automatic transmission fluid LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 818 of 4500

PRECAUTION

1. The automatic transmission is composed of highly precision-finished parts which need careful inspection

before reassembly because even a small nick could cause fluid leakage or affect performance. The

instructions here are organized so that you work on only one component group at a time. This will help

avoid confusion from similar-looking parts of different sub-assemblies being on your workbench at the

same time. The component groups should be inspected and repaired from the converter housing side.

Inspect, repair and reassemble as much as possible before proceeding to the next component group. If a

defect is found in a certain component group during reassembly, inspect and repair this group

immediately. If a component group cannot be assembled because parts are being ordered, be sure to keep

all parts of the group in a separate container while proceeding with disassembly, inspection, repair and

reassembly of other component groups. Recommended ATF: ATF WS

2. All disassembled parts should be washed clean and any fluid passages and holes should be blown through

with compressed air.

3. Dry all parts with compressed air. Never use shop rags.

4. When using compressed air, be careful not to not aim at yourself to prevent accidentally spraying ATF or

kerosene on your face.

5. Only recommended automatic transaxle fluid or kerosene should be used for cleaning.

6. After cleaning, the parts should be arranged in the correct order for efficient inspection, repairs, and

reassembly.

7. When disassembling a valve body, be sure to match each valve together with the corresponding spring.

8. New discs for the brakes and clutches that are to be used for replacement must be soaked in ATF for at

least 15 minutes before reassembly.

9. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

ATF prior to reassembly.

10. All gaskets and rubber O-rings should be replaced.

11. Do not apply adhesive cements to gaskets or similar parts.

12. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

13. When replacing a worn bushing, the sub-assembly containing the bushing must also be replaced.

14. Check thrust bearings and races for wear or damage. Replace them as necessary.

15. Use petroleum jelly to keep parts in place.

16. When working with FIPG material, perform the following: Using a razor blade and a gasket scraper,

remove all the old packing (FIPG) material from the gasket surface.

Thoroughly clean all components to remove any loose material.

Page 845 of 4500

3.REMOVE ENGINE UNDER COVER NO.2

4.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.2 (SEE REPLACEMENT

)

5.REMOVE INSTRUMENT PANEL GARNISH SUB-ASSY LH (SEE REPLACEMENT

)

6.REMOVE INSTRUMENT PANEL FINISH PANEL (SEE REPLACEMENT

)

7.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.1 (SEE REPLACEMENT

)

8.REMOVE SWITCH BRACE HOLE COVER (SEE REPLACEMENT

)

9.REMOVE INSTRUMENT PANEL SAFETY PAD SUB-ASSY NO.1 (SEE REPLACEMENT

)

10.REMOVE INSTRUMENT PANEL CUP HOLDER ASSY (SEE REPLACEMENT

)

11.REMOVE CONSOLE UPPER REAR PANEL SUB-ASSY (SEE REPLACEMENT

)

12.REMOVE CONSOLE BOX CARPET (SEE REPLACEMENT

)

13.REMOVE REAR CONSOLE ARMREST ASSY (SEE REPLACEMENT

)

14.REMOVE INSTRUMENT PANEL FINISH PANEL LOWER CENTER (SEE REPLACEMENT

)

15.REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB-ASSY CENTER (SEE

REPLACEMENT

)

16.REMOVE CONSOLE PANEL SUB-ASSY UPPER (SEE REPLACEMENT

)

17.REMOVE CONSOLE BOX (SEE REPLACEMENT

)

18.SEPARATE OXYGEN SENSOR (SEE REPLACEMENT

)

a. Separate the 2 heated oxygen sensors.

19.REMOVE FRONT FLOOR BRACE CENTER (SEE REPLACEMENT

)

20.REMOVE EXHAUST PIPE ASSY (SEE REPLACEMENT

)

21.REMOVE FRONT FLOOR HEAT INSULATOR NO.1 (SEE OVERHAUL

)

22.REMOVE PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

SST 09922-10010

23.DRAIN AUTOMATIC TRANSMISSION FLUID

a. Remove the drain plug, gasket and drain the ATF.

b.Install a new gasket and the drain plug.

Torque: 20 N.m (205 kgf.cm, 15 ft.lbf)

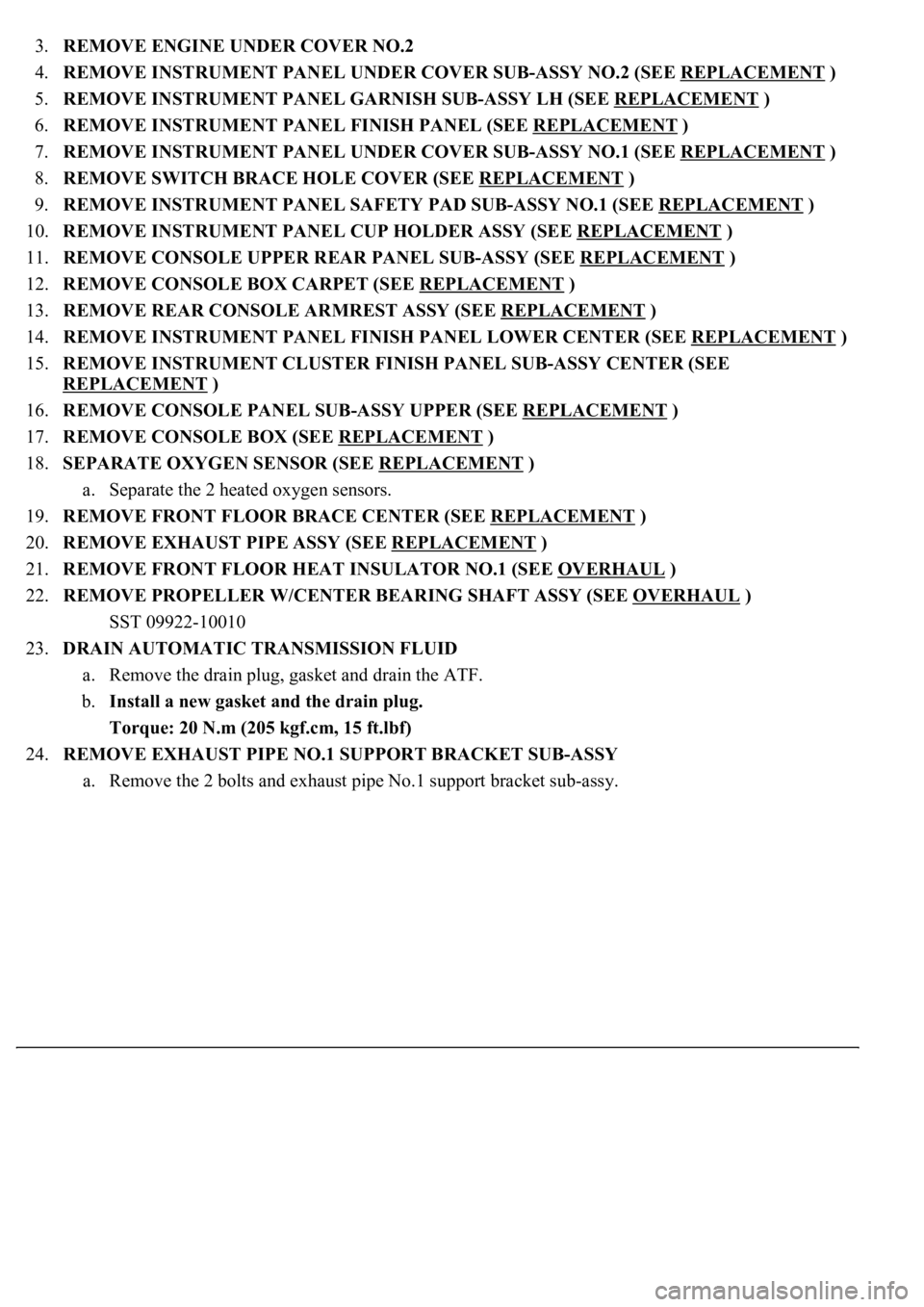

24.REMOVE EXHAUST PIPE NO.1 SUPPORT BRACKET SUB-ASSY

a. Remove the 2 bolts and exhaust pipe No.1 support bracket sub-ass

y.

Page 873 of 4500

Fig. 54: Installing Exhaust Pipe No.1 Support Bracket Sub-Assy With 2 Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

49.CONNECT BATTERY NEGATIVE TERMINAL

50.ADJUST SHIFT LEVER POSITION (SEE ADJUSTMENT

)

51.INSPECT SHIFT LEVER POSITION (SEE ADJUSTMENT

)

52.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

53.INSTALL FRONT FLOOR HEAT INSULATOR NO.1 (SEE OVERHAUL

)

54.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

55.INSTALL FRONT FLOOR BRACE CENTER (SEE REPLACEMENT

)

56.ADD AUTOMATIC TRANSMISSION FLUID (SEE ADJUSTMENT

)

Fluid type: ATF WS

Capacity: 1.7 liters (1.8 US qts, 1.5 lmp. qts)

57.INSTALL ENGINE UNDER COVER NO.2

58.INSTALL ENGINE UNDER COVER NO.1

59.RESET MEMORY (SEE INITIALIZATION

)

60.PERFORM INITIALIZATION (SEE INITIALIZATION

)

Page 880 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

REPLACEMENT

<00380056004c0051004a00030044000300550044005d0052005500030045004f00440047004800030044005100470003004a00440056004e0048005700030056004600550044005300480055000f000300550048005000520059004800030044004f004f00

030057004b004800030052004f004700030029002c0033002a[ material from the gasket surfaces.

Thoroughly clean all components to remove any loose material.

Clean both sealing surfaces with a non-residue solvent.

Apply FIPG in a continuous line width approximately 1 mm (0.04 in.) along the sealing surface.

Parts must be assembled within 10 minutes of application. Otherwise, the FIPG material must be

removed and reapplied.

1.DISCONNECT BATTERY NEGATIVE TERMINAL

2.DRAIN AUTOMATIC TRANSMISSION FLUID

a. Remove the drain plug, gasket and drain the ATF.

b. Install a new gasket and the drain plug.

Torque: 20 N.m (205 kgf.cm, 15 ft.lbf)

3.REMOVE AUTOMATIC TRANSMISSION OIL PAN SUB-ASSY

a. Remove the 20 bolts, oil pan and

gasket.

Page 893 of 4500

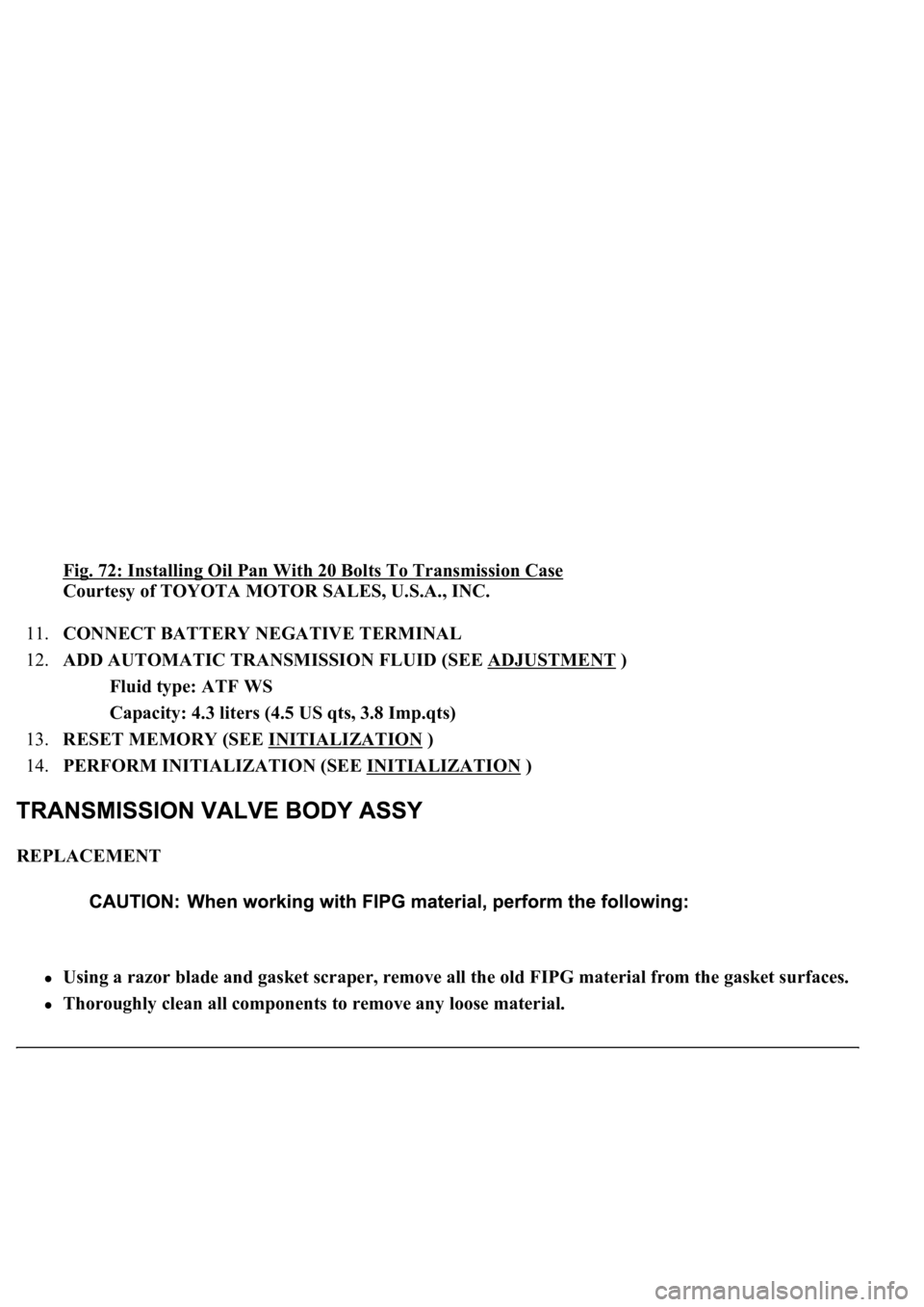

Fig. 72: Installing Oil Pan With 20 Bolts To Transmission Case

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

11.CONNECT BATTERY NEGATIVE TERMINAL

12.ADD AUTOMATIC TRANSMISSION FLUID (SEE ADJUSTMENT

)

Fluid type: ATF WS

Capacity: 4.3 liters (4.5 US qts, 3.8 Imp.qts)

13.RESET MEMORY (SEE INITIALIZATION

)

14.PERFORM INITIALIZATION (SEE INITIALIZATION

)

REPLACEMENT

<00380056004c0051004a00030044000300550044005d0052005500030045004f00440047004800030044005100470003004a00440056004e0048005700030056004600550044005300480055000f000300550048005000520059004800030044004f004f00

030057004b004800030052004f004700030029002c0033002a[ material from the gasket surfaces.

Thoroughly clean all components to remove any loose material.

Page 894 of 4500

Clean both sealing surfaces with a non-residue solvent.

Apply FIPG in a continuous line width approximately 1 mm (0.04 in.) along the sealing surface.

Parts must be assembled within 10 minutes of application. Otherwise, the FIPG material must be

removed and reapplied.

1.DISCONNECT BATTERY NEGATIVE TERMINAL

2.DRAIN AUTOMATIC TRANSMISSION FLUID

a. Remove the drain plug, gasket and drain the ATF.

b. Install a new gasket and the drain plug.

Torque: 20 N.m (205 kgf.cm, 15 ft.lbf)

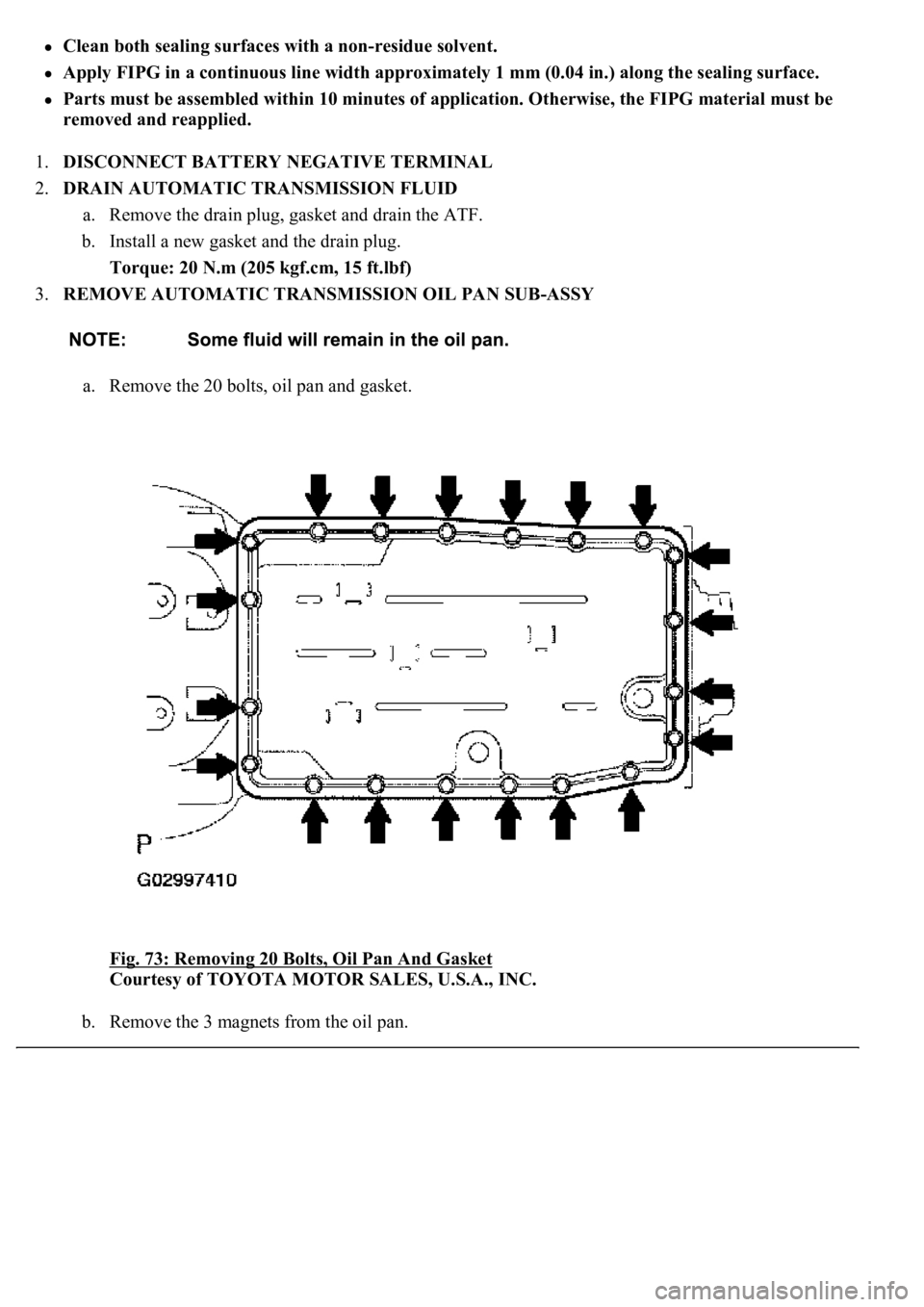

3.REMOVE AUTOMATIC TRANSMISSION OIL PAN SUB-ASSY

a. Remove the 20 bolts, oil pan and gasket.

Fig. 73: Removing 20 Bolts, Oil Pan And Gasket

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Remove the 3 magnets from the oil pan.

Page 912 of 4500

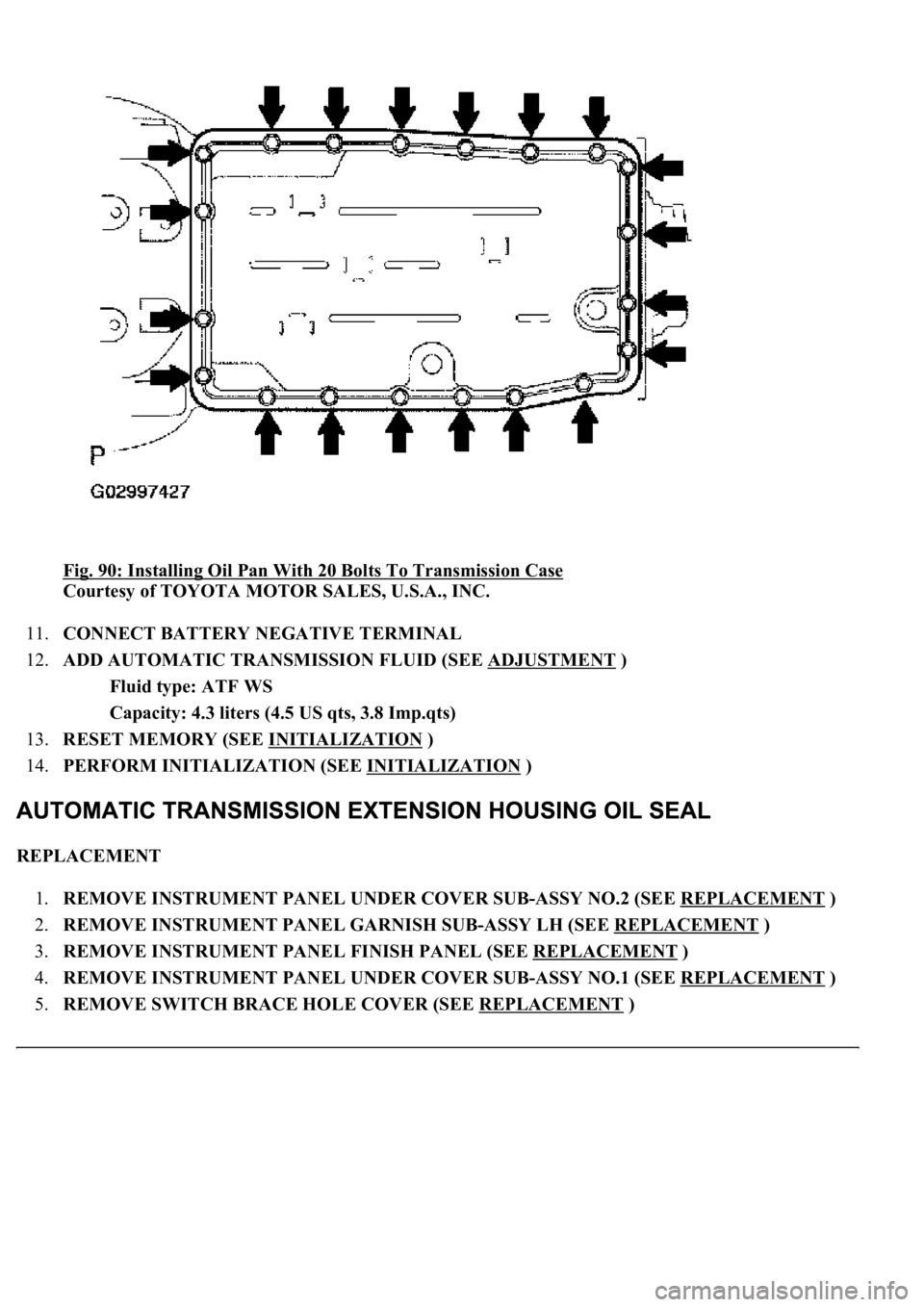

Fig. 90: Installing Oil Pan With 20 Bolts To Transmission Case

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

11.CONNECT BATTERY NEGATIVE TERMINAL

12.ADD AUTOMATIC TRANSMISSION FLUID (SEE ADJUSTMENT

)

Fluid type: ATF WS

Capacity: 4.3 liters (4.5 US qts, 3.8 Imp.qts)

13.RESET MEMORY (SEE INITIALIZATION

)

14.PERFORM INITIALIZATION (SEE INITIALIZATION

)

REPLACEMENT

1.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.2 (SEE REPLACEMENT

)

2.REMOVE INSTRUMENT PANEL GARNISH SUB-ASSY LH (SEE REPLACEMENT

)

3.REMOVE INSTRUMENT PANEL FINISH PANEL (SEE REPLACEMENT

)

4.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.1 (SEE REPLACEMENT

)

5.REMOVE SWITCH BRACE HOLE COVER (SEE REPLACEMENT

)

Page 913 of 4500

6.REMOVE INSTRUMENT PANEL SAFETY PAD SUB-ASSY NO.1 (SEE REPLACEMENT )

7.REMOVE INSTRUMENT PANEL CUP HOLDER ASSY (SEE REPLACEMENT

)

8.REMOVE CONSOLE UPPER REAR PANEL SUB-ASSY (SEE REPLACEMENT

)

9.REMOVE CONSOLE BOX CARPET (SEE REPLACEMENT

)

10.REMOVE REAR CONSOLE ARMREST ASSY (SEE REPLACEMENT

)

11.REMOVE INSTRUMENT PANEL FINISH PANEL LOWER CENTER (SEE REPLACEMENT

)

12.REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB-ASSY CENTER (SEE

REPLACEMENT

)

13.REMOVE CONSOLE PANEL SUB-ASSY UPPER (SEE REPLACEMENT

)

14.REMOVE CONSOLE BOX (SEE REPLACEMENT

)

15.SEPARATE OXYGEN SENSOR (SEE REPLACEMENT

)

16.REMOVE EXHAUST PIPE ASSY (SEE REPLACEMENT

)

17.REMOVE PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

18.DRAIN AUTOMATIC TRANSMISSION FLUID

a. Remove the drain plug, gasket and drain the ATF.

b. Install a new gasket and the drain plug.

Torque: 20 N.m (205 kgf.cm, 15 ft.lbf)

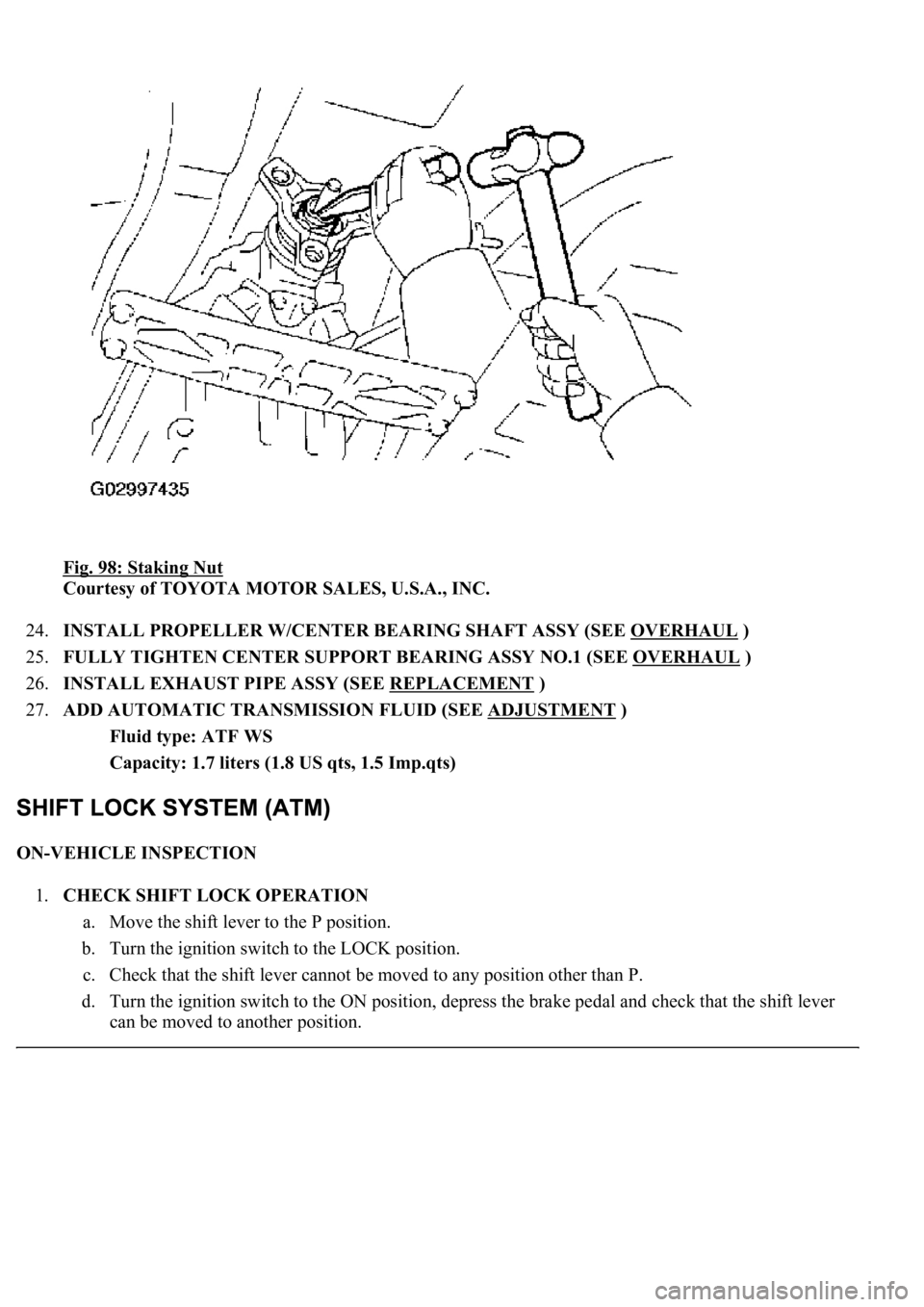

19.REMOVE AUTOMATIC TRANSMISSION FLANGE YOKE ASSY

a. Using SST and a hammer, loosen the staked part of the nut.

SST 09930-00010

HINT:

Move the shift lever to the P position.

Page 921 of 4500

Fig. 98: Staking Nut

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

24.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

25.FULLY TIGHTEN CENTER SUPPORT BEARING ASSY NO.1 (SEE OVERHAUL

)

26.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

27.ADD AUTOMATIC TRANSMISSION FLUID (SEE ADJUSTMENT

)

Fluid type: ATF WS

Capacity: 1.7 liters (1.8 US qts, 1.5 Imp.qts)

ON-VEHICLE INSPECTION

1.CHECK SHIFT LOCK OPERATION

a. Move the shift lever to the P position.

b. Turn the ignition switch to the LOCK position.

c. Check that the shift lever cannot be moved to any position other than P.

d. Turn the ignition switch to the ON position, depress the brake pedal and check that the shift lever

can be moved to another position.

Page 2414 of 4500

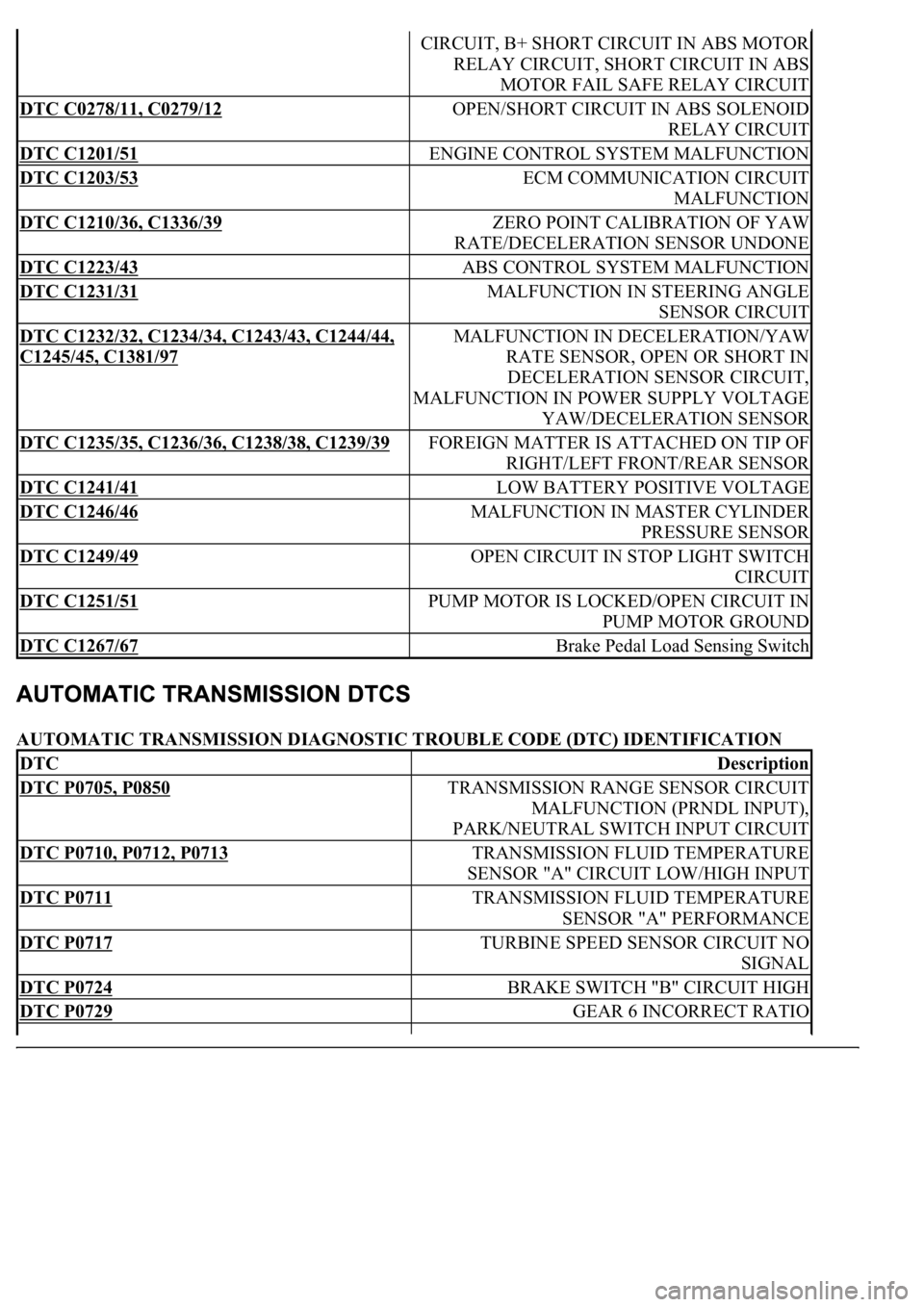

AUTOMATIC TRANSMISSION DIAGNOSTIC TROUBLE CODE (DTC) IDENTIFICATION

CIRCUIT, B+ SHORT CIRCUIT IN ABS MOTOR

RELAY CIRCUIT, SHORT CIRCUIT IN ABS

MOTOR FAIL SAFE RELAY CIRCUIT

DTC C0278/11, C0279/12 OPEN/SHORT CIRCUIT IN ABS SOLENOID

RELAY CIRCUIT

DTC C1201/51 ENGINE CONTROL SYSTEM MALFUNCTION

DTC C1203/53 ECM COMMUNICATION CIRCUIT

MALFUNCTION

DTC C1210/36, C1336/39 ZERO POINT CALIBRATION OF YAW

RATE/DECELERATION SENSOR UNDONE

DTC C1223/43 ABS CONTROL SYSTEM MALFUNCTION

DTC C1231/31 MALFUNCTION IN STEERING ANGLE

SENSOR CIRCUIT

DTC C1232/32, C1234/34, C1243/43, C1244/44,

C1245/45, C1381/97

MALFUNCTION IN DECELERATION/YAW

RATE SENSOR, OPEN OR SHORT IN

DECELERATION SENSOR CIRCUIT,

MALFUNCTION IN POWER SUPPLY VOLTAGE

YAW/DECELERATION SENSOR

DTC C1235/35, C1236/36, C1238/38, C1239/39 FOREIGN MATTER IS ATTACHED ON TIP OF

RIGHT/LEFT FRONT/REAR SENSOR

DTC C1241/41 LOW BATTERY POSITIVE VOLTAGE

DTC C1246/46 MALFUNCTION IN MASTER CYLINDER

PRESSURE SENSOR

DTC C1249/49 OPEN CIRCUIT IN STOP LIGHT SWITCH

CIRCUIT

DTC C1251/51 PUMP MOTOR IS LOCKED/OPEN CIRCUIT IN

PUMP MOTOR GROUND

DTC C1267/67 Brake Pedal Load Sensing Switch

DTCDescription

DTC P0705, P0850 TRANSMISSION RANGE SENSOR CIRCUIT

MALFUNCTION (PRNDL INPUT),

PARK/NEUTRAL SWITCH INPUT CIRCUIT

DTC P0710, P0712, P0713 TRANSMISSION FLUID TEMPERATURE

SENSOR "A" CIRCUIT LOW/HIGH INPUT

DTC P0711 TRANSMISSION FLUID TEMPERATURE

SENSOR "A" PERFORMANCE

DTC P0717 TURBINE SPEED SENSOR CIRCUIT NO

SIGNAL

DTC P0724 BRAKE SWITCH "B" CIRCUIT HIGH

DTC P0729 GEAR 6 INCORRECT RATIO