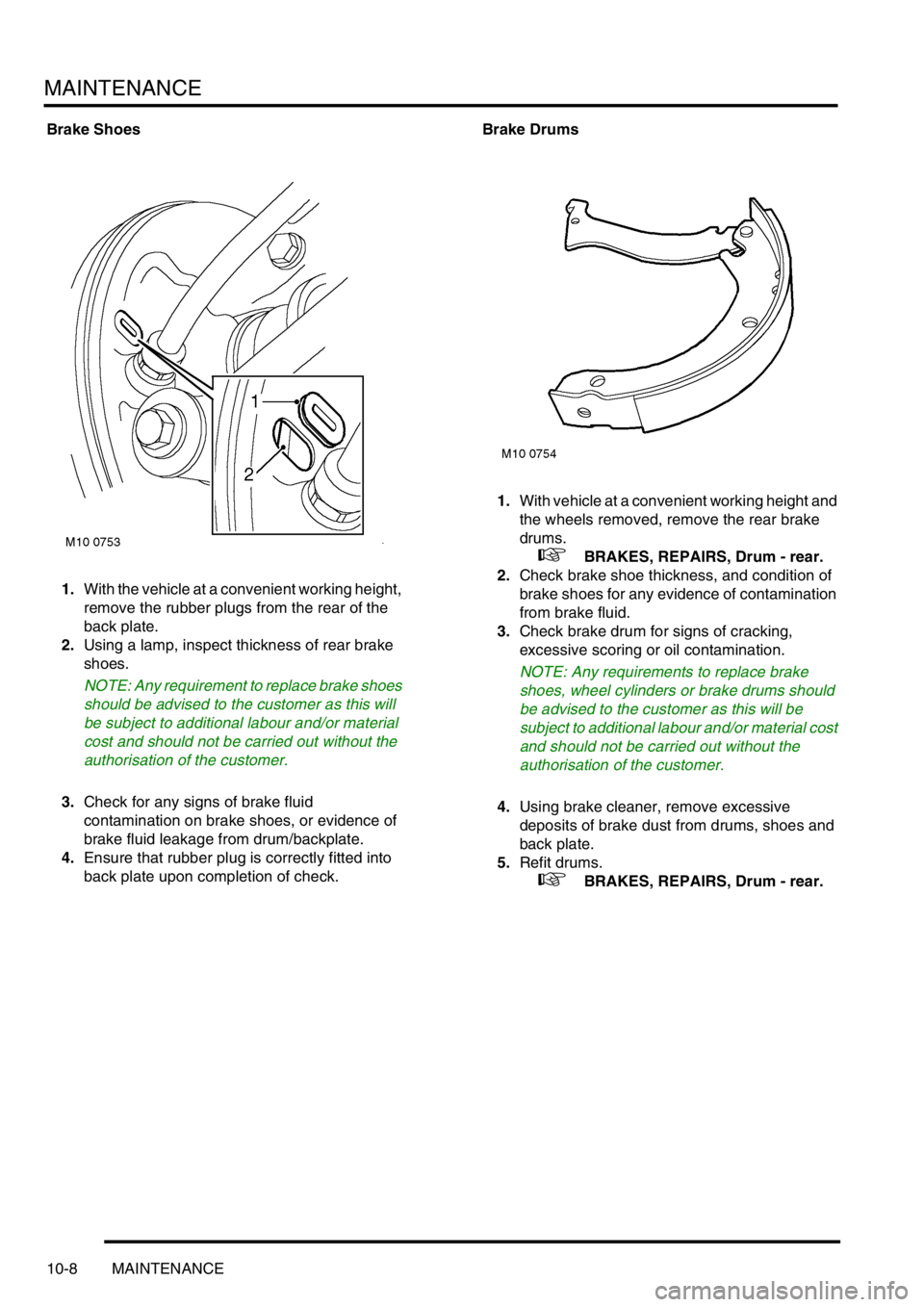

Brake Shoes

1.With the vehicle at a convenient working height,

remove the rubber plugs from the rear of the

back plate.

2.Using a lamp, inspect thickness of rear brake

shoes.

NOTE: Any requirement to replace brake shoes

should be advised to the customer as this will

be subject to additional labour and/or material

cost and should not be carried out without the

authorisation of the customer.

3.Check for any signs of brake fluid

contamination on brake shoes, or evidence of

brake fluid leakage from drum/backplate.

4.Ensure that rubber plug is correctly fitted into

back plate upon completion of check.Brake Drums

1.With vehicle at a convenient working height and

the wheels removed, remove the rear brake

drums.

+ BRAKES, REPAIRS, Drum - rear.

2.Check brake shoe thickness, and condition of

brake shoes for any evidence of contamination

from brake fluid.

3.Check brake drum for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirements to replace brake

shoes, wheel cylinders or brake drums should

be advised to the customer as this will be

subject to additional labour and/or material cost

and should not be carried out without the

authorisation of the customer.

4.Using brake cleaner, remove excessive

deposits of brake dust from drums, shoes and

back plate.

5.Refit drums.

+ BRAKES, REPAIRS, Drum - rear.