cooling LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 20 of 3229

All fuel hos es are made up of two lami nat ions , an armoured rubber out er sl eeve and an inner vi ton core. W henever a hos eis removed, make sure t hat t he i nner bore is i ns pected t o check t hat the vi ton l ini ng has not become s eparated from t heouter s leeve.

W ARNING: Never att empt t o repair fuel hos es or recti fy leaki ng 'quick-fit ' connect ors the fuel hos e and connectorsmus t be repl aced as an as s embly.

Fuel s ys tem hos e cl ips

Cert ain fuel s ys tem hose cl ips are of the 'break-off head' type where a s lot i n the screw head s hears off when t he clip ist ightened t o a s peci fi c torque. Thes e clips may be removed us ing a s crewdriver and mus t be repl aced wi th new clips onreas s embly. Clips must be ti ght ened unt il t he port ion of t he s lot s hears off. Do not att empt t o ti ghten cli ps by any othermet hod, do not ins t al l any other type of cli p.

Cooling sys tem hoses

CAUTION: The fol lowi ng precaut ions mus t be obs erved t o make s ure t hat the integrit y of the cooli ng sys t em hos esand t hei r connect ion t o t he s yst em is mai ntained.

Hos e ori ent ati on and connecti on

Correct orientat ion of cool ing s ys tem hoses i s important t o make s ure that hoses do not become fati gued or damagedt hrough cont act wi th adjacent component s.

W here ori ent ati on marks are provided on the hos e and corres ponding component , the marks mus t be ali gned when thehose is i nst all ed. Hos es mus t be ins t al led full y on t o t hei r connect ion poi nt s , usuall y a moul ded form on a pipe provi des aposi ti ve indicator.

Hos e clips

Page 177 of 3229

For addit ional informat ion, refer t o: Parking Brake Cabl e Adjus tment (206-05 Parki ng Brake and Actuat ion, GeneralProcedures).

Door Locks and Hinges

1. Check operat ion of all door locks, bonnet lock and fuel fi ll er flap.

2. Lubricate al l door check s t raps , bonnet cat ch and fuel fill er fl ap cat ch.

Cooling System

CAUTION: Anti-freeze concentration must be maintained at 50%.

1. Check s peci fi c gravit y of cool ant us ing a hydrometer.

• NOTE: A s uit able hydromet er is avail abl e from the Equipment Programme under Part Number 511 3302 001 00.

2. Top-up cool ing s ys tem if neces s ary.For addit ional informat ion, refer t o: Specificati ons (303-03A Engine Cool ing - I6 3.2L Pet rol , Specificati ons ).

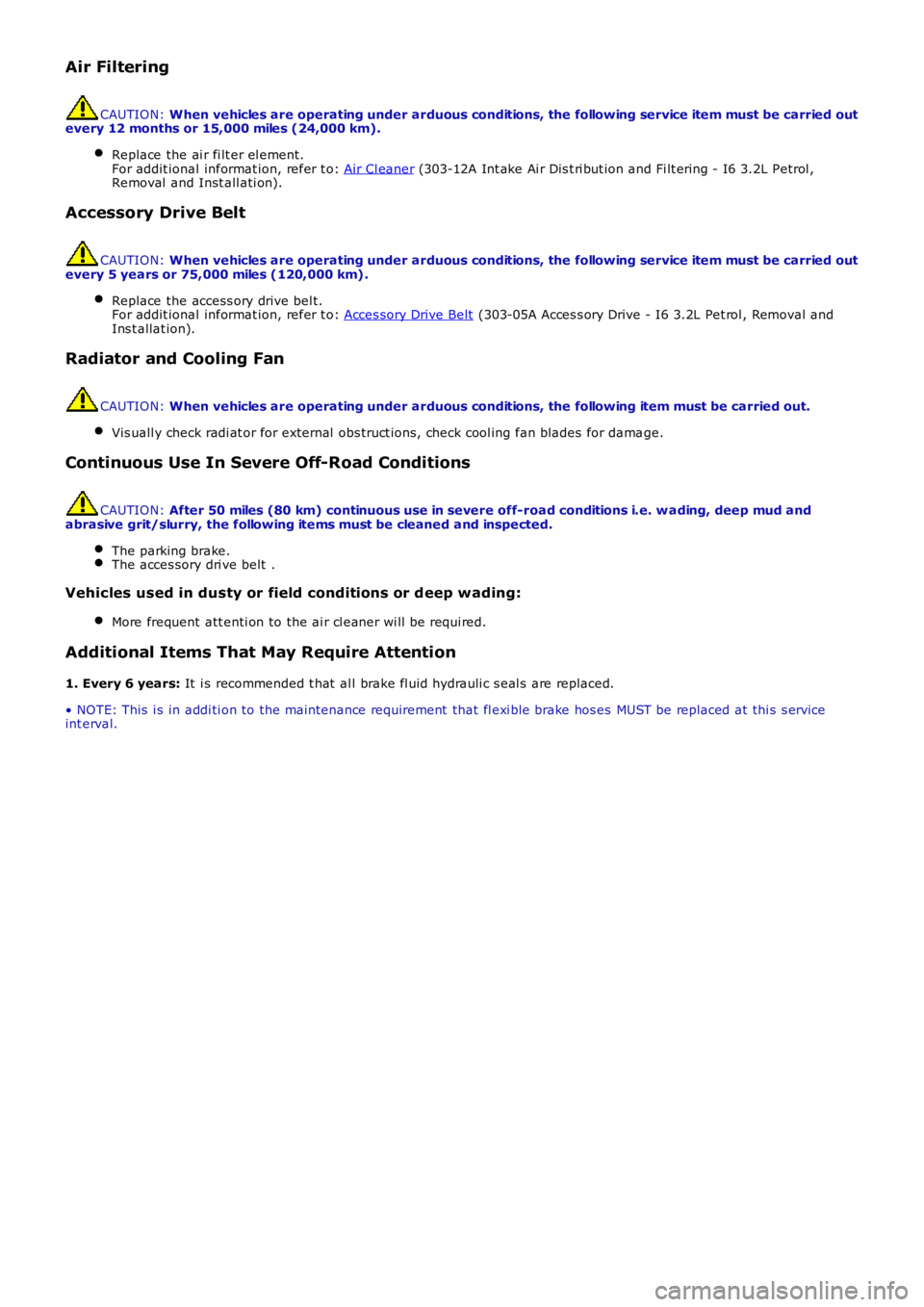

Cooling system - Check/Top-up

W ARNING: Since injury such as scalding could be caused by escaping steam or coolant, do not remove the fillercap from the coolant expansion tank whilst the system is hot.

• CAUTIO NS:

Engine coolant w ill damage the paint finished surfaces. If coolant is spilled, immediately remove the coolantand wash the area with water.

Always top-up with a 50% mixture of anti-freeze and water.

Check t he l evel of cool ant i n t he expans ion t ank. W it h t he engi ne col d, the coolant level must be to the UPPERLEVEL indicat or mark above the COLD FILL RANGE t ext on the s i de of the expans i on tank. Ignore any coolantwhich may be vis ible in t he t op s ect ion of t he t ank.If topping-up i s requi red, remove expans ion tank fill er cap and top-up coolant level to the UPPER LEVEL indicat ormark.For addit ional informat ion, refer t o: Specificati ons (303-03A Engine Cool ing - I6 3.2L Pet rol , Specificati ons ).Ins t all expans ion t ank fi ll er cap, ti ght en cap unti l ratchet is heard to 'cli ck'.

Coolant - Replace

Every 10 years: Repl ace the coolant.For addit ional informat ion, refer t o: Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol,General Procedures ).

Ignition System

Every 75,000 miles (120,000 km). Replace s park plugs .For addit ional informat ion, refer t o: Specificati ons (303-07B Glow Pl ug Sys t em, Specificati ons ).

Accessory Drive Belt

CAUTION: For vehi cl es operati ng under arduous condi ti ons s ee relevant s ecti on.

Check t he condi ti on of the access ory drive bel t.Remove all t races of mud and dirt from t he dri ve belt and pull eys .Check t he drive belt for si gns of s pli tt ing and wear.Every 105,000 miles (168,000 km) - Petrol models: Replace the accessory drive belt. For addi ti onalinformat ion, refer t o: Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2L Pet rol , Removal and Ins t allat ion).

Page 181 of 3229

Air Filtering

CAUTION: When vehicles are operating under arduous conditions, the following service item must be carried outevery 12 months or 15,000 miles (24,000 km).

Replace the ai r fi lt er el ement.For addit ional informat ion, refer t o: Air Cl eaner (303-12A Int ake Ai r Dis t ri but ion and Fi lt ering - I6 3.2L Petrol ,Removal and Inst all ati on).

Accessory Drive Belt

CAUTION: When vehicles are operating under arduous conditions, the following service item must be carried outevery 5 years or 75,000 miles (120,000 km).

Replace the access ory drive bel t.For addit ional informat ion, refer t o: Acces sory Drive Belt (303-05A Acces s ory Drive - I6 3.2L Pet rol , Removal andIns t allat ion).

Radiator and Cooling Fan

CAUTION: When vehicles are operating under arduous conditions, the following item must be carried out.

Vis uall y check radi at or for external obs truct ions , check cool ing fan blades for damage.

Continuous Use In Severe Off-Road Conditions

CAUTION: After 50 miles (80 km) continuous use in severe off-road conditions i.e. w ading, deep mud andabrasive grit/slurry, the following items must be cleaned and inspected.

The parking brake.The acces sory dri ve belt .

Vehicles used in dusty or field conditions or d eep wading:

More frequent att enti on to the ai r cl eaner wi ll be requi red.

Additional Items That May Require Attention

1. Every 6 years: It i s recommended t hat al l brake fl uid hydrauli c s eal s are replaced.

• NOTE: This i s in addi ti on to the maintenance requirement that fl exi ble brake hos es MUST be replaced at thi s s erviceint erval.

Page 188 of 3229

For addit ional informat ion, refer t o: Parking Brake Cabl e Adjus tment (206-05 Parki ng Brake and Actuat ion, General

Procedures).

Door Locks and Hinges

1. Check operat ion of all door locks, bonnet lock and fuel fi ll er flap.

2. Lubricate al l door check s t raps , bonnet cat ch and fuel fill er fl ap cat ch.

Cooling System CAUTION:

Anti-freeze concentration must be maintained at 50%.

1. Check s peci fi c gravit y of cool ant us ing a hydrometer.

• NOTE: A s uit able hydromet er is avail abl e from the Equipment Programme under Part N umber 511 3302 001 00.

2. Top-up cool ing s ys tem if neces s ary.

For addit ional informat ion, refer t o: Specificati ons (303-03B Engine Cool ing - TD4 2.2L Dies el, Speci fi cat ions ).

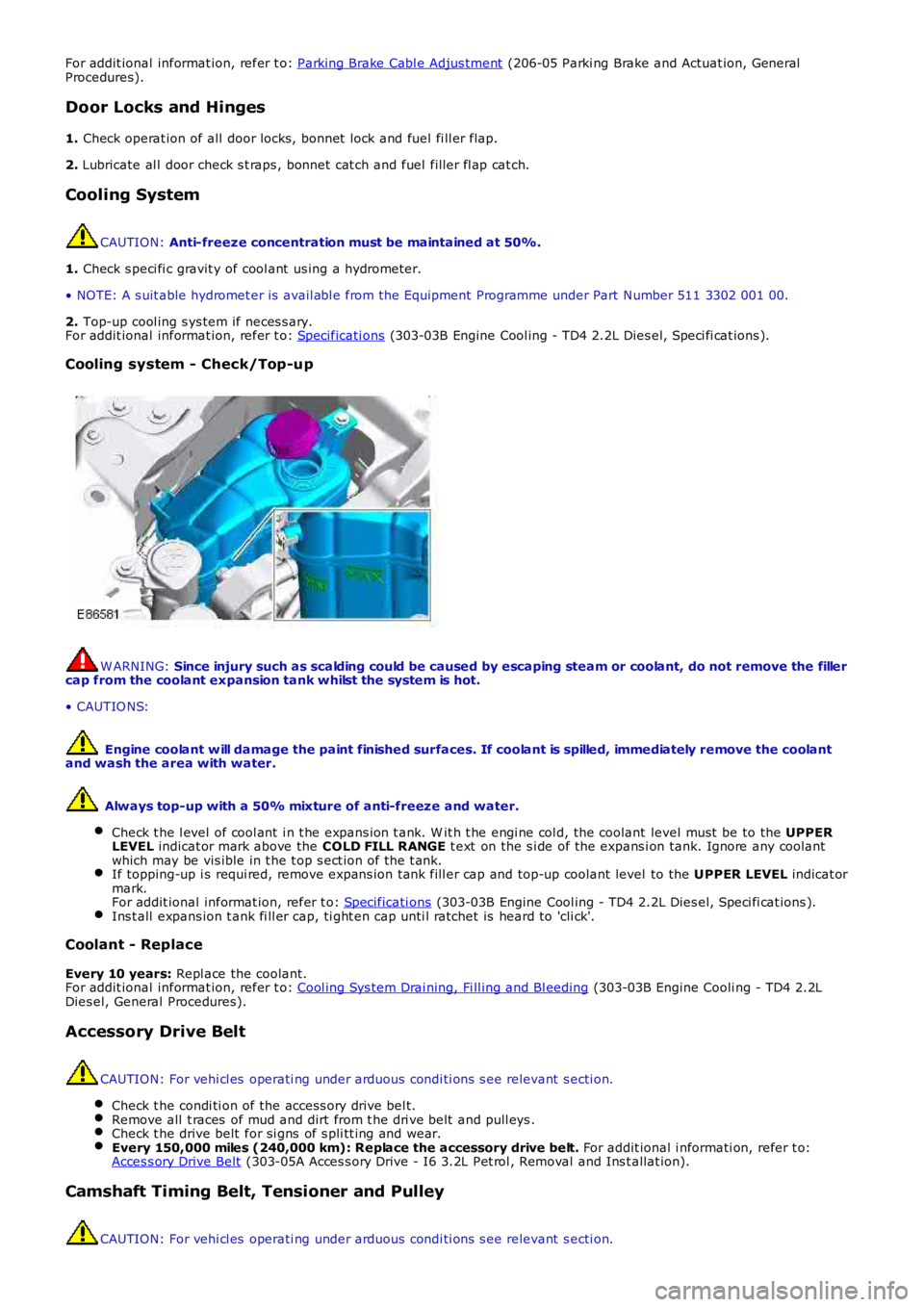

Cooling system - Check/Top-up W ARNING:

Since injury such as scalding could be caused by escaping steam or coolant, do not r emove the filler

cap from the coolant expansion tank whilst the system is hot.

• CAUTIO NS:

Engine coolant w ill damage the paint finished surfaces. If coolant is spilled, immed iately remove the coolant

and wash the area with water.

Always top-up with a 50% mixture of anti-freeze and water.

Check t he l evel of cool ant i n t he expans ion t ank. W it h t he engi ne col d, the coolant level must be to the UPPER

LEVEL indicat or mark above the COLD FILL RANGE t ext on the s i de of the expans i on tank. Ignore any coolant

which may be vis ible in t he t op s ect ion of t he t ank. If topping-up i s requi red, remove expans ion tank fill er cap and top-up coolant level

to the UPPER LEVEL indicat or

mark.

For addit ional informat ion, refer t o: Specificati ons (303-03B Engine Cool ing - TD4 2.2L Dies el, Speci fi cat ions ).

Ins t all expans ion t ank fi ll er cap, ti ght en cap unti l ratchet is heard to 'cli ck'.

Coolant - Replace

Every 10 years: Repl ace the coolant.

For addit ional informat ion, refer t o: Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03B Engine Cooli ng - TD4 2.2L

Dies el, General Procedures).

Accessory Drive Belt CAUTION: For vehi cl es operati ng under arduous condi ti ons s ee relevant s ecti on.

Check t he condi ti on of the access ory drive bel t. Remove all t races of mud and dirt from t he dri ve belt and pull eys .

Check t he drive belt for si gns of s pli tt ing and wear.

Every 150,000 miles (240,000 km): Replace the accessory drive belt.

For addit ional i nformati on, refer t o:

Acces s ory Drive Belt (303-05A Acces s ory Drive - I6 3.2L Pet rol , Removal and Ins t allat ion).

Camshaft Timing Belt, Tensioner and Pulley

CAUTION: For vehi cl es operati ng under arduous condi ti ons s ee relevant s ecti on.

Page 192 of 3229

Ins pect rear pads for wear.

Check brake cal ipers for s igns of fl ui d l eaks .

Check brake dis cs for condi ti on.

Check al l brake boos t er and brake s ys t em pipes and hos es for condi ti on, chafi ng and

leaks.Clean road wheel hub s pigot s and appl y greas e, Land Rover Part Number RY L 105020 t o

t he wheel mat ing surface

of each s pigot . Brake Fluid Replacement

CAUTION:

When vehicles are operating under arduous conditions, the following service item mus t be carried out

every 2 Years or 30,000 miles (48,000 km).

Replace brake fluid. Road Wheel Speed Sensors

CAUTION:

When vehicles are operating under arduous conditions, the following service item mus t be carried out

every 3 months or 3,750 miles (6,000 km).

Ins pect the road wheel s peed s ens or harness es for damage. Engine Oil and Filter

• CAUTIO NS:

When vehicles are operating under arduous conditions, the following service item mus t be carried out every 3

months or 3,750 miles (6,000 km).

Vehicles operating on high sulphur content fuel - above 0.7%, the oil and filter cha nge period MUST NOT

exceed 3 months or 3,750 miles (6,000 km).

Vehicles operating on moderate sulphur content fuel - 0.3 to 0.7%, the oil and filte r change period MUST NOT

exceed 6 months or 7,500 miles (12,000 km).

Renew engi ne oil and fil ter. Air Filtering

CAUTION:

When vehicles are operating under arduous conditions, the following service item mus t be carried out

every 12 months or 15,000 miles (24,000 km).

Replace the ai r fi lt er el ement.

For addit ional informat ion, refer t o: Air Cl eaner (303-12A Int ake Ai r Dis t ri but ion and Fi lt ering - I6 3.2L Petrol ,

Removal and Inst all ati on). Accessory Drive Belt

CAUTION:

When vehicles are operating under arduous conditions, the following service item mus t be carried out

every 5 years or 75,000 miles (120,000 km).

Replace the access ory drive bel t. For addi ti onal informat ion, refer to: Acces s ory Drive Belt (303-05A Acces s ory Drive

- I6 3.2L Pet rol, Removal and Ins tal lat ion). Camshaft Timing Belt, Tensioner and Pulley

CAUTION:

When vehicles are operating under arduous conditions, the following service item mus t be carried out

every 4 years or 60,000 miles (96,000 km).

Replace the cams haft t iming belt , tens ioner and pul ley.

For addit ional informat ion, refer t o: Timi ng Belt (303-01B Engi ne - TD4 2.2L Dies el, Removal and Inst all ati on).

Radiator/Charge Air Cooler and Cooling Fan

CAUTION:

When vehicles are operating under arduous conditions, the following items must be ca rried out.

Vis uall y check t he radiat or/charge air cool er for ext ernal obst ruct ions, check cooli ng fan bl ades for damage.Remove any debris from t he charge air cool er us i ng a l ow pres s ure hos e.

Continuous Use In Severe Off-Road Conditions

CAUTION:

After 50 miles (80 km) continuous use in severe off-road conditions i.e. w ading, dee p mud and

abrasive grit/slurry, the following items must be cleaned and inspected.

Page 605 of 3229

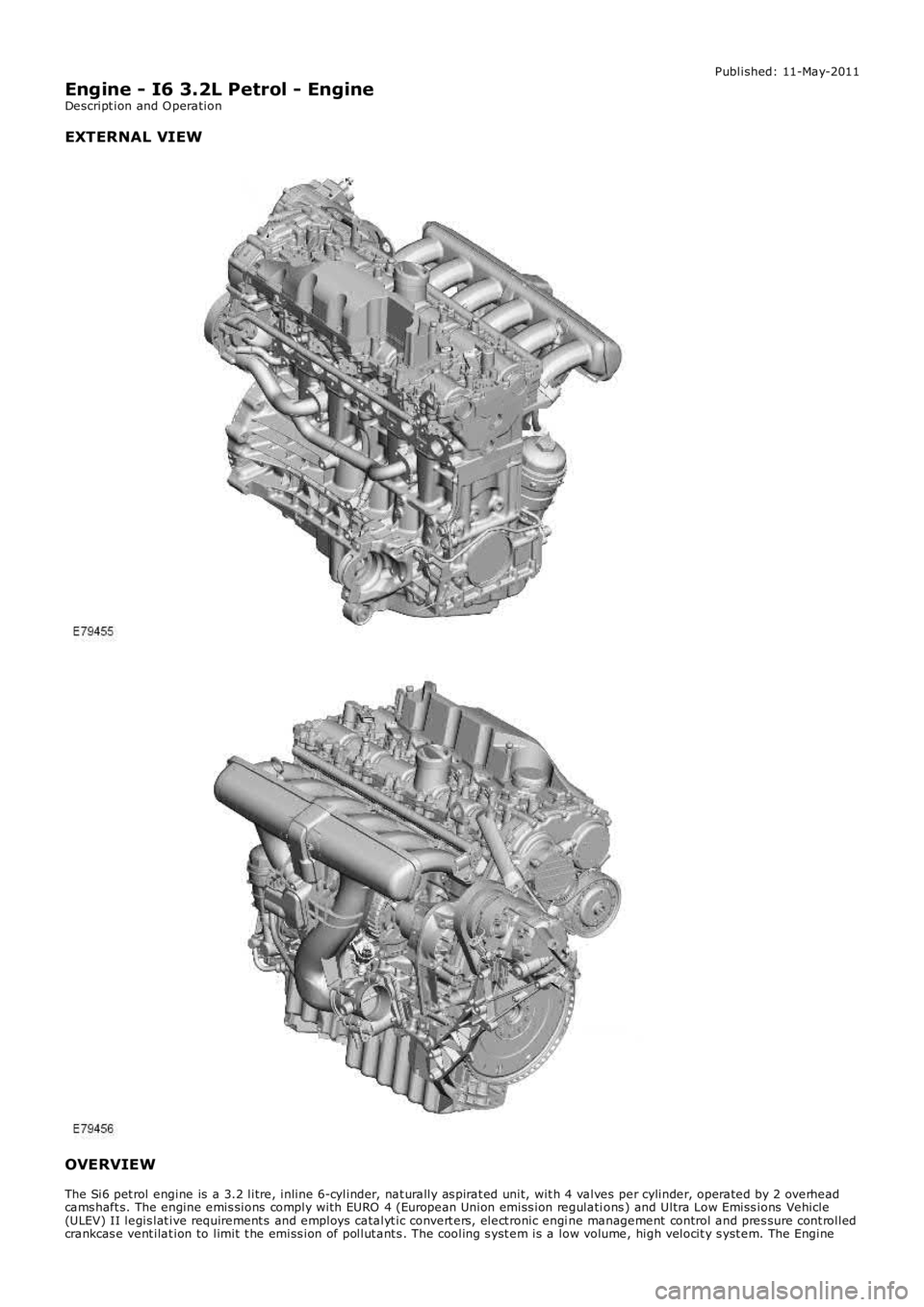

Published: 11-May-2011

Engine - I6 3.2L Petrol - Engine

Descript ion and O peration

EXTERNAL VIEW OVERVIEW

The Si6 pet rol engine is a 3.2 litre, inline 6-cylinder, nat urally as pirat ed unit, w it h 4 valves per cylinder, operated by 2 overhead

cams haft s. The engine emis sions comply with EURO 4 (European Union emiss ion regulati ons ) and Ultra Low Emiss ions Vehicle

(ULEV) II legis lat ive requirement s and employs catalyt ic convert ers , elect ronic engi ne management control and pres sure cont rolled

crankcas e vent ilat ion to limit t he emiss ion of pollut ant s . The cooling s yst em is a l ow volume, high velocit y s yst em. The Engine

Page 607 of 3229

A Rear End Ancillary Drive (READ) s yst emTwo fabricated s t ainles s s t eel t win s kin exhaust manifoldsA 3-pos ition Variable Intake Sys t em (VIS)An advanced Engine Management Syst em (EMS) incorporat ing elect ronic t hrot tle controlFour cat alyt ic converters

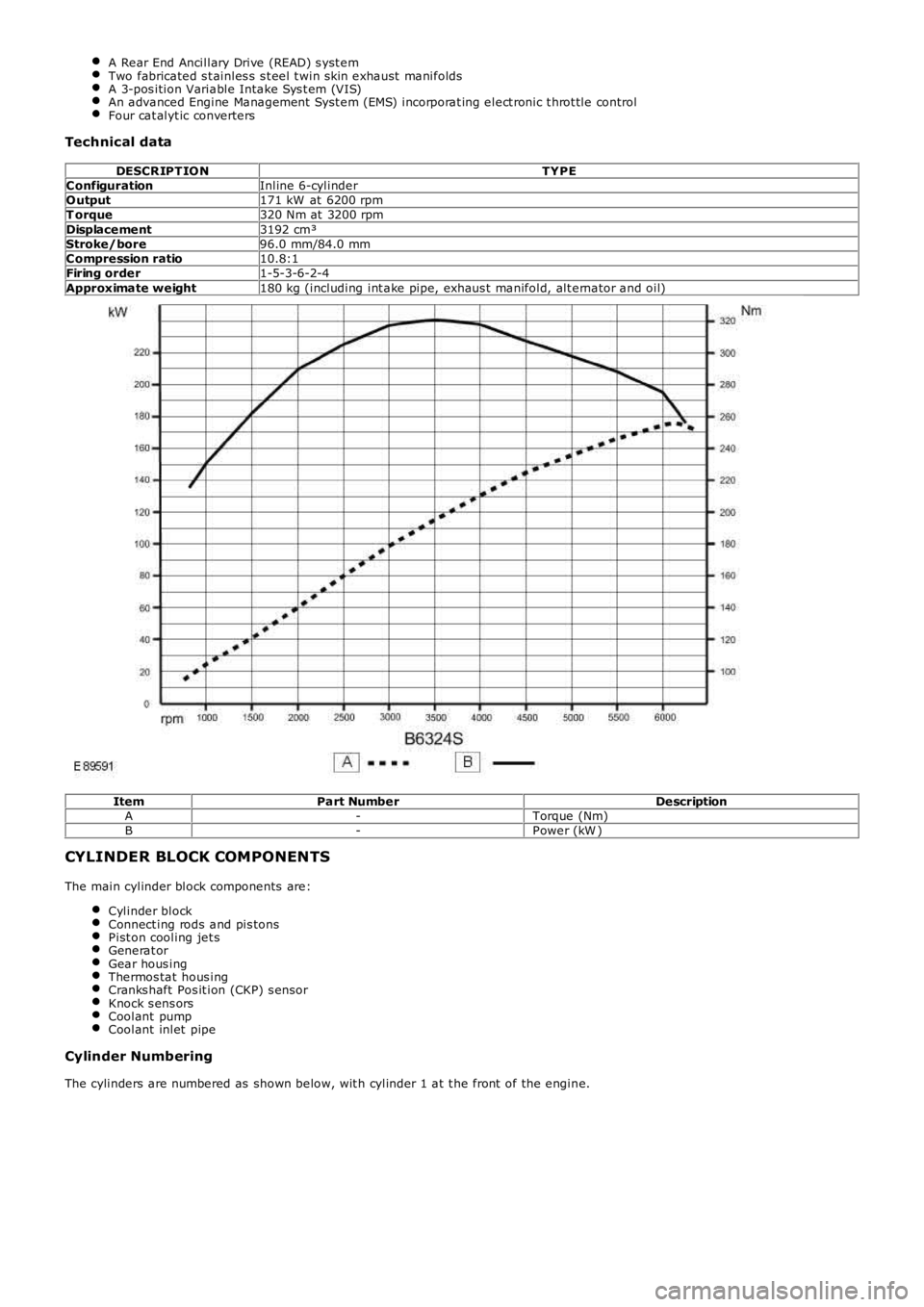

Technical data

DESCR IPT IO NT YPEConfigurationInline 6-cylinderO utput171 kW at 6200 rpmT orque320 Nm at 3200 rpmDisplacement3192 cm³Stroke/bore96.0 mm/84.0 mmCompression ratio10.8:1Firing order1-5-3-6-2-4Approximate weight180 kg (including int ake pipe, exhaus t manifold, alt ernator and oil)

ItemPart NumberDescriptionA-Torque (Nm)B-Power (kW )

CYLINDER BLOCK COMPONENTS

The main cylinder block components are:

Cylinder blockConnect ing rods and pis tonsPist on cooling jet sGenerat orGear hous ingThermos tat hous ingCranks haft Pos it ion (CKP) s ensorKnock s ens orsCoolant pumpCoolant inlet pipe

Cylinder Numbering

The cylinders are numbered as shown below, wit h cylinder 1 at t he front of the engine.

Page 609 of 3229

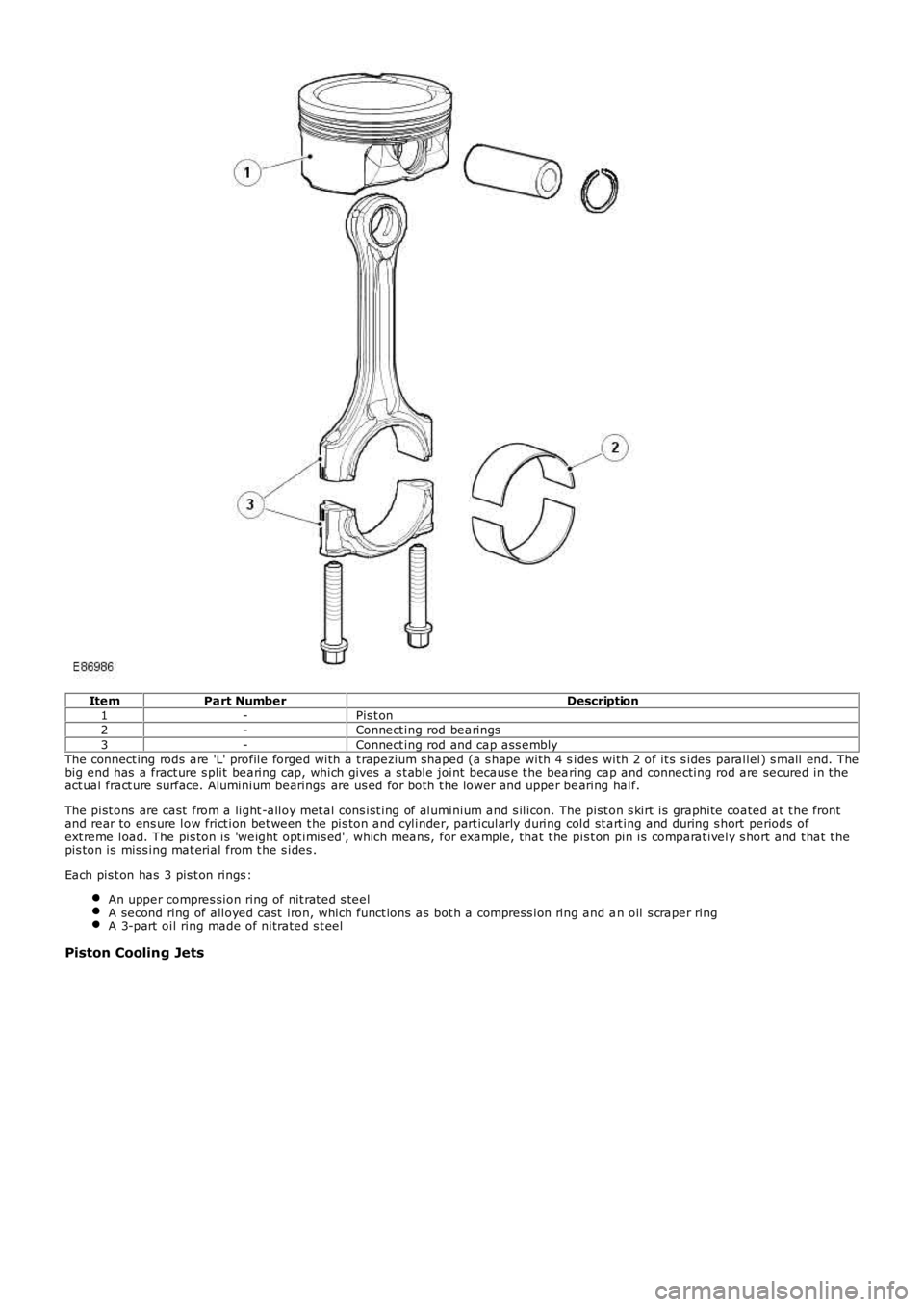

ItemPart NumberDescription1-Pis t on2-Connect ing rod bearings3-Connect ing rod and cap ass emblyThe connect ing rods are 'L' profile forged with a t rapezium shaped (a s hape with 4 sides with 2 of it s s ides parallel) s mall end. Thebig end has a fract ure s plit bearing cap, which gives a s t able joint becaus e t he bearing cap and connecting rod are secured in t heact ual fract ure surface. Aluminium bearings are us ed for both t he lower and upper bearing half.

The pist ons are cast from a light -alloy met al cons ist ing of aluminium and s ilicon. The pist on s kirt is graphite coated at t he frontand rear to ens ure low frict ion bet ween t he pis ton and cylinder, part icularly during cold st art ing and during s hort periods ofext reme load. The pis ton is 'weight opt imis ed', which means, for example, that t he pis t on pin is comparat ively s hort and t hat t hepis ton is miss ing mat erial from t he s ides .

Each pis t on has 3 pis t on rings :

An upper compres sion ring of nit rat ed s teelA second ring of alloyed cast iron, which funct ions as bot h a compress ion ring and an oil s craper ringA 3-part oil ring made of nitrated s t eel

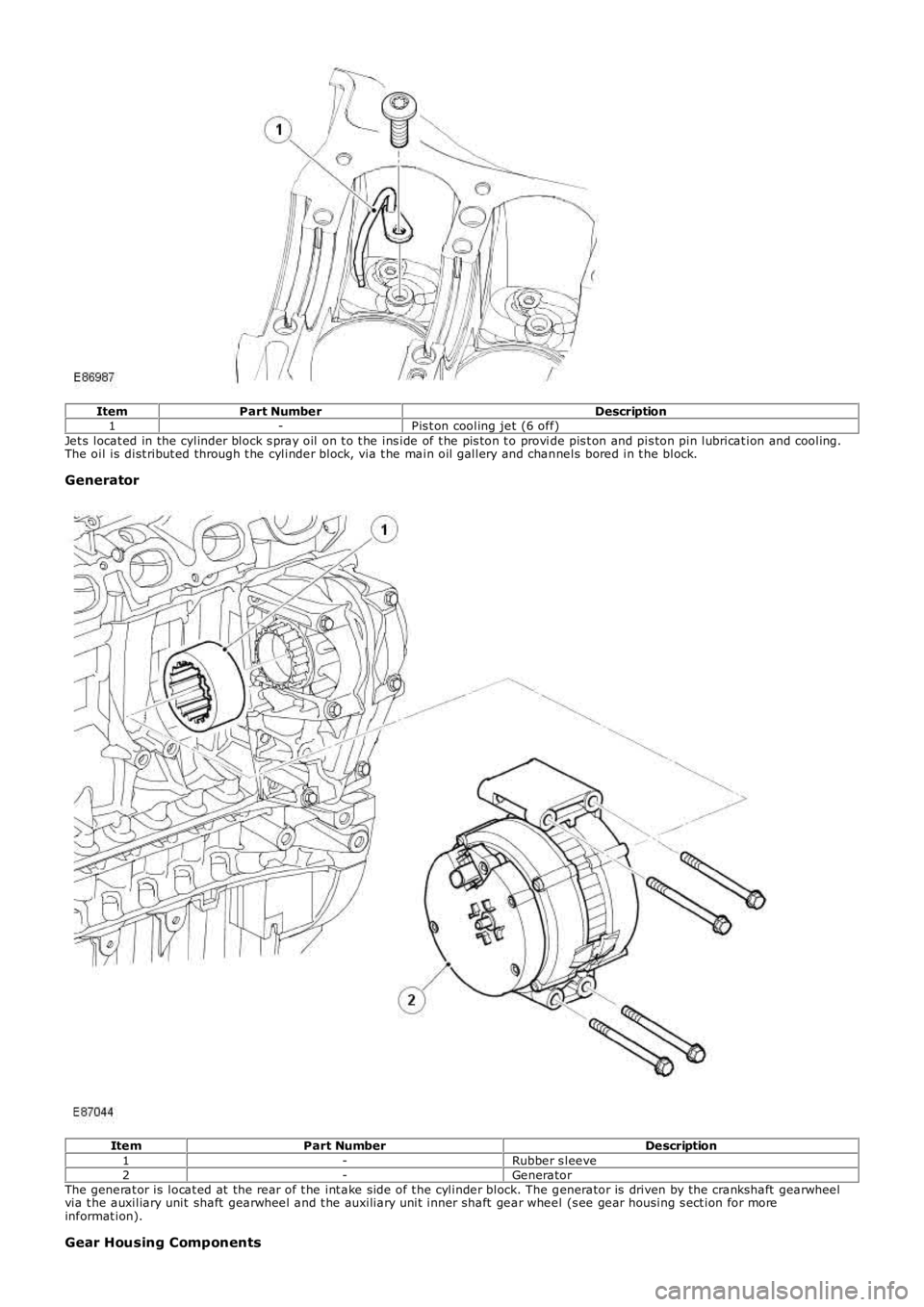

Piston Cooling Jets

Page 610 of 3229

ItemPart NumberDescription1-Pis t on cooling jet (6 off)Jet s locat ed in the cylinder block s pray oil on t o t he ins ide of t he pis ton t o provide pis t on and pis ton pin lubricat ion and cooling.The oil is dist ribut ed through t he cylinder block, via t he main oil gallery and channels bored in t he block.

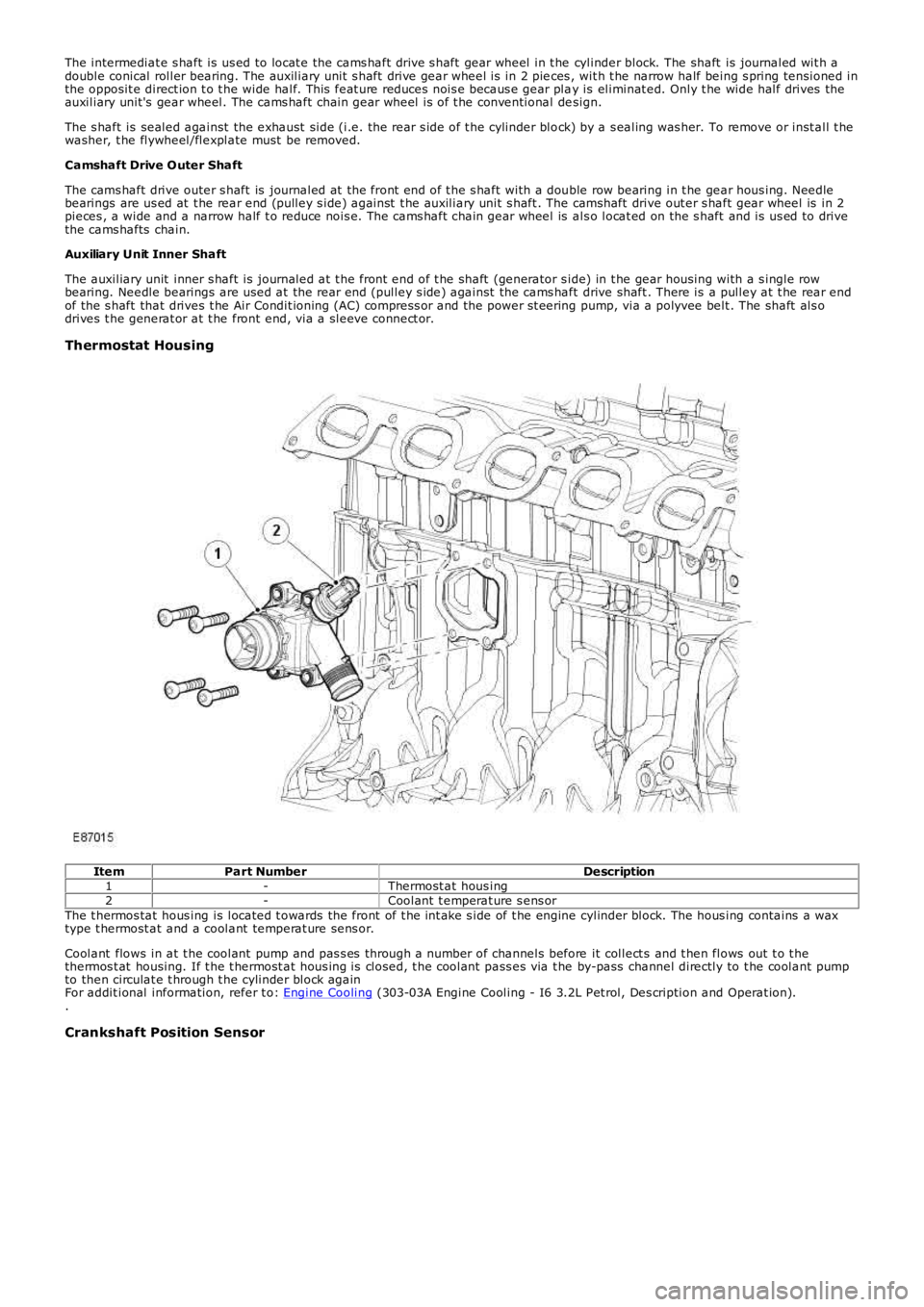

Generator

ItemPart NumberDescription1-Rubber s leeve2-GeneratorThe generat or is locat ed at the rear of t he int ake side of t he cylinder block. The generator is driven by the crankshaft gearwheelvia t he auxiliary unit shaft gearwheel and t he auxiliary unit inner shaft gear wheel (s ee gear housing s ect ion for moreinformat ion).

Gear Housing Components

Page 613 of 3229

The intermediat e s haft is us ed to locat e the cams haft drive s haft gear wheel in t he cylinder block. The shaft is journaled wit h adouble conical roller bearing. The auxiliary unit s haft drive gear wheel is in 2 pieces , wit h t he narrow half being s pring tensioned inthe opposit e direct ion t o t he wide half. This feat ure reduces nois e becaus e gear play is eliminat ed. Only t he wide half drives theauxiliary unit's gear wheel. The cams haft chain gear wheel is of t he conventional design.

The s haft is sealed against the exhaust side (i.e. the rear s ide of t he cylinder block) by a s ealing was her. To remove or inst all t hewasher, t he flywheel/flexplate must be removed.

Camshaft Drive O uter Shaft

The cams haft drive outer s haft is journaled at the front end of t he s haft with a double row bearing in t he gear hous ing. Needlebearings are us ed at t he rear end (pulley s ide) against t he auxiliary unit s haft . The camshaft drive out er s haft gear wheel is in 2pieces , a wide and a narrow half t o reduce nois e. The cams haft chain gear wheel is als o locat ed on the s haft and is us ed to drivethe cams hafts chain.

Auxiliary Unit Inner Shaft

The auxiliary unit inner s haft is journaled at t he front end of t he shaft (generator s ide) in t he gear housing with a s ingle rowbearing. Needle bearings are used at the rear end (pulley s ide) against the cams haft drive shaft . There is a pulley at t he rear endof the s haft that drives t he Air Condit ioning (AC) compress or and the power s t eering pump, via a polyvee belt . The shaft als odrives t he generat or at t he front end, via a sleeve connect or.

Thermostat Housing

ItemPart NumberDescription1-Thermost at hous ing2-Coolant t emperat ure s ens orThe t hermos tat hous ing is located t owards the front of t he int ake s ide of t he engine cylinder block. The hous ing contains a waxtype t hermost at and a coolant temperat ure sens or.

Coolant flows in at t he coolant pump and pas s es through a number of channels before it collect s and t hen flows out t o t hethermos t at housing. If t he t hermost at hous ing is closed, t he coolant pass es via t he by-pass channel directly to t he coolant pumpto then circulat e t hrough t he cylinder block againFor addit ional information, refer t o: Engine Cooling (303-03A Engine Cooling - I6 3.2L Pet rol, Des cription and Operat ion)..

Crankshaft Position Sensor