LEXUS ES300 2005 Repair Manual

Manufacturer: LEXUS, Model Year: 2005, Model line: ES300, Model: LEXUS ES300 2005Pages: 969, PDF Size: 24.08 MB

Page 871 of 969

RADIATOR CAP INSPECTION ┬▒ EG007-05 March 28, 2005

Page 6 of 7

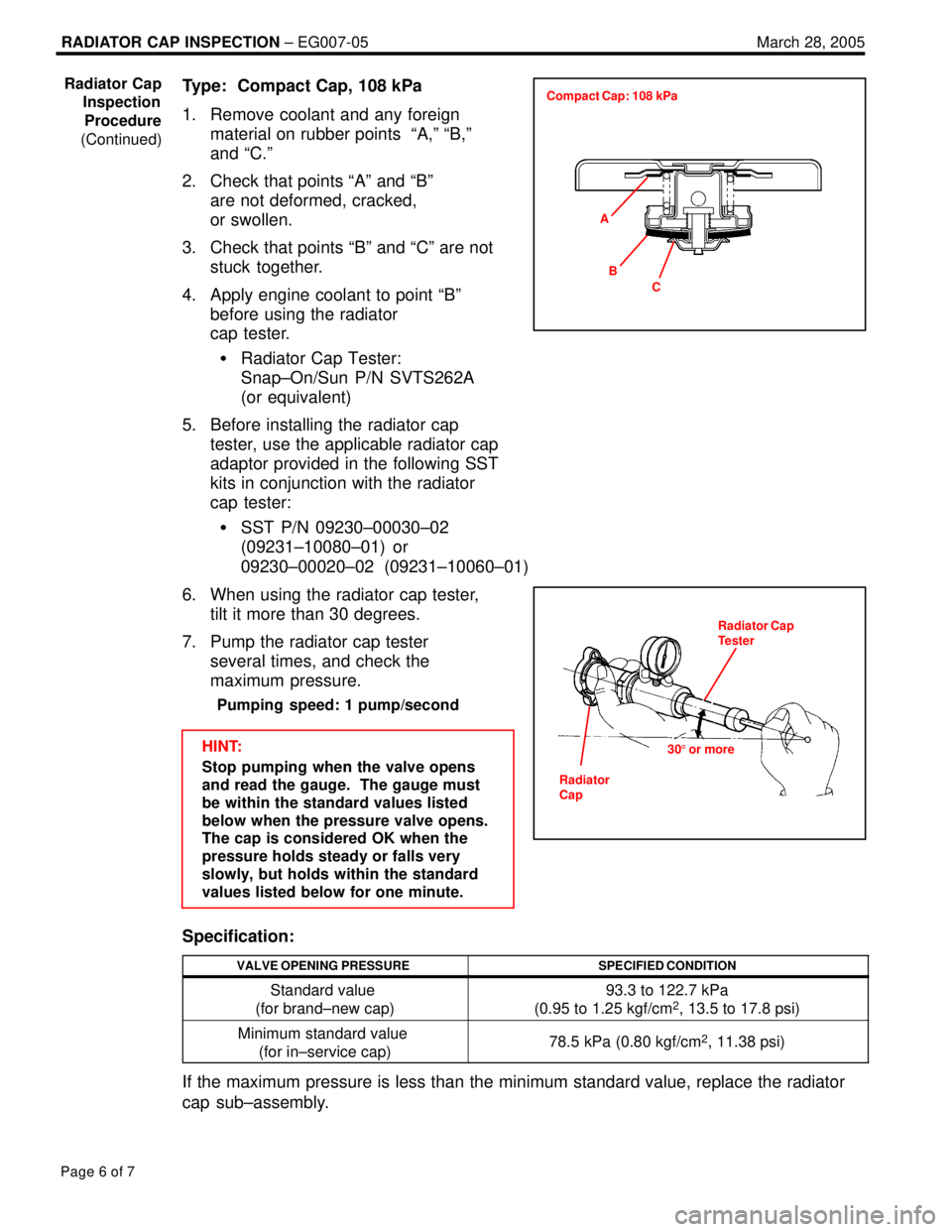

Type: Compact Cap, 108 kPa

1. Remove coolant and any foreign

material on rubber points ªA,º ªB,º

and ªC.º

2. Check that points ªAº and ªBº

are not deformed, cracked,

or swollen.

3. Check that points ªBº and ªCº are not

stuck together.

4. Apply engine coolant to point ªBº

before using the radiator

cap tester.

�Radiator Cap Tester:

Snap┬▒On/Sun P/N SVTS262A

(or equivalent)

5. Before installing the radiator cap

tester, use the applicable radiator cap

adaptor provided in the following SST

kits in conjunction with the radiator

cap tester:

�SST P/N 09230┬▒00030┬▒02

(09231┬▒10080┬▒01) or

09230┬▒00020┬▒02 (09231┬▒10060┬▒01)

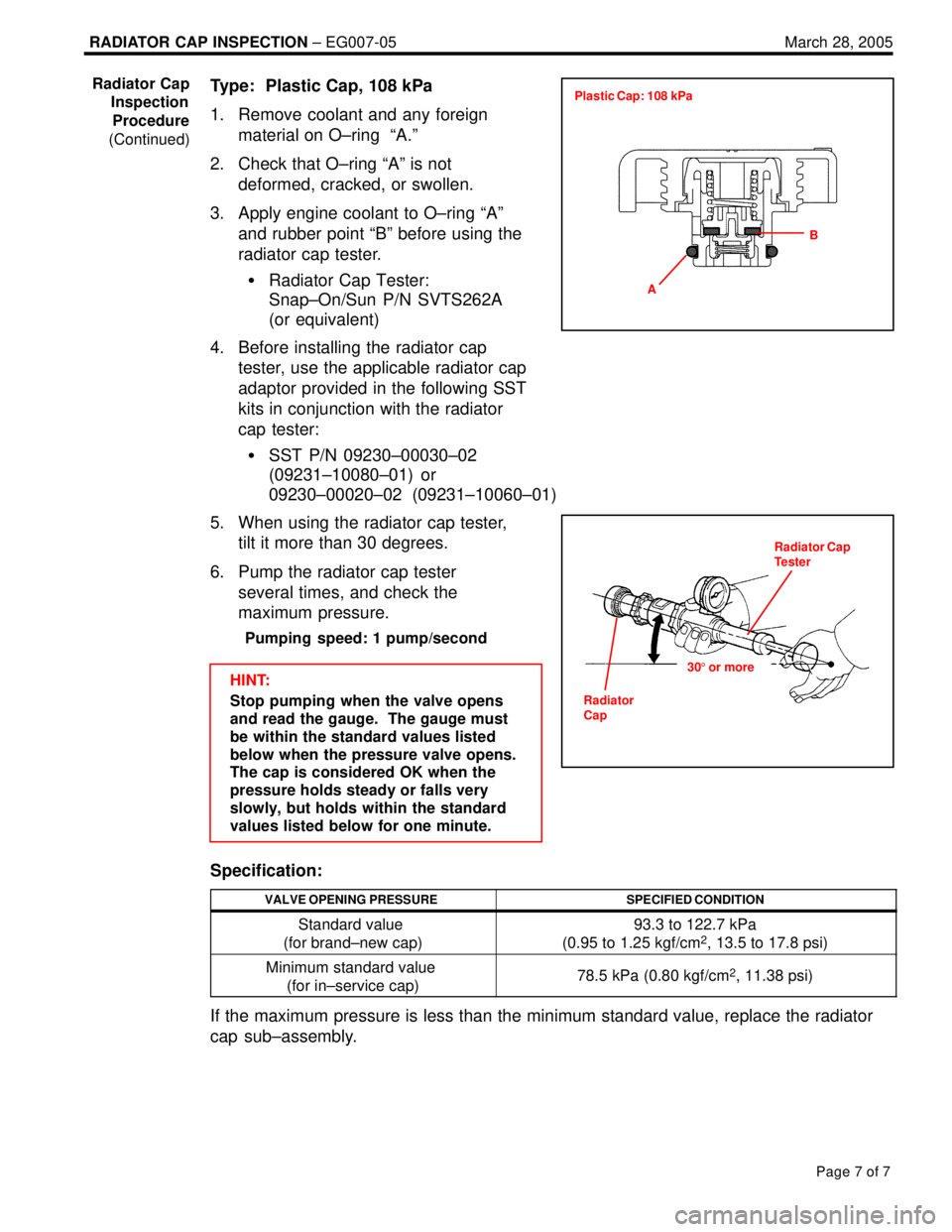

6. When using the radiator cap tester,

tilt it more than 30 degrees.

7. Pump the radiator cap tester

several times, and check the

maximum pressure.

Pumping speed: 1 pump/second

HINT:

Stop pumping when the valve opens

and read the gauge. The gauge must

be within the standard values listed

below when the pressure valve opens.

The cap is considered OK when the

pressure holds steady or falls very

slowly, but holds within the standard

values listed below for one minute.

Specification:

VALVE OPENING PRESSURESPECIFIED CONDITION

Standard value

(for brand┬▒new cap)93.3 to 122.7 kPa

(0.95 to 1.25 kgf/cm2, 13.5 to 17.8 psi)

Minimum standard value

(for in┬▒service cap)78.5 kPa (0.80 kgf/cm2, 11.38 psi)

If the maximum pressure is less than the minimum standard value, replace the radiator

cap sub┬▒assembly.

Radiator Cap

Inspection

Procedure

(Continued)

A

C B Compact Cap: 108 kPa

Radiator Cap

Tester

305 or more

Radiator

Cap

Page 872 of 969

RADIATOR CAP INSPECTION ┬▒ EG007-05 March 28, 2005

Page 7 of 7

Type: Plastic Cap, 108 kPa

1. Remove coolant and any foreign

material on O±ring ªA.º

2. Check that O±ring ªAº is not

deformed, cracked, or swollen.

3. Apply engine coolant to O±ring ªAº

and rubber point ªBº before using the

radiator cap tester.

�Radiator Cap Tester:

Snap┬▒On/Sun P/N SVTS262A

(or equivalent)

4. Before installing the radiator cap

tester, use the applicable radiator cap

adaptor provided in the following SST

kits in conjunction with the radiator

cap tester:

�SST P/N 09230┬▒00030┬▒02

(09231┬▒10080┬▒01) or

09230┬▒00020┬▒02 (09231┬▒10060┬▒01)

5. When using the radiator cap tester,

tilt it more than 30 degrees.

6. Pump the radiator cap tester

several times, and check the

maximum pressure.

Pumping speed: 1 pump/second

HINT:

Stop pumping when the valve opens

and read the gauge. The gauge must

be within the standard values listed

below when the pressure valve opens.

The cap is considered OK when the

pressure holds steady or falls very

slowly, but holds within the standard

values listed below for one minute.

Specification:

VALVE OPENING PRESSURESPECIFIED CONDITION

Standard value

(for brand┬▒new cap)93.3 to 122.7 kPa

(0.95 to 1.25 kgf/cm2, 13.5 to 17.8 psi)

Minimum standard value

(for in┬▒service cap)78.5 kPa (0.80 kgf/cm2, 11.38 psi)

If the maximum pressure is less than the minimum standard value, replace the radiator

cap sub┬▒assembly.

Radiator Cap

Inspection

Procedure

(Continued)

A

B Plastic Cap: 108 kPa

Radiator Cap

Tester

305 or more

Radiator

Cap

Page 873 of 969

Lexus Supports ASE CertificationPage 1 of 2

Title:

MAIN BEARING JOURNAL DIAMETER

STAMPING LOCATION REVISION

Models:

'04 ┬▒ '05 ES 330 & RX 330

Technical Service

Information Bulletin

October 14, 2004

EG011-04

The main bearing journal diameter stamp location has been changed on some 2004 and

2005 model year vehicles with 3MZ┬▒FE engines. The stamping on the front of the block

has been discontinued. Review this TSB for the stamping location.

�2004 ┬▒ 2005 model year ES 330 and RX 330 vehicles meeting the

following specifications:

�3MZ┬▒FE equipped vehicles with engine serial numbers starting after 0138096.

OP CODEDESCRIPTIONTIMEOFPT1T2

N/ANot Applicable to Warranty┬▒┬▒┬▒┬▒

ENGINE

Introduction

Applicable

Vehicles

Warranty

Information

Page 874 of 969

MAIN BEARING JOURNAL DIAMETER STAMPING LOCATION REVISION ┬▒ EG011-04October 14, 2004

Page 2 of 2

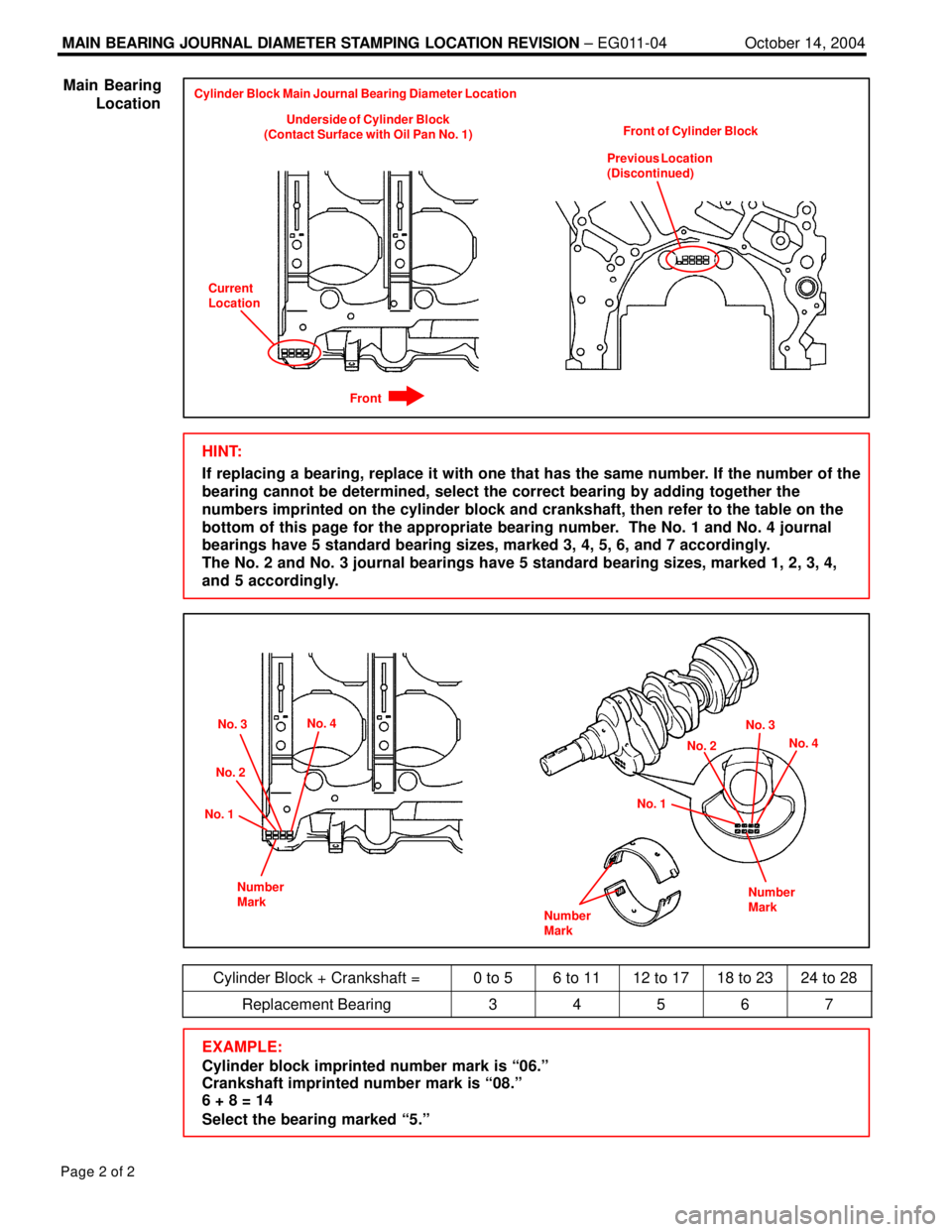

Underside of Cylinder Block

(Contact Surface with Oil Pan No. 1)Front of Cylinder Block Cylinder Block Main Journal Bearing Diameter Location

Current

LocationPrevious Location

(Discontinued)

Front

HINT:

If replacing a bearing, replace it with one that has the same number. If the number of the

bearing cannot be determined, select the correct bearing by adding together the

numbers imprinted on the cylinder block and crankshaft, then refer to the table on the

bottom of this page for the appropriate bearing number. The No. 1 and No. 4 journal

bearings have 5 standard bearing sizes, marked 3, 4, 5, 6, and 7 accordingly.

The No. 2 and No. 3 journal bearings have 5 standard bearing sizes, marked 1, 2, 3, 4,

and 5 accordingly.

No. 1No. 2No. 3No. 4

Number

Mark

No. 1No. 2No. 3

No. 4

Number

Mark

Number

Mark

Cylinder Block + Crankshaft =0 to 56 to 1112 to 1718 to 2324 to 28

Replacement Bearing34567

EXAMPLE:

Cylinder block imprinted number mark is ª06.º

Crankshaft imprinted number mark is ª08.º

6 + 8 = 14

Select the bearing marked ª5.º Main Bearing

Location

Page 875 of 969

Lexus Supports ASE CertificationPage 1 of 3

Technical Service

Information Bulletin

October 14, 2004

EG012-04Title:

ENTERING VIN DURING ECM (PCM)

REPLACEMENT AND/OR DTC P0630

Models:

All '04 ┬▒ '06 Models

TSIB REVISION NOTICE:

�June 3, 2005: Content has been updated to include 2004 and 2006 model year

vehicles. Step 4 of the VIN Write Procedure (page 2) and step 3 of the VIN Read

Procedure (page 3) have been clarified to include RX 400h vehicles.

Previous versions of this TSB should be discarded.

All 2005 and subsequent model year Lexus vehicles have the VIN (Vehicle Identification

Number) stored in the Electronic Control Module (ECM) (SAE term: Powertrain Control

Module/PCM) non┬▒volatile memory. The VIN is accessible on the data stream using the

Lexus Diagnostic Tester and can also be written to a new ECM (PCM) using a ªVIN

Read/Write┬║ utility.

Service ECMs (supply parts) are shipped without the VIN; therefore, as part of the ECM

(PCM) replacement procedure, the VIN must be written to the replacement ECM (PCM)

using the Diagnostic Tester utility function. Failure to write the VIN to the ECM (PCM) will

result in a M.I.L. ªONº condition and set DTC P0630: VIN Not Programmed or Mismatch ±

ECM (PCM).

It is very important to remember to enter the VIN on these vehicles. Vehicles with missing

VINs are subject to failing some state and local vehicle emissions Inspection and

Maintenance programs.

NOTE:

2004 model year vehicles which have been flash reprogrammed may contain updated

2005 model year OBD II logic. These vehicles will require VIN entry into the ECM (PCM)

after reprogramming.

�2004 model year vehicles that have been flash reprogrammed.

�All 2005 ┬▒ 2006 model year vehicles.

OP CODEDESCRIPTIONTIMEOFPT1T2

N/ANot Applicable to Warranty┬▒┬▒┬▒┬▒

ENGINE

Introduction

Applicable

Vehicles

Warranty

Information

Page 876 of 969

ENTERING VIN DURING ECM REPLACEMENT AND/OR DTC P0630 ┬▒ EG012-04 Revised October 14, 2004

Page 2 of 3

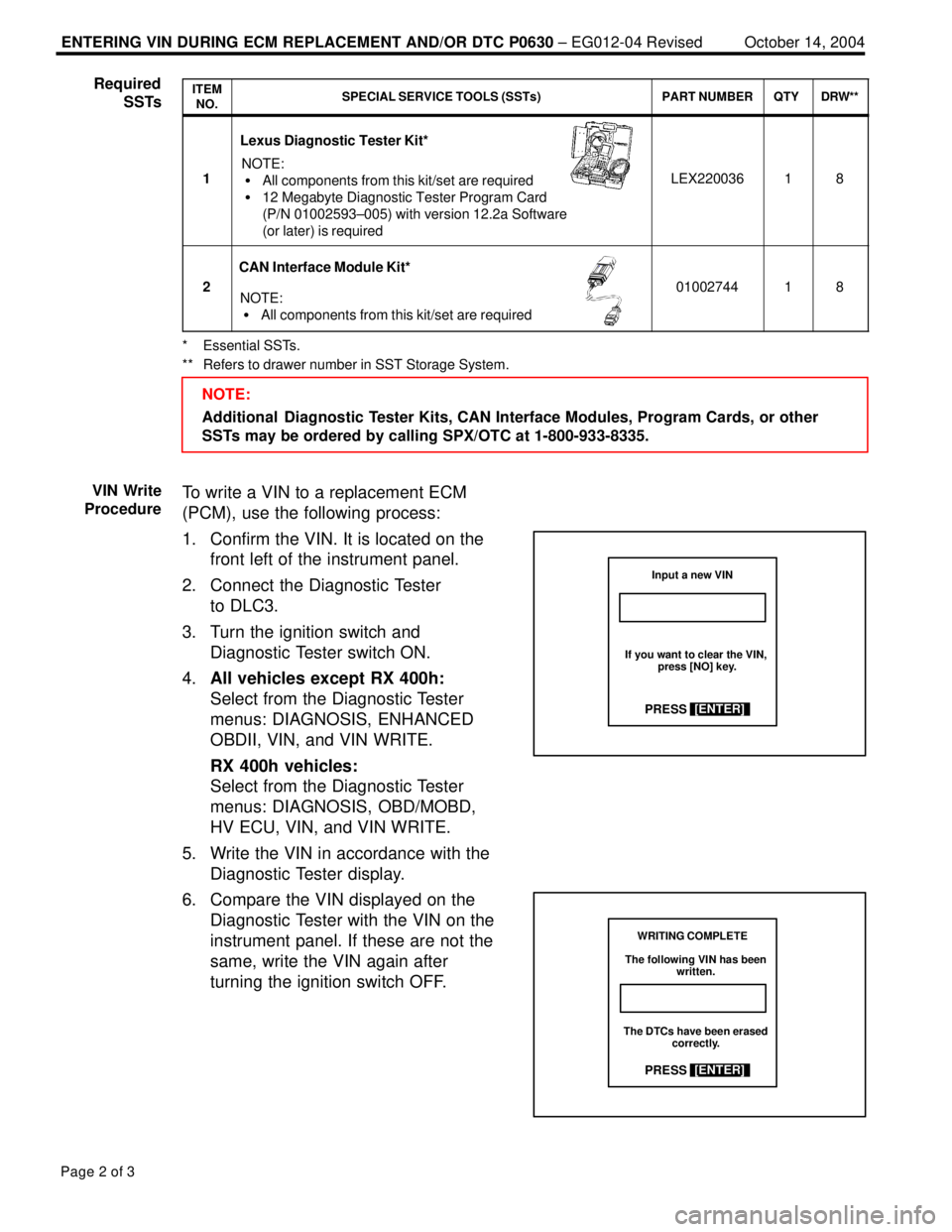

ITEM

NO.SPECIAL SERVICE TOOLS (SSTs)PART NUMBERQTYDRW**

1

Lexus Diagnostic Tester Kit*

NOTE:

�All components from this kit/set are required

�12 Megabyte Diagnostic Tester Program Card

(P/N 01002593┬▒005) with version 12.2a Software

(or later) is requiredLEX22003618

2

CAN Interface Module Kit*

NOTE:

�All components from this kit/set are required0100274418

* Essential SSTs.

** Refers to drawer number in SST Storage System.

NOTE:

Additional Diagnostic Tester Kits, CAN Interface Modules, Program Cards, or other

SSTs may be ordered by calling SPX/OTC at 1-800-933-8335.

To write a VIN to a replacement ECM

(PCM), use the following process:

1. Confirm the VIN. It is located on the

front left of the instrument panel.

2. Connect the Diagnostic Tester

to DLC3.

3. Turn the ignition switch and

Diagnostic Tester switch ON.

4.All vehicles except RX 400h:

Select from the Diagnostic Tester

menus: DIAGNOSIS, ENHANCED

OBDII, VIN, and VIN WRITE.

RX 400h vehicles:

Select from the Diagnostic Tester

menus: DIAGNOSIS, OBD/MOBD,

HV ECU, VIN, and VIN WRITE.

5. Write the VIN in accordance with the

Diagnostic Tester display.

6. Compare the VIN displayed on the

Diagnostic Tester with the VIN on the

instrument panel. If these are not the

same, write the VIN again after

turning the ignition switch OFF.

Required

SSTs

VIN Write

Procedure

Input a new VIN

PRESS[ENTER]

If you want to clear the VIN,

press [NO] key.

WRITING COMPLETE

PRESS[ENTER]

The following VIN has been

written.

The DTCs have been erased

correctly.

Page 877 of 969

ENTERING VIN DURING ECM REPLACEMENT AND/OR DTC P0630 ┬▒ EG012-04 Revised October 14, 2004

Page 3 of 3

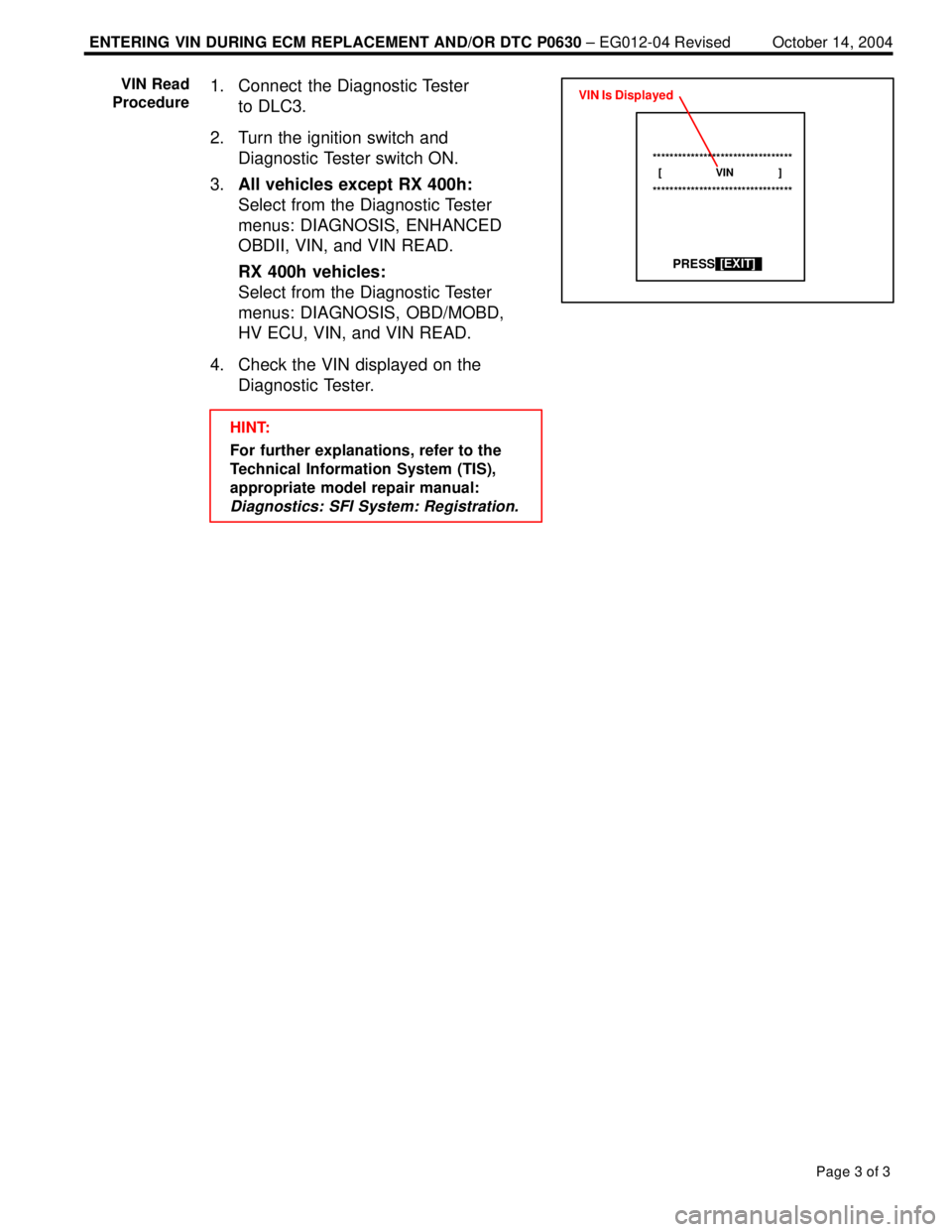

1. Connect the Diagnostic Tester

to DLC3.

2. Turn the ignition switch and

Diagnostic Tester switch ON.

3.All vehicles except RX 400h:

Select from the Diagnostic Tester

menus: DIAGNOSIS, ENHANCED

OBDII, VIN, and VIN READ.

RX 400h vehicles:

Select from the Diagnostic Tester

menus: DIAGNOSIS, OBD/MOBD,

HV ECU, VIN, and VIN READ.

4. Check the VIN displayed on the

Diagnostic Tester.

HINT:

For further explanations, refer to the

Technical Information System (TIS),

appropriate model repair manual:

Diagnostics: SFI System: Registration.

VIN Read

Procedure

[ VIN ]

PRESS[EXIT]

*********************************

*********************************

VIN Is Displayed

Page 878 of 969

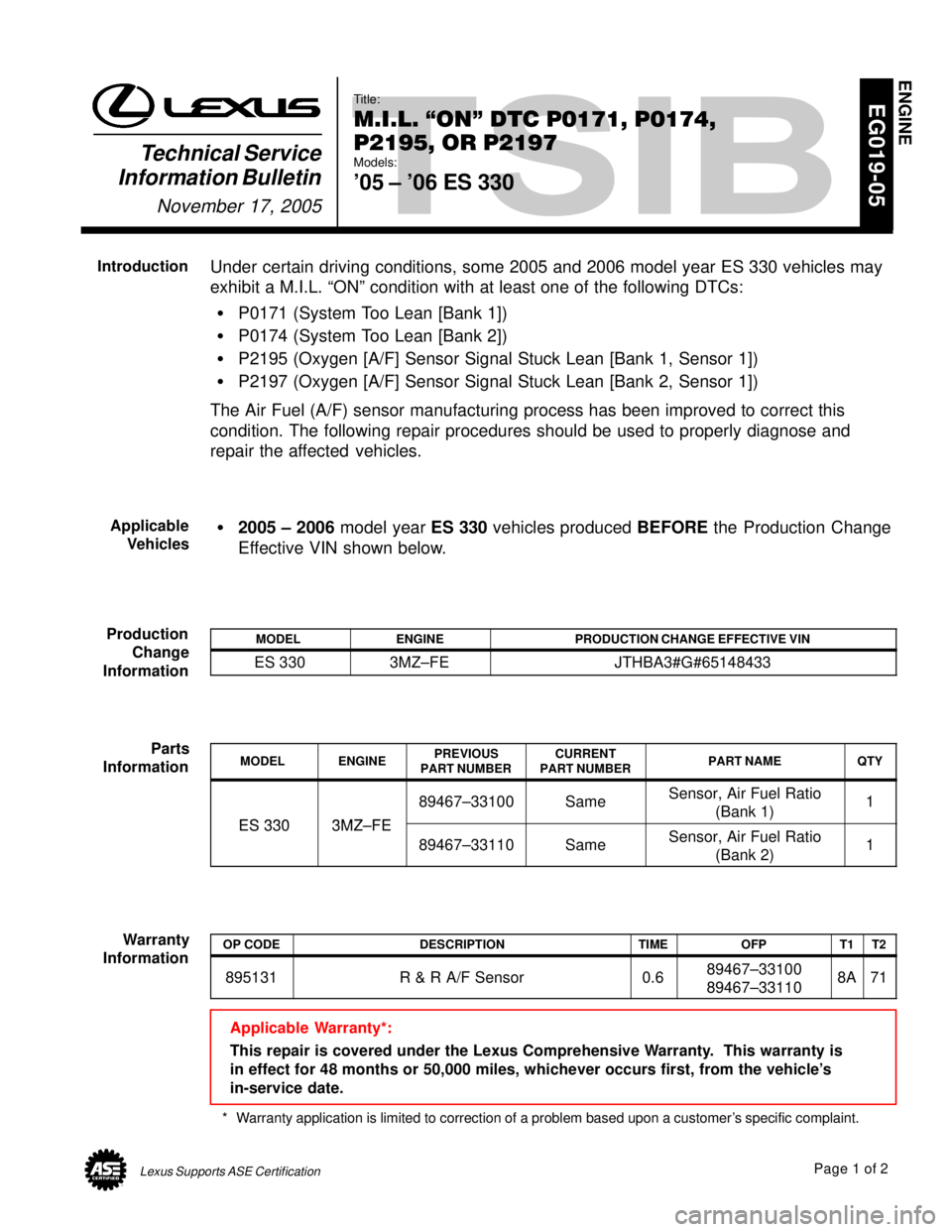

Lexus Supports ASE CertificationPage 1 of 2

Title:

M.I.L. ON" DTC P0171, P0174,

P2195, OR P2197

Models:

'05 ┬▒ '06 ES 330

Technical Service

Information Bulletin

November 17, 2005

EG019-05

Under certain driving conditions, some 2005 and 2006 model year ES 330 vehicles may

exhibit a M.I.L. ªONº condition with at least one of the following DTCs:

�P0171 (System Too Lean [Bank 1])

�P0174 (System Too Lean [Bank 2])

�P2195 (Oxygen [A/F] Sensor Signal Stuck Lean [Bank 1, Sensor 1])

�P2197 (Oxygen [A/F] Sensor Signal Stuck Lean [Bank 2, Sensor 1])

The Air Fuel (A/F) sensor manufacturing process has been improved to correct this

condition. The following repair procedures should be used to properly diagnose and

repair the affected vehicles.

�2005 ┬▒ 2006 model year ES 330 vehicles produced BEFORE the Production Change

Effective VIN shown below.

MODELENGINEPRODUCTION CHANGE EFFECTIVE VIN

ES 3303MZ┬▒FEJTHBA3#G#65148433

MODELENGINEPREVIOUS

PART NUMBERCURRENT

PART NUMBERPART NAMEQTY

ES 3303MZ FE

89467┬▒33100SameSensor, Air Fuel Ratio

(Bank 1)1

ES 3303MZ┬▒FE

89467┬▒33110SameSensor, Air Fuel Ratio

(Bank 2)1

OP CODEDESCRIPTIONTIMEOFPT1T2

895131R & R A/F Sensor0.689467┬▒33100

89467┬▒331108A71

Applicable Warranty*:

This repair is covered under the Lexus Comprehensive Warranty. This warranty is

in effect for 48 months or 50,000 miles, whichever occurs first, from the vehicle's

in-service date.

* Warranty application is limited to correction of a problem based upon a customer's specific complaint.

ENGINE

Introduction

Applicable

Vehicles

Production

Change

Information

Parts

Information

Warranty

Information

Page 879 of 969

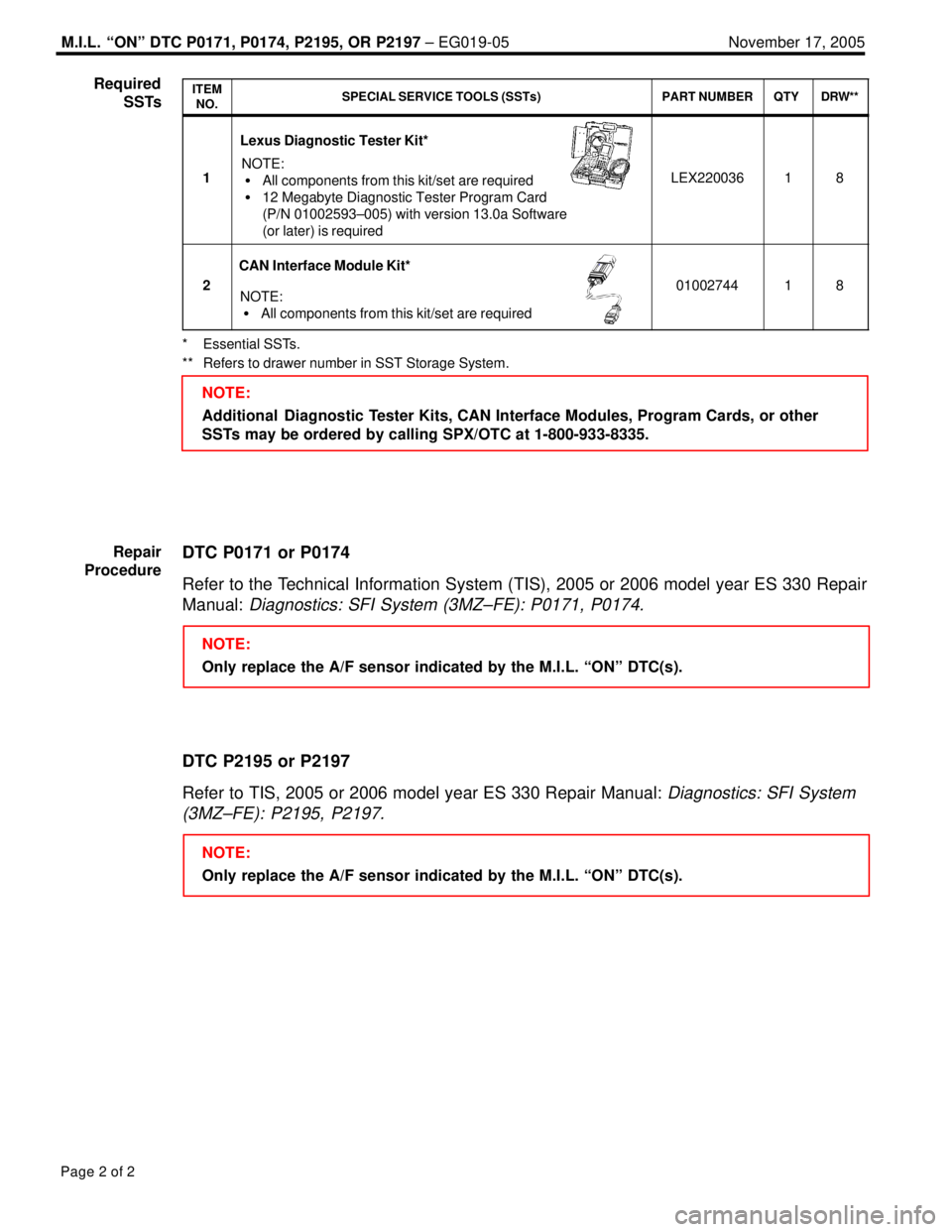

M.I.L. ªONº DTC P0171, P0174, P2195, OR P2197 ± EG019-05 November 17, 2005

Page 2 of 2

ITEM

NO.SPECIAL SERVICE TOOLS (SSTs)PART NUMBERQTYDRW**

1

Lexus Diagnostic Tester Kit*

NOTE:

�All components from this kit/set are required

�12 Megabyte Diagnostic Tester Program Card

(P/N 01002593┬▒005) with version 13.0a Software

(or later) is requiredLEX22003618

2

CAN Interface Module Kit*

NOTE:

�All components from this kit/set are required0100274418

* Essential SSTs.

** Refers to drawer number in SST Storage System.

NOTE:

Additional Diagnostic Tester Kits, CAN Interface Modules, Program Cards, or other

SSTs may be ordered by calling SPX/OTC at 1-800-933-8335.

DTC P0171 or P0174

Refer to the Technical Information System (TIS), 2005 or 2006 model year ES 330 Repair

Manual:

Diagnostics: SFI System (3MZ┬▒FE): P0171, P0174.

NOTE:

Only replace the A/F sensor indicated by the M.I.L. ªONº DTC(s).

DTC P2195 or P2197

Refer to TIS, 2005 or 2006 model year ES 330 Repair Manual:

Diagnostics: SFI System

(3MZ┬▒FE): P2195, P2197.

NOTE:

Only replace the A/F sensor indicated by the M.I.L. ªONº DTC(s). Required

SSTs

Repair

Procedure

Page 880 of 969

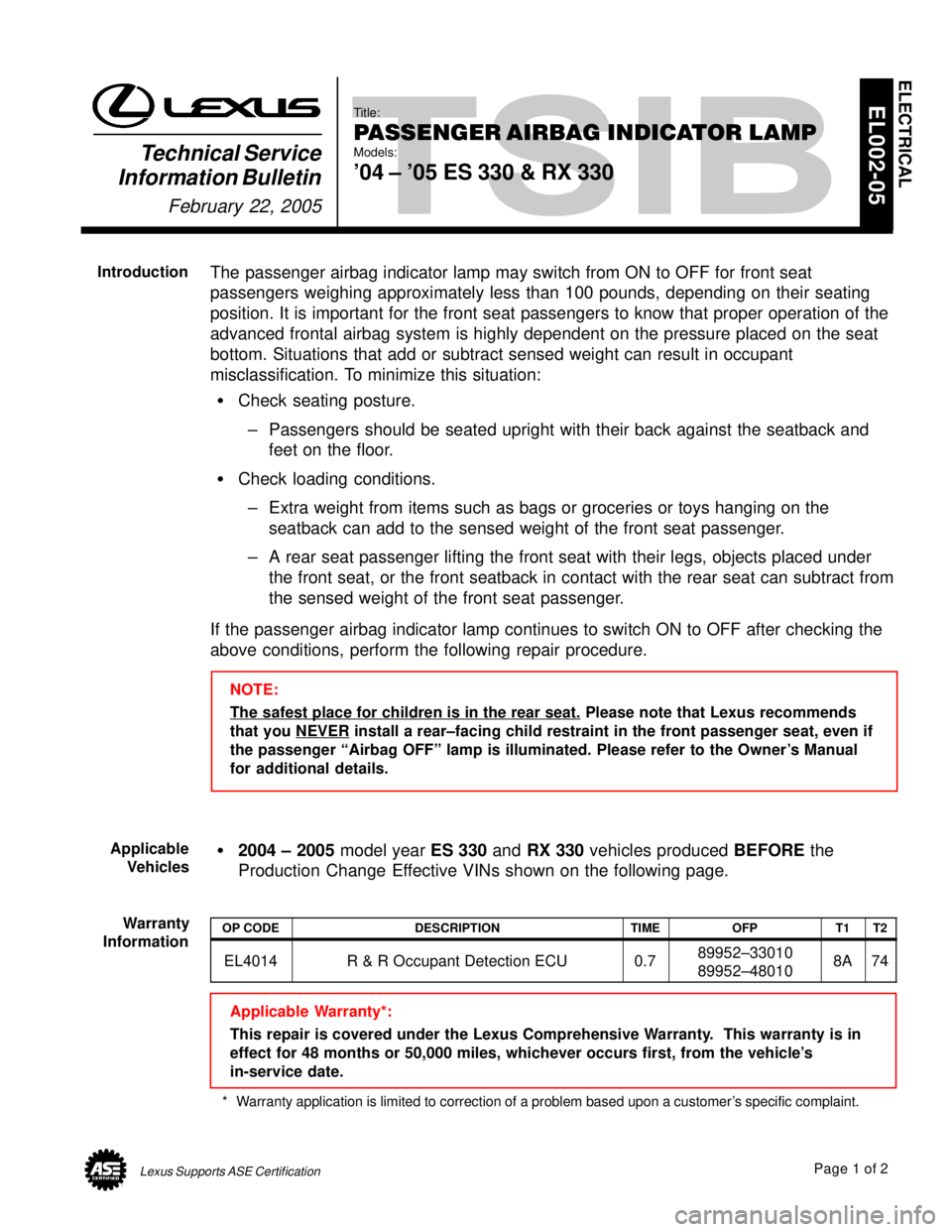

Lexus Supports ASE CertificationPage 1 of 2

Title:

PASSENGER AIRBAG INDICATOR LAMP

Models:

'04 ┬▒ '05 ES 330 & RX 330

Technical Service

Information Bulletin

February 22, 2005

EL002-05

The passenger airbag indicator lamp may switch from ON to OFF for front seat

passengers weighing approximately less than 100 pounds, depending on their seating

position. It is important for the front seat passengers to know that proper operation of the

advanced frontal airbag system is highly dependent on the pressure placed on the seat

bottom. Situations that add or subtract sensed weight can result in occupant

misclassification. To minimize this situation:

�Check seating posture.

┬▒ Passengers should be seated upright with their back against the seatback and

feet on the floor.

�Check loading conditions.

┬▒ Extra weight from items such as bags or groceries or toys hanging on the

seatback can add to the sensed weight of the front seat passenger.

┬▒ A rear seat passenger lifting the front seat with their legs, objects placed under

the front seat, or the front seatback in contact with the rear seat can subtract from

the sensed weight of the front seat passenger.

If the passenger airbag indicator lamp continues to switch ON to OFF after checking the

above conditions, perform the following repair procedure.

NOTE:

The safest place for children is in the rear seat.

Please note that Lexus recommends

that you NEVER

install a rear┬▒facing child restraint in the front passenger seat, even if

the passenger ªAirbag OFFº lamp is illuminated. Please refer to the Owner's Manual

for additional details.

�2004 ┬▒ 2005 model year ES 330 and RX 330 vehicles produced BEFORE the

Production Change Effective VINs shown on the following page.

OP CODEDESCRIPTIONTIMEOFPT1T2

EL4014R & R Occupant Detection ECU0.789952┬▒33010

89952┬▒480108A74

Applicable Warranty*:

This repair is covered under the Lexus Comprehensive Warranty. This warranty is in

effect for 48 months or 50,000 miles, whichever occurs first, from the vehicle's

in-service date.

* Warranty application is limited to correction of a problem based upon a customer's specific complaint.

ELECTRICAL

Introduction

Applicable

Vehicles

Warranty

Information