coolant temperature LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 59 of 3229

Publi s hed: 10-May-2011

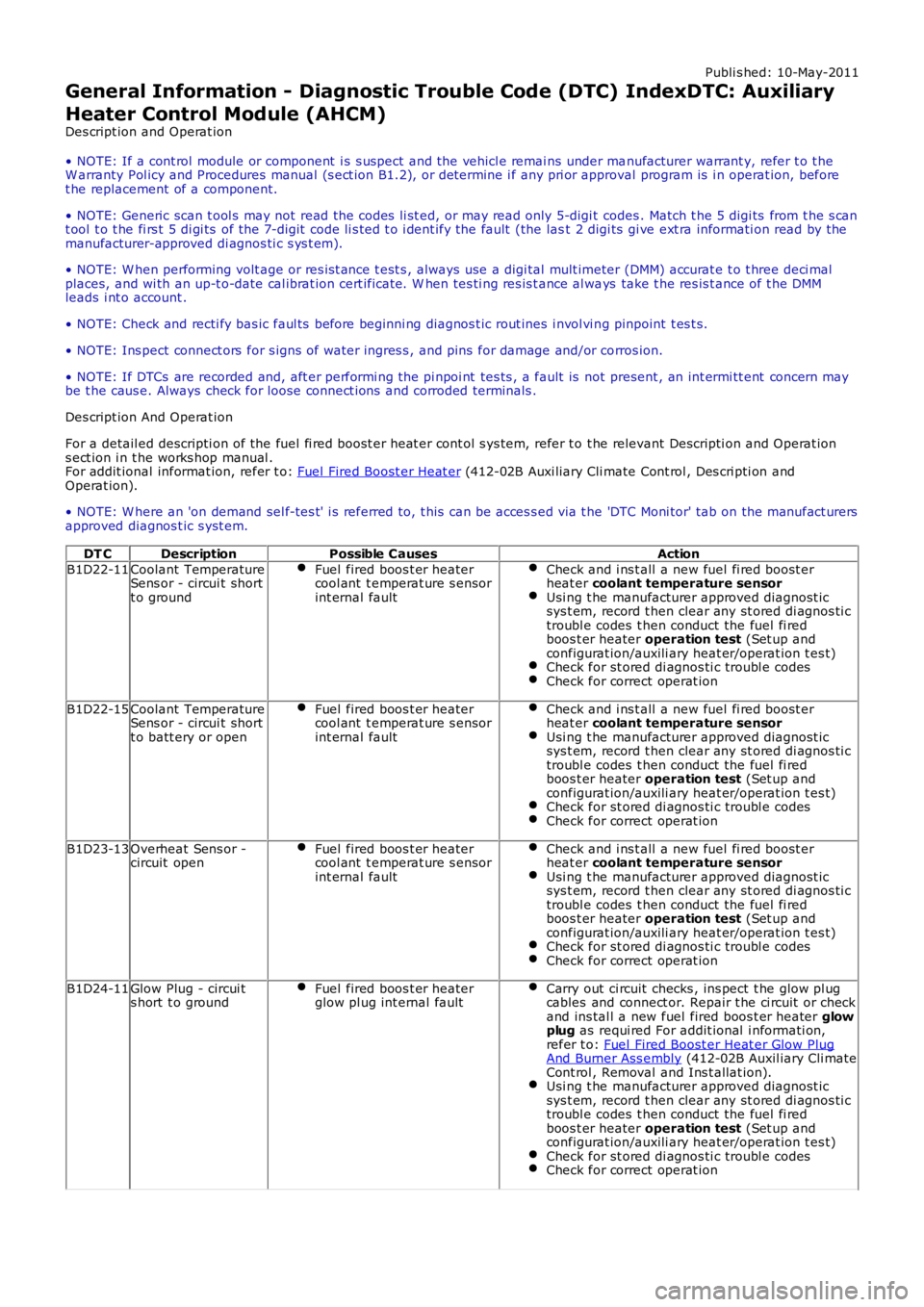

General Information - Diagnostic Trouble Code (DTC) IndexDTC: Auxiliary

Heater Control Module (AHCM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the fuel fi red boost er heat er cont ol s ys tem, refer t o t he relevant Descripti on and Operat ions ect ion i n t he works hop manual .For addit ional informat ion, refer t o: Fuel Fired Boost er Heat er (412-02B Auxi liary Cli mate Cont rol , Des cri pti on andOperat ion).

• NOTE: W here an 'on demand sel f-tes t' i s referred to, t his can be acces s ed via t he 'DTC Moni tor' tab on the manufact urersapproved diagnos t ic s yst em.

DT CDescriptionPossible CausesAction

B1D22-11Coolant TemperatureSens or - circui t shortt o ground

Fuel fired boos t er heatercool ant t emperat ure s ensorint ernal fault

Check and i ns t all a new fuel fi red boost erheat er coolant temperature sensorUsi ng t he manufacturer approved diagnost icsys t em, record t hen clear any st ored di agnos ti ctroubl e codes t hen conduct the fuel fi redboos t er heater operation test (Set up andconfigurat ion/auxili ary heat er/operat ion t es t)Check for st ored di agnos ti c troubl e codesCheck for correct operat ion

B1D22-15Coolant TemperatureSens or - circui t shortt o batt ery or open

Fuel fired boos t er heatercool ant t emperat ure s ensorint ernal fault

Check and i ns t all a new fuel fi red boost erheat er coolant temperature sensorUsi ng t he manufacturer approved diagnost icsys t em, record t hen clear any st ored di agnos ti ctroubl e codes t hen conduct the fuel fi redboos t er heater operation test (Set up andconfigurat ion/auxili ary heat er/operat ion t es t)Check for st ored di agnos ti c troubl e codesCheck for correct operat ion

B1D23-13Overheat Sens or -circuit openFuel fired boos t er heatercool ant t emperat ure s ensorint ernal fault

Check and i ns t all a new fuel fi red boost erheat er coolant temperature sensorUsi ng t he manufacturer approved diagnost icsys t em, record t hen clear any st ored di agnos ti ctroubl e codes t hen conduct the fuel fi redboos t er heater operation test (Set up andconfigurat ion/auxili ary heat er/operat ion t es t)Check for st ored di agnos ti c troubl e codesCheck for correct operat ion

B1D24-11Glow Plug - circui ts hort t o groundFuel fired boos t er heaterglow pl ug int ernal faultCarry out ci rcuit checks , ins pect t he glow pl ugcables and connect or. Repair t he ci rcuit or checkand ins tal l a new fuel fired boos t er heater glowplug as requi red For addit ional i nformati on,refer t o: Fuel Fired Boost er Heat er Glow PlugAnd Burner Ass embly (412-02B Auxil iary Cli mateCont rol , Removal and Ins t allat ion).Usi ng t he manufacturer approved diagnost icsys t em, record t hen clear any st ored di agnos ti ctroubl e codes t hen conduct the fuel fi redboos t er heater operation test (Set up andconfigurat ion/auxili ary heat er/operat ion t es t)Check for st ored di agnos ti c troubl e codesCheck for correct operat ion

Page 752 of 3229

Publi s hed: 11-May-2011

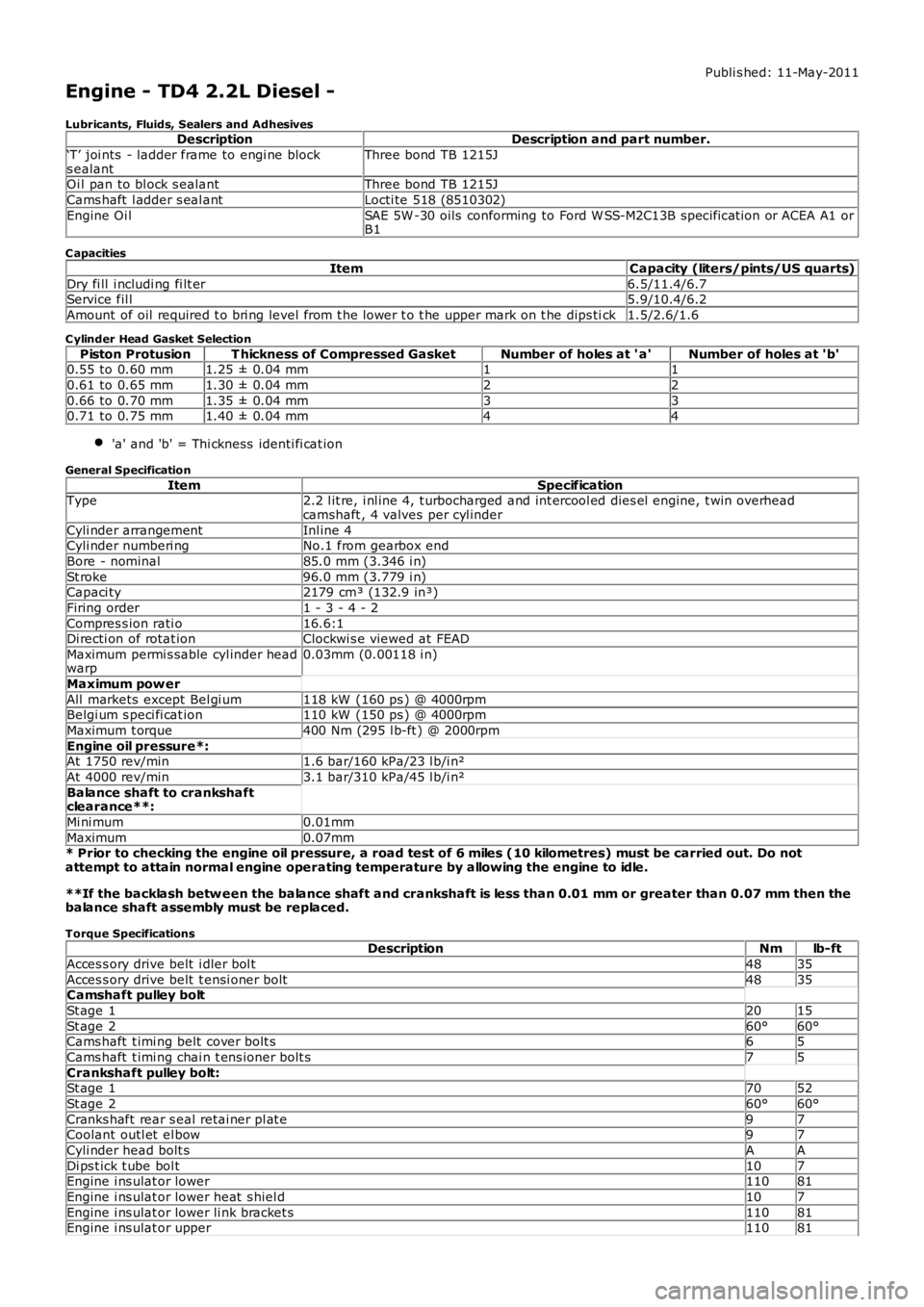

Engine - TD4 2.2L Diesel -

Lubricants, Fluids, Sealers and AdhesivesDescriptionDescription and part number.

‘T’ joi nts - ladder frame to engi ne blocks ealantThree bond TB 1215J

Oi l pan to bl ock s ealantThree bond TB 1215J

Cams haft l adder s eal antLocti te 518 (8510302)

Engine Oi lSAE 5W -30 oils conforming to Ford W SS-M2C13B specificat ion or ACEA A1 orB1

C apacities

ItemCapacity (liters/pints/US quarts)

Dry fi ll i ncludi ng fi lt er6.5/11.4/6.7Service fil l5.9/10.4/6.2

Amount of oil required t o bri ng level from t he lower t o t he upper mark on t he dips tick1.5/2.6/1.6

C ylinder Head Gasket Selection

Piston ProtusionT hickness of Compressed GasketNumber of holes at ' a'Number of holes at 'b'0.55 to 0.60 mm1.25 ± 0.04 mm11

0.61 to 0.65 mm1.30 ± 0.04 mm22

0.66 to 0.70 mm1.35 ± 0.04 mm330.71 to 0.75 mm1.40 ± 0.04 mm44

'a' and 'b' = Thi ckness identi fi cat ion

General Specification

ItemSpecificationType2.2 l it re, i nl ine 4, t urbocharged and int ercool ed dies el engine, t win overheadcamshaft , 4 valves per cyl inder

Cyli nder arrangementInl ine 4Cyli nder numberi ngNo.1 from gearbox end

Bore - nominal85.0 mm (3.346 i n)

St roke96.0 mm (3.779 i n)Capaci ty2179 cm³ (132.9 in³)

Firing order1 - 3 - 4 - 2

Compres s ion rati o16.6:1Di recti on of rotat ionClockwi s e viewed at FEAD

Maximum permi s sable cyl inder headwarp0.03mm (0.00118 i n)

Maximum pow er

All markets except Bel gi um118 kW (160 ps ) @ 4000rpmBelgi um s peci fi cat ion110 kW (150 ps ) @ 4000rpm

Maximum t orque400 Nm (295 l b-ft ) @ 2000rpm

Engine oil pressure*:At 1750 rev/min1.6 bar/160 kPa/23 l b/i n²

At 4000 rev/min3.1 bar/310 kPa/45 l b/i n²

Balance shaft to crankshaftclearance**:

Mi ni mum0.01mm

Maximum0.07mm* Prior to checking the engine oil pressure, a road test of 6 miles (10 kilometres) must be carried out. Do notattempt to attain normal engine operating temperature by allowing the engine to idle.

**If the backlash betw een the balance shaft and crankshaft is less than 0.01 mm or greater than 0.07 mm then thebalance shaft assembly must be replaced.

Torque SpecificationsDescriptionNmlb-ft

Acces s ory drive belt i dler bol t4835

Acces s ory drive belt t ensi oner bolt4835Camshaft pulley bolt

St age 12015

St age 260°60°Cams haft t imi ng belt cover bolt s65

Cams haft t imi ng chai n t ens ioner bolt s75

Crankshaft pulley bolt:St age 17052

St age 260°60°

Cranks haft rear s eal retai ner pl at e97Coolant outl et el bow97

Cyli nder head bolt sAA

Di ps t ick t ube bol t107Engine i ns ulat or lower11081

Engine i ns ulat or lower heat s hiel d107

Engine i ns ulat or lower li nk bracket s11081Engine i ns ulat or upper11081

Page 913 of 3229

Publi s hed: 11-May-2011

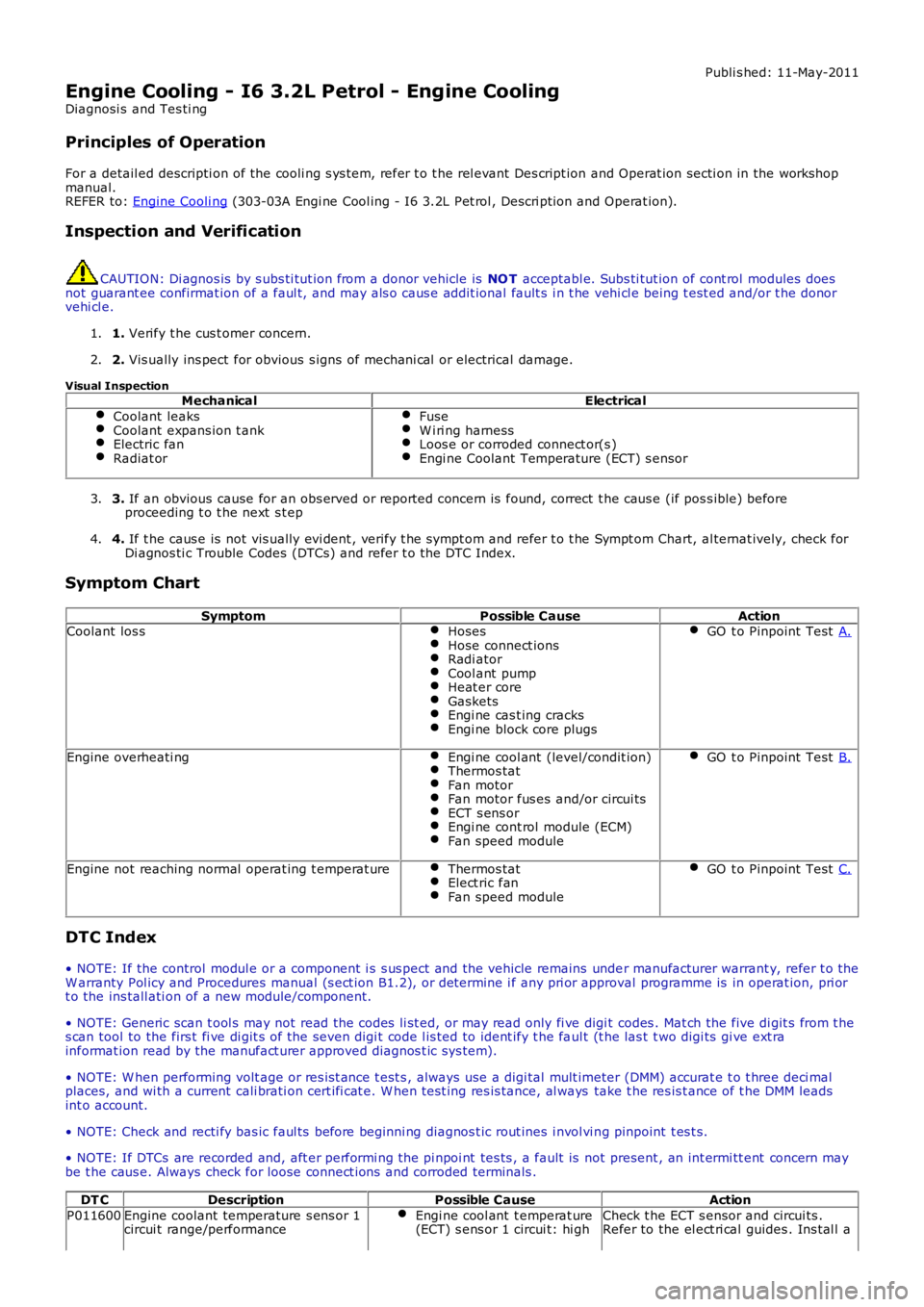

Engine Cooling - I6 3.2L Petrol - Engine Cooling

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshopmanual.REFER to: Engine Cooli ng (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Descri pti on and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual InspectionMechanicalElectrical

Coolant leaksCoolant expans ion t ankElectric fanRadiat or

FuseW i ri ng harnessLoos e or corroded connect or(s )Engi ne Coolant Temperature (ECT) s ensor

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart, al ternat ively, check forDi agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

Symptom Chart

SymptomPossible CauseActionCoolant los sHosesHose connect ionsRadi atorCool ant pumpHeat er coreGasketsEngi ne cas t ing cracksEngi ne block core plugs

GO t o Pinpoint Test A.

Engine overheati ngEngi ne cool ant (level/condit ion)Thermos tatFan motorFan motor fus es and/or circui tsECT s ens orEngi ne cont rol module (ECM)Fan speed module

GO t o Pinpoint Test B.

Engine not reaching normal operat ing t emperat ureThermos tatElect ric fanFan speed module

GO t o Pinpoint Test C.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve ext rainformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leadsint o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

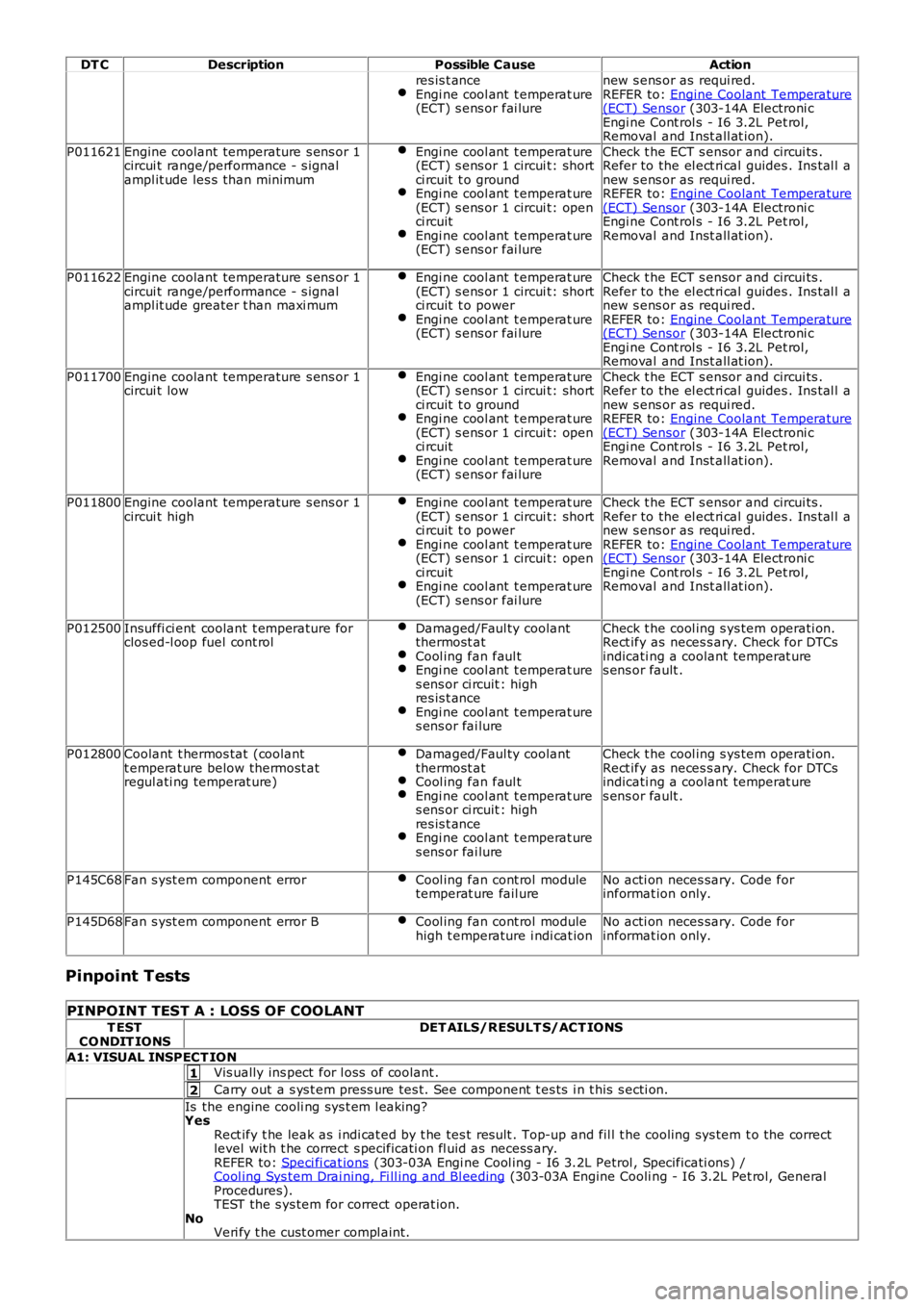

DT CDescriptionPossible CauseAction

P011600Engine coolant temperature s ens or 1circui t range/performanceEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: hi ghCheck t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l a

Page 914 of 3229

1

2

DT CDescriptionPossible CauseAction

res is t anceEngi ne cool ant t emperat ure(ECT) s ens or fai lure

new s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011621Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude les s than minimum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011622Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude greater t han maxi mum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011700Engine coolant temperature s ens or 1circui t lowEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011800Engine coolant temperature s ens or 1circui t highEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P012500Insuffi ci ent coolant t emperature forclos ed-l oop fuel cont rolDamaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P012800Coolant t hermos tat (coolantt emperat ure below thermost atregul ati ng temperat ure)

Damaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P145C68Fan s yst em component errorCool ing fan cont rol moduletemperat ure fail ureNo acti on neces sary. Code forinformat ion only.

P145D68Fan s yst em component error BCool ing fan cont rol modulehigh t emperature i ndi cat ionNo acti on neces sary. Code forinformat ion only.

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT

T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT IONVis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?YesRect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correctlevel wit h t he correct s pecificati on fl uid as necess ary.REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures).TEST the s ys tem for correct operat ion.NoVeri fy t he cust omer compl aint.

Page 915 of 3229

1

1

1

1

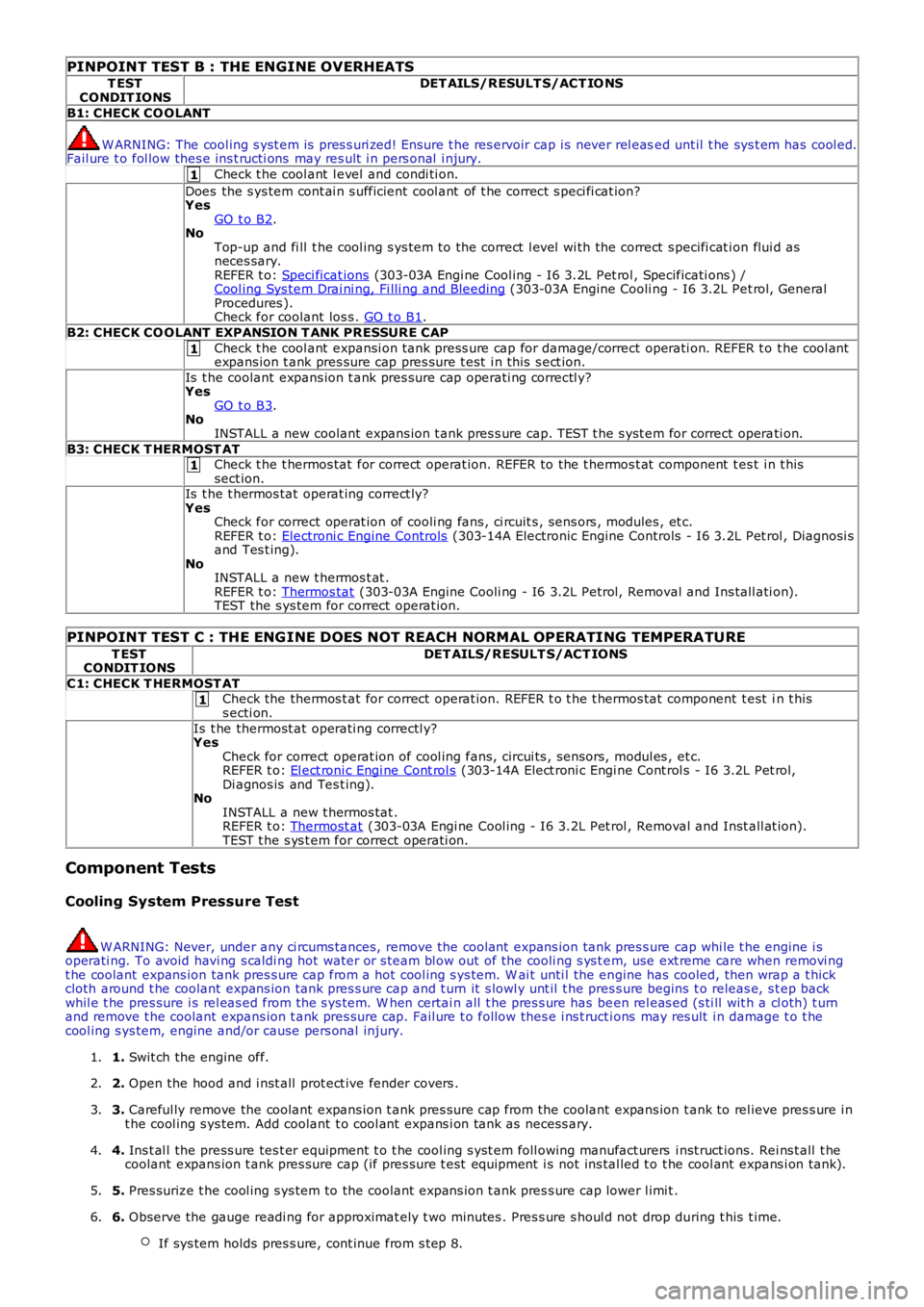

PINPOINT TEST B : THE ENGINE OVERHEATS

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

B1: CHECK CO OLANT

W ARNING: The cool ing s yst em is pres s uri zed! Ensure t he res ervoir cap i s never rel eased unt il t he sys t em has cool ed.Fail ure t o fol low thes e ins t ructi ons may res ult i n pers onal i njury.

Check t he cool ant l evel and condi ti on.

Does the s ys tem cont ai n s ufficient cool ant of t he correct s peci fi cat ion?YesGO t o B2.NoTop-up and fi ll t he cool ing s ys tem to the correct l evel wi th the correct s pecifi cat ion flui d asneces sary.REFER t o: Speci ficat ions (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Specificati ons ) /Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures ).Check for coolant los s . GO t o B1.

B2: CHECK CO OLANT EXPANSION T ANK PRESSURE CAP

Check t he cool ant expansi on tank press ure cap for damage/correct operati on. REFER t o t he cool antexpans ion t ank pres sure cap pres sure t est i n t his s ect ion.

Is t he coolant expans ion t ank pres sure cap operati ng correctl y?YesGO t o B3.NoINSTALL a new coolant expans ion t ank pres s ure cap. TEST t he s yst em for correct operati on.

B3: CHECK T HERMOST ATCheck t he t hermos tat for correct operat ion. REFER to the t hermos t at component t es t in t hissect ion.Is t he t hermos tat operat ing correct ly?YesCheck for correct operat ion of cooli ng fans , ci rcuit s , sens ors , modules , et c.REFER t o: Electroni c Engine Controls (303-14A Electronic Engine Controls - I6 3.2L Pet rol , Diagnosi sand Tes t ing).NoINSTALL a new t hermos t at .REFER t o: Thermos tat (303-03A Engine Cooli ng - I6 3.2L Petrol, Removal and Ins tall ati on).TEST the s ys tem for correct operat ion.

PINPOINT TEST C : THE ENG INE DOES NOT REACH NORMAL OPERATING TEMPERATURE

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

C1: CHECK T HERMOST ATCheck the thermos t at for correct operat ion. REFER t o t he t hermos tat component t est in t hiss ecti on.

Is t he thermost at operati ng correctl y?YesCheck for correct operat ion of cool ing fans, circui ts , s ensors, modul es , et c.REFER t o: El ect roni c Engi ne Cont rol s (303-14A Elect roni c Engi ne Cont rol s - I6 3.2L Pet rol,Di agnos is and Tes t ing).NoINSTALL a new t hermos tat .REFER t o: Thermost at (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Removal and Inst all at ion).TEST t he s ys t em for correct operati on.

Component Tests

Cooling System Pressure Test

W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure cap whi le t he engine i soperati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t em, use ext reme care when removi ngt he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the engine has cooled, then wrap a t hickcloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pres s ure begins t o releas e, s t ep backwhil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has been rel eas ed (s ti ll wit h a cl oth) t urnand remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ructi ons may res ult i n damage t o t hecool ing s ys tem, engine and/or cause pers onal injury.

1. Swit ch the engine off.1.

2. Open the hood and i nst all prot ect ive fender covers .2.

3. Careful ly remove the coolant expans ion t ank pres s ure cap from the coolant expans ion t ank to rel ieve pres s ure i nt he cool ing s ys tem. Add coolant t o cool ant expans i on tank as necess ary.3.

4. Ins t al l the press ure tes t er equipment t o t he cool ing s yst em foll owing manufact urers i nst ruct ions. Rei ns t all t hecoolant expans ion t ank pres sure cap (if pres s ure t est equipment i s not ins tal led t o t he cool ant expans i on tank).4.

5. Pres surize t he cool ing s ys tem to the coolant expans ion t ank pres s ure cap lower l imi t.5.

6. Observe the gauge readi ng for approximat ely t wo minutes . Pres s ure s houl d not drop during t his t ime.

If sys tem holds pres s ure, cont inue from s tep 8.

6.

Page 946 of 3229

Entrained gases i n t he cool ing s ys tem escape t hrough the t hermal control modul e degas l ine t o t he cool ant res ervoir.

The increas ing coolant temperature is felt at t he t hermos tat , and is regi s tered on the ins trument cl us t er coolantt emperature gage vi a t he ECM and ECT s ens or s i gnal.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

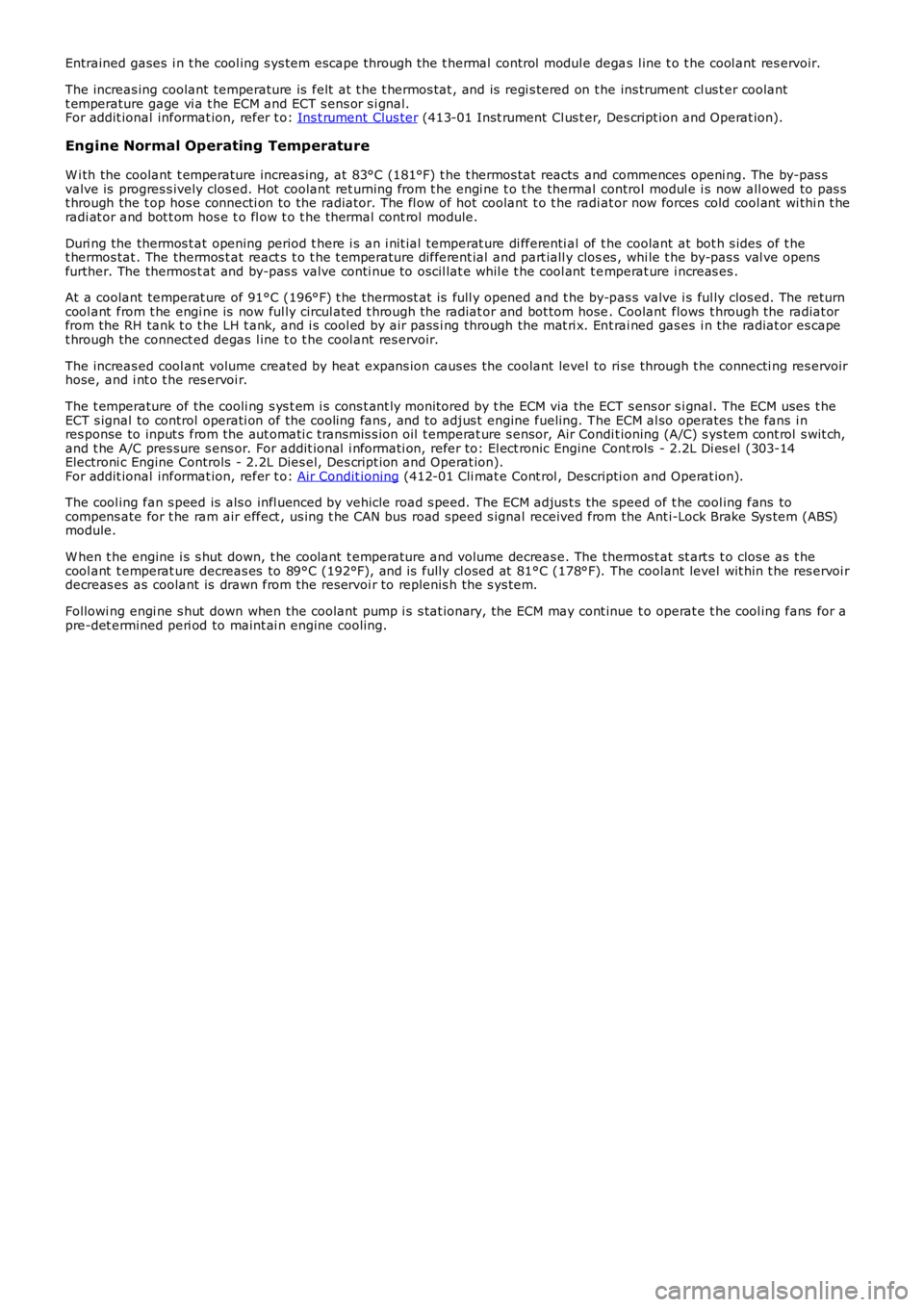

Engine Normal Operating Temperature

W i th the coolant t emperature increas ing, at 83°C (181°F) t he t hermos tat reacts and commences openi ng. The by-pas svalve is progres s ively clos ed. Hot coolant ret urning from t he engi ne t o t he thermal control modul e i s now all owed to pas st hrough the t op hos e connecti on to the radiator. The fl ow of hot coolant t o t he radiat or now forces cold cool ant wi thi n t heradi at or and bot t om hos e t o fl ow t o t he thermal cont rol module.

Duri ng the thermos t at opening period t here i s an i nit ial temperat ure di fferenti al of t he coolant at bot h s ides of t het hermos tat . The thermos t at react s t o t he t emperature different ial and part iall y closes , whi le t he by-pas s val ve opensfurther. The thermos t at and by-pas s valve conti nue to oscil lat e whil e t he cool ant t emperat ure i ncreas es .

At a coolant temperat ure of 91°C (196°F) t he thermost at is full y opened and t he by-pas s valve i s ful ly clos ed. The returncool ant from t he engi ne is now ful ly circul ated t hrough t he radiat or and bot tom hose. Coolant flows t hrough the radiat orfrom the RH tank t o t he LH t ank, and i s cool ed by air pass i ng through the mat ri x. Ent rai ned gas es i n the radiat or es capet hrough the connect ed degas l ine t o t he cool ant res ervoir.

The increas ed cool ant volume created by heat expans ion caus es the coolant level to ri se through t he connecti ng res ervoirhose, and i nt o t he res ervoi r.

The t emperature of the cooli ng s ys t em i s cons t ant ly moni tored by t he ECM via the ECT s ens or s i gnal. The ECM uses t heECT s ignal to control operati on of the cooling fans , and to adjus t engine fueling. The ECM al so operates t he fans i nres ponse to input s from the aut omati c t ransmis s ion oil t emperat ure s ensor, Air Condit ioning (A/C) s ys tem cont rol s wit ch,and t he A/C pres sure s ens or. For addit ional i nformati on, refer to: El ect ronic Engine Cont rols - 2.2L Di es el (303-14Electroni c Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).For addit ional informat ion, refer t o: Air Condit ioning (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

The cool ing fan s peed is als o infl uenced by vehicle road s peed. The ECM adjus t s the speed of t he cool ing fans tocompens ate for t he ram air effect , us ing t he CAN bus road speed s ignal received from the Ant i-Lock Brake Sys tem (ABS)module.

W hen t he engine i s s hut down, t he coolant t emperature and volume decreas e. The thermos t at st art s t o clos e as t hecool ant t emperat ure decreas es to 89°C (192°F), and is fully cl osed at 81°C (178°F). The coolant level wit hin t he res ervoi rdecreas es as coolant is drawn from the res ervoi r to replenis h the s ys tem.

Followi ng engi ne s hut down when the coolant pump i s s tat ionary, the ECM may cont inue t o operat e t he cool ing fans for apre-det ermined peri od to maint ai n engine cooling.

Page 947 of 3229

Publi s hed: 11-May-2011

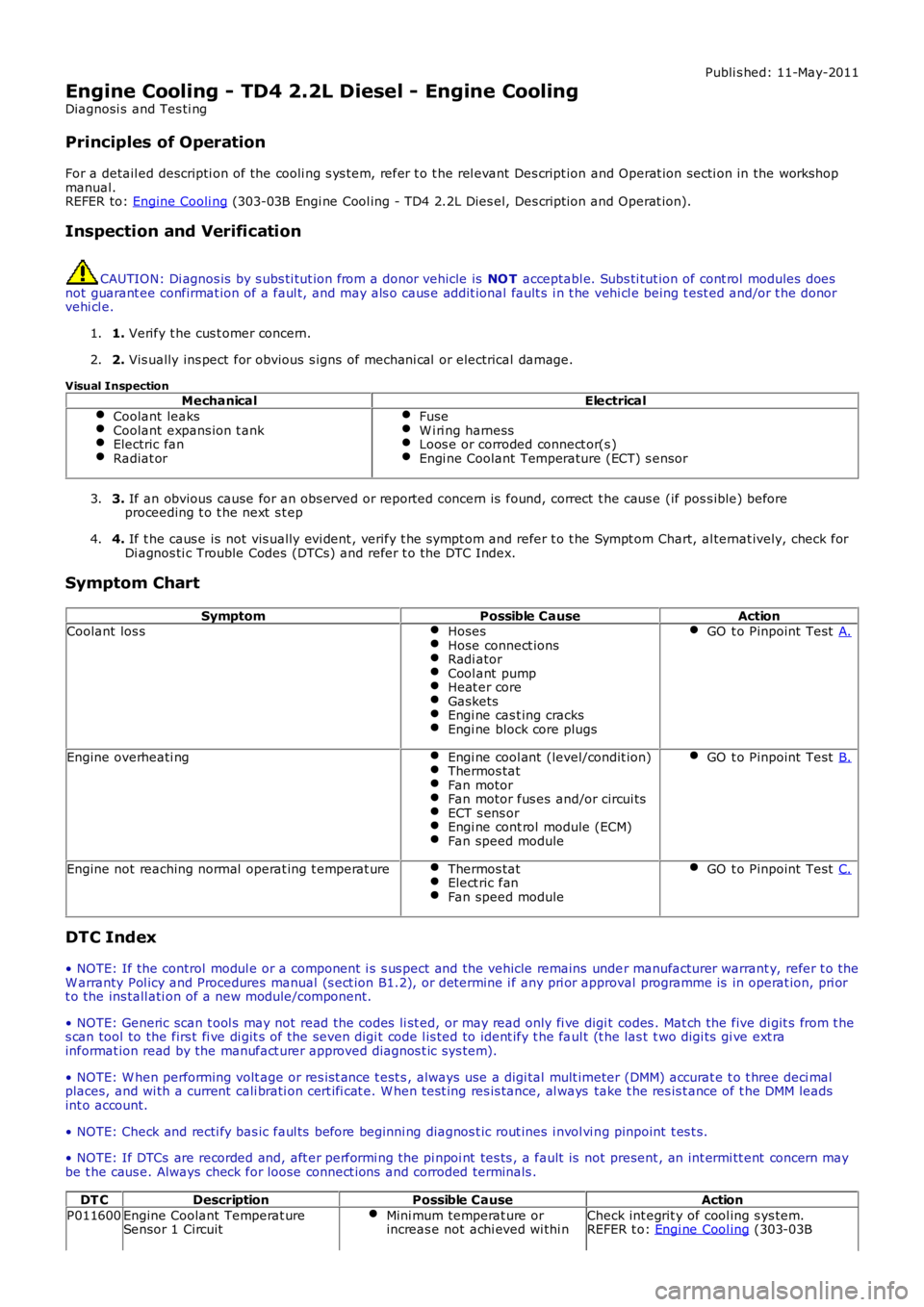

Engine Cooling - TD4 2.2L Diesel - Engine Cooling

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshop

manual.

REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is

NO T acceptabl e. Subs ti tut ion of cont rol modules does

not guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he v ehi cl e being t est ed and/or t he donor

vehi cl e.

1. Verify t he cus t omer concern.

1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.

2.

Visual Inspection Mechanical Electrical

Coolant leaks Coolant expans ion t ank

Electric fan

Radiat or Fuse

W i ri ng harness

Loos e or corroded connect or(s )

Engi ne Coolant Temperature (ECT) s ensor

3.

If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) before

proceeding t o t he next s t ep

3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Ch art, al ternat ively, check for

Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.

4.

Symptom Chart Symptom Possible CauseAction

Coolant los s Hoses Hose connect ions

Radi ator

Cool ant pump

Heat er core

Gaskets

Engi ne cas t ing cracks

Engi ne block core plugs GO t o Pinpoint Test

A.Engine overheati ng

Engi ne cool ant (level/condit ion) Thermos tat

Fan motor

Fan motor fus es and/or circui ts

ECT s ens or

Engi ne cont rol module (ECM)

Fan speed module GO t o Pinpoint Test

B.Engine not reaching normal operat ing t emperat ure

Thermos tat Elect ric fan

Fan speed module GO t o Pinpoint Test

C.DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains unde r manufacturer warrant y, refer t o the

W arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or appr oval programme is in operat ion, pri or

t o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digi t codes . Mat ch the five di git s from t he

s can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he fa ul t (t he las t t wo digi ts gi ve ext ra

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci mal

places, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leads

int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

DT C Description Possible Cause Action

P011600 Engine Coolant Temperat ure

Sensor 1 Circuit Mini mum temperat ure or

increas e not achi eved wi thi n Check int egrit y of cool ing s ys tem.

REFER t o: Engi ne Cool ing (303-03B

Page 949 of 3229

1

1

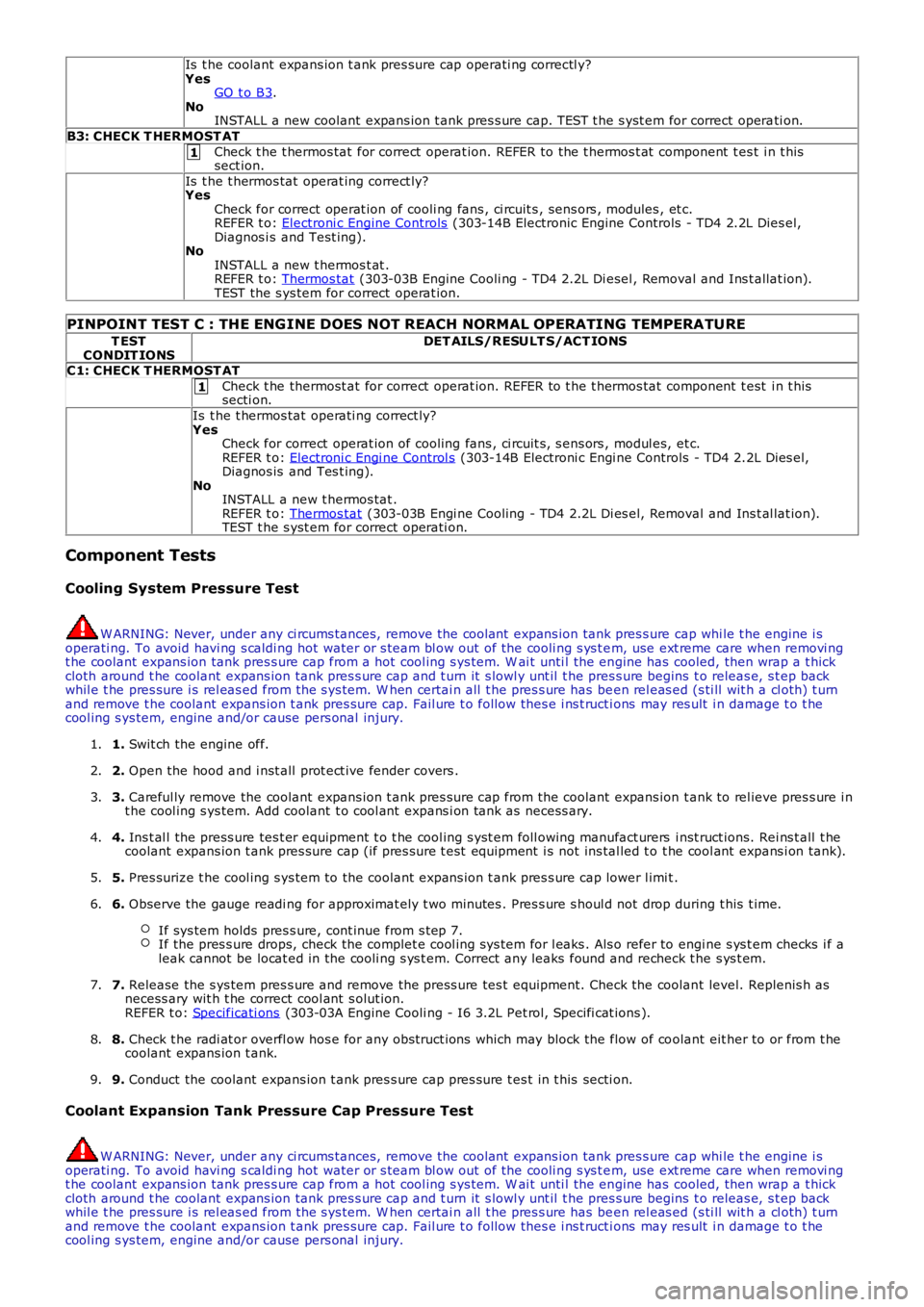

Is t he coolant expans ion t ank pres sure cap operati ng correctl y?

Yes GO t o B3 .

No INSTALL a new coolant expans ion t ank pres s ure cap. TEST t he s yst em for correct opera ti on.

B3: CHECK T HERMOST AT Check t he t hermos tat for correct operat ion. REFER to the t hermos t at component t es t i n t his

sect ion.

Is t he t hermos tat operat ing correct ly?

Yes

Check for correct operat ion of cooli ng fans , ci rcuit s , sens ors , modules , et c.

REFER t o: Electroni c Engine Controls (303-14B Electronic Engine Controls - TD4 2.2L Dies el,

Diagnos i s and Test ing).

No

INSTALL a new t hermos t at .

REFER t o: Thermos tat (303-03B Engine Cooli ng - TD4 2.2L Di esel , Removal and Ins t allat ion).

TEST the s ys tem for correct operat ion.

PINPOINT TEST C : THE ENG INE DOES NOT REACH NORMAL OPERATING TEMPERATURE T EST

CONDIT IONS DET AILS/RESULT S/ACT IONS

C1: CHECK T HERMOST AT Check t he thermost at for correct operat ion. REFER to t he t hermos tat component t est i n t his

secti on.

Is t he t hermos tat operati ng correct ly?

Yes Check for correct operat ion of cooling fans , ci rcuit s, s ens ors , modul es, et c.

REFER t o: Electroni c Engi ne Control s (303-14B Electroni c Engi ne Controls - TD4 2.2L Dies el,

Diagnos is and Tes t ing).

No INSTALL a new t hermos tat .

REFER t o: Thermos tat (303-03B Engi ne Cooling - TD4 2.2L Di es el, Removal and Ins t al lat ion).

TEST t he s yst em for correct operati on.

Component Tests

Cooling System Pressure Test W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure

cap whi le t he engine i s

operati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t e m, use ext reme care when removi ng

t he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the en gine has cooled, then wrap a t hick

cloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pr es s ure begins t o releas e, s t ep back

whil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has be en rel eas ed (s ti ll wit h a cl oth) t urn

and remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ruct i ons may res ult i n damage t o t he

cool ing s ys tem, engine and/or cause pers onal injury.

1. Swit ch the engine off.

1.

2. Open the hood and i nst all prot ect ive fender covers .

2.

3. Careful ly remove the coolant expans ion t ank pres s ure cap from the coolant expans ion t ank to rel ieve pres s ure i n

t he cool ing s ys tem. Add coolant t o cool ant expans i on tank as necess ary.

3.

4. Ins t al l the press ure tes t er equipment t o t he cool ing s yst em foll owing manufact urers i nst ruct ions. Rei ns t all t he

coolant expans ion t ank pres sure cap (if pres s ure t est equipment i s not ins tal led t o t he cool ant expans i on tank).

4.

5. Pres surize t he cool ing s ys tem to the coolant expans ion t ank pres s ure cap lower l imi t .

5.

6. Observe the gauge readi ng for approximat ely t wo minutes . Pres s ure s houl d not drop du ring t his t ime.

If sys tem holds pres s ure, cont inue from s tep 7. If the pres s ure drops, check the complet e cool ing s ys tem for l eaks . Als o refer to en

gi ne s ys t em checks i f a

leak cannot be locat ed in the cooli ng s ys t em. Correct any leaks found and recheck t h e s ys t em.6.

7. Release the s ys tem pres s ure and remove the press ure tes t equipment. Check the coolan t level. Replenis h as

necess ary wit h t he correct cool ant s olut ion.

REFER t o: Specificati ons (303-03A Engine Cooli ng - I6 3.2L Pet rol, Specifi cat ions ).

7.

8. Check t he radi at or overfl ow hos e for any obs truct ions which may block the flow of co olant eit her to or from t he

coolant expans ion t ank.

8.

9. Conduct the coolant expans ion t ank pres s ure cap pres s ure t es t in t his secti on.

9.

Coolant Expansion Tank Pressure Cap Pressure Test W ARNING: Never, under any ci rcums tances, remove the coolant expans ion tank pres s ure

cap whi le t he engine i s

operati ng. To avoid havi ng s caldi ng hot water or s team bl ow out of the cooli ng s ys t e m, use ext reme care when removi ng

t he coolant expans ion tank pres s ure cap from a hot cool ing s ys tem. W ai t unti l the en gine has cooled, then wrap a t hick

cloth around t he coolant expans ion tank pres s ure cap and t urn it s lowl y unt il t he pr es s ure begins t o releas e, s t ep back

whil e t he pres sure i s rel eas ed from the s ys tem. W hen certai n all t he pres s ure has be en rel eas ed (s ti ll wit h a cl oth) t urn

and remove t he coolant expans ion t ank pres sure cap. Fail ure t o follow thes e i ns t ruct i ons may res ult i n damage t o t he

cool ing s ys tem, engine and/or cause pers onal injury.

Page 1133 of 3229

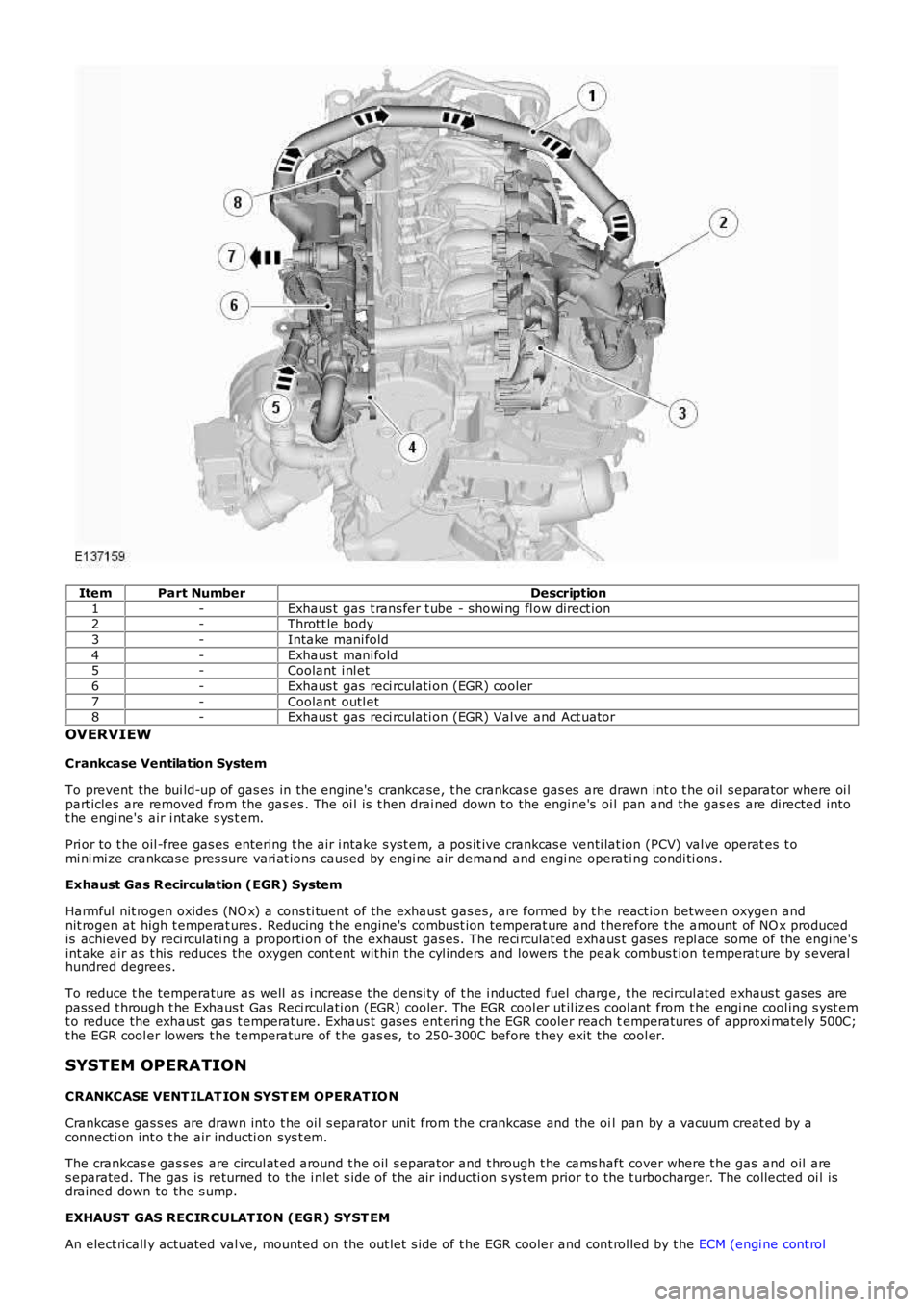

ItemPart NumberDescription

1-Exhaus t gas t rans fer t ube - showi ng fl ow direct ion2-Throt t le body

3-Intake mani fold

4-Exhaus t mani fold5-Coolant i nl et

6-Exhaus t gas reci rculati on (EGR) cooler

7-Coolant outl et8-Exhaus t gas reci rculati on (EGR) Val ve and Act uator

OVERVIEW

Crankcase Ventilation System

To prevent the bui ld-up of gas es in the engine's crankcase, t he crankcas e gas es are drawn int o t he oil s eparator where oi lpart icles are removed from the gas es . The oi l is t hen drai ned down to the engine's oi l pan and the gas es are di rected intot he engi ne's air i nt ake s ys t em.

Pri or to t he oil -free gas es entering t he air i ntake s yst em, a pos it ive crankcas e venti lat ion (PCV) val ve operat es t omi ni mi ze crankcase pres sure vari at ions caused by engi ne air demand and engi ne operati ng condi ti ons .

Exhaust Gas R ecirculation (EGR) System

Harmful nit rogen oxides (NO x) a cons ti tuent of the exhaust gas es, are formed by t he react ion between oxygen andnit rogen at high t emperat ures . Reducing t he engine's combust ion temperat ure and t herefore t he amount of NO x producedis achieved by reci rculati ng a proporti on of the exhaust gas es. The reci rculat ed exhaus t gas es repl ace some of the engine'sint ake air as t hi s reduces the oxygen cont ent wit hin t he cyl inders and lowers t he peak combus t ion t emperat ure by s everalhundred degrees.

To reduce t he temperature as well as i ncreas e t he densi ty of t he i nducted fuel charge, t he recircul ated exhaus t gas es arepass ed t hrough t he Exhaus t Gas Reci rculati on (EGR) cooler. The EGR cool er ut il izes cool ant from t he engi ne cool ing s yst emt o reduce the exhaust gas t emperat ure. Exhaus t gas es ent ering t he EGR cooler reach temperatures of approxi matel y 500C;t he EGR cool er lowers t he t emperature of t he gas es , to 250-300C before t hey exit t he cool er.

SYSTEM OPERATION

CRANKCASE VENT ILAT ION SYST EM OPERAT IO N

Crankcas e gas s es are drawn int o t he oil s eparator unit from the crankcase and the oil pan by a vacuum creat ed by aconnecti on int o t he air inducti on sys t em.

The crankcas e gas ses are circul at ed around t he oil s eparator and t hrough t he cams haft cover where t he gas and oil ares eparated. The gas is returned to the i nlet s ide of t he air inducti on s ys t em prior to the t urbocharger. The collected oi l isdrai ned down to the s ump.

EXHAUST GAS RECIR CULAT ION (EGR) SYST EM

An elect ricall y actuated val ve, mounted on the out let s ide of t he EGR cooler and cont rol led by t he ECM (engi ne cont rol

Page 1134 of 3229

module), regulates t he amount of exhaus t gas es reci rculated into the ai r int ake s ys tem. The ECM uses s i gnals fromvarious engine s ens ors and calculates a res pons e bas ed on t he embedded software algori thm t o cont rol exhaus t gasrecircul ati on. The ECM trans mi ts this cont rol s ignal t o t he valve's actuat or, which i s clos ed-loop controlled wit h t he mas sair flow (MAF) s ens or providi ng the feedback t o t he ECM.

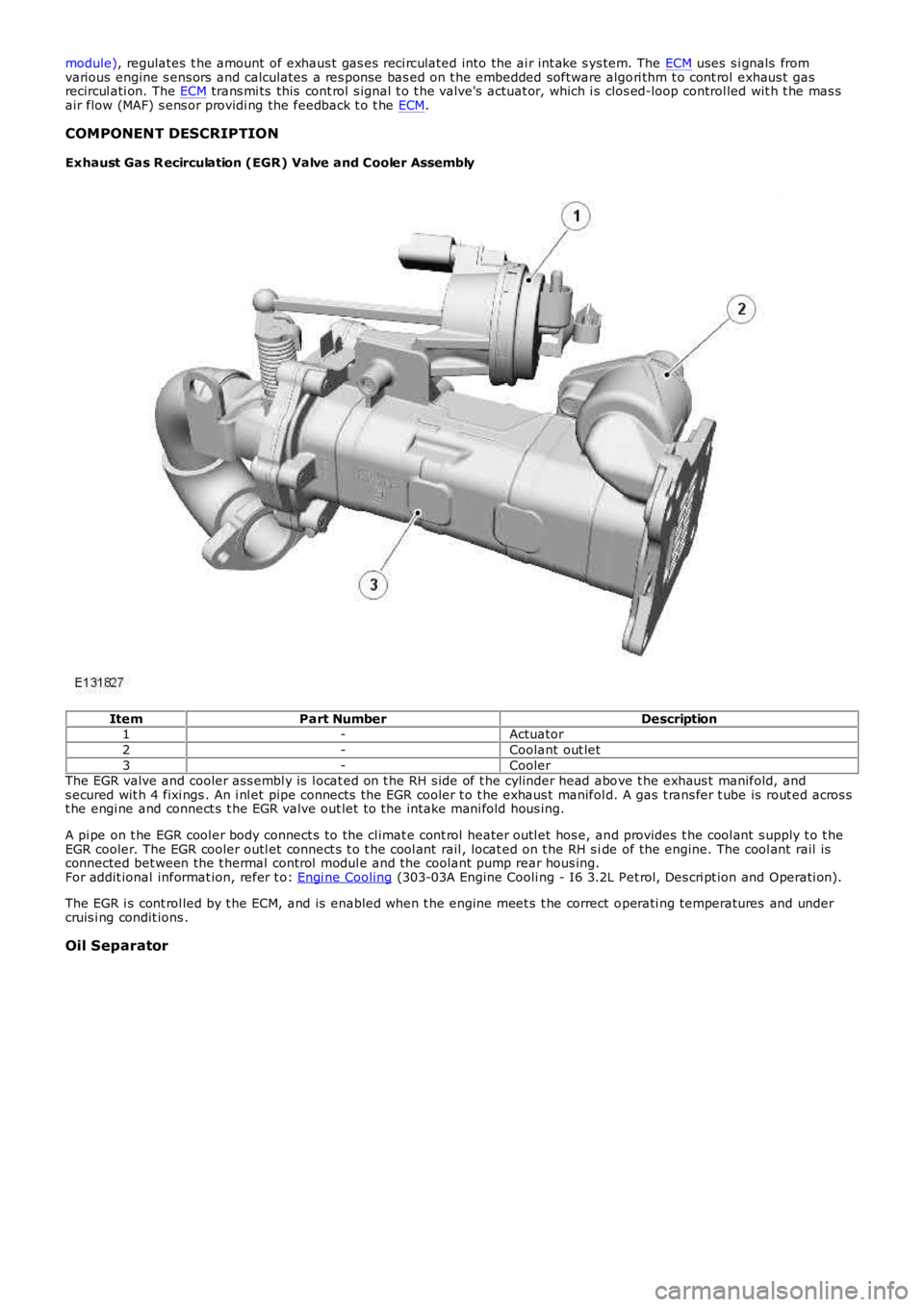

COMPONENT DESCRIPTION

Exhaust Gas R ecirculation (EGR) Valve and Cooler Assembly

ItemPart NumberDescription1-Actuator

2-Coolant out let

3-CoolerThe EGR valve and cooler ass embl y is l ocat ed on t he RH s ide of t he cylinder head above t he exhaus t manifold, ands ecured wit h 4 fixi ngs . An i nl et pipe connects the EGR cooler t o t he exhaus t manifold. A gas t rans fer t ube is rout ed acros st he engi ne and connect s t he EGR valve out let t o the intake mani fold hous ing.

A pi pe on t he EGR cool er body connect s to the cl imat e cont rol heater outl et hos e, and provides t he cool ant s upply t o t heEGR cooler. The EGR cooler outl et connect s t o t he cool ant rail , locat ed on t he RH s ide of the engine. The cool ant rail isconnected bet ween the t hermal control modul e and the coolant pump rear hous ing.For addit ional informat ion, refer t o: Engi ne Cooling (303-03A Engine Cooli ng - I6 3.2L Pet rol, Des cri pt ion and Operati on).

The EGR i s cont rol led by t he ECM, and is enabled when t he engine meet s t he correct operati ng temperatures and undercruis i ng condit ions .

Oil Separator