wheel bolts LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 17 of 3229

Encaps ulated ('pat ched') bolt s and s crews have a t hread l ocking agent appl ied t o t he t hreads during manufact ure. Mos tt hread locking agent s are col ored, the band of color extending for 360 degrees around the t hread. Some l ocking agentshowever, are neutral in color and may not be s o eas il y identi fi ed apart from a s li ght ly darker area of thread where t helocking agent has been appli ed. The l ocking agent is releas ed and acti vat ed by t he ti ght ening proces s and is thenchemical ly cured to provide t he locking acti on.

Self-locking bolts and screws

Unles s s tat ed in a s peci fic repair procedure, sel f-locki ng bolt s and s crews i.e. nylon patched or tril obul ar t hread can bereus ed provided t hat res is t ance i s fel t when the locki ng port ion enters t he femal e thread.

Nylon pat ched bolt s and s crews have a l ocking agent eit her appli ed t o, or i ns erted in t he threaded porti on. They areidenti fi ed by t he pres ence of a colored s ect ion of t hread extending approximat ely 180 degrees around the t hread or by acol ored pl ug ins ert ed int o t he bol t.

Tri lobular bolt s have a s pecial t hread form which creates a s light i nt erference wit h t he t hread of the hol e or nut i nto whichit i s s crewed.

CAUTION: Do Not reuse sel f-locki ng fas t eners in crit ical locat ions e.g. drive pl at es/flywheel or engine beari ngs . Donot ins tal l non s elf-locki ng fas teners where a sel f-locki ng fas t ener i s s pecified.

Tri lobular bolt s s hould not be used as a s ubs t it ut e for pat ched bol ts .

Nut identification

A nut wi th an ISO metric t hread i s marked on one face or one of the hexagonal fl ats wit h t he st rengt h grade s ymbol 8, 12,14. Some nuts wi th the st rength grade 4, 5 or 6 are als o marked and s ome have the metric s ymbol M on t he hexagonal fl atoppos it e t he s trengt h grade marking.

Page 420 of 3229

Publi s hed: 11-May-2011

Front Disc Brake -

General SpecificationItemSpecification

Front dis cVenti lated

Front disc diameter:3.2 Pet rol316 mm (12.4 i n)

2.2 Dies el300 mm (11.8 i n)

Front dis c t hicknes s new (All engines )28 mm (1.10 i n)Service l imit (All engi nes )26 mm (1.024 i n)

Maximum dis c run-out - dis c ins t al led0.080 mm (0.003 i n)

Pad mi nimum thi cknes s2 mm (0.078 i n)Pis t on diamet er60 mm (2.362 i n)

Torque SpecificationsDescriptionNmlb-ft

Brake cali per bl eed screw86

Brake cali per mount ing pl at e t o wheel knuckle bolt s *200148Brake cali per gui de pin bolt s2821

Brake di sc dus t s hield bol ts107

Brake di sc Torx s crew3526Brake flexi hose uni on to cal iper3224

Brake hos e retaini ng bracket t o damper bol t2216

* New nuts/bolts must be fitted

Page 433 of 3229

Publi s hed: 11-May-2011

Rear Disc Brake -

General SpecificationItemSpecification

Rear disc:

3.2 Pet rol engineVent il at ed2.2 Dies el engineSol id

Rear disc diameter:

Venti lat ed302 mm (11.9 in)Soli d302 mm (11.9 in)

Rear disc thickness new :

Venti lat ed20 mm (0.79 in)Soli d12 mm (0.47 in)

Service limit:

Venti lat ed18 mmSoli d10 mm

Pad mi nimum thi cknes s2 mm

Maximum dis c run out - Dis c ins t al led0.080 mm

Torque Specifications

DescriptionNmlb-ftBrake cali per bl eed screw107

Brake cali per fixed carrier t o wheel knuckl e bolt s*11081

Brake cali per gui de pin bolt s3022Brake di sc dus t s hield bol ts1310

Brake di sc Torx s crew3526

Brake flexi hose uni ons to cali per1511Brake hos e retaini ng bracket t o wheel knuckle bolt2216

* New nuts/bolts must be installed

Page 570 of 3229

Publi s hed: 11-May-2011

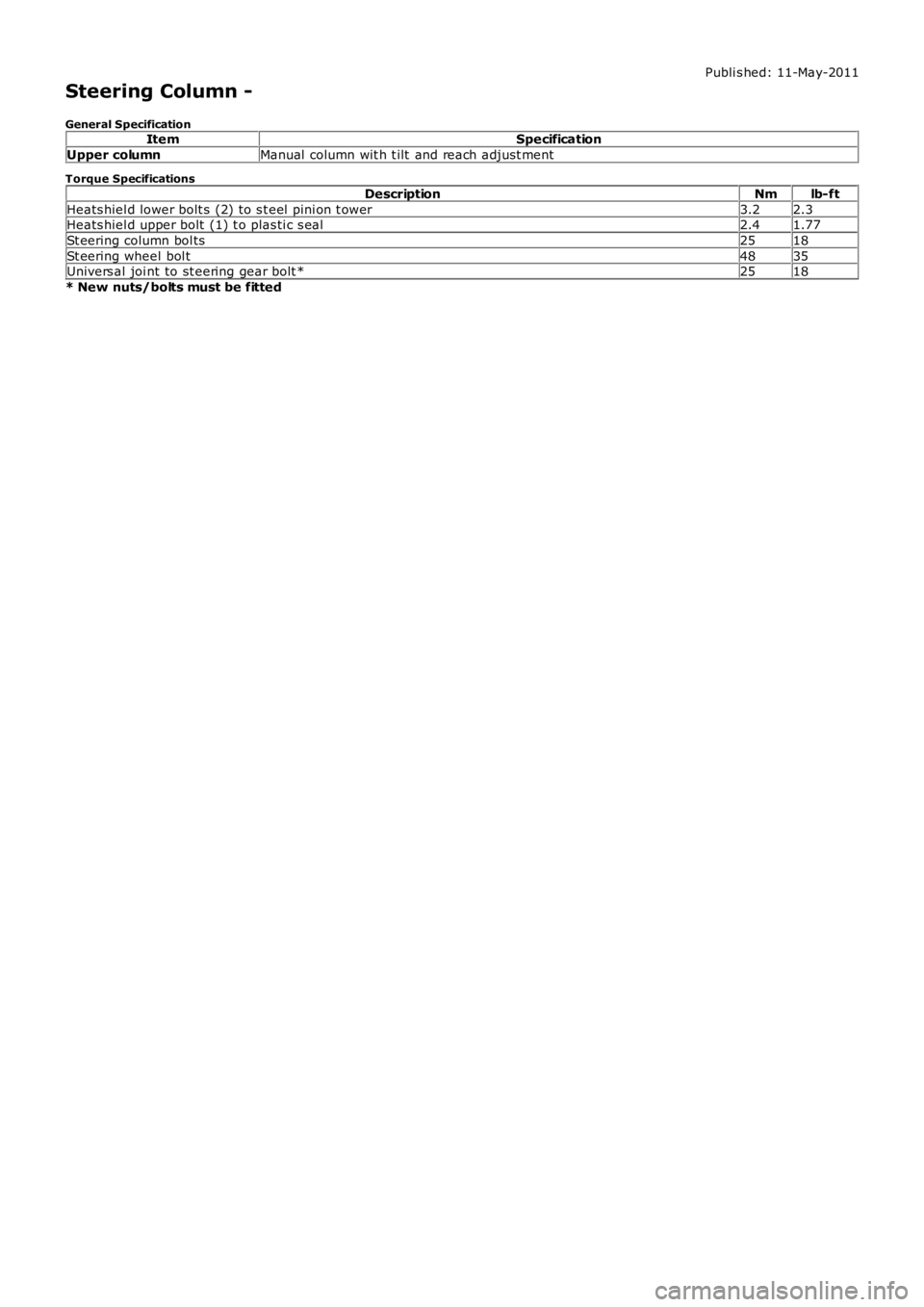

Steering Column -

General SpecificationItemSpecification

Upper columnManual column wit h t ilt and reach adjust ment

Torque Specifications

DescriptionNmlb-ft

Heats hiel d lower bolt s (2) to s t eel pi ni on t ower3.22.3Heats hiel d upper bolt (1) t o plas ti c s eal2.41.77

St eering column bol ts2518

St eering wheel bol t4835Univers al joi nt to st eering gear bolt *2518

* New nuts/bolts must be fitted

Page 604 of 3229

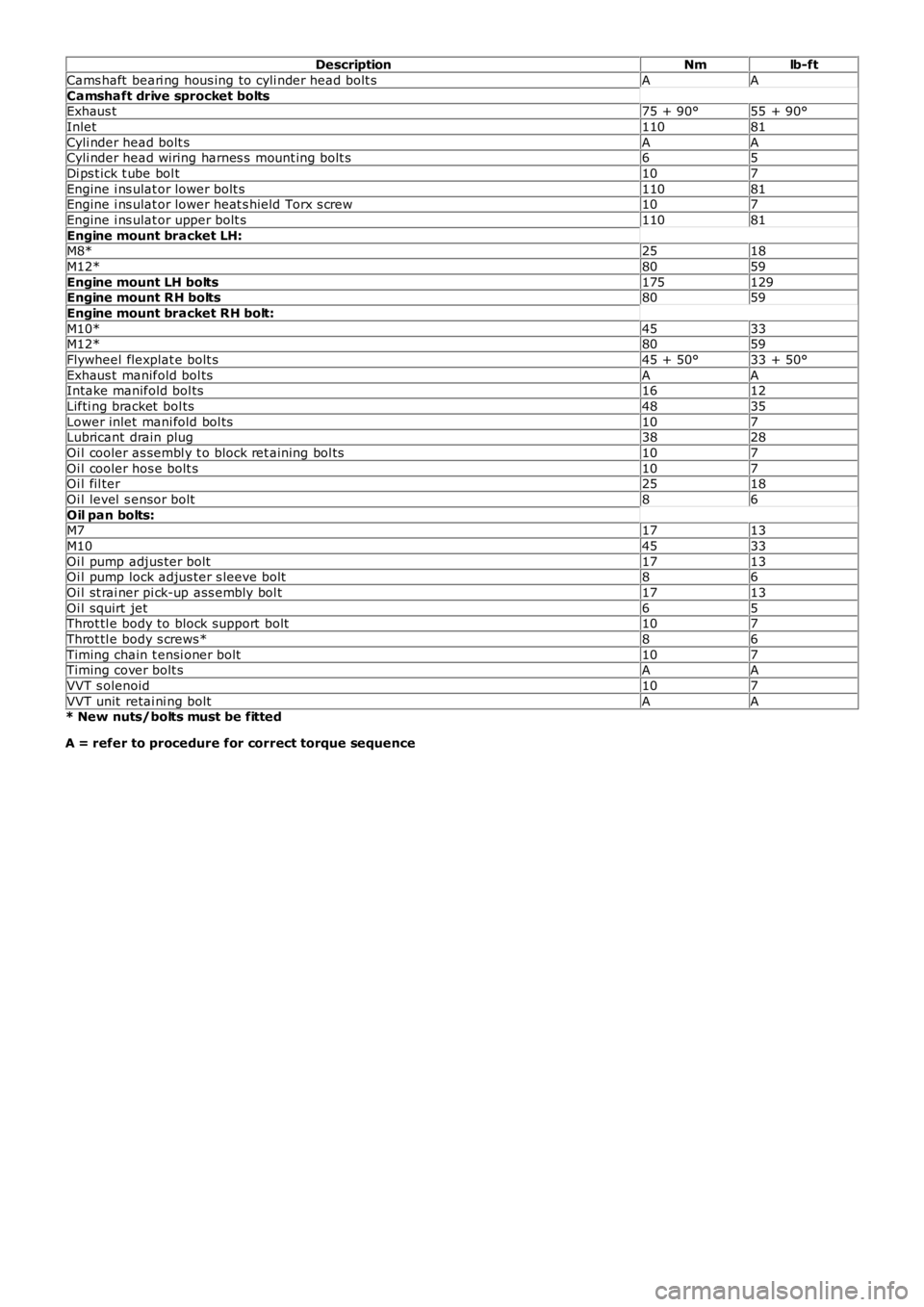

DescriptionNmlb-ft

Cams haft beari ng hous ing to cyli nder head bolt sAA

Camshaft drive sprocket boltsExhaus t75 + 90°55 + 90°

Inlet11081

Cyli nder head bolt sAACyli nder head wiring harnes s mount ing bolt s65

Di ps t ick t ube bol t107

Engine i ns ulat or lower bolt s11081Engine i ns ulat or lower heat s hield Torx s crew107

Engine i ns ulat or upper bolt s11081

Engine mount bracket LH:M8*2518

M12*8059

Engine mount LH bolts175129Engine mount RH bolts8059

Engine mount bracket RH bolt:

M10*4533M12*8059

Flywheel flexplat e bolt s45 + 50°33 + 50°

Exhaus t manifold bol tsAAIntake manifold bol ts1612

Lifti ng bracket bol ts4835

Lower inlet mani fold bol ts107Lubricant drain plug3828

Oi l cooler as sembl y t o block ret aining bol ts107

Oi l cooler hos e bolt s107Oi l fil ter2518

Oi l level s ensor bolt86

Oil pan bolts:M71713

M104533

Oi l pump adjus ter bolt1713Oi l pump lock adjus ter s leeve bolt86

Oi l st rai ner pi ck-up ass embly bol t1713

Oi l squirt jet65Throt tl e body to block support bolt107

Throt tl e body s crews*86

Timing chain t ensi oner bolt107Timing cover bolt sAA

VVT s olenoid107

VVT unit retai ni ng boltAA* New nuts/bolts must be fitted

A = refer to procedure for correct torque sequence

Page 753 of 3229

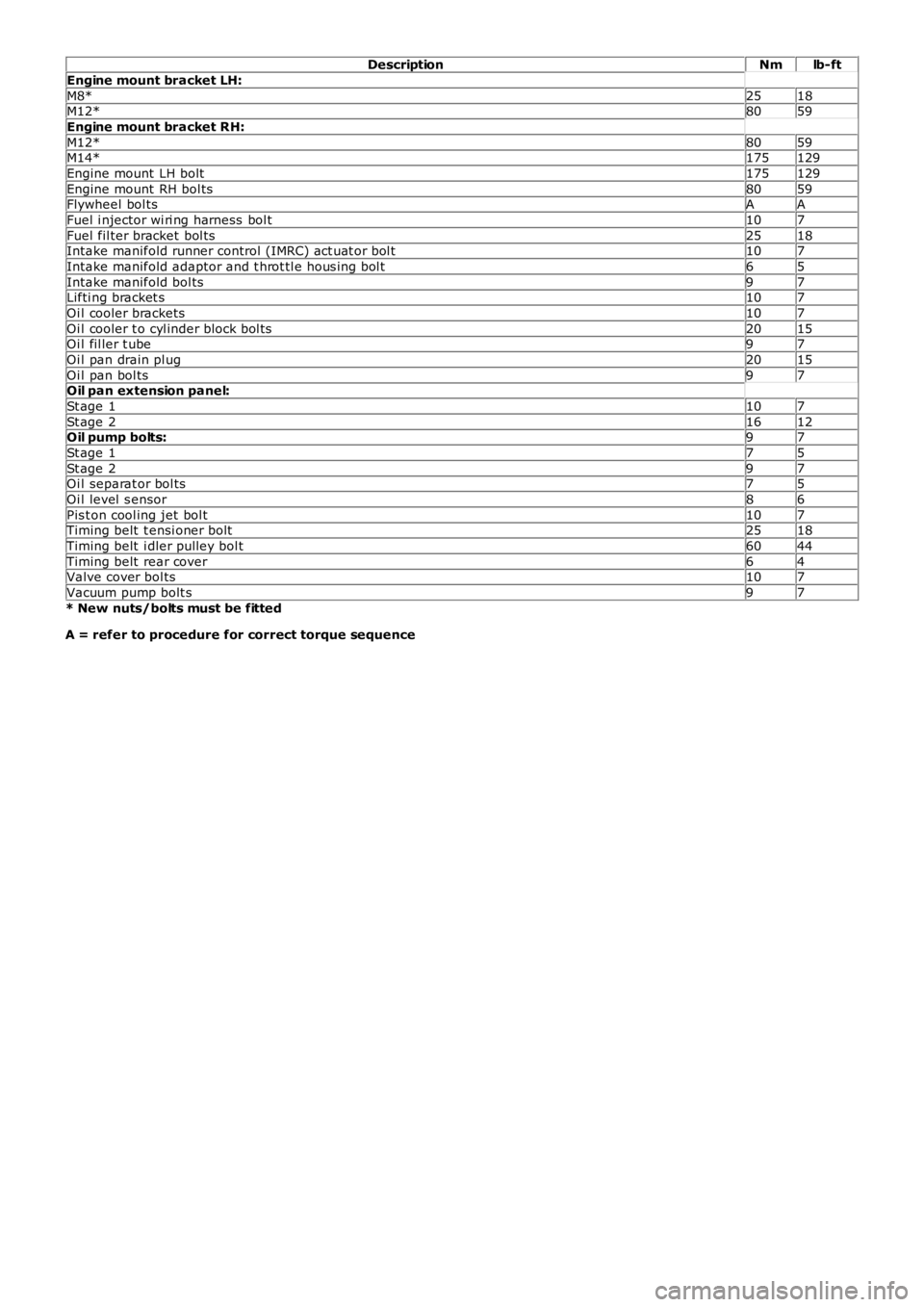

DescriptionNmlb-ft

Engine mount bracket LH:

M8*2518M12*8059

Engine mount bracket RH:

M12*8059M14*175129

Engine mount LH bolt175129

Engine mount RH bol ts8059Flywheel bol tsAA

Fuel i njector wi ri ng harness bol t107

Fuel fil ter bracket bol ts2518Intake manifold runner control (IMRC) act uat or bol t107

Intake manifold adaptor and t hrot tl e hous i ng bol t65

Intake manifold bol ts97Lifti ng bracket s107

Oi l cooler brackets107

Oi l cooler t o cyl inder block bol ts2015Oi l fil ler t ube97

Oi l pan drain pl ug2015

Oi l pan bol ts97Oil pan extension panel:

St age 1107

St age 21612Oil pump bolts:97

St age 175

St age 297Oi l separat or bol ts75

Oi l level s ensor86

Pis t on cool ing jet bol t107Timing belt t ensi oner bolt2518

Timing belt i dler pulley bol t6044

Timing belt rear cover64Valve cover bol ts107

Vacuum pump bolt s97

* New nuts/bolts must be fitted

A = refer to procedure for correct torque sequence

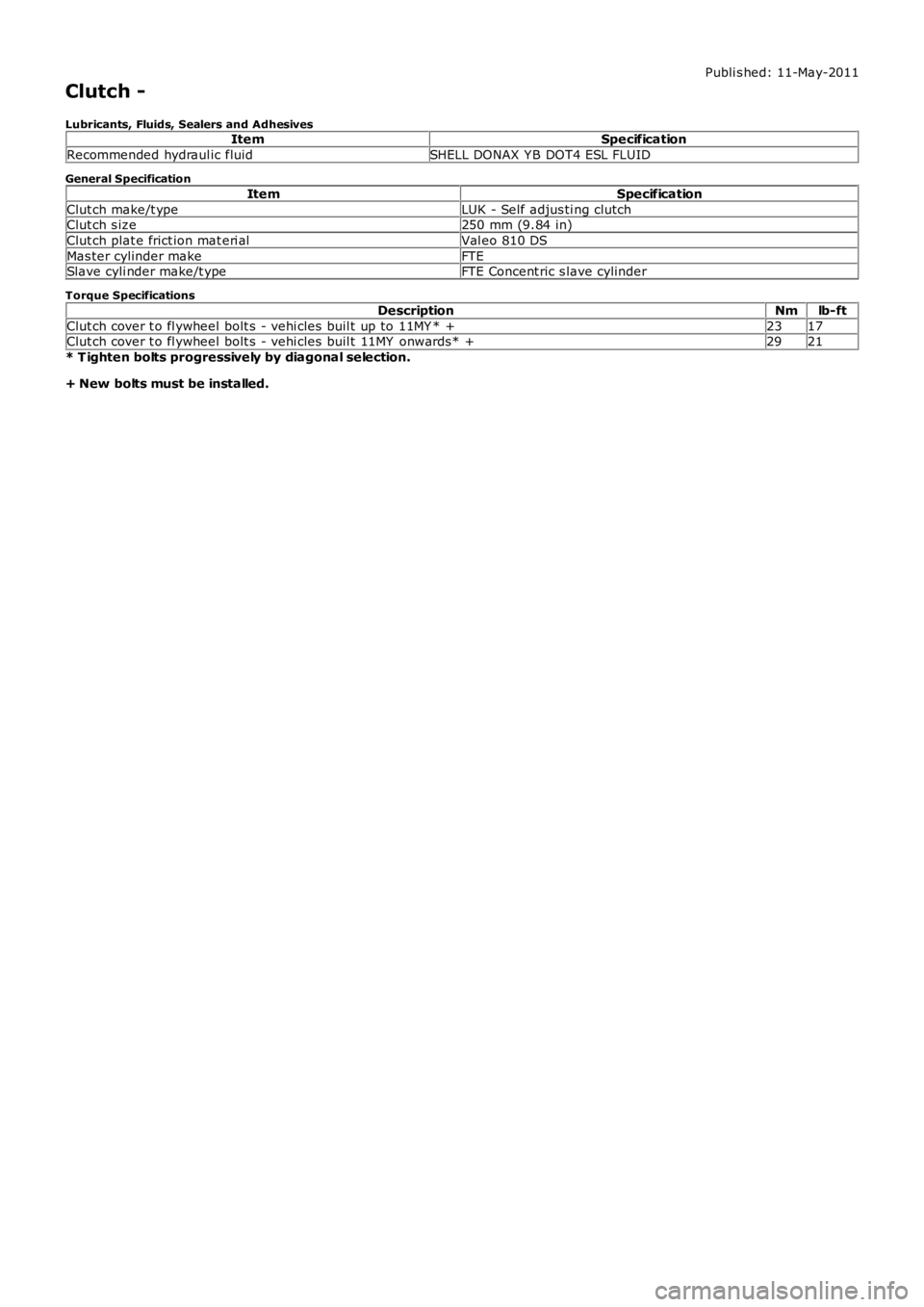

Page 1409 of 3229

Publi s hed: 11-May-2011

Clutch -

Lubricants, Fluids, Sealers and AdhesivesItemSpecification

Recommended hydraul ic fluidSHELL DONAX Y B DOT4 ESL FLUID

General Specification

ItemSpecification

Clut ch make/t ypeLUK - Self adjus ti ng clutchClut ch s ize250 mm (9.84 in)

Clut ch plat e frict ion mat eri alVal eo 810 DS

Mas ter cylinder makeFTESlave cyli nder make/t ypeFTE Concent ric s lave cylinder

Torque Specifications

DescriptionNmlb-ft

Clut ch cover t o fl ywheel bolt s - vehi cles buil t up to 11MY * +2317Clut ch cover t o fl ywheel bolt s - vehi cles buil t 11MY onwards* +2921

* T ighten bolts progressively by diagonal selection.

+ New bolts must be installed.

Page 2607 of 3229

Publ is hed: 11-May-2011

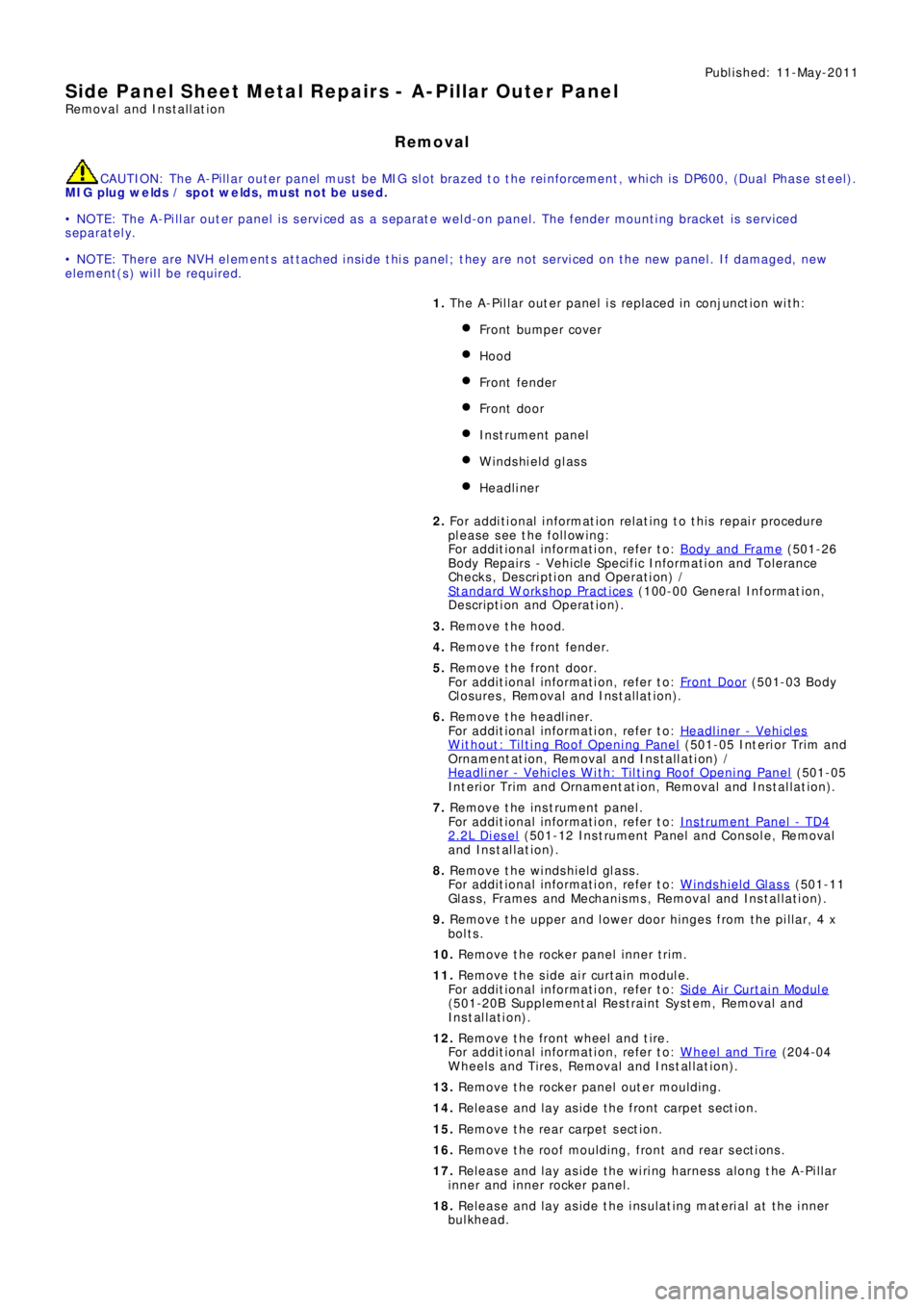

Side Panel Sheet Metal Repairs - A-Pillar Outer Panel

Removal and Installation

Removal

CAUTION: The A-Pillar outer panel must be MIG slot brazed to the reinforcement, which is DP600, (Dual Phase steel).

MIG plug we lds / spot we lds, must not be used.

• NOTE: The A-Pillar outer panel is serviced as a separate weld-on panel. The fender mounting bracket is serviced

separately.

• NOTE: There are NVH elements attached inside this panel; they are not serviced on the new panel. If damaged, new

element(s) will be required.

1. The A-Pillar out er panel is replaced in conjunct ion wit h:

Front bumper cover

Hood

Front fender

Front door

Instrument panel

Windshield glass

Headliner

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the hood.

4. Remove the front fender.

5. Remove the front door.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Door

(501-03 Body

Closures, Removal and Installation).

6. Remove the headliner.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Headliner - Vehicles

Without: Tilting Roof Opening Panel (501-05 Int eri or Tri m and

Ornamentation, Removal and Installation) /

Headliner - Vehicles With: Tilting Roof Opening Panel

(501-05

Int erior Trim and Ornamentat ion, Removal and Installat ion).

7. Re move t he i ns t rume nt pa ne l .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Instrument Panel - TD4

2.2L Di es el (501-12 Ins t rument Panel and Cons ole, Removal

and Installation).

8. Remove the windshield glass.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Glass

(501-11

Glass, Frames and Mechanisms, Removal and Installation).

9. Remove t he upper and l ower door hi nges from t he pi l lar, 4 x

bolts.

10. Re mo ve t he ro cke r p a ne l i nne r t ri m.

11. Re mo ve t he s i d e a i r curt a i n mo d ul e .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Si d e A i r Curt a i n Mo d ul e

(501-20B Suppl ement al Res t rai nt Sys t em, Removal and

Installation).

12. Remove the front wheel and tire.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Wheel and Tire

(204-04

Wheels and Tires, Removal and Installation).

13. Remove the rocker panel outer moulding.

14. Release and lay aside the front carpet section.

15. Re mo ve t he re a r ca rp e t s e ct i o n.

16. Remove the roof moulding, front and rear sections.

17. Release and lay aside the wiring harness along the A-Pillar

i nne r a nd i nne r ro cke r p a ne l .

18. Release and lay aside the insulating material at the inner

bulkhead.

Page 2704 of 3229

18. WARNING: Make sure that a new steering column flexible coupling bolt is

installed.

Connect the steering column to the steering gear.

Torque: 25 Nm18.

Connect and s ecure t he cat alys t moni t or s ens or el ect ri cal connect ors . 19.

Install the 2 subframe mounting bolts and remove the jack. 20.

Install the engine undershield.

Refer to: Engine Undershield

(501-02 Front End Body Panel s, Removal and

Installation). 21.

Install the wheels and tires.

Refer to: W heel and Tire

(204-04 W heels and Tires , Removal and Ins t all at i on). 22.

Refill and bleed the power steering.

Refer to: Power Steering System Bleeding

(211-00 St eeri ng Sys t em - General

Informat ion, General Procedures). 23.

Using only four wheel alignment equipment approved by Land Rover, check and adjust

the wheel alignment. 24.

Page 2715 of 3229

1. CAUTION: Make sure that new bolts are installed.

Clean the component mating faces.

With assistance, install the subframe.With assistance, align and secure the differential.Tighten the rear bolts.

Torque: 110 Nm

Tighten the front bolts.

Torque: 175 Nm

1.

2.

CAUTION: Make sure that new bolts are installed.

Align the suspension arms to the subframe and install the bolts, do

not fully tighten at this stage. 2.

Using the special tool, support the subframe. 3.

Connect the transmission breather lines. 4.

5. CAUTIONS:

Make sure that no components catch.

Make sure that new bolts are installed.

With assistance, position the subframe to the body and tighten the

bolts.

Torque: 175 Nm

5.

6.

CAUTION: Make sure that new bolts are installed.

Install the stabilizer clamp bolts, but do not tighten fully at this

stage. 6.

Connect the Active On-demand Coupling module electrical connector. 7.

Re mo ve t he p o we rt ra i n j a ck.

General Equi pment : P o w e rt ra i n Ja ck

8.

9.

CAUTION: Make sure that new bolts are installed.

Install the trailing arm to body brackets.

Torque: 110 Nm9.

10.

CAUTION: Make sure that the brake hose is not twisted

and is correctly located.

Clean the component mating faces.

Install the brake caliper anchor plate.

Torque: 110 Nm

Repeat the above procedure for the other side.

10.

Secure the wheel speed sensor and lead.

11.