LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Page 4116 of 4500

<0029004c004a001100030014001a001d0003003000480044005600580055004c0051004a0003003500480056004c0056005700440051004600480003002500480057005a00480048005100030037004800550050004c00510044004f005600030017000300

240051004700030018[

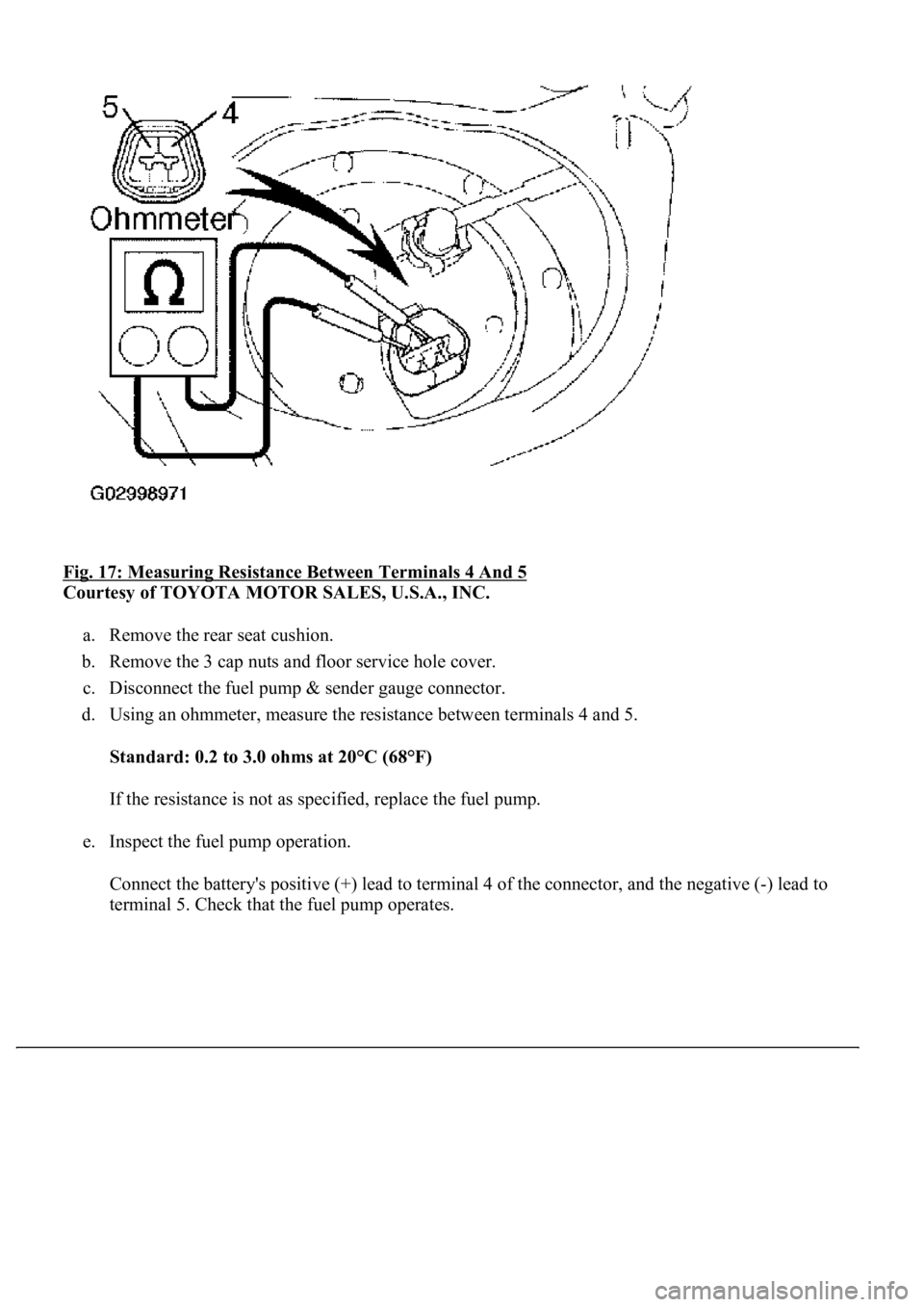

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Remove the rear seat cushion.

b. Remove the 3 cap nuts and floor service hole cover.

c. Disconnect the fuel pump & sender gauge connector.

d. Using an ohmmeter, measure the resistance between terminals 4 and 5.

Standard: 0.2 to 3.0 ohms at 20°C (68°F)

If the resistance is not as specified, replace the fuel pump.

e. Inspect the fuel pump operation.

Connect the battery's positive (+) lead to terminal 4 of the connector, and the negative (-) lead to

terminal 5. Check that the fuel pump operates.

Page 4120 of 4500

Fig. 21: Installing O-Ring To Injector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

g. Install a new O-ring to the injector.

h. Connect SST (union and hose) to the injector, and hold the injector and union with SST (clamp).

SST 09268-41047 (09268-41110, 09268-41300)

i. Put the injector into the graduated cylinder.

j. Connect the hand-held tester (with CAN VIM) to the DLC3.

k. Connect the battery negative (-) cable to the battery.

l. Turn the ignition switch ON and push the hand-held tester main switch ON.

m. Select the ACTIVE TEST mode on the hand-held tester.

n. Please refer to the han

d-held tester operator's manual for further details.

Page 4121 of 4500

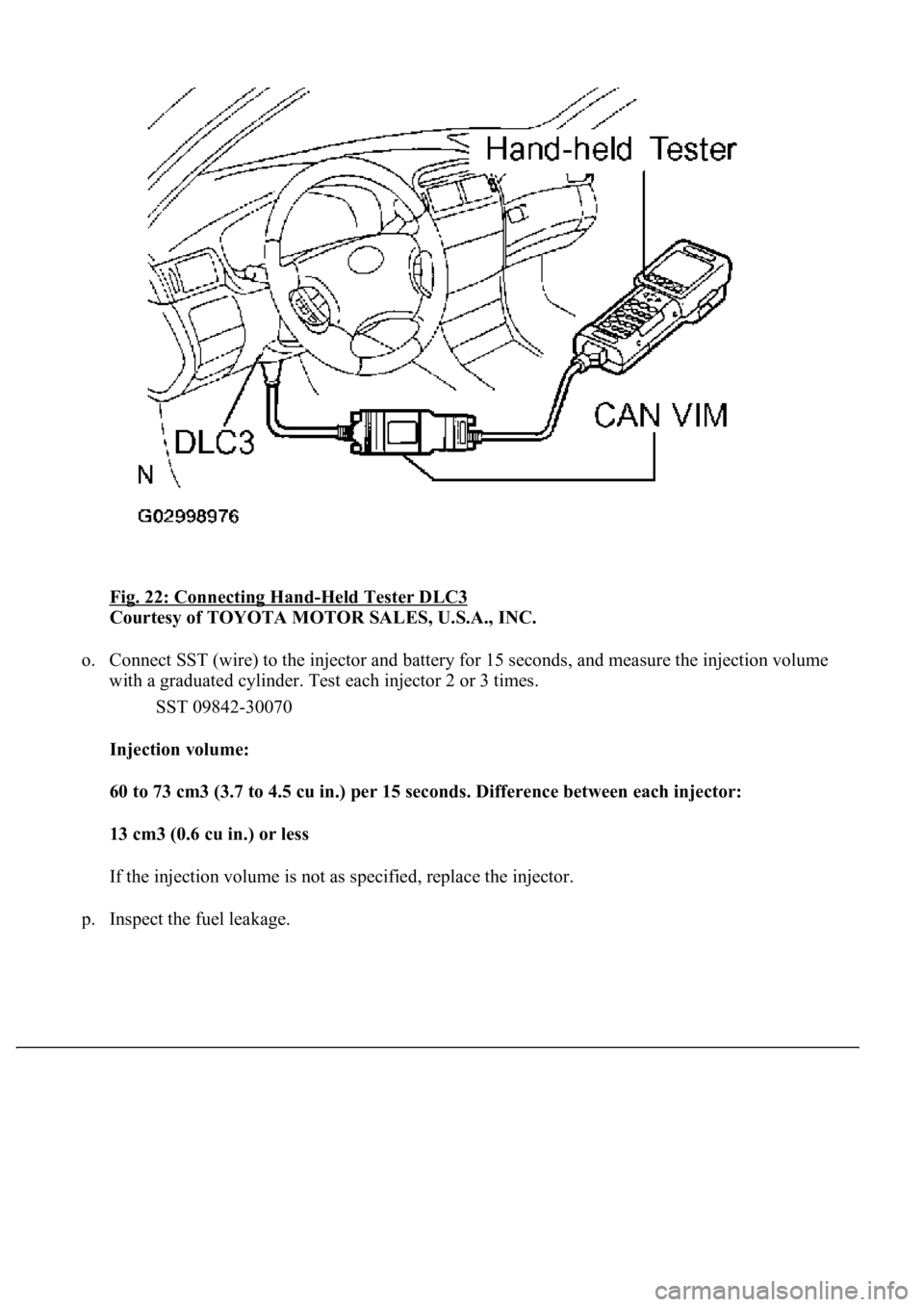

Fig. 22: Connecting Hand-Held Tester DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

o. Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume

with a graduated cylinder. Test each injector 2 or 3 times.

SST 09842-30070

Injection volume:

60 to 73 cm3 (3.7 to 4.5 cu in.) per 15 seconds. Difference between each injector:

13 cm3 (0.6 cu in.) or less

If the injection volume is not as specified, replace the injector.

p. Inspect the fuel leaka

ge.

Page 4122 of 4500

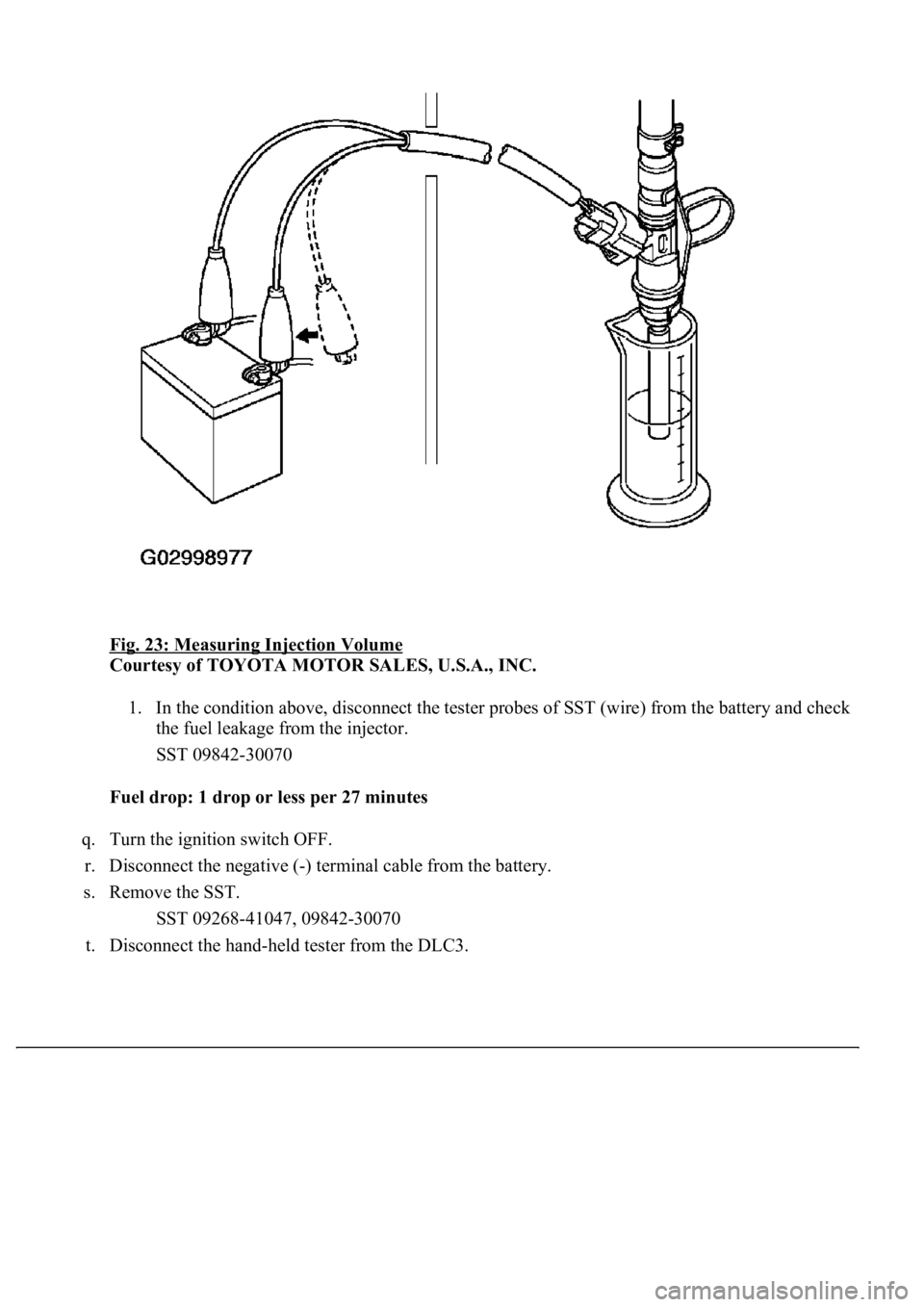

Fig. 23: Measuring Injection Volume

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1. In the condition above, disconnect the tester probes of SST (wire) from the battery and check

the fuel leakage from the injector.

SST 09842-30070

Fuel drop: 1 drop or less per 27 minutes

q. Turn the ignition switch OFF.

r. Disconnect the negative (-) terminal cable from the battery.

s. Remove the SST.

SST 09268-41047, 09842-30070

t. Disconnect the han

d-held tester from the DLC3.

Page 4124 of 4500

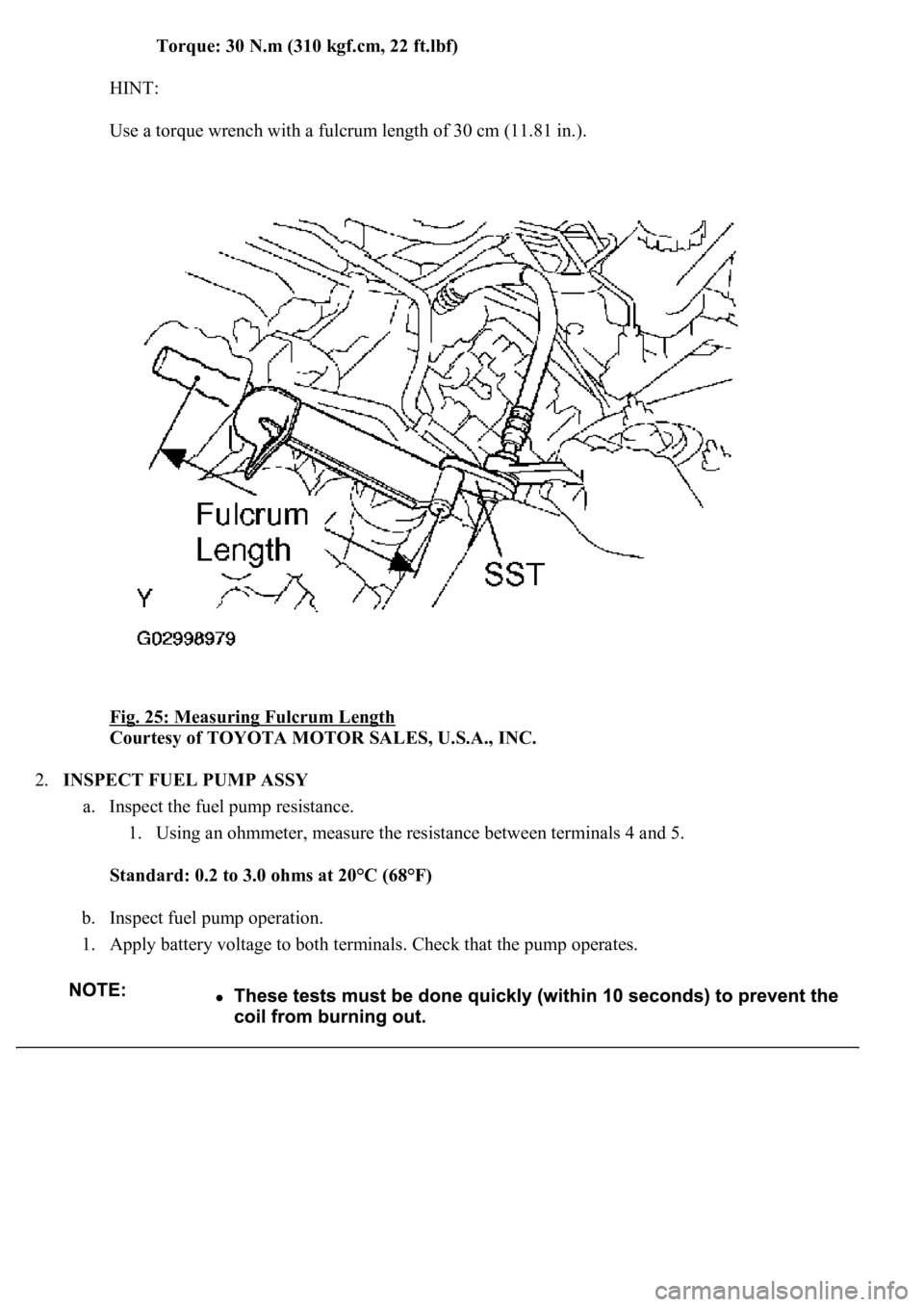

Torque: 30 N.m (310 kgf.cm, 22 ft.lbf)

HINT:

Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

Fig. 25: Measuring Fulcrum Length

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.INSPECT FUEL PUMP ASSY

a. Inspect the fuel pump resistance.

1. Using an ohmmeter, measure the resistance between terminals 4 and 5.

Standard: 0.2 to 3.0 ohms at 20°C (68°F)

b. Inspect fuel pump operation.

1. Apply battery voltage to both terminals. Check that the pump operates.

Page 4129 of 4500

REPLACEMENT

1.WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See PRECAUTION

)

2.DISCONNECT BATTERY NEGATIVE TERMINAL

3.REMOVE V-BANK COVER

a. Remove the 2 nuts and V-bank cover.

4.REMOVE AIR CLEANER INLET NO.1

5.REMOVE INTAKE AIR CONNECTOR PIPE

a. Disconnect the air hose and ventilation hose No. 1.

b. Loosen the hose clamp.

c. Remove the bolt and intake air connector pipe.

6.REMOVE V-BANK COVER BRACKET NO.1

7.REMOVE V-BANK COVER BRACKET NO.2

8.REMOVE V-BANK COVER BRACKET NO.3

9.REMOVE V-VANK COVER BRACKET NO.4

10.REMOVE VACUUM SWITCHING VALVE ASSY

11.DISCONNECT ENGINE WIRE

Page 4134 of 4500

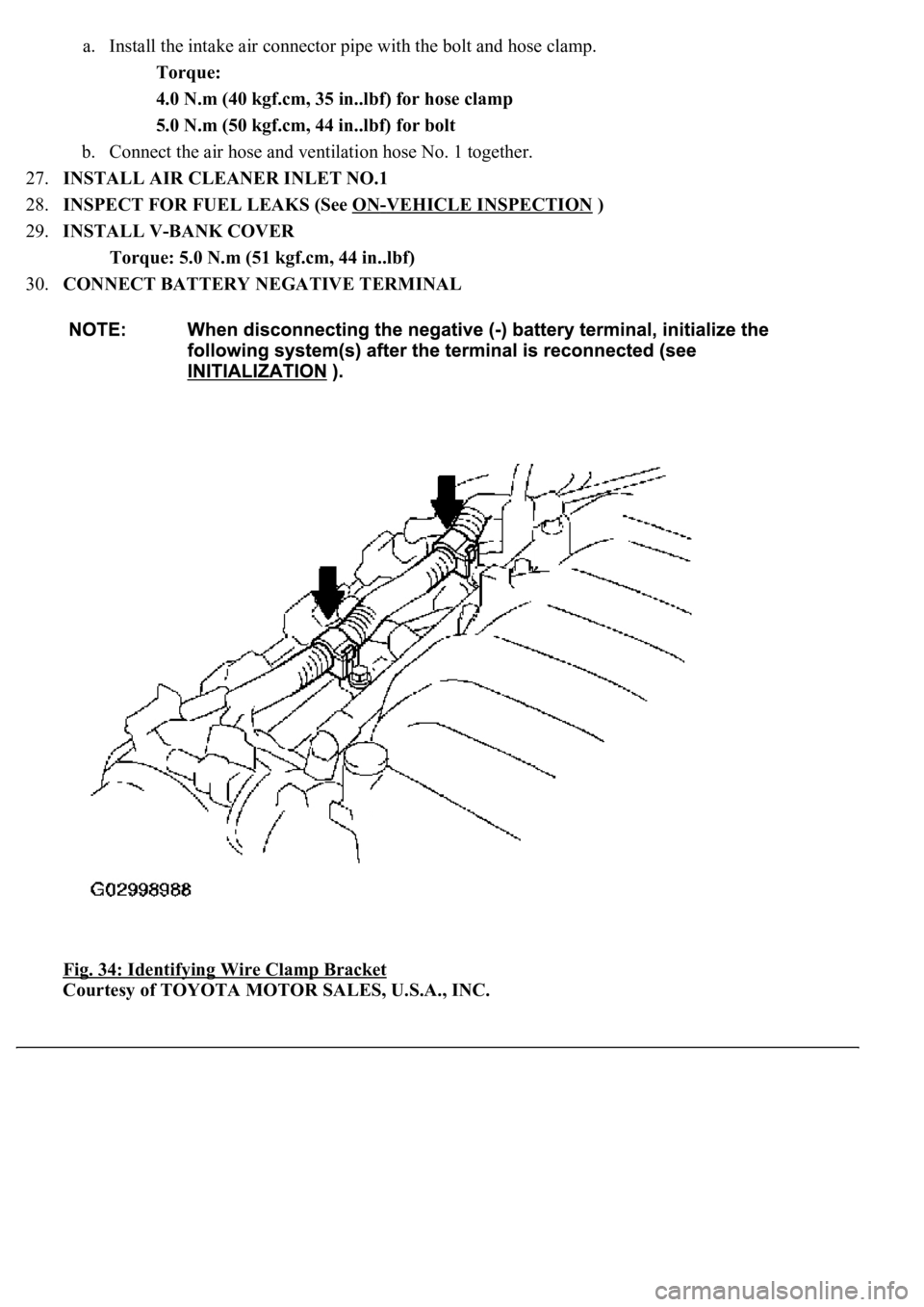

a. Install the intake air connector pipe with the bolt and hose clamp.

Torque:

4.0 N.m (40 kgf.cm, 35 in..lbf) for hose clamp

5.0 N.m (50 kgf.cm, 44 in..lbf) for bolt

b. Connect the air hose and ventilation hose No. 1 together.

27.INSTALL AIR CLEANER INLET NO.1

28.INSPECT FOR FUEL LEAKS (See ON

-VEHICLE INSPECTION )

29.INSTALL V-BANK COVER

Torque: 5.0 N.m (51 kgf.cm, 44 in..lbf)

30.CONNECT BATTERY NEGATIVE TERMINAL

Fig. 34: Identifying Wire Clamp Bracket

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 4137 of 4500

REPLACEMENT

1.WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See PRECAUTION

)

2.DISCONNECT BATTERY NEGATIVE TERMINAL

3.DRAIN FUEL (See PRECAUTION

)

4.REMOVE SEPARATE TYPE REAR SEAT CUSHION ASSY LH (SEPARATED TYPE REAR

SEAT) (See OVERHAUL

)

5.REMOVE BENCH TYPE REAR SEAT CUSHION ASSY (FIXED TYPE REAR SEAT) (See

OVERHAUL

)

6.REMOVE REAR FLOOR SERVICE HOLE COVER NO.2

a. Remove the 3 cap nuts and service hole cover.

7.REMOVE FUEL TANK MAIN TUBE SUB-ASSY

Page 4149 of 4500

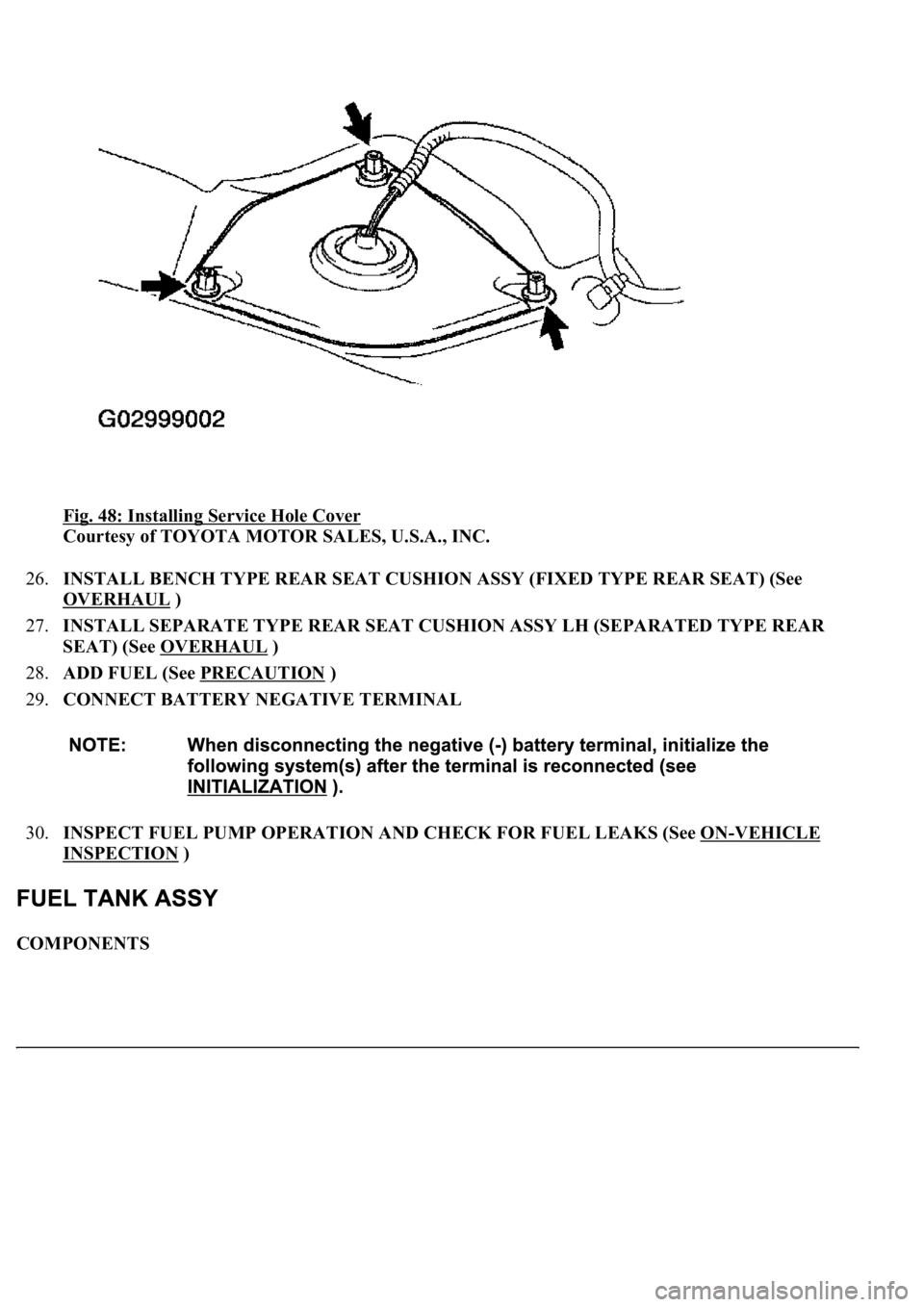

Fig. 48: Installing Service Hole Cover

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

26.INSTALL BENCH TYPE REAR SEAT CUSHION ASSY (FIXED TYPE REAR SEAT) (See

OVERHAUL

)

27.INSTALL SEPARATE TYPE REAR SEAT CUSHION ASSY LH (SEPARATED TYPE REAR

SEAT) (See OVERHAUL

)

28.ADD FUEL (See PRECAUTION

)

29.CONNECT BATTERY NEGATIVE TERMINAL

30.INSPECT FUEL PUMP OPERATION AND CHECK FOR FUEL LEAKS (See ON

-VEHICLE

INSPECTION )

COMPONENTS

Page 4151 of 4500

1.WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See PRECAUTION )

2.DISCONNECT BATTERY NEGATIVE TERMINAL

3.DRAIN FUEL (See PRECAUTION

)

4.REMOVE SEPARATE TYPE REAR SEAT CUSHION ASSY LH (SEPARATED TYPE REAR

SEAT) (See OVERHAUL

)

5.REMOVE BENCH TYPE REAR SEAT CUSHION ASSY (FIXED TYPE REAR SEAT) (See

OVERHAUL

)

6.REMOVE REAR FLOOR SERVICE HOLE COVER NO.2 (See REPLACEMENT

)

7.REMOVE FUEL TANK MAIN TUBE SUB-ASSY

a. Disconnect the connector in the fuel tank side.

1. Remove the tube joint clip.

2. Pull out the fuel main tube.

3. Plu

g the port of the fuel suction plate with a clean rubber cap.