bulb LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1951 of 3229

Publi s hed: 11-May-2011

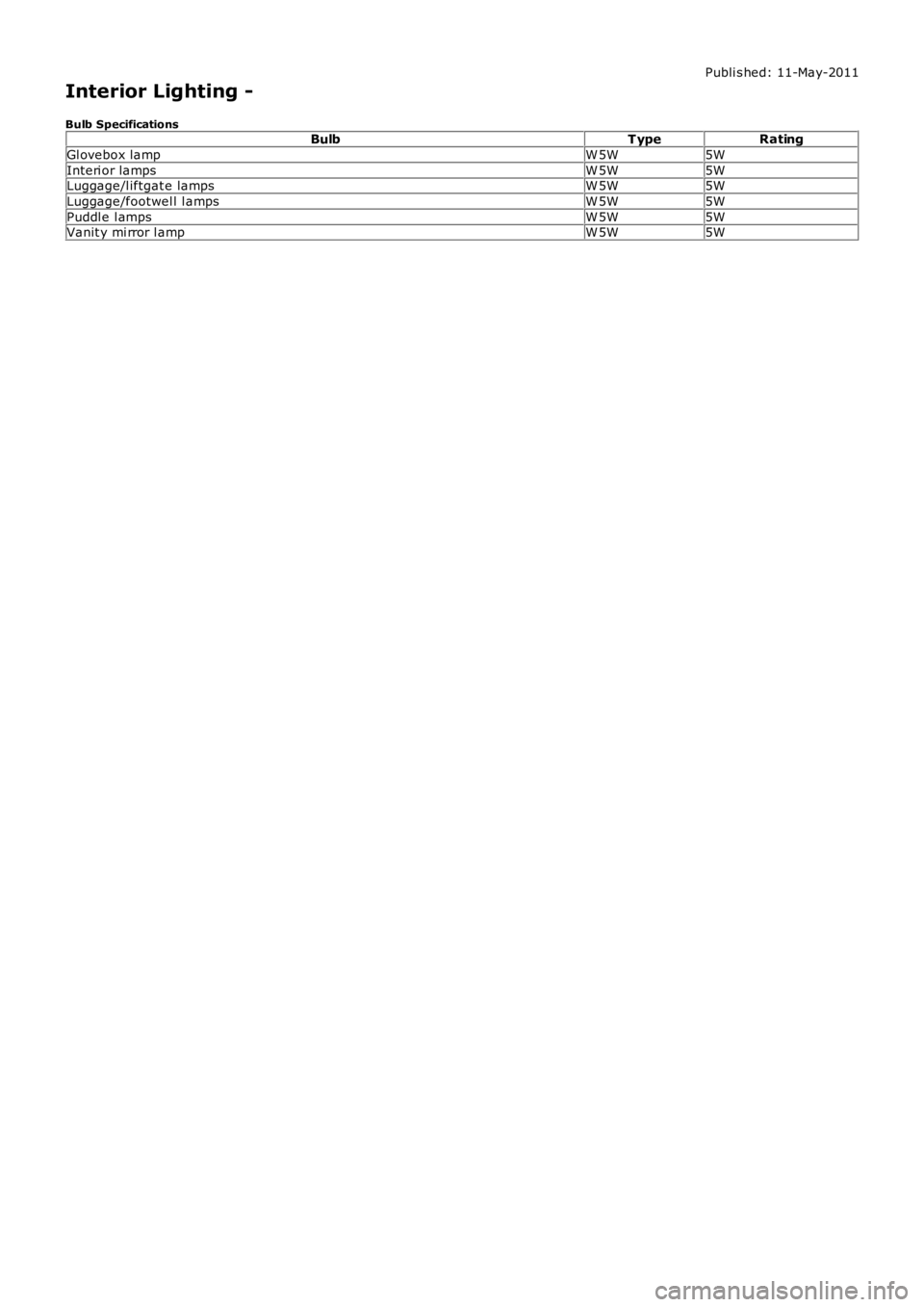

Interior Lighting -

Bulb SpecificationsBulbT ypeRating

Gl ovebox lampW 5W5W

Interi or lampsW 5W5WLuggage/l iftgat e lampsW 5W5W

Luggage/footwel l l ampsW 5W5W

Puddl e l ampsW 5W5WVanit y mi rror l ampW 5W5W

Page 1956 of 3229

Publi s hed: 11-May-2011

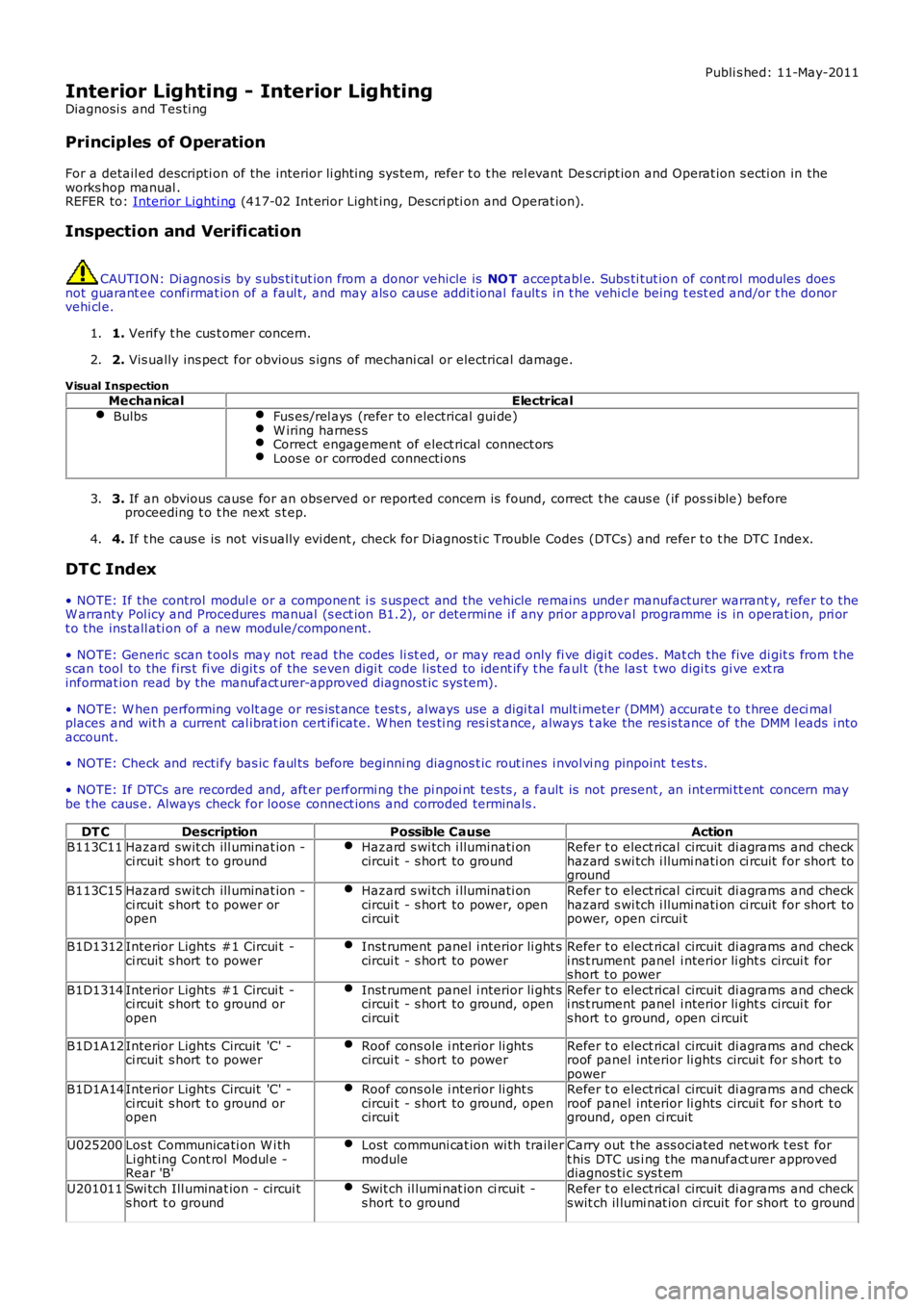

Interior Lighting - Interior Lighting

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the interior li ght ing sys tem, refer t o t he rel evant Des cript ion and Operat ion s ecti on in theworks hop manual .REFER to: Interior Lighti ng (417-02 Int erior Light ing, Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

BulbsFus es/rel ays (refer to electrical gui de)W iring harnes sCorrect engagement of elect rical connect orsLoos e or corroded connecti ons

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer-approved diagnost ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces and wit h a current cal ibrat ion cert ificate. W hen tes ti ng res i st ance, always take the res is tance of the DMM l eads i ntoaccount.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DT CDescriptionPossible CauseActionB113C11Hazard swit ch ill uminat ion -ci rcuit s hort t o groundHazard s wi tch i lluminati oncircui t - s hort to groundRefer t o elect rical circuit di agrams and checkhazard s wi tch i llumi nati on ci rcuit for short toground

B113C15Hazard swit ch ill uminat ion -ci rcuit s hort t o power oropen

Hazard s wi tch i lluminati oncircui t - s hort to power, opencircui t

Refer t o elect rical circuit di agrams and checkhazard s wi tch i llumi nati on ci rcuit for short topower, open circui t

B1D1312Interior Lights #1 Circui t -ci rcuit s hort t o powerInst rument panel i nterior li ght scircui t - s hort to powerRefer t o elect rical circuit di agrams and checki ns t rument panel i nterior li ght s circui t fors hort t o power

B1D1314Interior Lights #1 Circui t -ci rcuit s hort t o ground oropen

Inst rument panel i nterior li ght scircui t - s hort to ground, opencircui t

Refer t o elect rical circuit di agrams and checki ns t rument panel i nterior li ght s circui t fors hort t o ground, open ci rcuit

B1D1A12Interior Lights Circuit 'C' -ci rcuit s hort t o powerRoof cons ole i nterior li ght scircui t - s hort to powerRefer t o elect rical circuit di agrams and checkroof panel interior li ghts circui t for s hort t opowerB1D1A14Interior Lights Circuit 'C' -ci rcuit s hort t o ground oropen

Roof cons ole i nterior li ght scircui t - s hort to ground, opencircui t

Refer t o elect rical circuit di agrams and checkroof panel interior li ghts circui t for s hort t oground, open ci rcuit

U025200Los t Communicati on W i thLi ght ing Cont rol Modul e -Rear 'B'

Lost communi cat ion wi th trailermoduleCarry out t he ass ociated net work t es t fort his DTC us i ng the manufact urer approveddiagnos ti c sys t em

U201011Swi tch Ill uminat ion - circui ts hort t o groundSwit ch il lumi nat ion ci rcuit -s hort t o groundRefer t o elect rical circuit di agrams and checks wit ch il lumi nat ion ci rcuit for short to ground

Page 1960 of 3229

Publi s hed: 11-May-2011

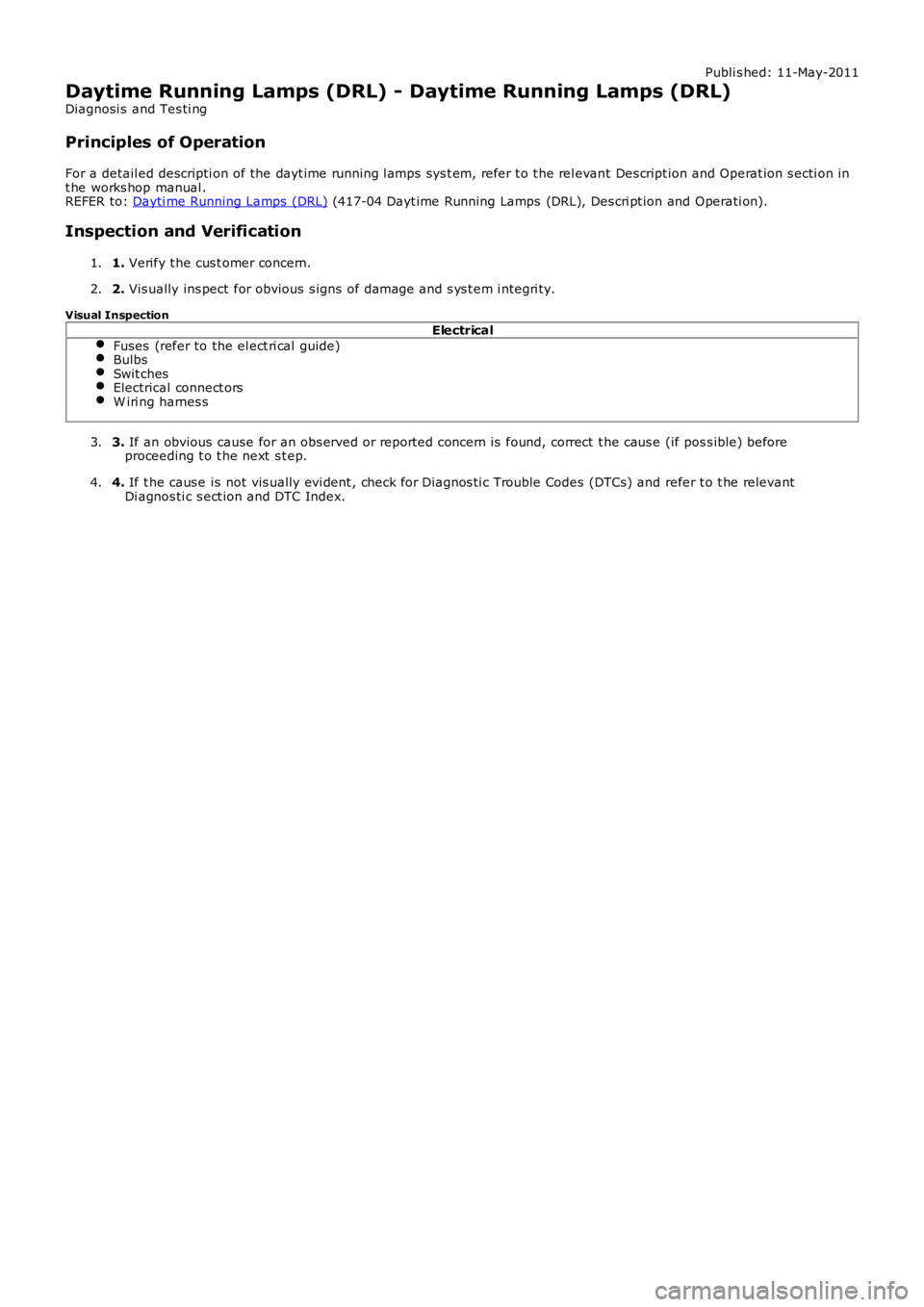

Daytime Running Lamps (DRL) - Daytime Running Lamps (DRL)

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the dayt ime running l amps sys t em, refer t o t he rel evant Des cript ion and Operat ion s ecti on int he works hop manual .REFER to: Dayti me Running Lamps (DRL) (417-04 Dayt ime Running Lamps (DRL), Des cri pt ion and Operati on).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.2.

Visual Inspection

Electrical

Fuses (refer to the el ect ri cal guide)BulbsSwit chesElectrical connect orsW iri ng harnes s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he relevantDi agnos ti c s ect ion and DTC Index.4.

Page 2452 of 3229

Publi s hed: 21-Nov-2011

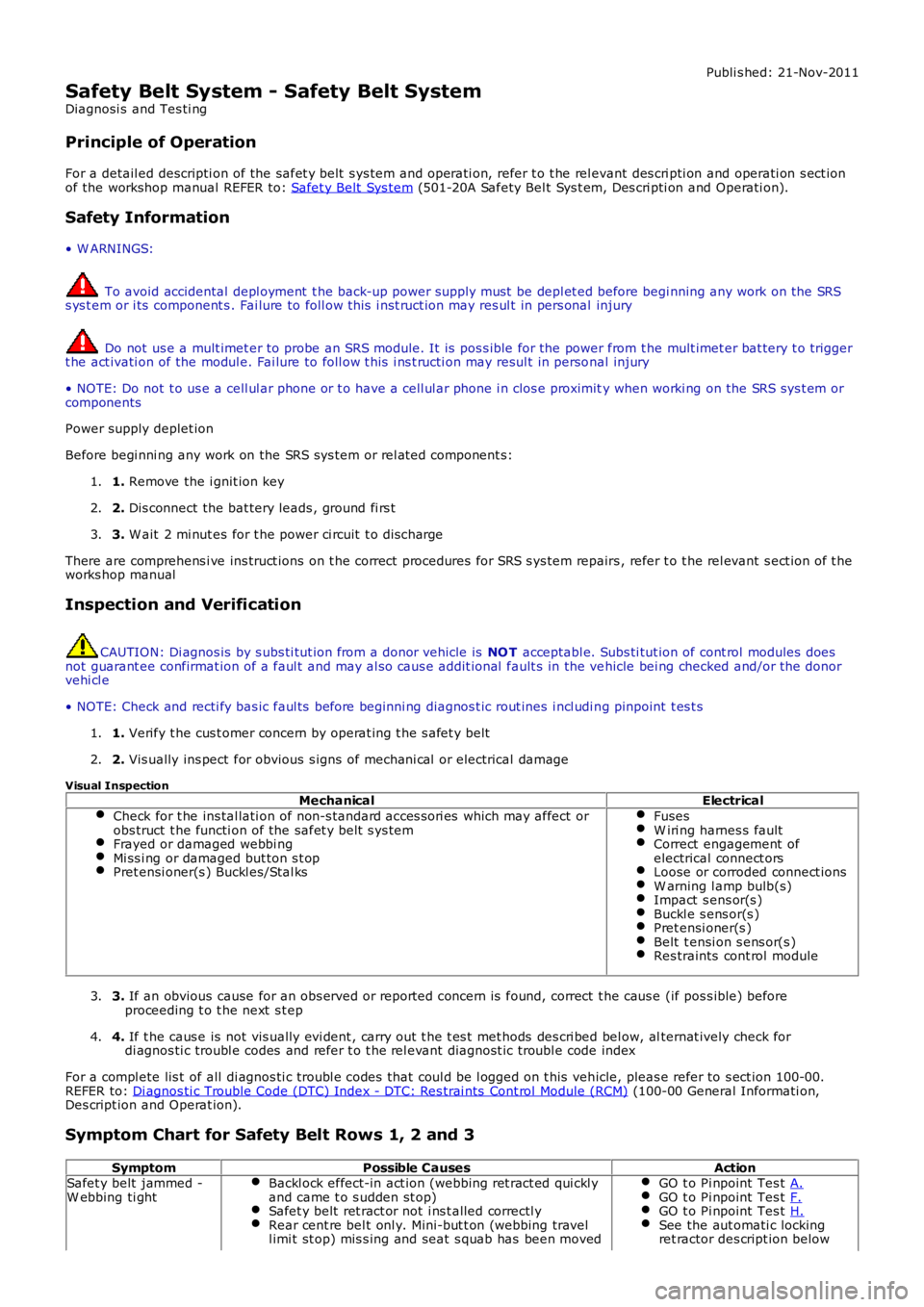

Safety Belt System - Safety Belt System

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the safet y belt s ys tem and operati on, refer t o t he relevant des cri pti on and operati on s ect ionof the workshop manual REFER to: Safet y Belt Sys tem (501-20A Safety Bel t Sys t em, Des cri pti on and Operati on).

Safety Information

• W ARNINGS:

To avoid accidental depl oyment t he back-up power supply must be depl et ed before begi nning any work on the SRSs ys t em or i ts component s . Fai lure to foll ow t his i nst ruct ion may res ul t in pers onal injury

Do not us e a mult imet er to probe an SRS module. It is pos s ible for the power from the mult imet er bat tery t o triggert he act ivati on of the modul e. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury

• NOTE: Do not t o us e a cell ul ar phone or t o have a cell ul ar phone i n clos e proximity when worki ng on the SRS sys t em orcomponents

Power supply deplet ion

Before begi nni ng any work on the SRS sys tem or rel at ed component s:

1. Remove the i gnit ion key1.

2. Dis connect the bat tery leads , ground fi rs t2.

3. W ait 2 mi nut es for t he power ci rcuit t o dis charge3.

There are comprehens i ve ins truct ions on t he correct procedures for SRS s ys tem repairs , refer t o t he rel evant s ect ion of t heworks hop manual

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t and may al so caus e addit ional fault s in the vehicle bei ng checked and/or the donorvehi cl e

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i ncl udi ng pinpoint t es t s

1. Verify t he cus t omer concern by operat ing t he s afet y belt1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage2.

Visual InspectionMechanicalElectrical

Check for t he ins tal lati on of non-s tandard acces s ori es which may affect orobs truct t he functi on of the safet y belt s ys temFrayed or damaged webbi ngMi ss i ng or damaged but ton s t opPret ensi oner(s ) Buckl es/Stal ks

FusesW iri ng harnes s faultCorrect engagement ofelectrical connect orsLoose or corroded connect ionsW arning l amp bulb(s)Impact s ens or(s )Buckl e s ens or(s )Pret ensi oner(s )Belt t ensi on s ens or(s )Res traints cont rol module

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , carry out t he t es t met hods des cri bed bel ow, alternat ively check fordi agnos ti c troubl e codes and refer t o t he rel evant diagnost ic troubl e code index4.

For a compl ete lis t of all di agnos ti c troubl e codes that coul d be l ogged on t his vehicle, pleas e refer to s ect ion 100-00.REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Res trai nts Cont rol Module (RCM) (100-00 General Informati on,Des cript ion and Operat ion).

Symptom Chart for Safety Belt Rows 1, 2 and 3

SymptomPossible CausesActionSafet y belt jammed -W ebbing ti ghtBackl ock effect-in act ion (webbing ret ract ed qui ckl yand came t o s udden st op)Safet y belt ret ract or not i ns t alled correctl yRear cent re bel t onl y. Mini-but t on (webbing travell imi t st op) mis s ing and seat s quab has been moved

GO t o Pi npoint Tes t A.GO t o Pi npoint Tes t F.GO t o Pi npoint Tes t H.See the aut omati c lockingret ractor des cript ion below

Page 2486 of 3229

Publi s hed: 11-May-2011

Supplemental Restraint System - Air Bag Supplemental Restraint System

(SRS)

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the ai r bag s upplement al res traints sys tem, refer t o the rel evant Des cript ion and Operat ions ect ion i n t he works hop manual .REFER to: Ai r Bag and Safety Bel t Pretens ioner Suppl ement al Res t raint Sys tem (SRS) (501-20B Suppl ement al Res t rai ntSyst em, Des cript ion and Operat ion).

Inspection and Verification

W ARNING: TO AVOID ACCIDENTAL DEPLOY MENT AND POSSIBLE PERSONAL INJURY , THE BACKUP POWER SUPPLYMUST BE DEPLETED BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)COMPONENTS. TO DEPLETE THE BACKUP POW ER SUPPLY ENERGY , DISCONNECT THE BATTERY GRO UND CABLE AND W AITTW O MINUTES. FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY .

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Given t he l egal impl icati ons of a res t raint s s ys t em fail ure, harness repairs to Air Bag module ci rcuit s are notacceptable. W here t he t ext refers to "REPAIR the circui t", t hi s wi ll normal ly mean the repl acement of a harnes s .

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual Inspection

ElectricalBatt ery condit ion, s tat e of chargeMake s ure al l elect rical connect or(s) are engaged correct ly on the ai r bag ci rcuit sW iri ng harnes sAir bag modul e(s )Make s ure the rest rai nts control modul e (RCM) is correct ly ins tall edFuse(s )Sensor(s )Pret ensi oner(s )W arning l amp bulb(s)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check Rest rai nts Cont rol Modul e (RCM) and Occupancy Cl ass i ficat ion Syst em(OCS) module for Diagnos t ic Troubl e Codes (DTCs ) and refer t o t he DTC Index.4.

Given t he complexit y of the s ys tem and the pot enti al for damage/injury, t he preferred met hod of di agnos is i s via theManufacturer approved diagnost ic sys tem.

If the Manufacturer approved di agnos ti c s ys t em i s not avai lable, use a s can tool to ext ract DTCs and refer to the DTCIndex.

DTC Index

• NOTE: If the control modul e is sus pect and t he vehicle remains under manufact urer warranty, refer to the W arrant y Poli cyand Procedures manual (s ect ion B1.2), or determine i f any prior approval programme is i n operat ion, prior t o t heins t al lat ion of a new modul e.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Res trai nts Cont rol Module (RCM) (100-00 General Informati on,Des cript ion and Operat ion).

Page 2723 of 3229

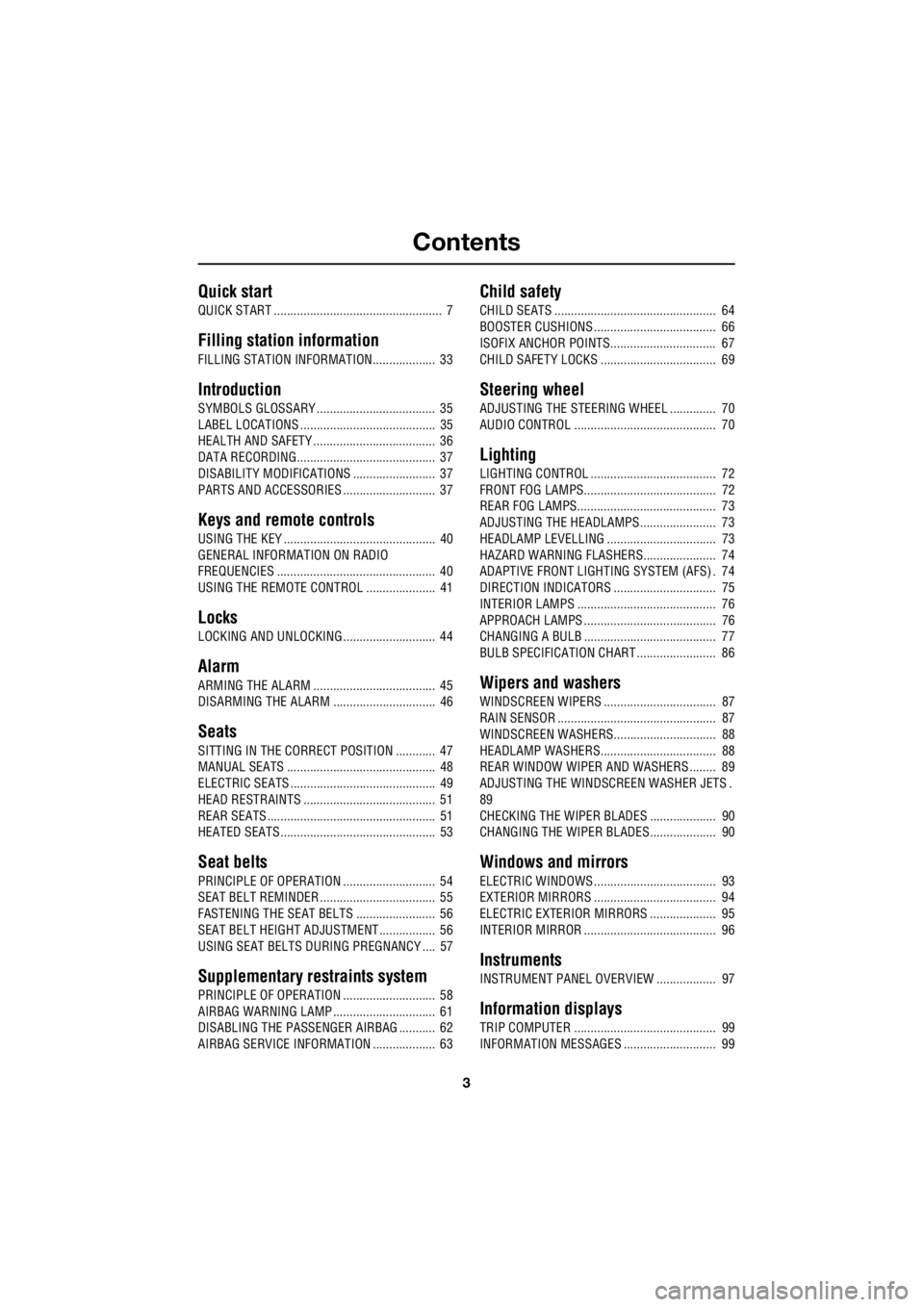

Contents

3

R

Quick start

QUICK START ................................................... 7

Filling station information

FILLING STATION INFORMATION................... 33

Introduction

SYMBOLS GLOSSARY .................................... 35

LABEL LOCATIONS ......................................... 35

HEALTH AND SAFETY ..................................... 36

DATA RECORDING.......................................... 37

DISABILITY MODIFICATIONS ......................... 37

PARTS AND ACCESSORIES ............................ 37

Keys and remote controls

USING THE KEY .............................................. 40

GENERAL INFORMATION ON RADIO

FREQUENCIES ................................................ 40

USING THE REMOTE CONTROL ..................... 41

Locks

LOCKING AND UNLOCKING ............................ 44

Alarm

ARMING THE ALARM ..................................... 45

DISARMING THE ALARM ............................... 46

Seats

SITTING IN THE CORRECT POSITION ............ 47

MANUAL SEATS ............................................. 48

ELECTRIC SEATS ............................................ 49

HEAD RESTRAINTS ........................................ 51

REAR SEATS................................................... 51

HEATED SEATS............................................... 53

Seat belts

PRINCIPLE OF OPERATION ............................ 54

SEAT BELT REMINDER ................................... 55

FASTENING THE SEAT BELTS ........................ 56

SEAT BELT HEIGHT ADJUSTMENT................. 56

USING SEAT BELTS DURI NG PREGNANCY .... 57

Supplementary restraints system

PRINCIPLE OF OPERATION ............................ 58

AIRBAG WARNING LAMP ............................... 61

DISABLING THE PASSENGER AIRBAG ........... 62

AIRBAG SERVICE INFORMATION ................... 63

Child safety

CHILD SEATS ................................................. 64

BOOSTER CUSHIONS ..................................... 66

ISOFIX ANCHOR POINTS................................ 67

CHILD SAFETY LOCKS ................................... 69

Steering wheel

ADJUSTING THE STEERING WHEEL .............. 70

AUDIO CONTROL ........................................... 70

Lighting

LIGHTING CONTROL ...................................... 72

FRONT FOG LAMPS........................................ 72

REAR FOG LAMPS.......................................... 73

ADJUSTING THE HEADLAMPS....................... 73

HEADLAMP LEVELLING ................................. 73

HAZARD WARNING FLASHERS...................... 74

ADAPTIVE FRONT LIGHTING SYSTEM (AFS) . 74

DIRECTION INDICATORS ............................... 75

INTERIOR LAMPS .......................................... 76

APPROACH LAMPS ........................................ 76

CHANGING A BULB ........................................ 77

BULB SPECIFICATION CHART ........................ 86

Wipers and washers

WINDSCREEN WIPERS .................................. 87

RAIN SENSOR ................................................ 87

WINDSCREEN WASHERS............................... 88

HEADLAMP WASHERS................................... 88

REAR WINDOW WIPER AND WASHERS ........ 89

ADJUSTING THE WINDSCREEN WASHER JETS .

89

CHECKING THE WIPER BLADES .................... 90

CHANGING THE WIPER BLADES.................... 90

Windows and mirrors

ELECTRIC WINDOWS ..................................... 93

EXTERIOR MIRRORS ..................................... 94

ELECTRIC EXTERIOR MIRRORS .................... 95

INTERIOR MIRROR ........................................ 96

Instruments

INSTRUMENT PANEL OVERVIEW .................. 97

Information displays

TRIP COMPUTER ........................................... 99

INFORMATION MESSAGES ............................ 99

Page 2781 of 3229

61

Supplementary restraints system

R

Airbag deployment effectsAIRBAG WARNING LAMP

The airbag warning indicator is

mounted in the instrument pack,

and will illuminate as a bulb check

when the ignition is turned on.

If any of the following warning indicator

conditions occur, the vehicle should be

checked by your Land Ro ver Dealer/Authorised

repairer immediately.

• The warning indicator fails to illuminate

when the ignition is turned on.

• The warning indicator fails to extinguish

within six seconds of the ignition being

turned on.

• The warning indicator illuminates at any

time other than the bulb check, when the

ignition is turned on.WARNINGS

When an airbag inflates a fine powder

is released. This is normal, and not an

indication of a malf unction. However,

the powder may cause irritation to the skin,

and should be throughly flushed from eyes,

and any cuts or abrasions.

After inflation some airbag

components are at high temperatures.

To prevent injury, do no touch the

airbag components until they have cooled.

In order to react with sufficient speed,

airbags are deployed by an explosive

charge. Consequently airbag

deployment is accompan ied by a very loud

noise which may cause discomfort and

temporary loss of hearing.

WARNING

If the warning indicator signals that a

fault is present in the system, do not

use a child restraint on the front

passenger seat. Doing so will increase the risk

of death or serious injury to the child.

Page 2793 of 3229

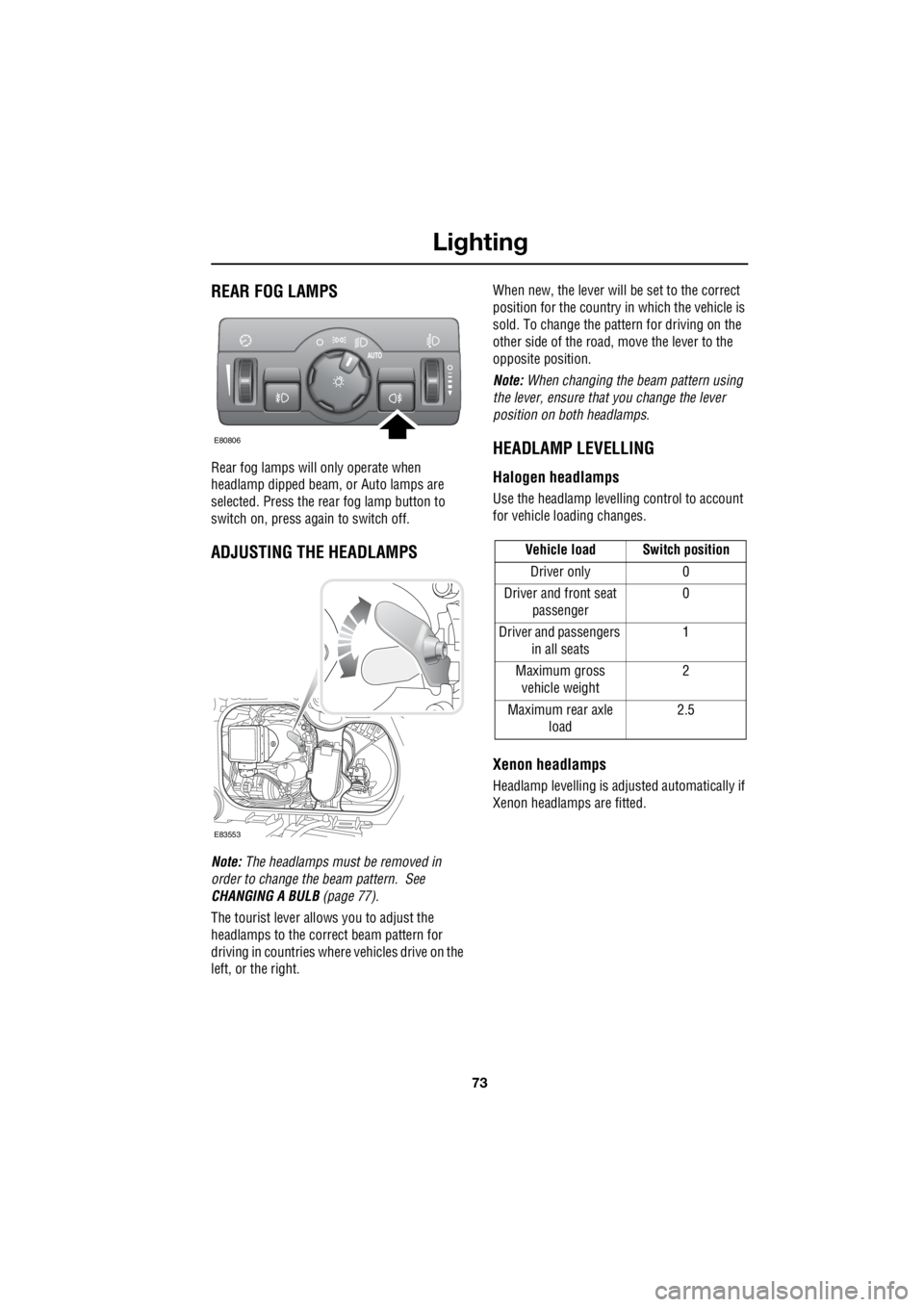

73

Lighting

R

REAR FOG LAMPS

Rear fog lamps will only operate when

headlamp dipped beam, or Auto lamps are

selected. Press the rear fog lamp button to

switch on, press again to switch off.

ADJUSTING THE HEADLAMPS

Note: The headlamps must be removed in

order to change the beam pattern. See

CHANGING A BULB (page 77).

The tourist lever allows you to adjust the

headlamps to the correct beam pattern for

driving in countries where vehicles drive on the

left, or the right. When new, the lever will be set to the correct

position for the country in which the vehicle is

sold. To change the pattern for driving on the

other side of the road, move the lever to the

opposite position.

Note: When changing the beam pattern using

the lever, ensure that you change the lever

position on both headlamps.

HEADLAMP LEVELLING

Halogen headlamps

Use the headlamp levell ing control to account

for vehicle loading changes.

Xenon headlamps

Headlamp levelling is adju sted automatically if

Xenon headlamps are fitted.

E80806

E83553

Vehicle load Switch position

Driver only 0

Driver and front seat passenger 0

Driver and passengers in all seats 1

Maximum gross vehicle weight 2

Maximum rear axle load 2.5

Page 2797 of 3229

77

Lighting

R

CHANGING A BULB

General information

Note: In certain territori es it is a legal

requirement to carry spare bulbs. A

replacement bulb kit is available as an

approved accessory from your Land Rover

Dealer/Authorised Repairer.

Halogen bulbs

Halogen bulbs are used for main beam, dipped

beam, and front fog lamps. Take care not to

touch the glass part of the bulb with your

fingers; always use a cl oth to handle the bulb.

If necessary use methylated spirits to remove

finger prints. Xenon lamps

Seek advice a bout the correct

disposal of Bi-X enon lamp units

from a Land Rover

Dealer/Authorised Repairer, or your local

authority.

CAUTION

Alway replace bulbs with the correct

type and specification. If you are in any

doubt contact your Land Rover

Dealer/Authorised Repairer for advice.

WARNINGS

Replacement or maintenance of

Xenon lamps should only be carried

out by suitably qualified personnel.

High voltage is requi red to ignite the

gas and metal vapour which are used

to power Xenon lamps. Contact with

this voltage can cause serious injuries.

Bi-Xenon lamp units operate at a very

high temperature. Ensure that the

lamp units have cooled before

attempting to touch them.

Xenon lamp units contain Mercury

which is highly to xic, and can be

extremely harmful.

Page 2798 of 3229

Lighting

78

L

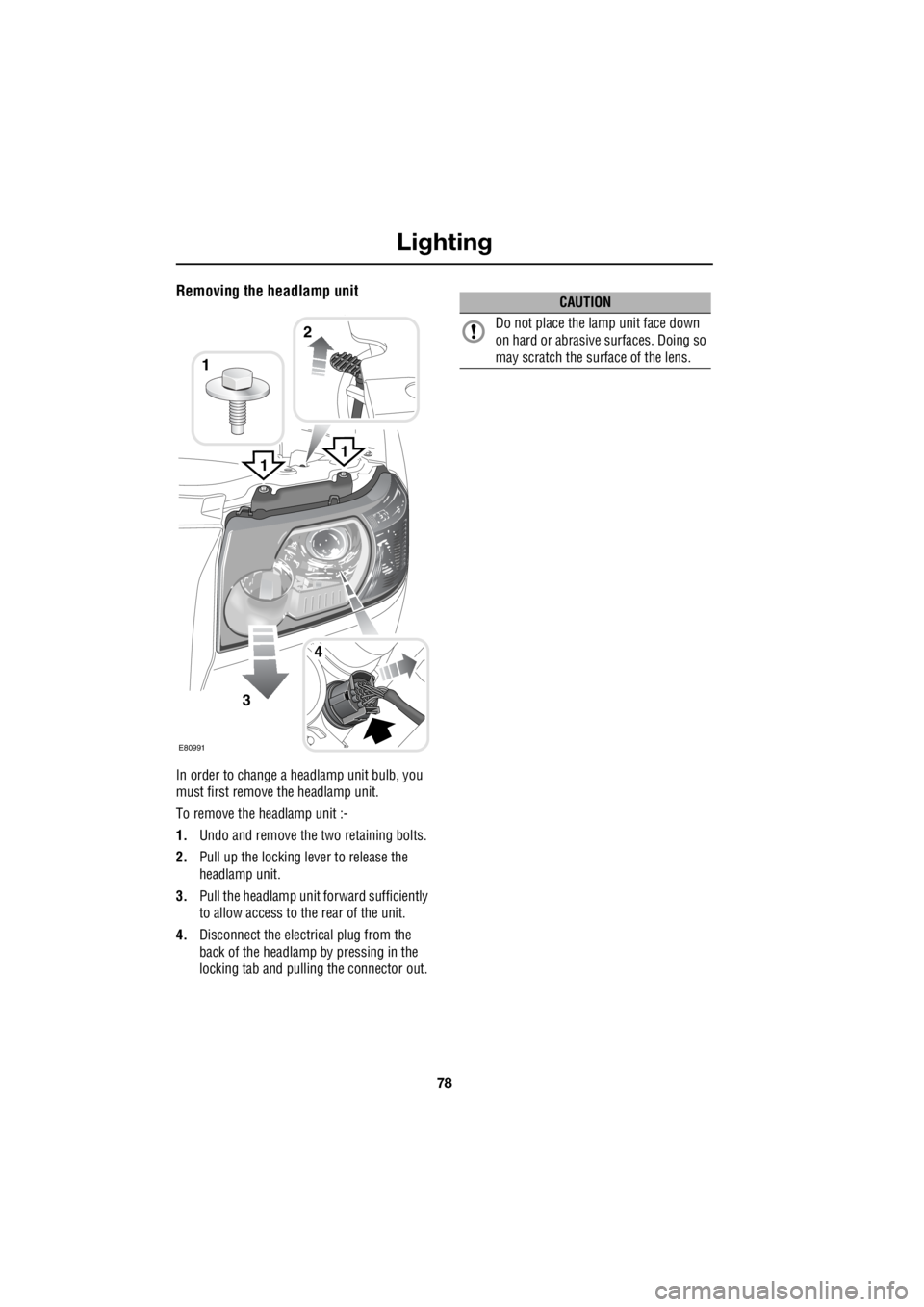

Removing the headlamp unit

In order to change a headlamp unit bulb, you

must first remove the headlamp unit.

To remove the headlamp unit :-

1. Undo and remove the two retaining bolts.

2. Pull up the locking lever to release the

headlamp unit.

3. Pull the headlamp unit forward sufficiently

to allow access to the rear of the unit.

4. Disconnect the electrical plug from the

back of the headlamp by pressing in the

locking tab and pulling the connector out.

1

3

4

1

E80991

2

1

CAUTION

Do not place the la mp unit face down

on hard or abrasive surfaces. Doing so

may scratch the surface of the lens.