engine LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2676 of 4500

SYSTEM DESCRIPTION

1.SYSTEM DESCRIPTION

a. The ECT (Electronic controlled automatic transmission) is an automatic transmission that

electronically controls shift timing using the ECM. The ECM detects electrical signals that indicate

engine and driving conditions, and controls the shift point, based on driver habits and road

conditions. As a result, fuel efficiency and power transmission performance are improved.

<0036004b004c0049005700030056004b00520046004e0003004b00440056000300450048004800510003005500480047005800460048004700030045005c0003004600520051005700550052004f004f004c0051004a00030057004b004800030048005100

4a004c00510048000300440051004700030057005500440051[smission simultaneously. In

addition, the ECT has features such as follows:

Diagnostic function.

Fail-safe function when a malfunction occurs.

HOW TO PROCEED WITH TROUBLESHOOTING

HINT:

The ECM of this system is connected to the CAN and multiplex communication system. Therefore,

before starting troubleshooting, make sure to check that there is no trouble in the CAN and multiplex

communication system.

<0037004b00480003004b0044005100470010004b0048004f0047000300570048005600570048005500030046004400510003004500480003005800560048004700030044005700030056005700480053005600030016000f00030017000f00030019000f00

030044005100470003001c00110003[

1.Vehicle Brought to Workshop

2.Customer Problem Analysis (See CUSTOMER PROBLEM ANALYSIS CHECK

)

3.Connect the OBD II scan tool or hand-held tester to DLC3

4.Check and Clear DTCs and Freeze Frame Data (See DTC CHECK/CLEAR

)

5.Visual Inspection

6.Setting the Check Mode Diagnosis (See CHECK MODE PROCEDURE

)

7.Problem Symptom Confirmation (See ROAD TEST

)

Symptom does not occur: Go to step 8

Symptom occurs: Go to step 9

8.Symptom Simulation (See HOW TO PROCEED WITH TROUBLESHOOTING

)

9.DTC Check (See DTC CHECK/CLEAR

)

DTC is not output: Go to step 10

DTC is output: Go to step 17

10.Basic Inspection (See ADJUSTMENT

- AUTOMATIC TRANSMISSION FLUID ,

ADJUSTMENT

- PARK/NEUTRAL POSITION SWITCH ASSY and ADJUSTMENT -

FLOOR SHIFT ASSY

)

Page 2679 of 4500

a. D position test:

Shift into the D position and fully depress the accelerator pedal and check the following points.

1. Check up-shift operation.

Check that 1 --> 2,2 --> 3,3 --> 4,4 --> 5 and 5 --> 6th up-shifts take place, and that the shift

points conform to the automatic shift schedule (see SERVICE DATA

).

HINT:

6th and 5th Gear Up-shift Prohibition Control

Engine coolant temperature is 55 °C (131 °F) or less and vehicle speed is at 51 km/h

(32 mph) or less. 4th Gear Up-shift Prohibition Control

Engine coolant temperature is 47 °C (117 °F) or less and vehicle speed is at 49 km/h

(30 mph) or less. Lock-up Prohibition Control

Brake pedal is depressed.

Accelerator pedal is released.

<00280051004a004c005100480003004600520052004f0044005100570003005700480050005300480055004400570058005500480003004c00560003001900130003008300260003000b001400170013000300830029000c0003005200550003004f004800

560056001100030003[

2. Check for shift shock and slip.

Check for shock and slip at the 1 --> 2,2 --> 3, 3 --> 4, 4 --> 5 and 5 --> 6th up-shifts.

3. Check for abnormal noise and vibration.

Check for abnormal noise and vibration when up-shifting from 1 --> 2, 2 --> 3, 3 --> 4, 4 -->

5 and 5 --> 6 while driving with the shift lever in the D position, and also check while driving

in the lock-up condition.

HINT:

The check for the cause of abnormal noise and vibration must be done thoroughly as it could

also be due to loss of balance in the differential, torque converter clutch, etc.

4. Check kick-down operation.

<0026004b00480046004e000300590048004b004c0046004f004800030056005300480048004700560003005a004b0048005100030057004b004800030015005100470003005700520003001400560057000f00030016005500470003005700520003001500

510047000f000300170057004b000300570052000300160055[d, 5th to 4th, and 6th to 5th

kick-downs take place while driving with the shift lever in the D position. Confirm that each

speed is within the applicable vehicle speed range indicated in the automatic shift schedule

(see SERVICE DATA

).

5. Check for abnormal shock and slip at kic

k-down.

Page 2680 of 4500

6. Check the lock-up mechanism.

Drive in the D position (4th, 5th or 6th gear), at a steady speed (lock-up ON).

Lightly depress the accelerator pedal and check that the engine speed does not change

abruptly.

HINT:

There is no lock-up function in the 1st, 2nd and 3rd gears.

If there is a big jump in engine speed, there is no lock-up.

b. S position test

Shift to the S position, depress the accelerator pedal and check the following points:

1. Check shift operation.

While driving in the D position and 6th gear, shift into the S position and back to the D

position. Check that the gear change 6 --> 5 down-shift and 5 --> 6 up-shift can be

performed.

With the shift lever in the S position (while the vehicle is stopped), shift into the "+"

position to check that the shift position on the combination meter changes as follows: 1

--> 2, 2 --> 3, 3 --> 4, 4 --> 5 and 5 --> 6.

While driving in the 5(S) position and 4th gear (at a vehicle speed of approximately 55

to 65 km/h (34 to 40 mph)), shift into the "-" position and check if the 4th gear down-

shift occurs and the engine brake performs properly.

While driving in the 4(S) position and 4th gear (at a vehicle speed of approximately 30

to 40 km/h (19 to 25 mph)), shift into the "-" position and check if the 3rd gear down-

shift occurs and the engine brake performs properly.

While driving in the 3(S) position and 3rd gear (at a vehicle speed of approximately 20

to 30 km/h (12 to 19 mph)), shift into the "-" position and check if the 2nd gear down-

shift occurs and the engine brake performs properly.

<003a004b004c004f0048000300470055004c0059004c0051004a0003004c005100030057004b004800030015000b0036000c0003005300520056004c0057004c00520051000300440051004700030015005100470003004a0048004400550003000b004400

5700030044000300590048004b004c0046004f004800030056[peed of approximately 10

to 20 km/h (6 to 12 mph)), shift into the "-" position and check if the 1st gear down-

shift occurs and the engine brake performs properly.

HINT:

Manual shift (S position) is prohibited under either of the following conditions:

Down-shifting may cause engine overrun.

The driver continuously down-shifts. (Down-shifting to 1st gear may not be performed.)

c. R position test:

Shift into the R position, lightly depress the accelerator pedal, and check that the vehicle moves

backward without any abnormal noise or vibration.

Page 2681 of 4500

d. P position test:

Stop the vehicle on a grade (more than 5°) and after shifting into the P position, release the parking

brake. Then, check that the parking lock pawl holds the vehicle in place.

MECHANICAL SYSTEM TESTS

1.PERFORM MECHANICAL SYSTEM TESTS

a. Measure the stall speed.

The object of this test is to check the overall performance of the transmission and engine by

measuring the stall speeds in the D and R positions.

1. Chock the 4 wheels.

2. Connect an OBD II scan tool or hand-held tester to the DLC3.

3. Fully apply the parking brake.

4. Keep your left foot pressed firmly on the brake pedal.

5. Start the engine.

6. Shift into the D position. Press all the way down on the accelerator pedal with your right

foot.

7. Quickly read the stall speed at this time.

Stall speed: 2,400 +/- 150 rpm

8. Do the same test in the R position.

Stall speed: 2,400 +/- 150 rpm

Evaluation:

Page 2682 of 4500

Fig. 7: Mechanical Systems Problem Symptoms Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Measure the time lag.

1. When the shift lever is shifted while the engine is idling, there will be a certain time lapse or

lag before the shock can be felt. This is used for checking the condition of the direct clutch,

forward clutch, and 1st and reverse brake.

2. Connect an OBD II scan tool or hand-held tester to the DLC3.

3. Fully apply the parking brake.

4. Start and warm up the engine and check idle speed.

Idle speed: approx. 700 rpm (In N position and A/C OFF)

5. Shift the lever from N to D position. Using a stop watch, measure the time from when the

lever is shifted until the shock is felt.

Time lag: N --> D less than 1.2 seconds

6. In the same way, measure the time lag for N --> R.

Time lag: N --> R less than 1.5 seconds

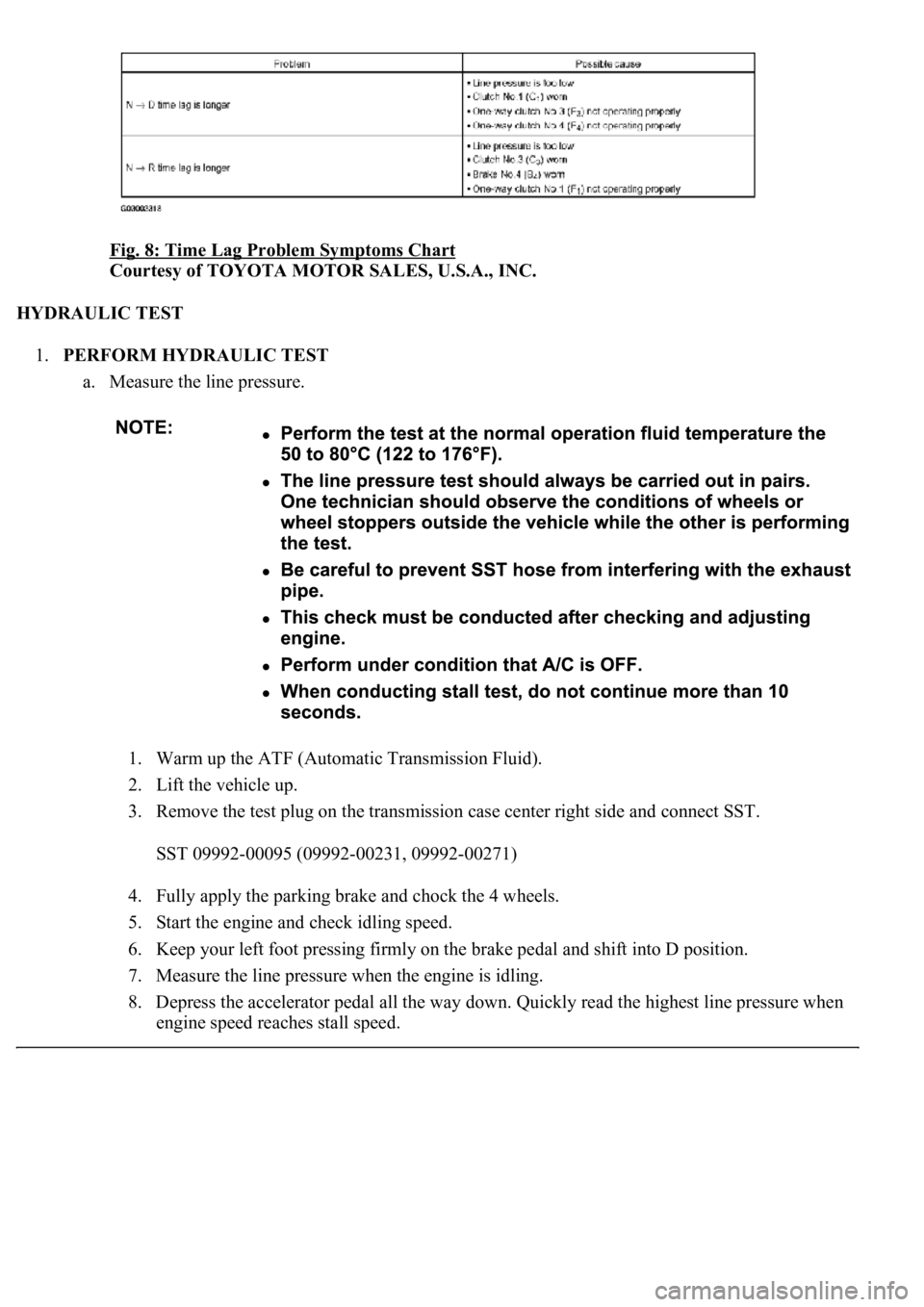

Evaluation (If N --> D or N --> R time lag is longer than the specified):

Page 2683 of 4500

Fig. 8: Time Lag Problem Symptoms Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HYDRAULIC TEST

1.PERFORM HYDRAULIC TEST

a. Measure the line pressure.

1. Warm up the ATF (Automatic Transmission Fluid).

2. Lift the vehicle up.

3. Remove the test plug on the transmission case center right side and connect SST.

SST 09992-00095 (09992-00231, 09992-00271)

4. Fully apply the parking brake and chock the 4 wheels.

5. Start the engine and check idling speed.

6. Keep your left foot pressing firmly on the brake pedal and shift into D position.

7. Measure the line pressure when the engine is idling.

8. Depress the accelerator pedal all the way down. Quickly read the highest line pressure when

en

gine speed reaches stall speed.

Page 2687 of 4500

HINT:

The ECM memorizes the condition that the ECT controls the automatic transmission assy and engine assy

according to those characteristics. Therefore, when the automatic transmission assy, engine assy, or ECM

has been replaced, it is necessary to reset the memory so that the ECM can memorize the new

information. Reset procedure is as follows.

a. Turn the ignition switch off.

b. Connect the hand-held tester together with the CAN VIM (controller area network vehicle interface

module) to the DLC3.

c. Turn the ignition switch to the ON position and push the hand-held tester main switch on.

d. Select the item "DIAGNOSIS/ENHANCED OBD II".

e. Perform the reset memory procedure from the ENGINE menu.

HINT:

The ECM is learned b

y performing the ROAD TEST.

Page 2695 of 4500

a. Perform this drive pattern as one method to simulate the detection conditions of the ECT

malfunctions. (The DTCs may not be detected due the actual driving conditions. And some codes

may not be detected through this drive pattern.)

HINT:

Preparation for driving

Warm up the engine sufficiently. (Engine coolant temperature is 60 °C (140 °F) or higher)

Drive the vehicle when the atmospheric temperature is -10 °C (14 °F) or higher. (Malfunction is not

detected when the atmospheric temperature is -10 °C (14 °F) or less)

Notice in driving

Drive the vehicle through all gears.

Stop --> 1st --> 2nd --> 3rd --> 4th --> 5th --> 6th --> 6th (lock-up ON).

Perform engine brake test in the S position.

While driving in the 6(S) position and 6th gear lock-up, shift into the "-" position and down-shift

<0049005500520050000300190057004b000300570052000300180057004b000f000300180057004b000300570052000300170057004b000f000300170057004b0003005700520003001600550047000f000300160055004700030057005200030015005100

47000f00030015005100470003005700520003001400560057[.

<0026004b00480046004e00030057004b0044005700030057004b0048000300480051004a004c005100480003004500550044004e00480003005300480055004900520055005000560003005300550052005300480055004f005c0003005a004b0048005100

48005900480055000300470052005a005100100056004b004c[ft takes place.

Repeat the above driving pattern three times or more.

Page 2704 of 4500

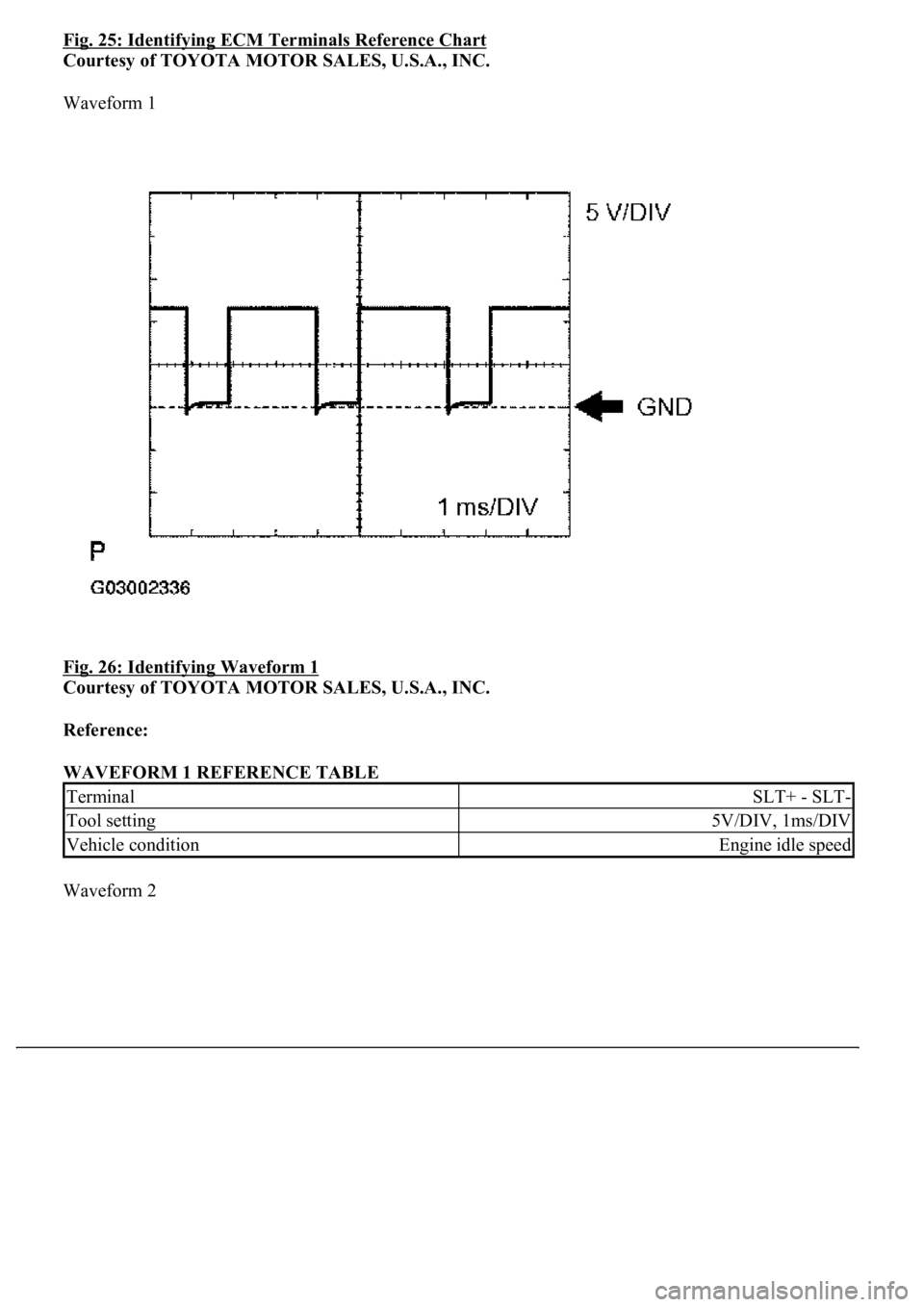

Fig. 25: Identifying ECM Terminals Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Waveform 1

Fig. 26: Identifying Waveform 1

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Reference:

WAVEFORM 1 REFERENCE TABLE

Waveform 2

TerminalSLT+ - SLT-

Tool setting5V/DIV, 1ms/DIV

Vehicle conditionEngine idle speed

Page 2706 of 4500

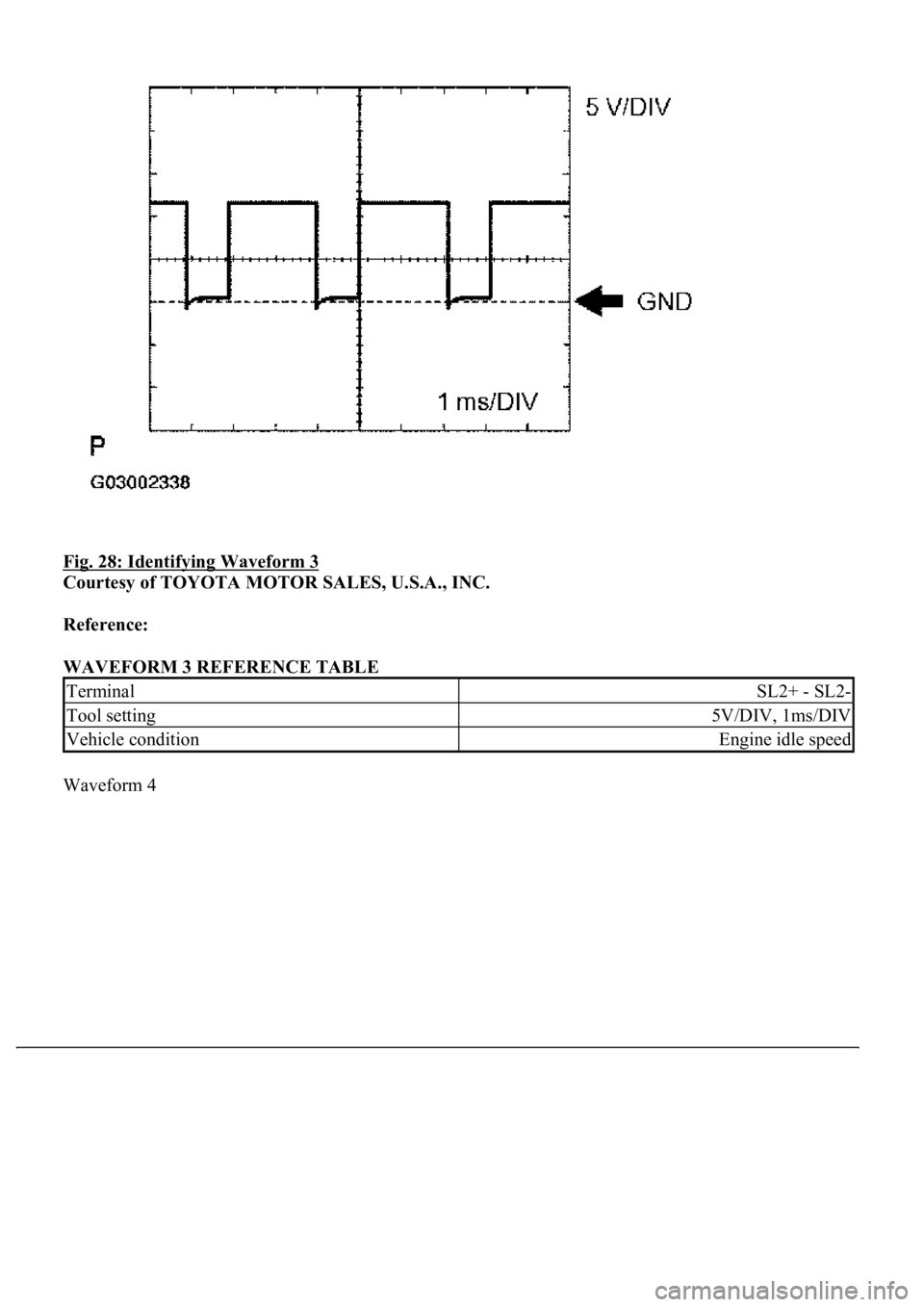

Fig. 28: Identifying Waveform 3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Reference:

WAVEFORM 3 REFERENCE TABLE

Waveform 4

TerminalSL2+ - SL2-

Tool setting5V/DIV, 1ms/DIV

Vehicle conditionEngine idle speed