automatic transmission fluid LEXUS LS430 2003 Factory User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2670 of 4500

control ECU, PCM

FC idleDeceleration fuel cut

Idle air control valveIdle speed control

VSV for CCV, Canister close valve VSV for

canister controlEvaporative emissions canister vent valve

VSV for EVAP, Vacuum switching valve assembly

No. 1, EVAP VAV, Purge VSVEvaporative emissions canister purge valve

VSV for pressure switching valve, Bypass VSVEvaporative emission pressure switching valve

Vapor pressure sensor, EVAP pressure sensor,

Evaporative emission control system pressure

sensorFuel tank pressure sensor

Charcoal canisterEvaporative emissions canister

ORVR systemOn-boad refueling vapor recovery system

Intake manifold runner controlIntake manifold tuning system

Intake manifold runner valve, IMRV, IACV (runner

valve)Intake manifold tuning valve

Intake control VSVIntake manifold tuning solenoid valve

AFSAir fuel ratio sensor

O2 sensorHeater oxygen sensor

Oxygen sensor pumping current circuitOxygen sensor output signal

Oxygen sensor reference ground circuitOxygen sensor signal ground

Accel position sensorAccelerator pedal position sensor

Throttle actuator control motor, Actuator control

motor, Electronic throttle motor, Throttle control

motorElectronic throttle actuator

Electronic throttle control system, Throttle actuator

control systemElectronic throttle control system

Throttle/pedal position sensor, Throttle/pedal

position switch, Throttle position sensor/switchThrottle position sensor

Turbo press sensorTurbocharger pressure sensor

Turbo VSVTurbocharger pressure control solenoid valve

P/S pressure switchPower-steering pressure switch

VSV for ACMActive control engine mount

Speed sensor, Vehicle speed sensor "A", Speed

sensor for skid control ECUVehicle speed sensor

ATF temperature sensor, Trans, fluid temp, sensor,

ATF temperature sensor "A"Transmission fluid temperature sensor

Electronic controlled automatic transmission, ECTElectronically controlled automatic

Intermediate shaft speed sensor "A"Counter gear speed sensor

Part and system nameDefinition

Output speed sensorOutput shaft speed sensor

<002c00510053005800570003005600530048004800470003005600480051005600520055000f0003002c005100530058005700030057005800550045004c005100480003005600530048004800470003005600480051005600520055000300050024000500

0f0003[

Speed sensor (NT), Turbine speed sensorInput turbine speed sensor

Page 2676 of 4500

SYSTEM DESCRIPTION

1.SYSTEM DESCRIPTION

a. The ECT (Electronic controlled automatic transmission) is an automatic transmission that

electronically controls shift timing using the ECM. The ECM detects electrical signals that indicate

engine and driving conditions, and controls the shift point, based on driver habits and road

conditions. As a result, fuel efficiency and power transmission performance are improved.

<0036004b004c0049005700030056004b00520046004e0003004b00440056000300450048004800510003005500480047005800460048004700030045005c0003004600520051005700550052004f004f004c0051004a00030057004b004800030048005100

4a004c00510048000300440051004700030057005500440051[smission simultaneously. In

addition, the ECT has features such as follows:

Diagnostic function.

Fail-safe function when a malfunction occurs.

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

The ECM of this system is connected to the CAN and multiplex communication system. Therefore,

before starting troubleshooting, make sure to check that there is no trouble in the CAN and multiplex

communication system.

<0037004b00480003004b0044005100470010004b0048004f0047000300570048005600570048005500030046004400510003004500480003005800560048004700030044005700030056005700480053005600030016000f00030017000f00030019000f00

030044005100470003001c00110003[

1.Vehicle Brought to Workshop

2.Customer Problem Analysis (See CUSTOMER PROBLEM ANALYSIS CHECK

)

3.Connect the OBD II scan tool or hand-held tester to DLC3

4.Check and Clear DTCs and Freeze Frame Data (See DTC CHECK/CLEAR

)

5.Visual Inspection

6.Setting the Check Mode Diagnosis (See CHECK MODE PROCEDURE

)

7.Problem Symptom Confirmation (See ROAD TEST

)

Symptom does not occur: Go to step 8

Symptom occurs: Go to step 9

8.Symptom Simulation (See HOW TO PROCEED WITH TROUBLESHOOTING

)

9.DTC Check (See DTC CHECK/CLEAR

)

DTC is not output: Go to step 10

DTC is output: Go to step 17

10.Basic Inspection (See ADJUSTMENT

- AUTOMATIC TRANSMISSION FLUID ,

ADJUSTMENT

- PARK/NEUTRAL POSITION SWITCH ASSY and ADJUSTMENT -

FLOOR SHIFT ASSY

)

Page 2683 of 4500

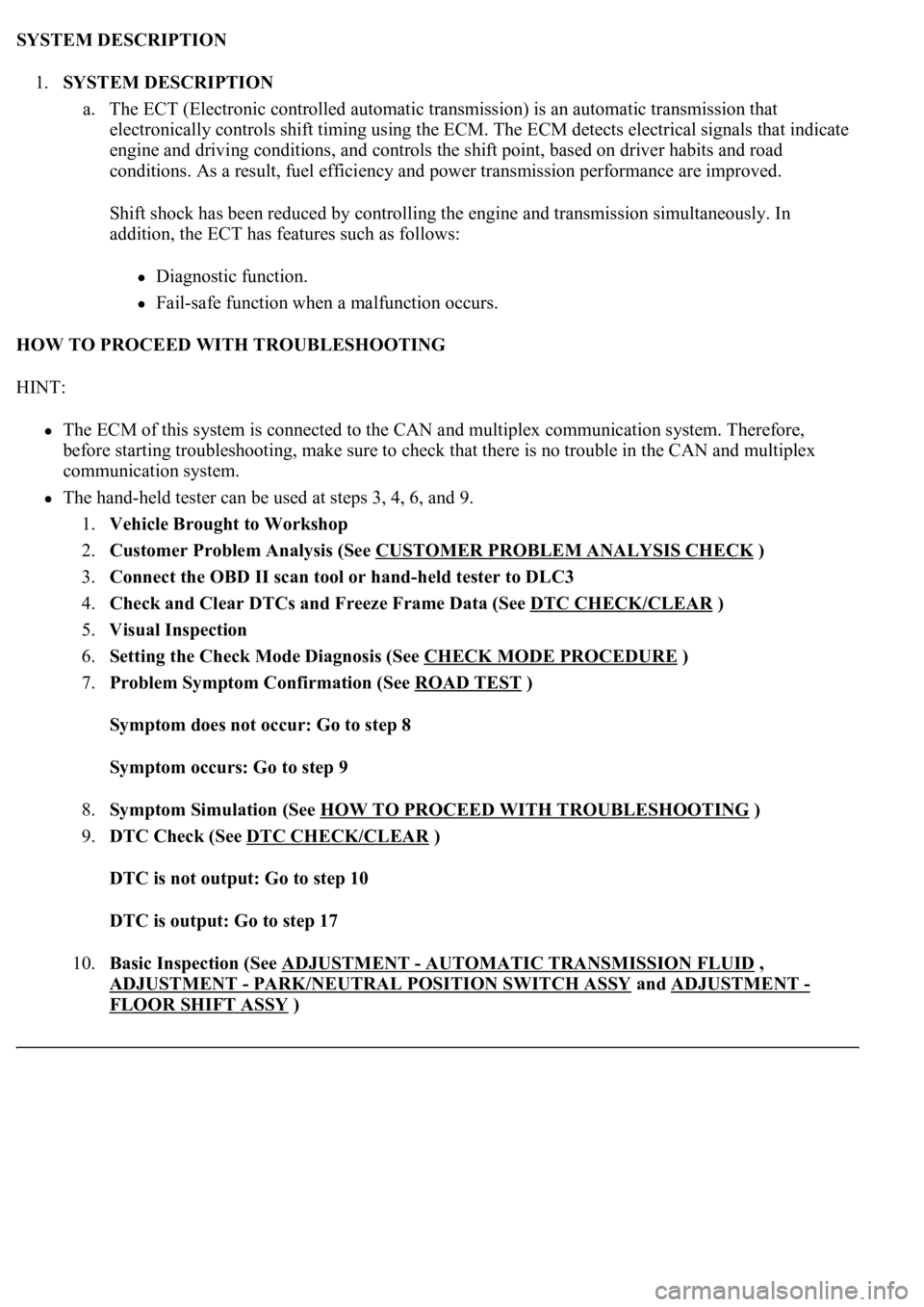

Fig. 8: Time Lag Problem Symptoms Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HYDRAULIC TEST

1.PERFORM HYDRAULIC TEST

a. Measure the line pressure.

1. Warm up the ATF (Automatic Transmission Fluid).

2. Lift the vehicle up.

3. Remove the test plug on the transmission case center right side and connect SST.

SST 09992-00095 (09992-00231, 09992-00271)

4. Fully apply the parking brake and chock the 4 wheels.

5. Start the engine and check idling speed.

6. Keep your left foot pressing firmly on the brake pedal and shift into D position.

7. Measure the line pressure when the engine is idling.

8. Depress the accelerator pedal all the way down. Quickly read the highest line pressure when

en

gine speed reaches stall speed.

Page 2740 of 4500

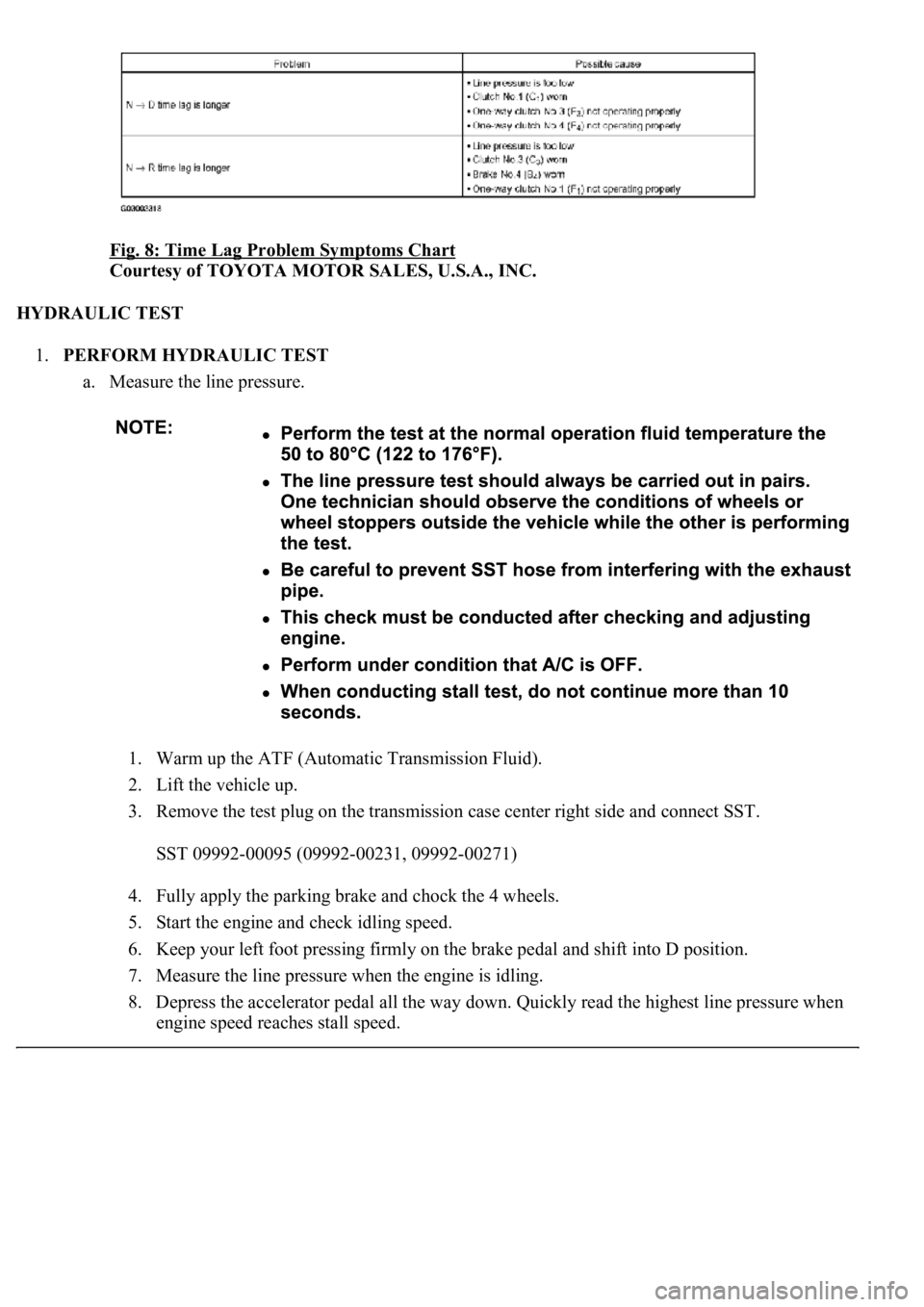

Fig. 57: ECM Connector Terminals Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (SeeELECTRONIC CIRCUIT

INSPECTION PROCEDURE )

OK: REPLACE ECM (See REPLACEMENT

)

DTC P0710, P0712, P0713: TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT

LOW/HIGH INPUT

CIRCUIT DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid temperature into a resistance

value which is input into the ECM.

The ECM applies a voltage to the temperature sensor through ECM terminal OIL.

The sensor resistance changes with the transmission fluid temperature. As the temperature becomes higher, the

sensor resistance decreases.

One terminal of the sensor is grounded so that the sensor resistance decreases and the voltage goes down as the

temperature becomes higher.

The ECM calculates the fluid temperature based on the volta

ge signal.

Page 2742 of 4500

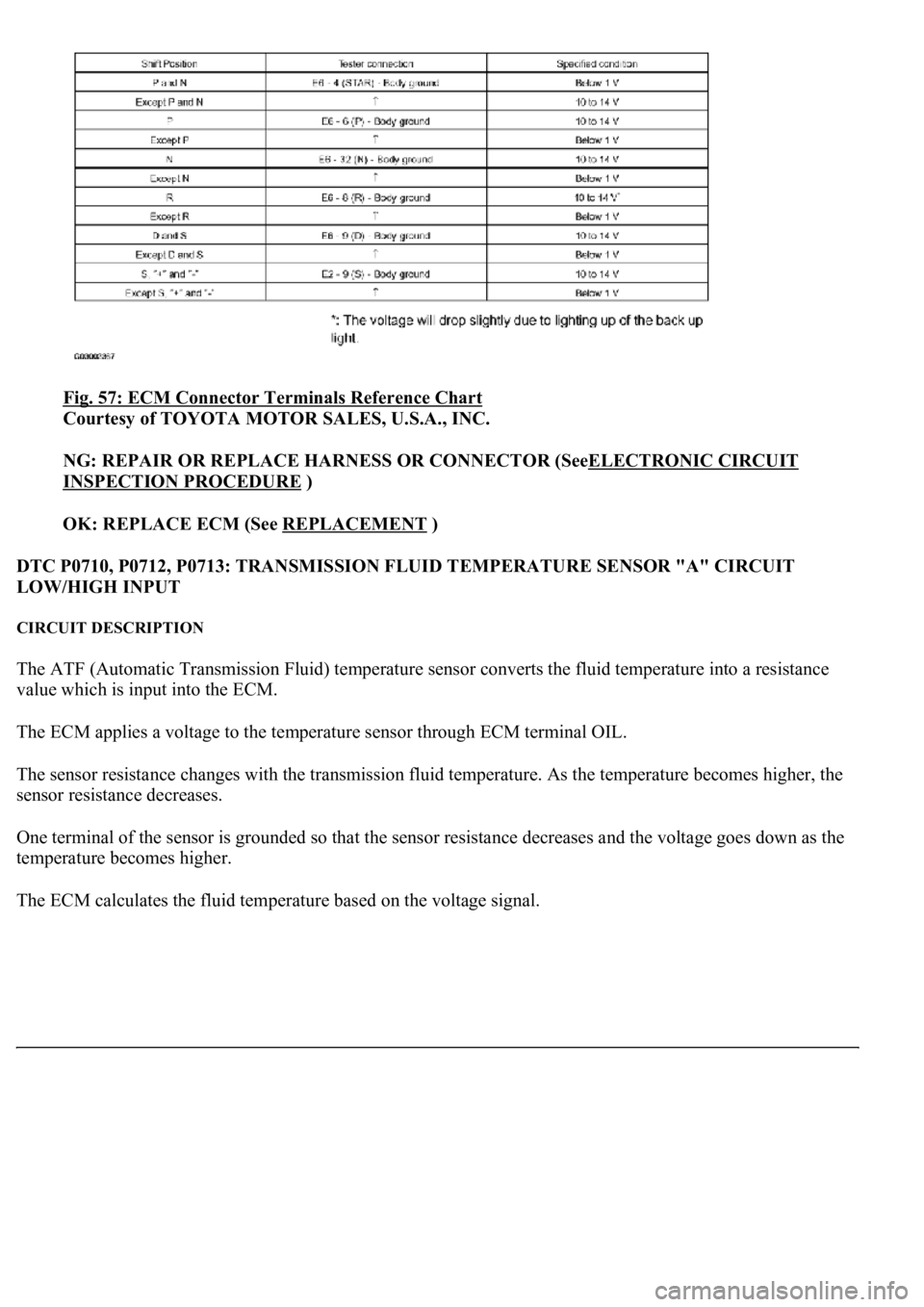

Fig. 59: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

These DTCs indicate an open or short in the automatic transmission fluid (ATF) temperature sensor circuit. The

automatic transmission fluid (ATF) temperature sensor converts ATF temperature to an electrical resistance

value. Based on the resistance, the ECM determines the ATF temperature, and the ECM detects an opens or

shorts in the ATF temperature circuit. If the resistance value of the ATF temperature is less than 79ohms*1 or

more than 156kohms*2, the ECM interprets this as a fault in the ATF sensor or wiring. The ECM will turn on

the MIL and store the DTC.

*1: 150°C (302°F) or more is indicated regardless of the actual ATF temperature.

*2: -40°C (-40°F) is indicated regardless of the actual ATF temperature.

HINT:

The ATF temperature can be checked on the OBD II scan tool or hand-held tester display.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

Related DTCsP0710: ATF temperature sensor/Range check

(Chattering) P0712: ATF temperature

sensor/Range check (Low resistance) P0713: ATF

temperature sensor/Range check (High resistance)

Required sensors/ComponentsATF temperature sensor (TFT sensor)

Frequency of operationContinuous

Duration0.5 sec.

MIL operationImmediate

Sequence of operationNone

Page 2748 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

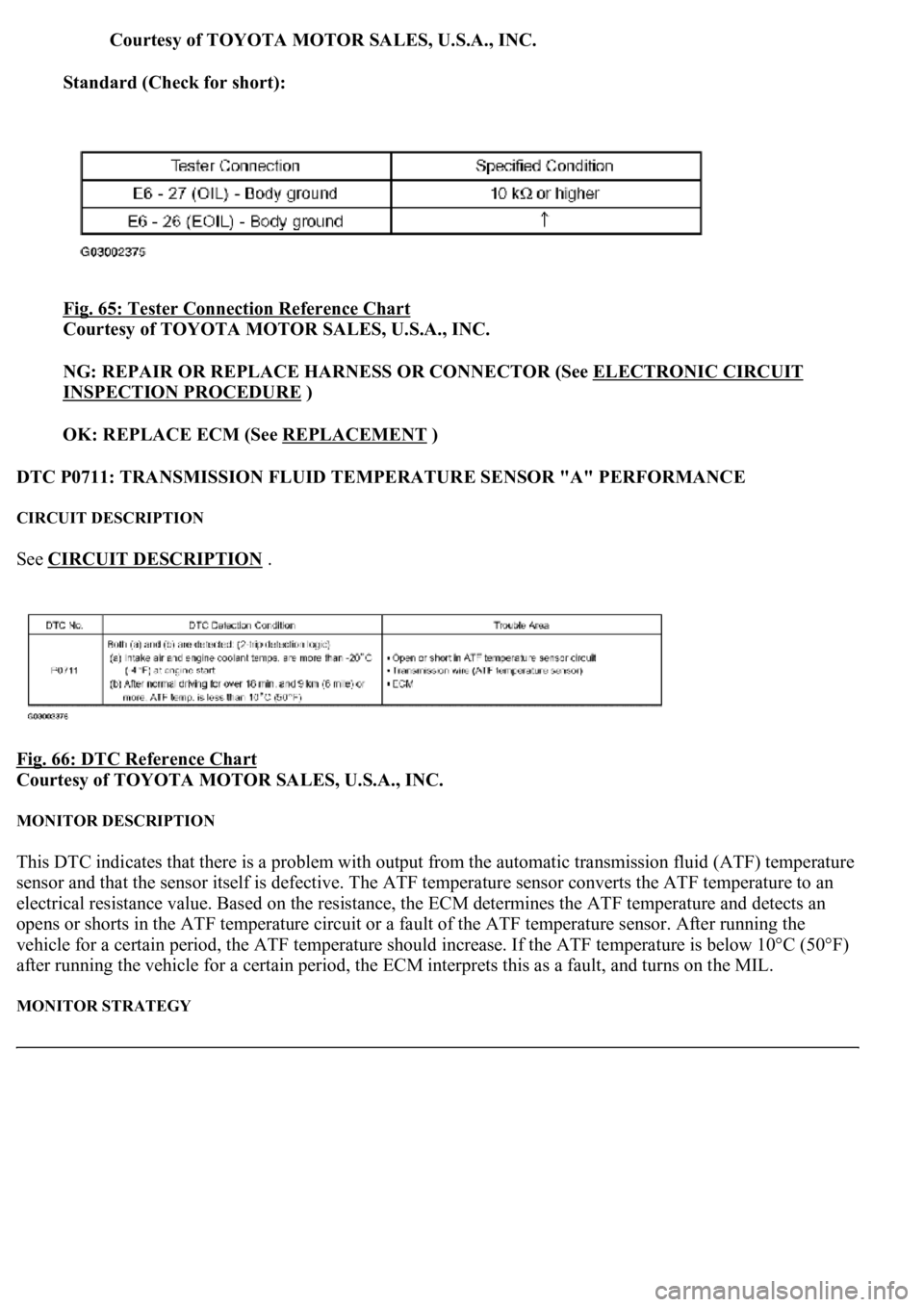

Standard (Check for short):

Fig. 65: Tester Connection Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (See ELECTRONIC CIRCUIT

INSPECTION PROCEDURE )

OK: REPLACE ECM (See REPLACEMENT

)

DTC P0711: TRANSMISSION FLUID TEMPERATURE SENSOR "A" PERFORMANCE

CIRCUIT DESCRIPTION

See CIRCUIT DESCRIPTION .

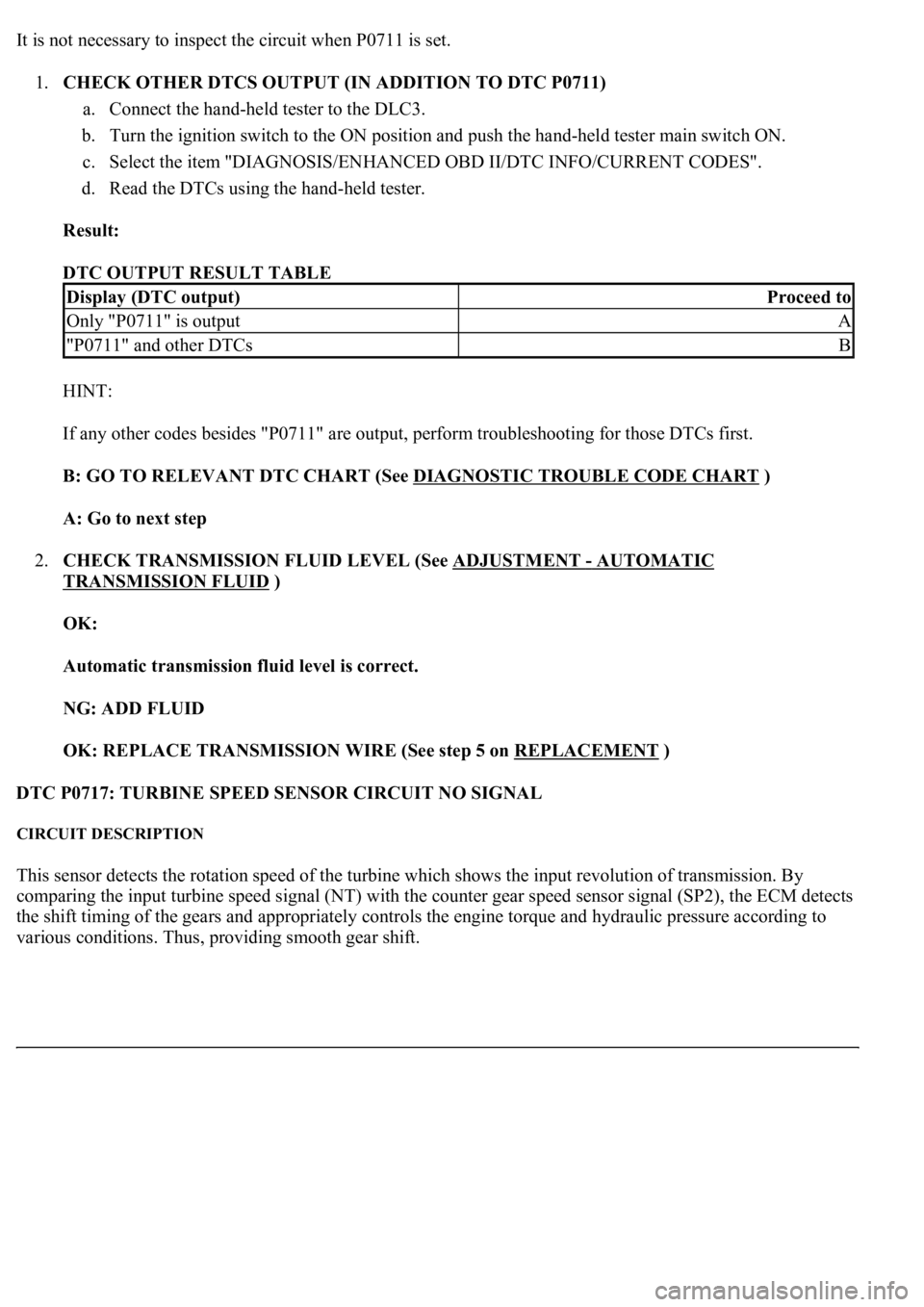

Fig. 66: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

This DTC indicates that there is a problem with output from the automatic transmission fluid (ATF) temperature

sensor and that the sensor itself is defective. The ATF temperature sensor converts the ATF temperature to an

electrical resistance value. Based on the resistance, the ECM determines the ATF temperature and detects an

opens or shorts in the ATF temperature circuit or a fault of the ATF temperature sensor. After running the

vehicle for a certain period, the ATF temperature should increase. If the ATF temperature is below 10°C (50°F)

after running the vehicle for a certain period, the ECM interprets this as a fault, and turns on the MIL.

MONITOR STRATEGY

Page 2751 of 4500

It is not necessary to inspect the circuit when P0711 is set.

1.CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0711)

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and push the hand-held tester main switch ON.

c. Select the item "DIAGNOSIS/ENHANCED OBD II/DTC INFO/CURRENT CODES".

d. Read the DTCs using the hand-held tester.

Result:

DTC OUTPUT RESULT TABLE

HINT:

If any other codes besides "P0711" are output, perform troubleshooting for those DTCs first.

B: GO TO RELEVANT DTC CHART (See DIAGNOSTIC TROUBLE CODE CHART

)

A: Go to next step

2.CHECK TRANSMISSION FLUID LEVEL (See ADJUSTMENT

- AUTOMATIC

TRANSMISSION FLUID )

OK:

Automatic transmission fluid level is correct.

NG: ADD FLUID

OK: REPLACE TRANSMISSION WIRE (See step 5 on REPLACEMENT

)

DTC P0717: TURBINE SPEED SENSOR CIRCUIT NO SIGNAL

CIRCUIT DESCRIPTION

This sensor detects the rotation speed of the turbine which shows the input revolution of transmission. By

comparing the input turbine speed signal (NT) with the counter gear speed sensor signal (SP2), the ECM detects

the shift timing of the gears and appropriately controls the engine torque and hydraulic pressure according to

various conditions. Thus, providin

g smooth gear shift.

Display (DTC output)Proceed to

Only "P0711" is outputA

"P0711" and other DTCsB

Page 3313 of 4500

13.DRAIN AUTOMATIC TRANSMISSION FLUID

14.REMOVE RADIATOR ASSY (See REPLACEMENT

)

15.DISCONNECT FUEL PIPE SUB-ASSY NO.2 (See REPLACEMENT

)

16.REMOVE FAN AND GENERATOR V BELT (See REPLACEMENT

)

17.DISCONNECT ENGINE WIRE

a. Disconnect the engine wire from the ECM box.

b. Remove the nut, and disconnect the generator wire from the generator.

c. Disconnect the wire for generator wire from the wire clamp on generator.

d. Remove the bolt, and disconnect the ground cable from the stay on the generator.

e. Remove the 2 bolts, and disconnect the PS oil hose from the No. 1 oil pan.

f. Remove the bolt, and disconnect the ground strap from the body.

18.DISCONNECT AIR HOSE NO.5

19.DISCONNECT FUEL VAPOR FEED HOSE NO.2

20.DISCONNECT HEATER WATER INLET HOSE A

21.DISCONNECT HEATER WATER OUTLET HOSE A (FROM HEATER UNIT)

22.DISCONNECT VANE PUMP OIL RESERVOIR ASSY

23.DISCONNECT VANE PUMP ASSY

a. Disconnect the 2 PS air hoses.

b. Remove the 2 screws and RH engine under cover.

c. Disconnect the PS oil pressure switch connector.

d. Remove the 2 bolts and nut, and disconnect the pump from the engine.

e. Support the pump securely.

24.DISCONNECT COOLER COMPRESSOR ASSY

a. Disconnect the compressor connector.

b. Disconnect the wire clamp from the wire bracket on the compressor.

c. Remove the bolt, nut and stay.

d. Remove the bolt, and disconnect the wire bracket from the compressor.

e. Remove the bolt, and disconnect the compressor from the engine.

f. Support the cooler compressor securely.

25.REMOVE FRONT FLOOR BRACE CENTER

a. Remove the 4 bolts and brace center.

26.REMOVE EXHAUST PIPE ASSY (See REPLACEMENT

)

27.REMOVE W/ CATALYST CONVERTER ASSY

28.REMOVE FRONT FLOOR HEAT INSULATOR NO.1

29.REMOVE PARKING BRAKE CABLE HEAT INSULATOR

30.REMOVE PROPELLER W/ CENTER BEARING SHAFT ASSY (See OVERHAUL

)

31.REMOVE FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSY

32.REMOVE STEERING SLIDING W/ SHAFT YOKE SUB-ASSY

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.