check engine LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 3350 of 4500

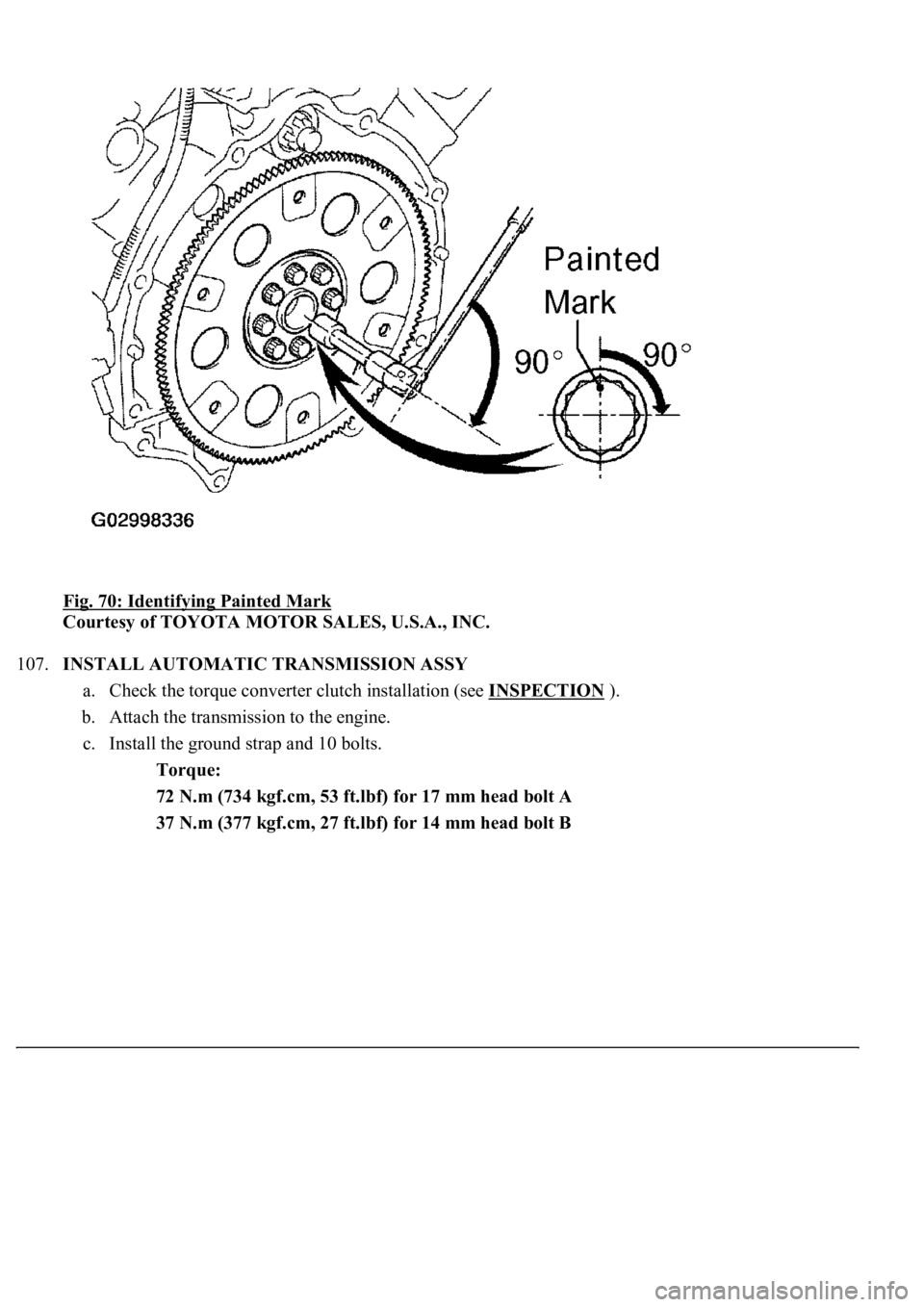

Fig. 70: Identifying Painted Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

107.INSTALL AUTOMATIC TRANSMISSION ASSY

a. Check the torque converter clutch installation (see INSPECTION

).

b. Attach the transmission to the engine.

c. Install the ground strap and 10 bolts.

Torque:

72 N.m (734 kgf.cm, 53 ft.lbf) for 17 mm head bolt A

37 N.m (377 kgf.cm, 27 ft.lbf) for 14 mm head bolt B

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.

Page 3496 of 4500

46.INSTALL OIL COOLER OUTLET TUBE NO.1

47.INSTALL OIL COOLER INLET TUBE NO.

48.INSTALL AIR CLEANER INLET NO.1

Torque: 5.0 N.m (51 kgf.cm, 44 in.lbf)

49.INSTALL INTAKE AIR CONNECTOR PIPE

Torque: 5.0 N.m (51 kgf.cm, 44 in.lbf)

50.INSTALL V-BANK COVER

Torque: 5.0 N.m (51 kgf.cm, 44 in.lbf)

51.REFILL ENGINE COOLANT (See REPLACEMENT

)

52.CHECK FOR ENGINE COOLANT LEAKS (See ON

-VEHICLE INSPECTION )

53.INSTALL ENGINE UNDER COVER NO.1

54.CONNECT BATTERY NEGATIVE TERMINAL

REPLACEMENT

1.REMOVE TIMING BELT (See REPLACEMENT

)

2.REMOVE CYLINDER HEAD COVER SUB-ASSY (See REPLACEMENT

)

3.PISTON & VALVE BREAK PREVENT WORK

a. Turn the crankshaft timing pulley counterclockwise by 45° and match the cut part with the

illustrated position.

HINT:

When the No. 1 cylinder is positioned at 45° BTDC, the valve and piston do not interfere with each other

even when the valve is fully open.

Page 3562 of 4500

Fig. 278: Tightening Cylinder Head Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

18.INSTALL CYLINDER HEAD SUB-ASSY

a. Check that the cut part of the crankshaft timing pulley is in the position shown in the illustration,

and that the piston is below the TDC of compression.

b. Install the cylinder head together with the manifold RH to the cylinder block.

c. Apply a light coat of engine oil on the threads and under the head of the cylinder head bolts.

d. Put the washer on the bolt, and insert the bolt with washer into the cylinder head.

Page 3575 of 4500

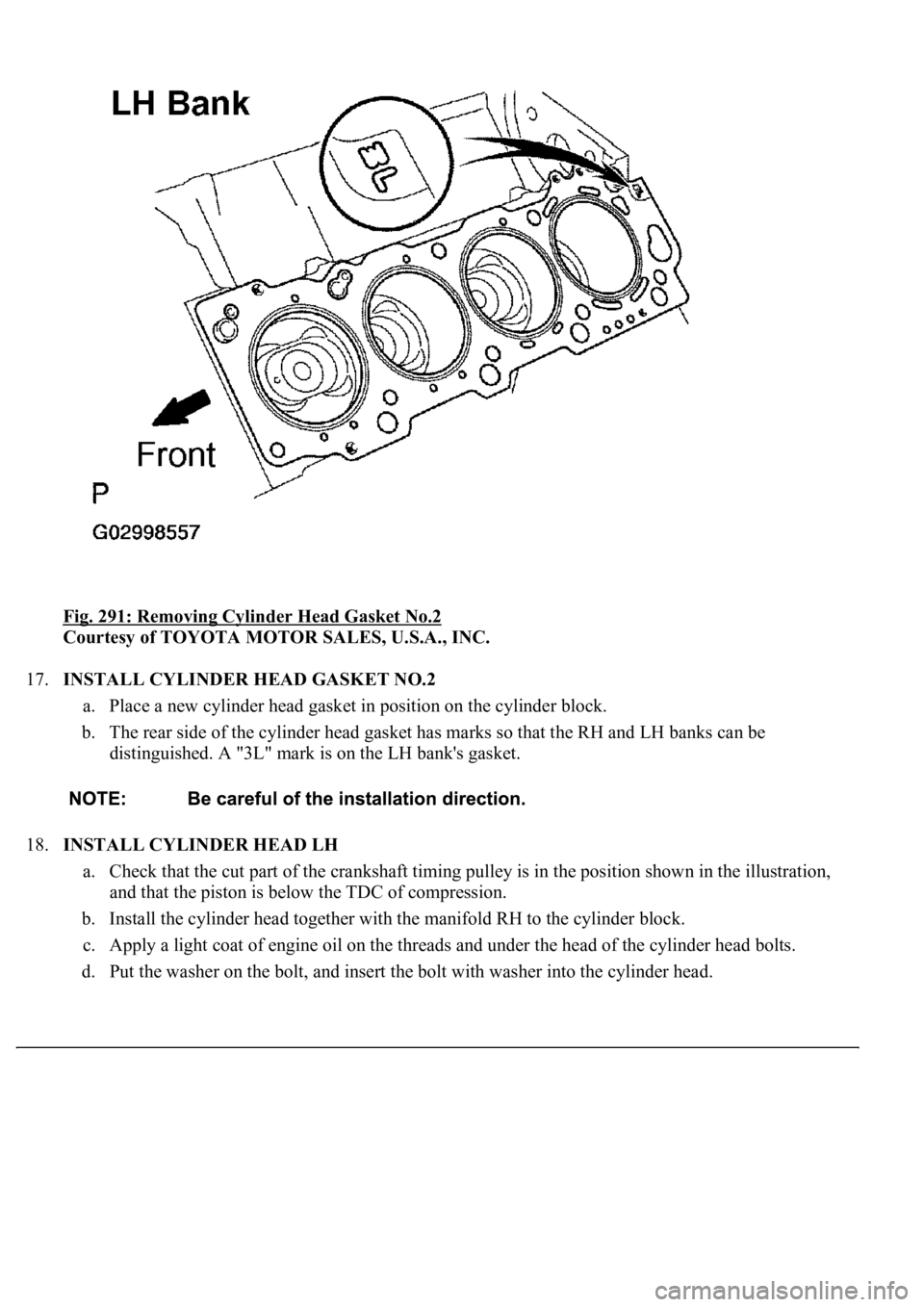

Fig. 291: Removing Cylinder Head Gasket No.2

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

17.INSTALL CYLINDER HEAD GASKET NO.2

a. Place a new cylinder head gasket in position on the cylinder block.

b. The rear side of the cylinder head gasket has marks so that the RH and LH banks can be

distinguished. A "3L" mark is on the LH bank's gasket.

18.INSTALL CYLINDER HEAD LH

a. Check that the cut part of the crankshaft timing pulley is in the position shown in the illustration,

and that the piston is below the TDC of compression.

b. Install the cylinder head together with the manifold RH to the cylinder block.

c. Apply a light coat of engine oil on the threads and under the head of the cylinder head bolts.

d. Put the washer on the bolt, and insert the bolt with washer into the c

ylinder head.

Page 3589 of 4500

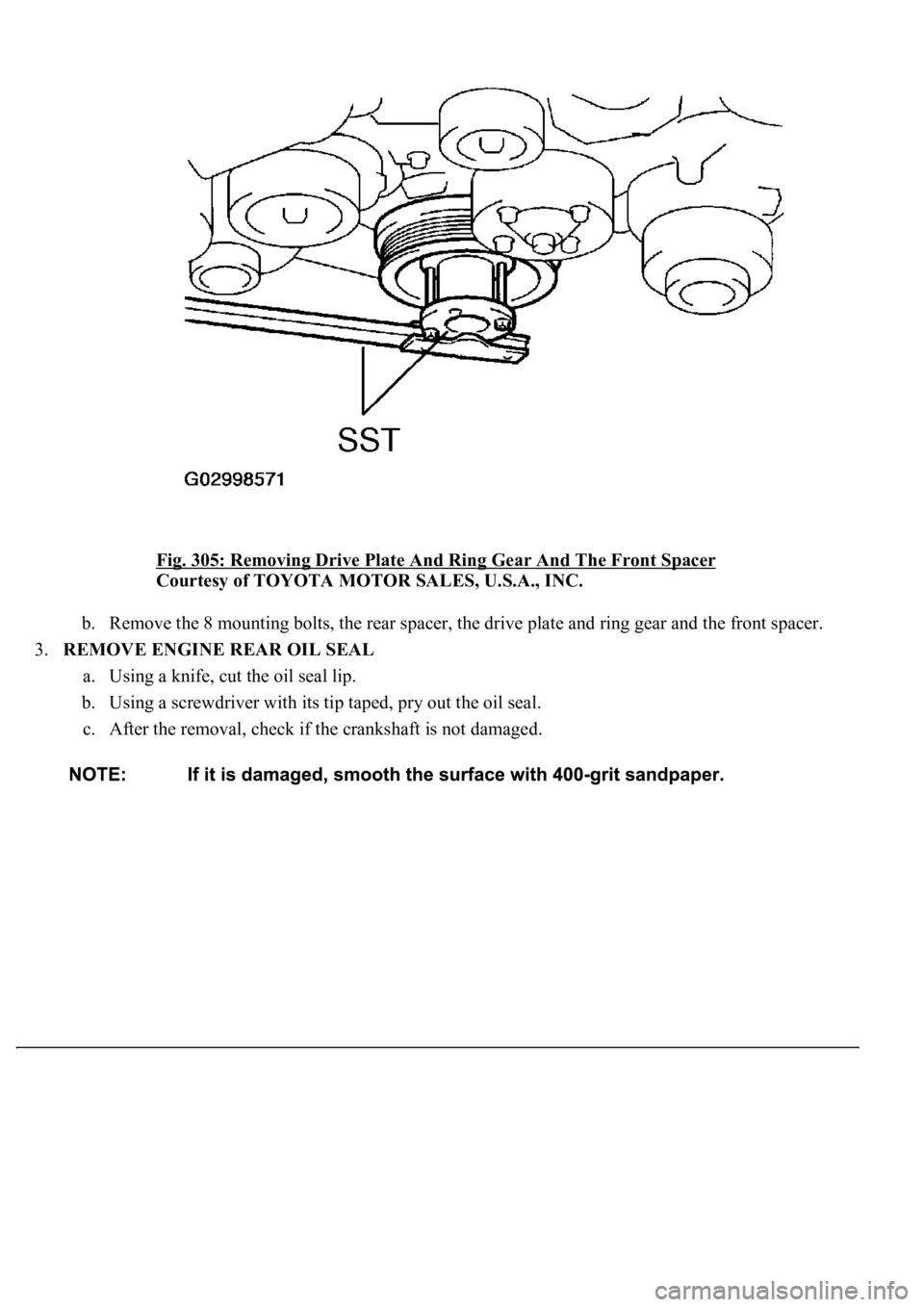

Fig. 305: Removing Drive Plate And Ring Gear And The Front Spacer

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Remove the 8 mounting bolts, the rear spacer, the drive plate and ring gear and the front spacer.

3.REMOVE ENGINE REAR OIL SEAL

a. Using a knife, cut the oil seal lip.

b. Using a screwdriver with its tip taped, pry out the oil seal.

c. After the removal, check if the crankshaft is not damaged.

Page 3967 of 4500

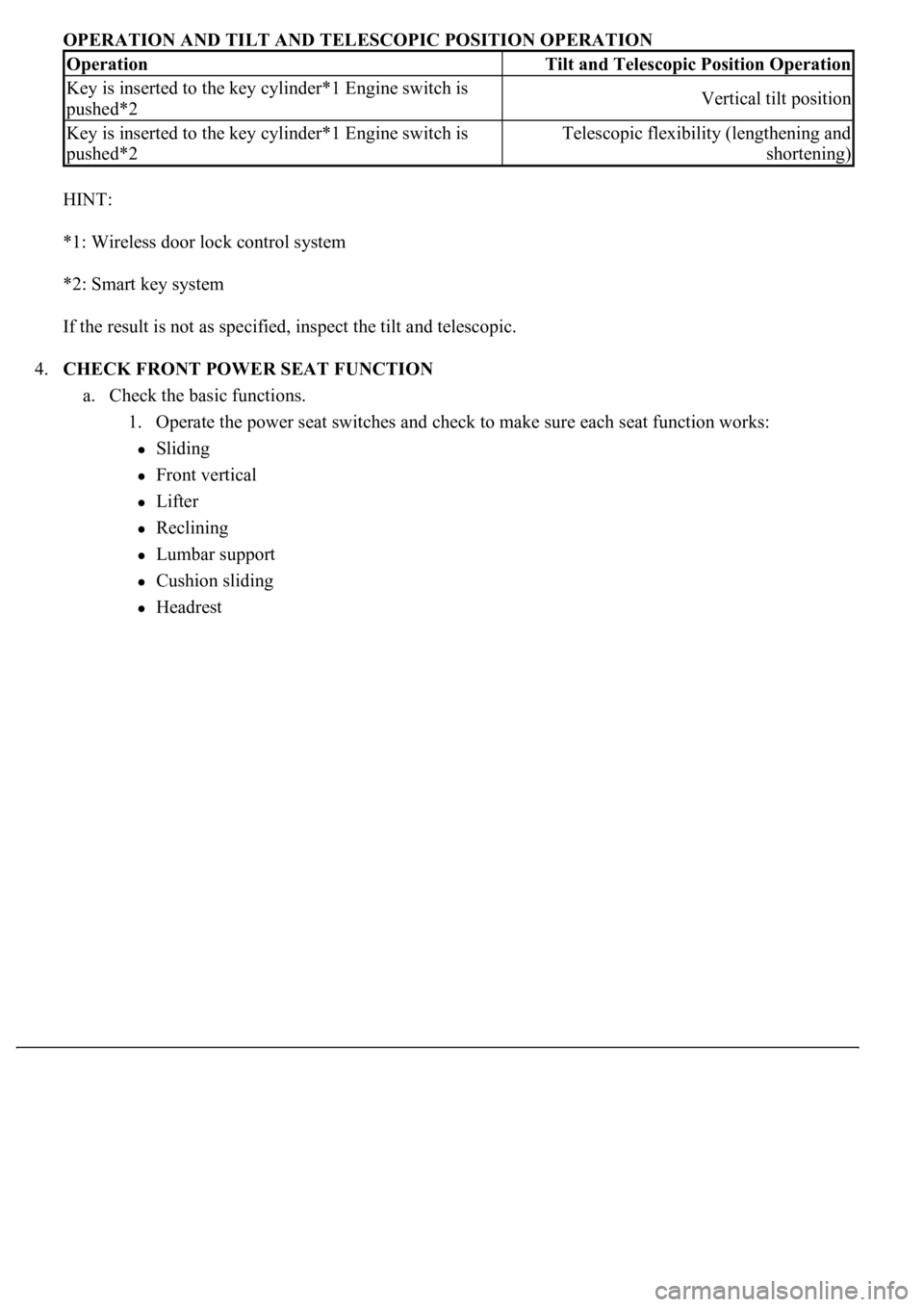

OPERATION AND TILT AND TELESCOPIC POSITION OPERATION

HINT:

*1: Wireless door lock control system

*2: Smart key system

If the result is not as specified, inspect the tilt and telescopic.

4.CHECK FRONT POWER SEAT FUNCTION

a. Check the basic functions.

1. Operate the power seat switches and check to make sure each seat function works:

Sliding

Front vertical

Lifter

Reclining

Lumbar support

Cushion sliding

Headrest

OperationTilt and Telescopic Position Operation

Key is inserted to the key cylinder*1 Engine switch is

pushed*2Vertical tilt position

Key is inserted to the key cylinder*1 Engine switch is

pushed*2Telescopic flexibility (lengthening and

shortening)

Page 4103 of 4500

SYSTEM

3.KEEP GASOLINE AWAY FROM RUBBER AND LEATHER PARTS

4.DISCHARGE FUEL SYSTEM PRESSURE

a. Using the F/PMP relay:

1. Remove the engine room R/B cover upper.

2. Remove the F/PMP relay.

3. Start the engine.

4. After the engine has stopped, turn the ignition switch OFF.

5. Crank the engine. Check that the engine does not start.

6. Remove the fuel tank cap to discharge pressure from the fuel tank.

7. Disconnect the negative (-) battery terminal cable.

8. Reinstall the F/PMP relay.

b. Using the fuel pump connector:

1. Remove the rear seat cushion.

2. Remove the rear floor service hole cover.

3. Disconnect the fuel pump connector.

4. Start the engine.

5. After the engine has stopped, turn the ignition switch OFF.

6. Crank the engine. Check that the engine does not start.

7. Remove the fuel tank cap to discharge pressure from the fuel tank.

8. Disconnect the cable from the negative (-) battery terminal.

9. Reconnect the fuel pump connector.

10. Install the rear floor service hole cover.

11. Install the rear seat.

Page 4110 of 4500

Fig. 11: Covering Disconnected Pipe And Connector With Plastic Bag

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

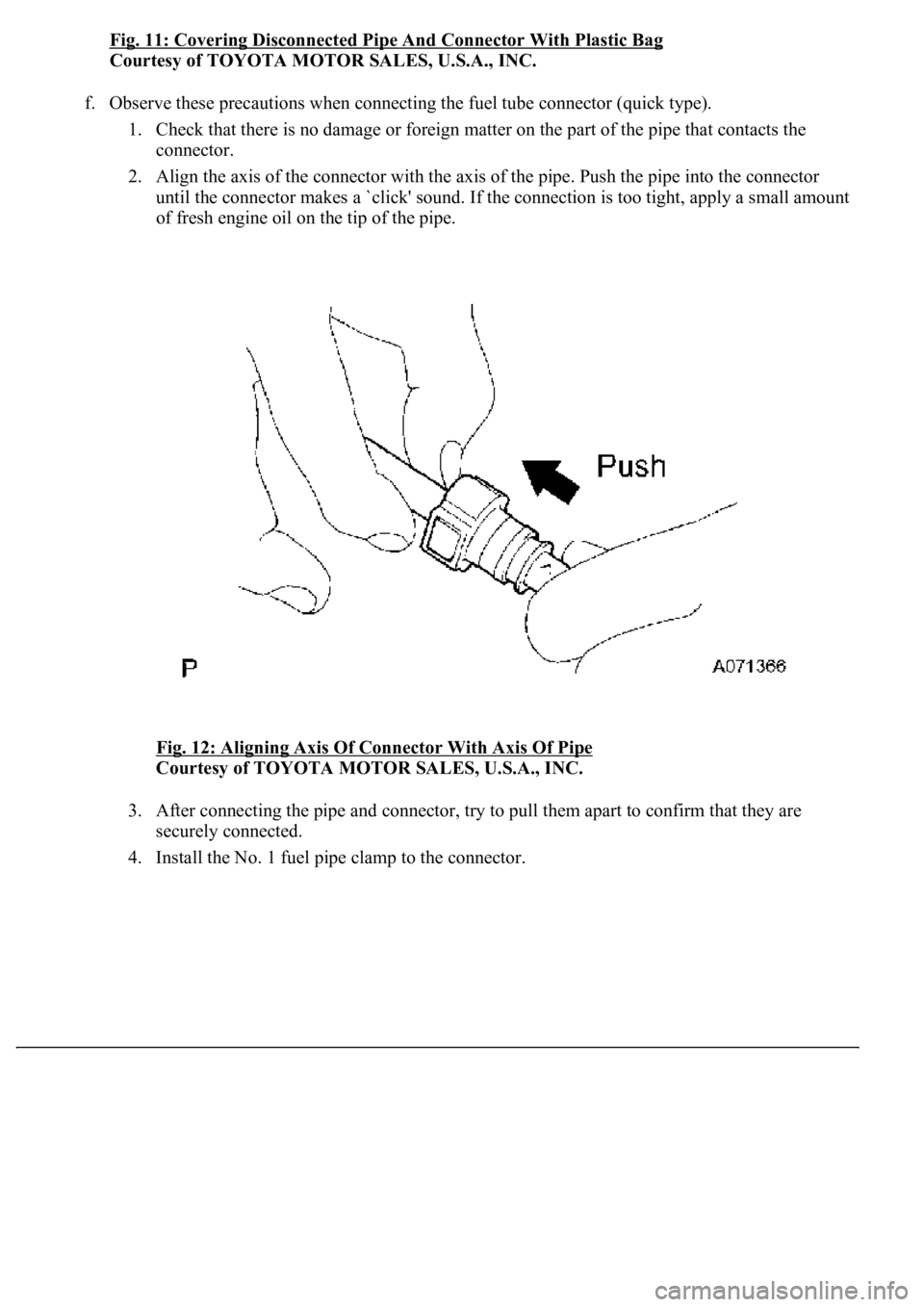

f. Observe these precautions when connecting the fuel tube connector (quick type).

1. Check that there is no damage or foreign matter on the part of the pipe that contacts the

connector.

2. Align the axis of the connector with the axis of the pipe. Push the pipe into the connector

until the connector makes a `click' sound. If the connection is too tight, apply a small amount

of fresh engine oil on the tip of the pipe.

Fig. 12: Aligning Axis Of Connector With Axis Of Pipe

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. After connecting the pipe and connector, try to pull them apart to confirm that they are

securely connected.

4. Install the No. 1 fuel pipe clamp to the connector.

Page 4112 of 4500

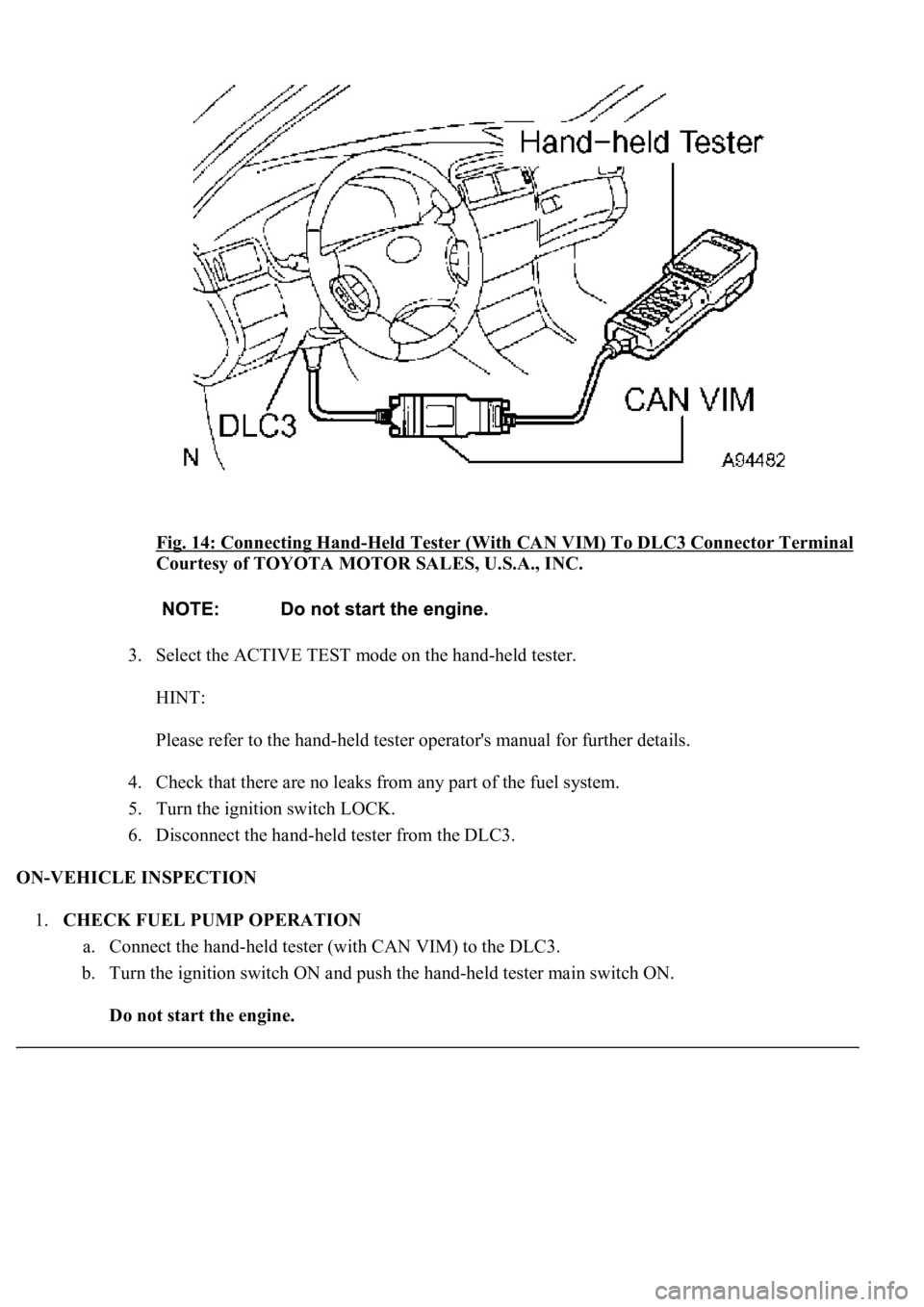

Fig. 14: Connecting Hand-Held Tester (With CAN VIM) To DLC3 Connector Terminal

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Select the ACTIVE TEST mode on the hand-held tester.

HINT:

Please refer to the hand-held tester operator's manual for further details.

4. Check that there are no leaks from any part of the fuel system.

5. Turn the ignition switch LOCK.

6. Disconnect the hand-held tester from the DLC3.

ON-VEHICLE INSPECTION

1.CHECK FUEL PUMP OPERATION

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON and push the hand-held tester main switch ON.

Do not start the engine.