tow LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 6 of 1007

CONTENTS

CONTENTS 3

TORQUE WRENCH SETTINGS .............................................................. 06-1

Maintenance ................................................................................................................................... 06-1

Engine – Td4................................................................................................................................... 06-2

Engine – K1.8 ................................................................................................................................. 06-4

Engine – KV6 .................................................................................................................................. 06-6

Emission Control ............................................................................................................................. 06-8

Engine Management System – EDC .............................................................................................. 06-9

Engine Management System – MEMS ........................................................................................... 06-10

Engine Management System – Siemens ........................................................................................ 06-11

Fuel Delivery System – Diesel ........................................................................................................ 06-12

Fuel delivery system – Petrol .......................................................................................................... 06-13

Cooling System – Td4..................................................................................................................... 06-14

Cooling System – K1.8 ................................................................................................................... 06-14

Cooling System – KV6 .................................................................................................................... 06-14

Manifolds and Exhaust System – Td4 ............................................................................................ 06-15

Manifolds and Exhaust Systems – K1.8 ......................................................................................... 06-16

Manifolds and Exhaust Systems – KV6 .......................................................................................... 06-17

Clutch .............................................................................................................................................. 06-18

Manual Gearbox – PG1 .................................................................................................................. 06-19

Manual Gearbox – Getrag .............................................................................................................. 06-20

Intermediate Reduction Drive ......................................................................................................... 06-21

Automatic Gearbox – Jatco ............................................................................................................. 06-22

Driveshafts ...................................................................................................................................... 06-23

Rear Axles and Final Drive ............................................................................................................. 06-24

Steering........................................................................................................................................... 06-25

Front Suspension and Subframe .................................................................................................... 06-26

Rear Suspension and Subframe ..................................................................................................... 06-27

Brakes ............................................................................................................................................. 06-28

Supplementary Restraint Systems .................................................................................................. 06-29

Body ................................................................................................................................................ 06-30

Heating and Ventilation ................................................................................................................... 06-32

Air Conditioning............................................................................................................................... 06-33

Wipers and Washers ....................................................................................................................... 06-34

Electrical ......................................................................................................................................... 06-35

LIFTING AND TOWING ........................................................................... 08-1

Jacking ............................................................................................................................................ 08-1

Towing ............................................................................................................................................ 08-2

Emergency starting ......................................................................................................................... 08-4

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS ...................... 09-1

Capacities ....................................................................................................................................... 09-1

Fluids .............................................................................................................................................. 09-2

Lubrication ...................................................................................................................................... 09-3

Sealants .......................................................................................................................................... 09-4

Page 17 of 1007

CONTENTS

14 CONTENTS

INTERIOR TRIM COMPONENTS ............................................................. 76-3-1

REPAIRS

Sun visor ......................................................................................................................................... 76-3-1

Trim casing - rear quarter - lower - 3 door ...................................................................................... 76-3-1

Trim casing - rear quarter - lower - 5 door ...................................................................................... 76-3-2

Trim casing - rear quarter - upper - 3 door ..................................................................................... 76-3-3

Trim casing - rear quarter - upper - 5 door ..................................................................................... 76-3-4

Trim finisher - 'A' post - upper - renew ............................................................................................ 76-3-5

Trim finisher - 'B/C' post - upper - renew ........................................................................................ 76-3-6

Trim finisher - 'B' post - lower - 5 door ............................................................................................ 76-3-7

Trim casing - body side - rear - 3 door............................................................................................ 76-3-8

Console - front - up to 04MY........................................................................................................... 76-3-9

Console assembly - front - from 04MY ........................................................................................... 76-3-11

Console - rear ................................................................................................................................. 76-3-12

Cup holder - fascia - from 04MY ..................................................................................................... 76-3-13

Fascia - up to 04MY........................................................................................................................ 76-3-14

Fascia - from 04MY ........................................................................................................................ 76-3-19

Drink tray assembly - fascia - up to 04MY ...................................................................................... 76-3-23

Stowage box - fascia ...................................................................................................................... 76-3-23

Carpet - luggage compartment ....................................................................................................... 76-3-24

Glove box........................................................................................................................................ 76-3-25

Headlining - 3 door ......................................................................................................................... 76-3-25

Headlining - 5 door ......................................................................................................................... 76-3-27

SCREENS ................................................................................................. 76-4-1

REPAIRS

Windscreen ..................................................................................................................................... 76-4-1

Glass - body side - rear .................................................................................................................. 76-4-3

SEATS ....................................................................................................... 76-5-1

REPAIRS

Front seat ....................................................................................................................................... 76-5-1

Rear seat - LH ............................................................................................................................... 76-5-1

Rear seat - RH ............................................................................................................................... 76-5-2

Cushion & squab - rear seat - bench type - 3 door ........................................................................ 76-5-2

Cover - one piece - front seat cushion ........................................................................................... 76-5-3

Cover - rear seat cushion - RH ..................................................................................................... 76-5-4

Cover - rear seat cushion - LH........................................................................................................ 76-5-6

Cover - cushion - rear single seat - 3 door .................................................................................... 76-5-7

Finisher - seat base - front - each .................................................................................................. 76-5-8

Finisher - cushion side - front seat ................................................................................................. 76-5-9

Manual mechanism - lumbar support - front seat .......................................................................... 76-5-9

Latch - rear squab - RH ................................................................................................................. 76-5-11

Latch - rear squab - LH ................................................................................................................... 76-5-11

Cover - squab - front seat .............................................................................................................. 76-5-12

Cover - squab - rear seat - side - LH .............................................................................................. 76-5-13

Cover - squab - rear seat - RH ...................................................................................................... 76-5-14

Cover - squab - rear single seat - 3 door ....................................................................................... 76-5-16

Page 33 of 1007

GENERAL INFORMATION

03-2

Environmental Protection Precautions

It is illegal to pour used oil on to the ground, down

sewers or drains, or into water courses.

Burning of used engine oil in small space heaters or

boilers should only be considered for units of

approved design and in compliance with the

equipment manufacturer's recommendations. The

heating system must meet the regulatory standards

of HMIP for small burners of less than 0.4 MW. If in

doubt check with the appropriate local authority and/

or manufacturer of the approved appliance.

Dispose of used oil and filters through authorised

waste disposal contractors and licensed waste

disposal sites, or through the waste oil reclamation

trade. If in doubt, contact the Local Authority for

advice on disposal facilities.

Safety instructions

Whenever possible, use a lift or pit when working

beneath vehicle, in preference to jacking. Chock

wheels as well as applying parking brake.

Jacking

Always use the recommended jacking points. The

recommended jacking points are shown in

theLIFTING AND TOWING sub-section of the

INFORMATION section.

Always ensure that any lifting apparatus has

sufficient load capacity for the weight to be lifted.

Ensure the vehicle is standing on level ground prior

to lifting or jacking.

Apply the handbrake and chock the wheels.

WARNING: Do not work on or under a vehicle

supported only by a jack. Always support the

vehicle on safety stands.

Do not leave tools, lifting equipment, spilt oil, etc.,

around or on the work bench area. Always keep a

clean and tidy work area.

Brake shoes and pads

Always fit the correct grade and specification of

brake linings. When renewing brake pads and brake

shoes always replace as complete axle sets only.

Page 40 of 1007

GENERAL INFORMATION

03-9

Oil seals

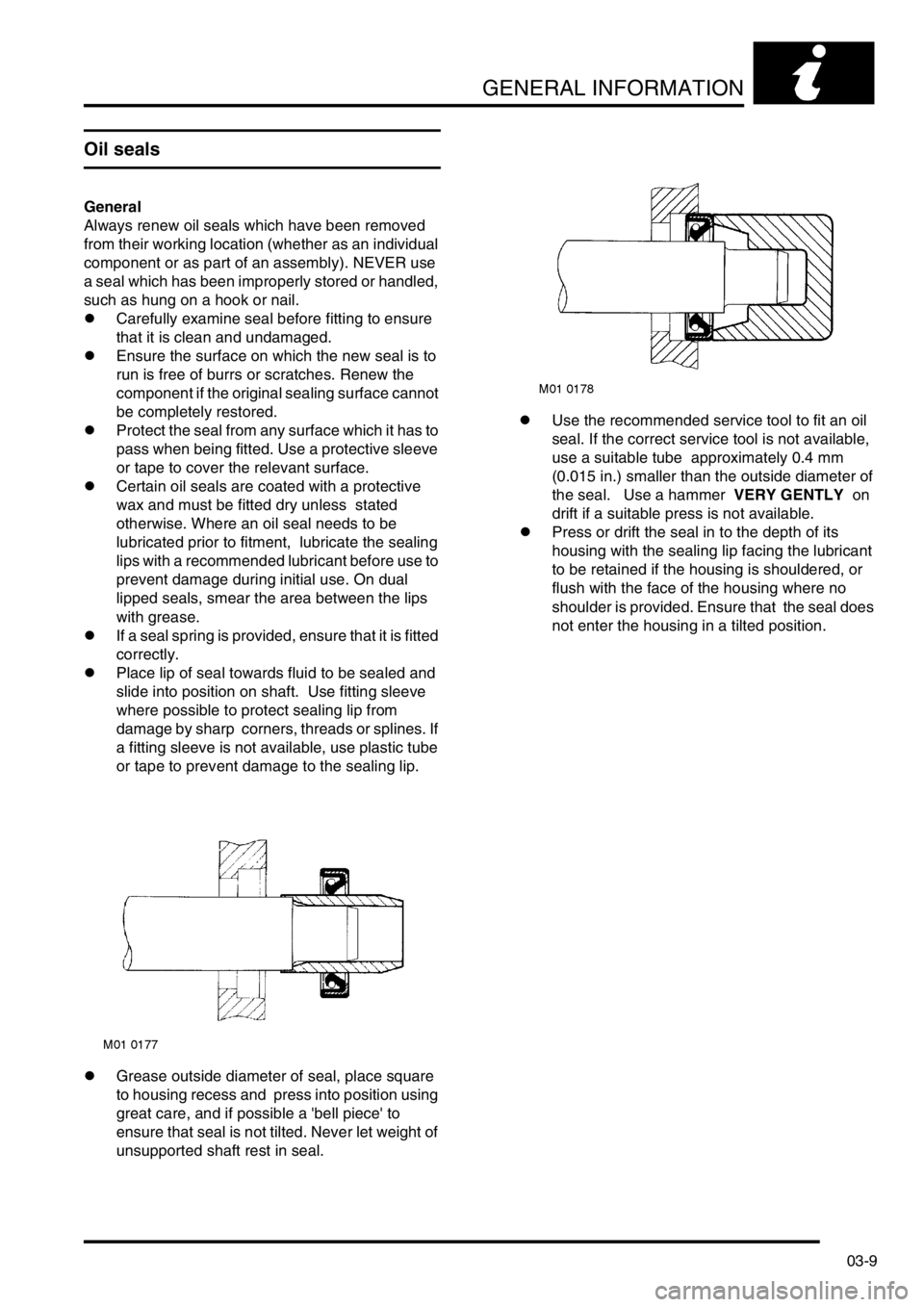

General

Always renew oil seals which have been removed

from their working location (whether as an individual

component or as part of an assembly). NEVER use

a seal which has been improperly stored or handled,

such as hung on a hook or nail.

lCarefully examine seal before fitting to ensure

that it is clean and undamaged.

lEnsure the surface on which the new seal is to

run is free of burrs or scratches. Renew the

component if the original sealing surface cannot

be completely restored.

lProtect the seal from any surface which it has to

pass when being fitted. Use a protective sleeve

or tape to cover the relevant surface.

lCertain oil seals are coated with a protective

wax and must be fitted dry unless stated

otherwise. Where an oil seal needs to be

lubricated prior to fitment, lubricate the sealing

lips with a recommended lubricant before use to

prevent damage during initial use. On dual

lipped seals, smear the area between the lips

with grease.

lIf a seal spring is provided, ensure that it is fitted

correctly.

lPlace lip of seal towards fluid to be sealed and

slide into position on shaft. Use fitting sleeve

where possible to protect sealing lip from

damage by sharp corners, threads or splines. If

a fitting sleeve is not available, use plastic tube

or tape to prevent damage to the sealing lip.

lGrease outside diameter of seal, place square

to housing recess and press into position using

great care, and if possible a 'bell piece' to

ensure that seal is not tilted. Never let weight of

unsupported shaft rest in seal.lUse the recommended service tool to fit an oil

seal. If the correct service tool is not available,

use a suitable tube approximately 0.4 mm

(0.015 in.) smaller than the outside diameter of

the seal. Use a hammer VERY GENTLY on

drift if a suitable press is not available.

lPress or drift the seal in to the depth of its

housing with the sealing lip facing the lubricant

to be retained if the housing is shouldered, or

flush with the face of the housing where no

shoulder is provided. Ensure that the seal does

not enter the housing in a tilted position.

Page 46 of 1007

GENERAL INFORMATION

03-15

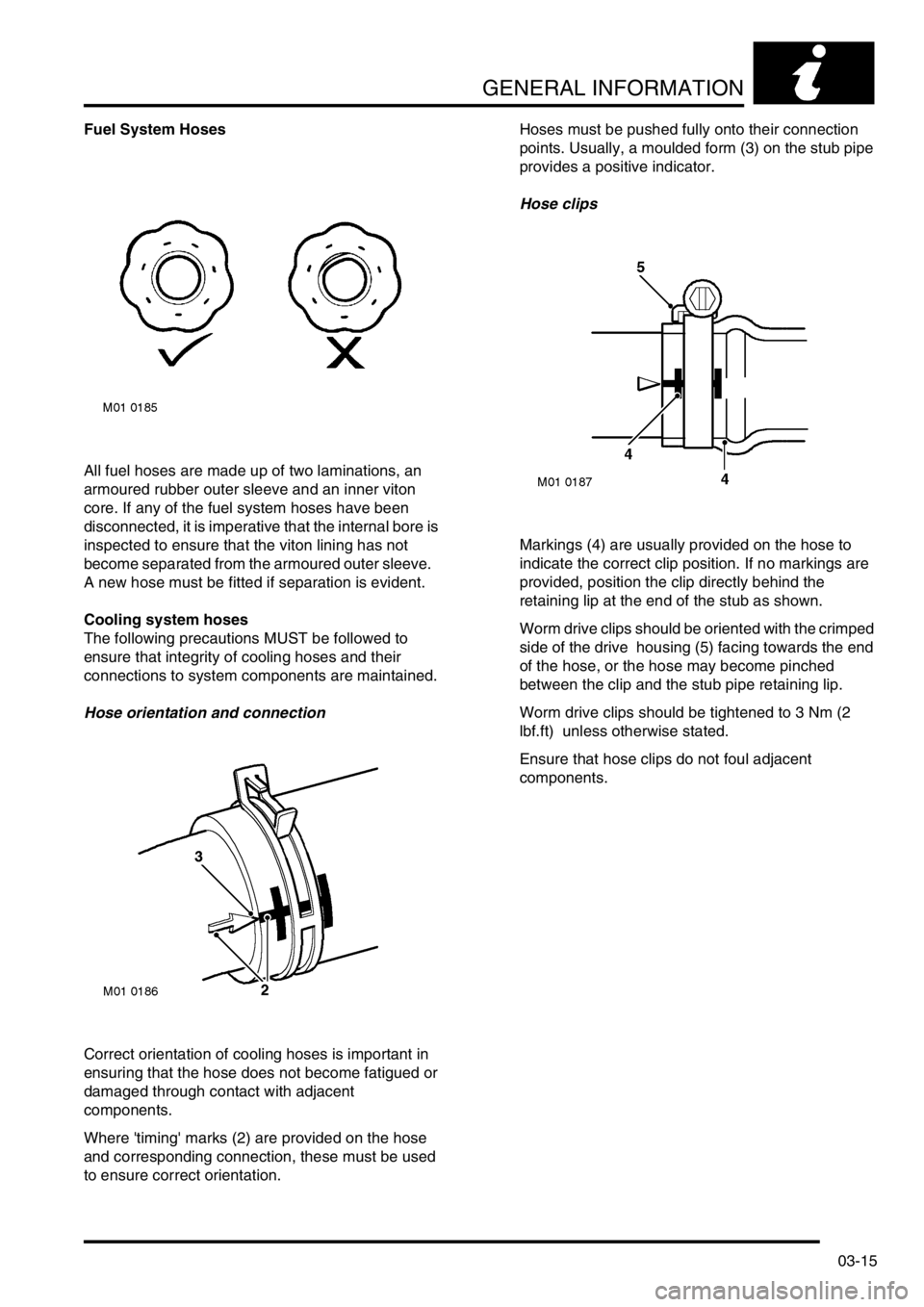

Fuel System Hoses

All fuel hoses are made up of two laminations, an

armoured rubber outer sleeve and an inner viton

core. If any of the fuel system hoses have been

disconnected, it is imperative that the internal bore is

inspected to ensure that the viton lining has not

become separated from the armoured outer sleeve.

A new hose must be fitted if separation is evident.

Cooling system hoses

The following precautions MUST be followed to

ensure that integrity of cooling hoses and their

connections to system components are maintained.

Hose orientation and connection

Correct orientation of cooling hoses is important in

ensuring that the hose does not become fatigued or

damaged through contact with adjacent

components.

Where 'timing' marks (2) are provided on the hose

and corresponding connection, these must be used

to ensure correct orientation.Hoses must be pushed fully onto their connection

points. Usually, a moulded form (3) on the stub pipe

provides a positive indicator.

Hose clips

Markings (4) are usually provided on the hose to

indicate the correct clip position. If no markings are

provided, position the clip directly behind the

retaining lip at the end of the stub as shown.

Worm drive clips should be oriented with the crimped

side of the drive housing (5) facing towards the end

of the hose, or the hose may become pinched

between the clip and the stub pipe retaining lip.

Worm drive clips should be tightened to 3 Nm (2

lbf.ft) unless otherwise stated.

Ensure that hose clips do not foul adjacent

components.

Page 54 of 1007

GENERAL INFORMATION

03-23

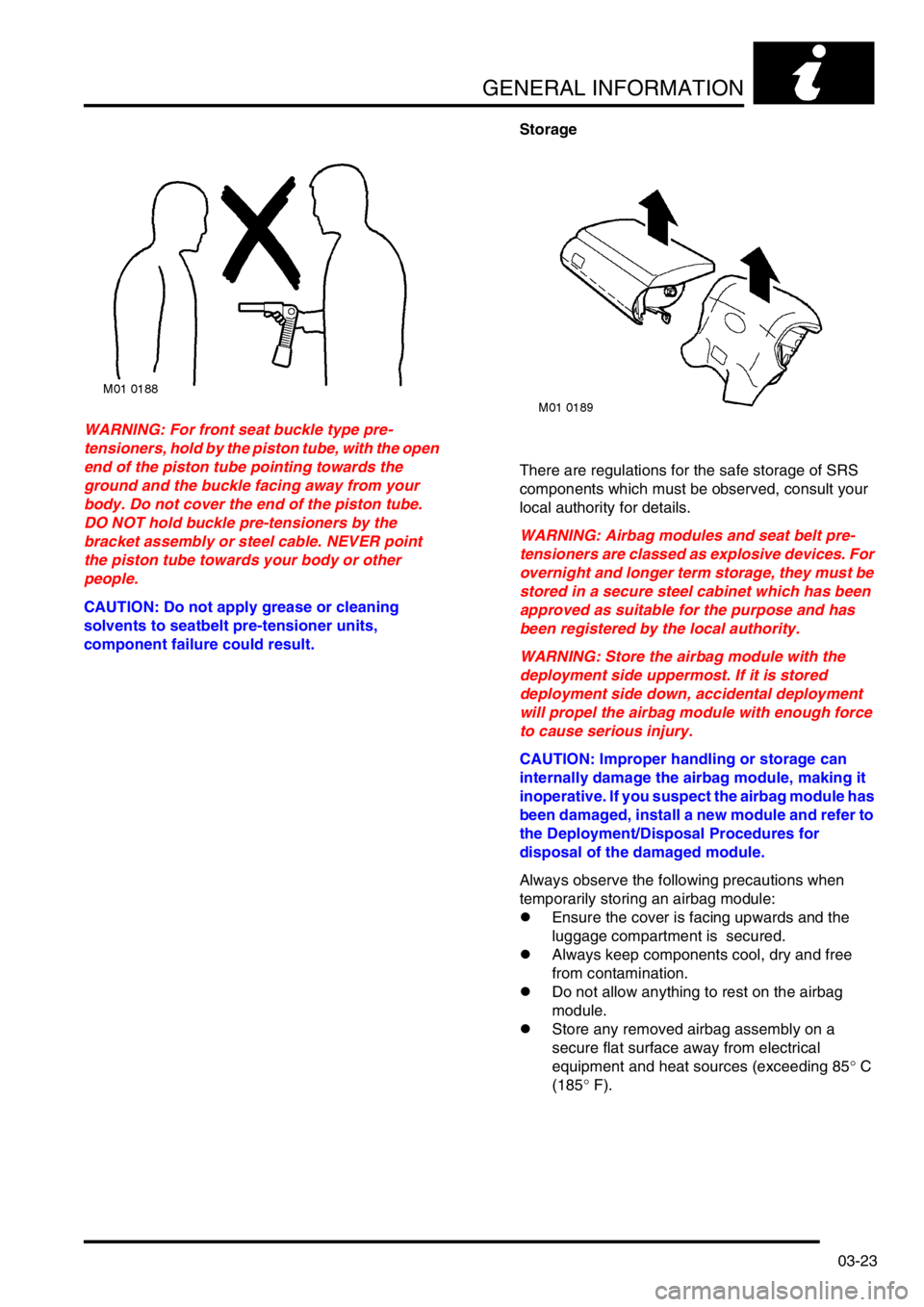

WARNING: For front seat buckle type pre-

tensioners, hold by the piston tube, with the open

end of the piston tube pointing towards the

ground and the buckle facing away from your

body. Do not cover the end of the piston tube.

DO NOT hold buckle pre-tensioners by the

bracket assembly or steel cable. NEVER point

the piston tube towards your body or other

people.

CAUTION: Do not apply grease or cleaning

solvents to seatbelt pre-tensioner units,

component failure could result.Storage

There are regulations for the safe storage of SRS

components which must be observed, consult your

local authority for details.

WARNING: Airbag modules and seat belt pre-

tensioners are classed as explosive devices. For

overnight and longer term storage, they must be

stored in a secure steel cabinet which has been

approved as suitable for the purpose and has

been registered by the local authority.

WARNING: Store the airbag module with the

deployment side uppermost. If it is stored

deployment side down, accidental deployment

will propel the airbag module with enough force

to cause serious injury.

CAUTION: Improper handling or storage can

internally damage the airbag module, making it

inoperative. If you suspect the airbag module has

been damaged, install a new module and refer to

the Deployment/Disposal Procedures for

disposal of the damaged module.

Always observe the following precautions when

temporarily storing an airbag module:

lEnsure the cover is facing upwards and the

luggage compartment is secured.

lAlways keep components cool, dry and free

from contamination.

lDo not allow anything to rest on the airbag

module.

lStore any removed airbag assembly on a

secure flat surface away from electrical

equipment and heat sources (exceeding 85° C

(185° F).

Page 57 of 1007

GENERAL INFORMATION

03-26

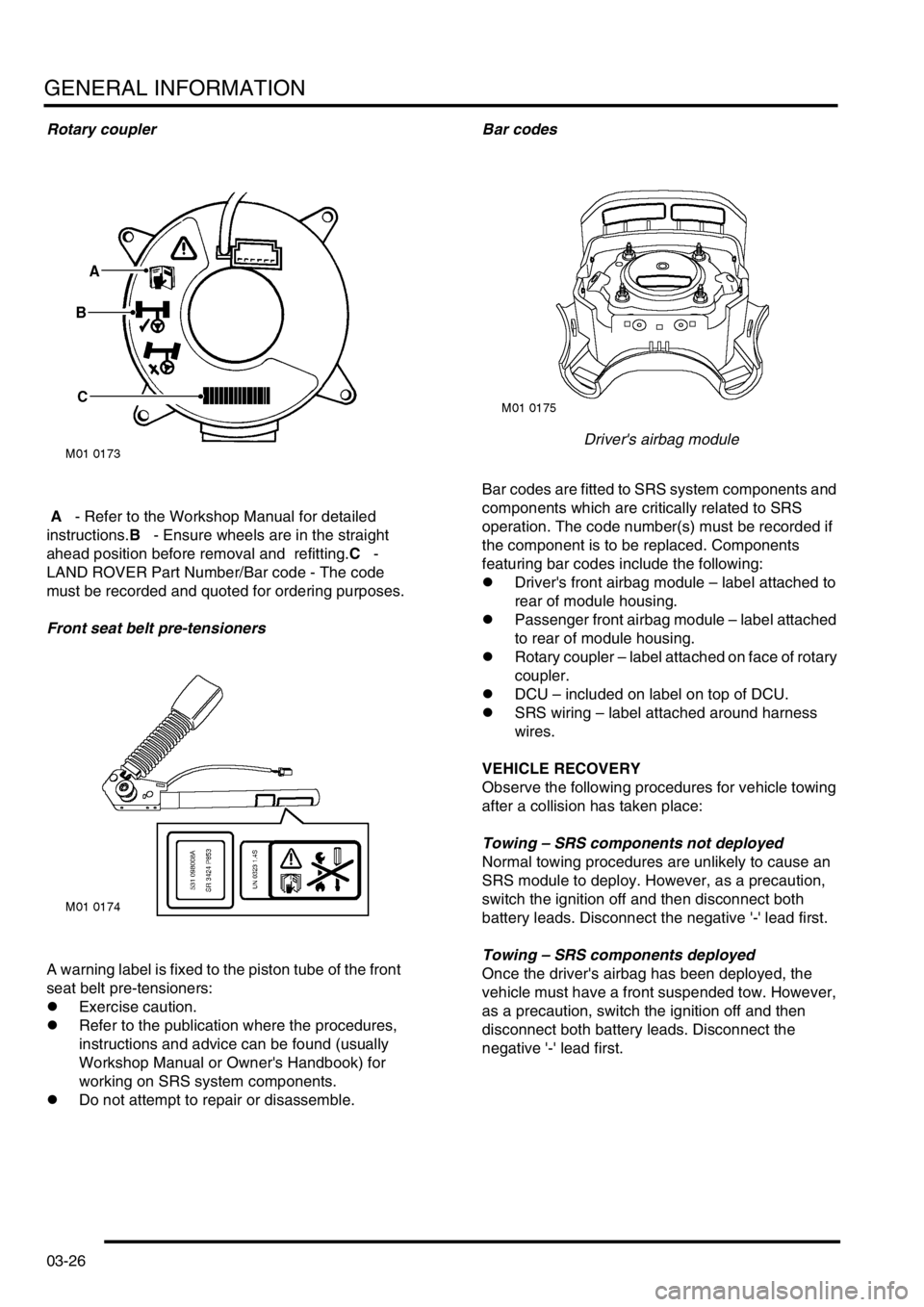

Rotary coupler

A - Refer to the Workshop Manual for detailed

instructions.B - Ensure wheels are in the straight

ahead position before removal and refitting.C -

LAND ROVER Part Number/Bar code - The code

must be recorded and quoted for ordering purposes.

Front seat belt pre-tensioners

A warning label is fixed to the piston tube of the front

seat belt pre-tensioners:

lExercise caution.

lRefer to the publication where the procedures,

instructions and advice can be found (usually

Workshop Manual or Owner's Handbook) for

working on SRS system components.

lDo not attempt to repair or disassemble.Bar codes

Driver's airbag module

Bar codes are fitted to SRS system components and

components which are critically related to SRS

operation. The code number(s) must be recorded if

the component is to be replaced. Components

featuring bar codes include the following:

lDriver's front airbag module – label attached to

rear of module housing.

lPassenger front airbag module – label attached

to rear of module housing.

lRotary coupler – label attached on face of rotary

coupler.

lDCU – included on label on top of DCU.

lSRS wiring – label attached around harness

wires.

VEHICLE RECOVERY

Observe the following procedures for vehicle towing

after a collision has taken place:

Towing – SRS components not deployed

Normal towing procedures are unlikely to cause an

SRS module to deploy. However, as a precaution,

switch the ignition off and then disconnect both

battery leads. Disconnect the negative '-' lead first.

Towing – SRS components deployed

Once the driver's airbag has been deployed, the

vehicle must have a front suspended tow. However,

as a precaution, switch the ignition off and then

disconnect both battery leads. Disconnect the

negative '-' lead first.

Page 70 of 1007

GENERAL DATA

04-7

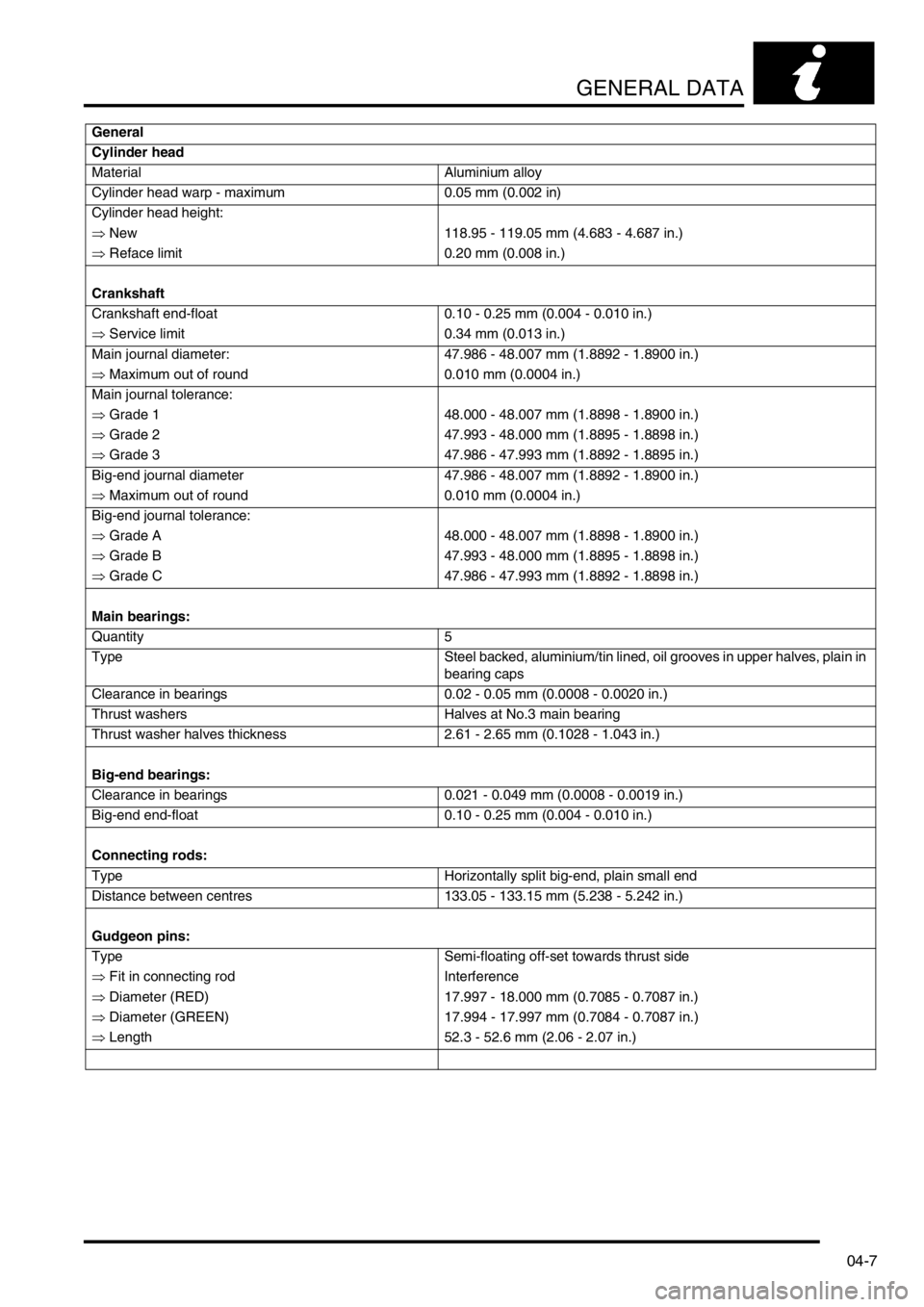

Cylinder head

Material Aluminium alloy

Cylinder head warp - maximum 0.05 mm (0.002 in)

Cylinder head height:

⇒ New 118.95 - 119.05 mm (4.683 - 4.687 in.)

⇒ Reface limit 0.20 mm (0.008 in.)

Crankshaft

Crankshaft end-float 0.10 - 0.25 mm (0.004 - 0.010 in.)

⇒ Service limit 0.34 mm (0.013 in.)

Main journal diameter: 47.986 - 48.007 mm (1.8892 - 1.8900 in.)

⇒ Maximum out of round 0.010 mm (0.0004 in.)

Main journal tolerance:

⇒ Grade 1 48.000 - 48.007 mm (1.8898 - 1.8900 in.)

⇒ Grade 2 47.993 - 48.000 mm (1.8895 - 1.8898 in.)

⇒ Grade 3 47.986 - 47.993 mm (1.8892 - 1.8895 in.)

Big-end journal diameter 47.986 - 48.007 mm (1.8892 - 1.8900 in.)

⇒ Maximum out of round 0.010 mm (0.0004 in.)

Big-end journal tolerance:

⇒ Grade A 48.000 - 48.007 mm (1.8898 - 1.8900 in.)

⇒ Grade B 47.993 - 48.000 mm (1.8895 - 1.8898 in.)

⇒ Grade C 47.986 - 47.993 mm (1.8892 - 1.8898 in.)

Main bearings:

Quantity 5

Type Steel backed, aluminium/tin lined, oil grooves in upper halves, plain in

bearing caps

Clearance in bearings 0.02 - 0.05 mm (0.0008 - 0.0020 in.)

Thrust washers Halves at No.3 main bearing

Thrust washer halves thickness 2.61 - 2.65 mm (0.1028 - 1.043 in.)

Big-end bearings:

Clearance in bearings 0.021 - 0.049 mm (0.0008 - 0.0019 in.)

Big-end end-float 0.10 - 0.25 mm (0.004 - 0.010 in.)

Connecting rods:

Type Horizontally split big-end, plain small end

Distance between centres 133.05 - 133.15 mm (5.238 - 5.242 in.)

Gudgeon pins:

Type Semi-floating off-set towards thrust side

⇒ Fit in connecting rod Interference

⇒ Diameter (RED) 17.997 - 18.000 mm (0.7085 - 0.7087 in.)

⇒ Diameter (GREEN) 17.994 - 17.997 mm (0.7084 - 0.7087 in.)

⇒ Length 52.3 - 52.6 mm (2.06 - 2.07 in.) General

Page 76 of 1007

GENERAL DATA

04-13

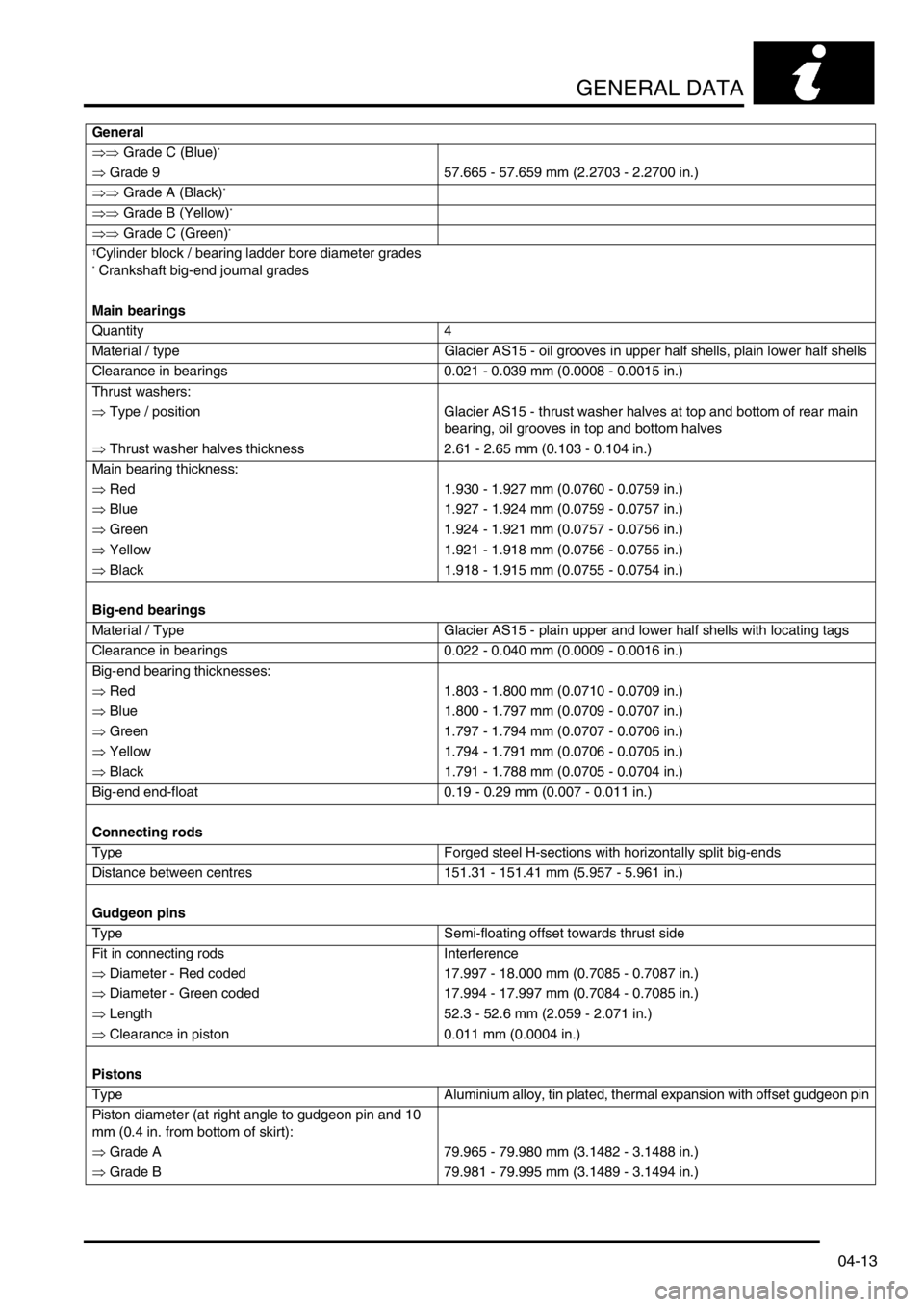

⇒⇒ Grade C (Blue)*

⇒ Grade 9 57.665 - 57.659 mm (2.2703 - 2.2700 in.)

⇒⇒ Grade A (Black)

*

⇒⇒ Grade B (Yellow)*

⇒⇒ Grade C (Green)*

†

Cylinder block / bearing ladder bore diameter grades* Crankshaft big-end journal grades

Main bearings

Quantity 4

Material / type Glacier AS15 - oil grooves in upper half shells, plain lower half shells

Clearance in bearings 0.021 - 0.039 mm (0.0008 - 0.0015 in.)

Thrust washers:

⇒ Type / position Glacier AS15 - thrust washer halves at top and bottom of rear main

bearing, oil grooves in top and bottom halves

⇒ Thrust washer halves thickness 2.61 - 2.65 mm (0.103 - 0.104 in.)

Main bearing thickness:

⇒ Red 1.930 - 1.927 mm (0.0760 - 0.0759 in.)

⇒ Blue 1.927 - 1.924 mm (0.0759 - 0.0757 in.)

⇒ Green 1.924 - 1.921 mm (0.0757 - 0.0756 in.)

⇒ Yellow 1.921 - 1.918 mm (0.0756 - 0.0755 in.)

⇒ Black 1.918 - 1.915 mm (0.0755 - 0.0754 in.)

Big-end bearings

Material / Type Glacier AS15 - plain upper and lower half shells with locating tags

Clearance in bearings 0.022 - 0.040 mm (0.0009 - 0.0016 in.)

Big-end bearing thicknesses:

⇒ Red 1.803 - 1.800 mm (0.0710 - 0.0709 in.)

⇒ Blue 1.800 - 1.797 mm (0.0709 - 0.0707 in.)

⇒ Green 1.797 - 1.794 mm (0.0707 - 0.0706 in.)

⇒ Yellow 1.794 - 1.791 mm (0.0706 - 0.0705 in.)

⇒ Black 1.791 - 1.788 mm (0.0705 - 0.0704 in.)

Big-end end-float 0.19 - 0.29 mm (0.007 - 0.011 in.)

Connecting rods

Type Forged steel H-sections with horizontally split big-ends

Distance between centres 151.31 - 151.41 mm (5.957 - 5.961 in.)

Gudgeon pins

Type Semi-floating offset towards thrust side

Fit in connecting rods Interference

⇒ Diameter - Red coded 17.997 - 18.000 mm (0.7085 - 0.7087 in.)

⇒ Diameter - Green coded 17.994 - 17.997 mm (0.7084 - 0.7085 in.)

⇒ Length 52.3 - 52.6 mm (2.059 - 2.071 in.)

⇒ Clearance in piston 0.011 mm (0.0004 in.)

Pistons

Type Aluminium alloy, tin plated, thermal expansion with offset gudgeon pin

Piston diameter (at right angle to gudgeon pin and 10

mm (0.4 in. from bottom of skirt):

⇒ Grade A 79.965 - 79.980 mm (3.1482 - 3.1488 in.)

⇒ Grade B 79.981 - 79.995 mm (3.1489 - 3.1494 in.) General

Page 95 of 1007

GENERAL DATA

04-32

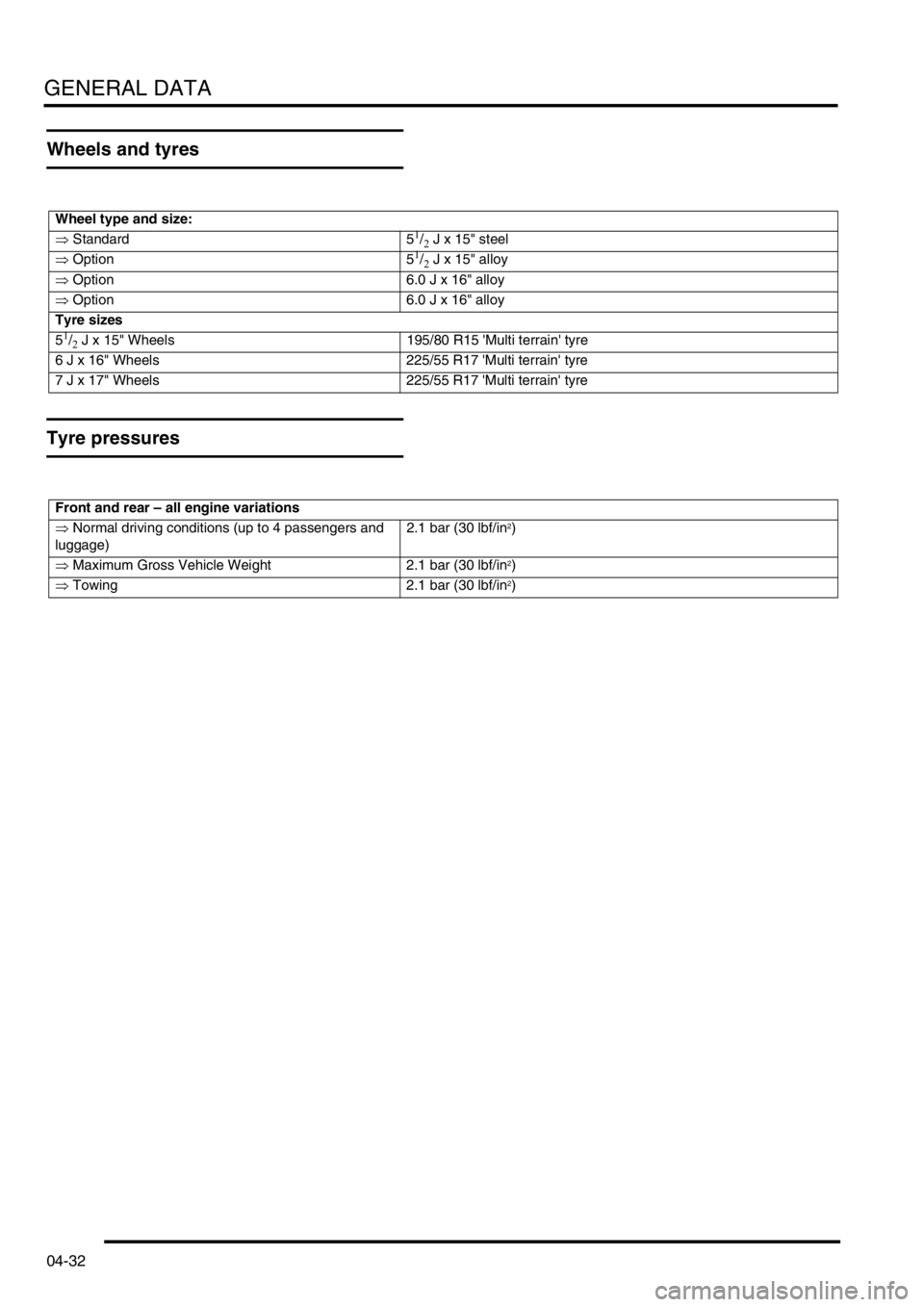

Wheels and tyres

Tyre pressures

Wheel type and size:

⇒ Standard 51/2 J x 15" steel

⇒ Option 51/2 J x 15" alloy

⇒ Option 6.0 J x 16" alloy

⇒ Option 6.0 J x 16" alloy

Tyre sizes

5

1/2 J x 15" Wheels 195/80 R15 'Multi terrain' tyre

6 J x 16" Wheels 225/55 R17 'Multi terrain' tyre

7 J x 17" Wheels 225/55 R17 'Multi terrain' tyre

Front and rear – all engine variations

⇒ Normal driving conditions (up to 4 passengers and

luggage)2.1 bar (30 lbf/in

2)

⇒ Maximum Gross Vehicle Weight 2.1 bar (30 lbf/in

2)

⇒ Towing 2.1 bar (30 lbf/in

2)