battery LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 3990 of 4500

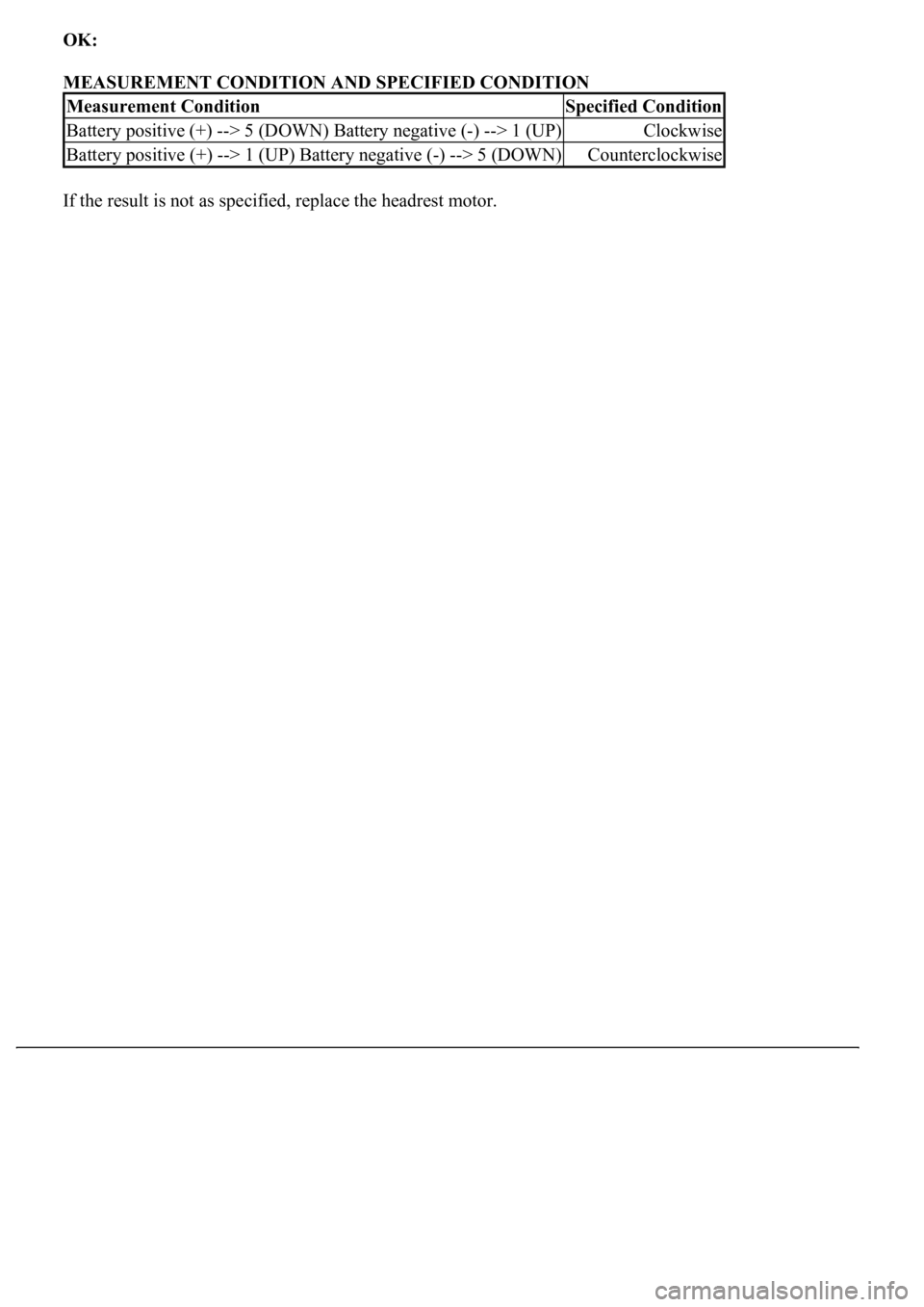

OK:

MEASUREMENT CONDITION AND SPECIFIED CONDITION

If the result is not as specified, replace the headrest motor.

Measurement ConditionSpecified Condition

Battery positive (+) --> 5 (DOWN) Battery negative (-) --> 1 (UP)Clockwise

Battery positive (+) --> 1 (UP) Battery negative (-) --> 5 (DOWN)Counterclockwise

Page 4082 of 4500

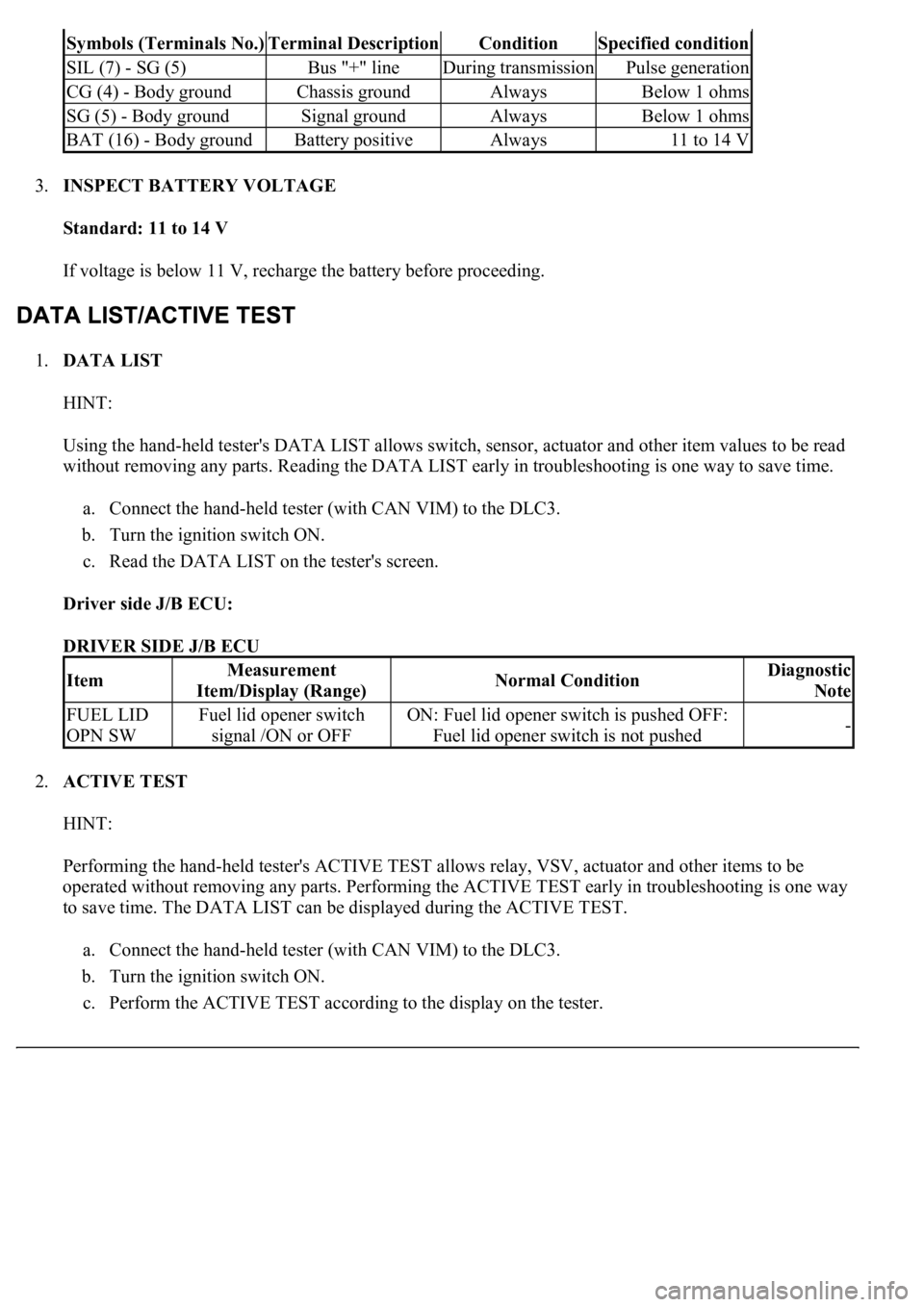

3.INSPECT BATTERY VOLTAGE

Standard: 11 to 14 V

If voltage is below 11 V, recharge the battery before proceeding.

1.DATA LIST

HINT:

Using the hand-held tester's DATA LIST allows switch, sensor, actuator and other item values to be read

without removing any parts. Reading the DATA LIST early in troubleshooting is one way to save time.

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON.

c. Read the DATA LIST on the tester's screen.

Driver side J/B ECU:

DRIVER SIDE J/B ECU

2.ACTIVE TEST

HINT:

Performing the hand-held tester's ACTIVE TEST allows relay, VSV, actuator and other items to be

operated without removing any parts. Performing the ACTIVE TEST early in troubleshooting is one way

to save time. The DATA LIST can be displayed during the ACTIVE TEST.

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON.

c. Perform the ACTIVE TEST accordin

g to the display on the tester.

Symbols (Terminals No.)Terminal DescriptionConditionSpecified condition

SIL (7) - SG (5)Bus "+" lineDuring transmissionPulse generation

CG (4) - Body groundChassis groundAlwaysBelow 1 ohms

SG (5) - Body groundSignal groundAlwaysBelow 1 ohms

BAT (16) - Body groundBattery positiveAlways11 to 14 V

ItemMeasurement

Item/Display (Range)Normal ConditionDiagnostic

Note

FUEL LID

OPN SWFuel lid opener switch

signal /ON or OFFON: Fuel lid opener switch is pushed OFF:

Fuel lid opener switch is not pushed-

Page 4085 of 4500

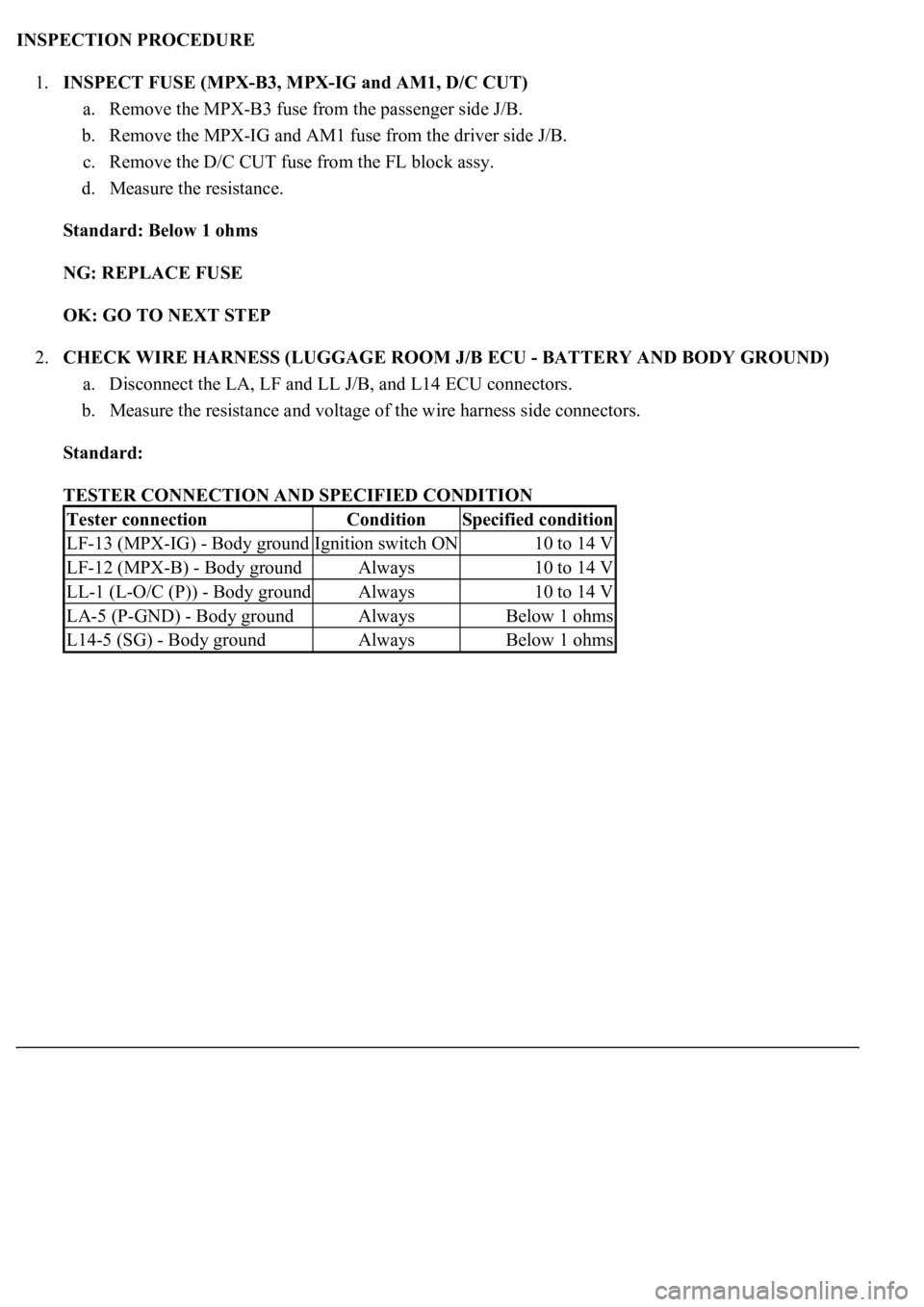

INSPECTION PROCEDURE

1.INSPECT FUSE (MPX-B3, MPX-IG and AM1, D/C CUT)

a. Remove the MPX-B3 fuse from the passenger side J/B.

b. Remove the MPX-IG and AM1 fuse from the driver side J/B.

c. Remove the D/C CUT fuse from the FL block assy.

d. Measure the resistance.

Standard: Below 1 ohms

NG: REPLACE FUSE

OK: GO TO NEXT STEP

2.CHECK WIRE HARNESS (LUGGAGE ROOM J/B ECU - BATTERY AND BODY GROUND)

a. Disconnect the LA, LF and LL J/B, and L14 ECU connectors.

b. Measure the resistance and voltage of the wire harness side connectors.

Standard:

TESTER CONNECTION AND SPECIFIED CONDITION

Tester connectionConditionSpecified condition

LF-13 (MPX-IG) - Body groundIgnition switch ON10 to 14 V

LF-12 (MPX-B) - Body groundAlways10 to 14 V

LL-1 (L-O/C (P)) - Body groundAlways10 to 14 V

LA-5 (P-GND) - Body groundAlwaysBelow 1 ohms

L14-5 (SG) - Body groundAlwaysBelow 1 ohms

Page 4093 of 4500

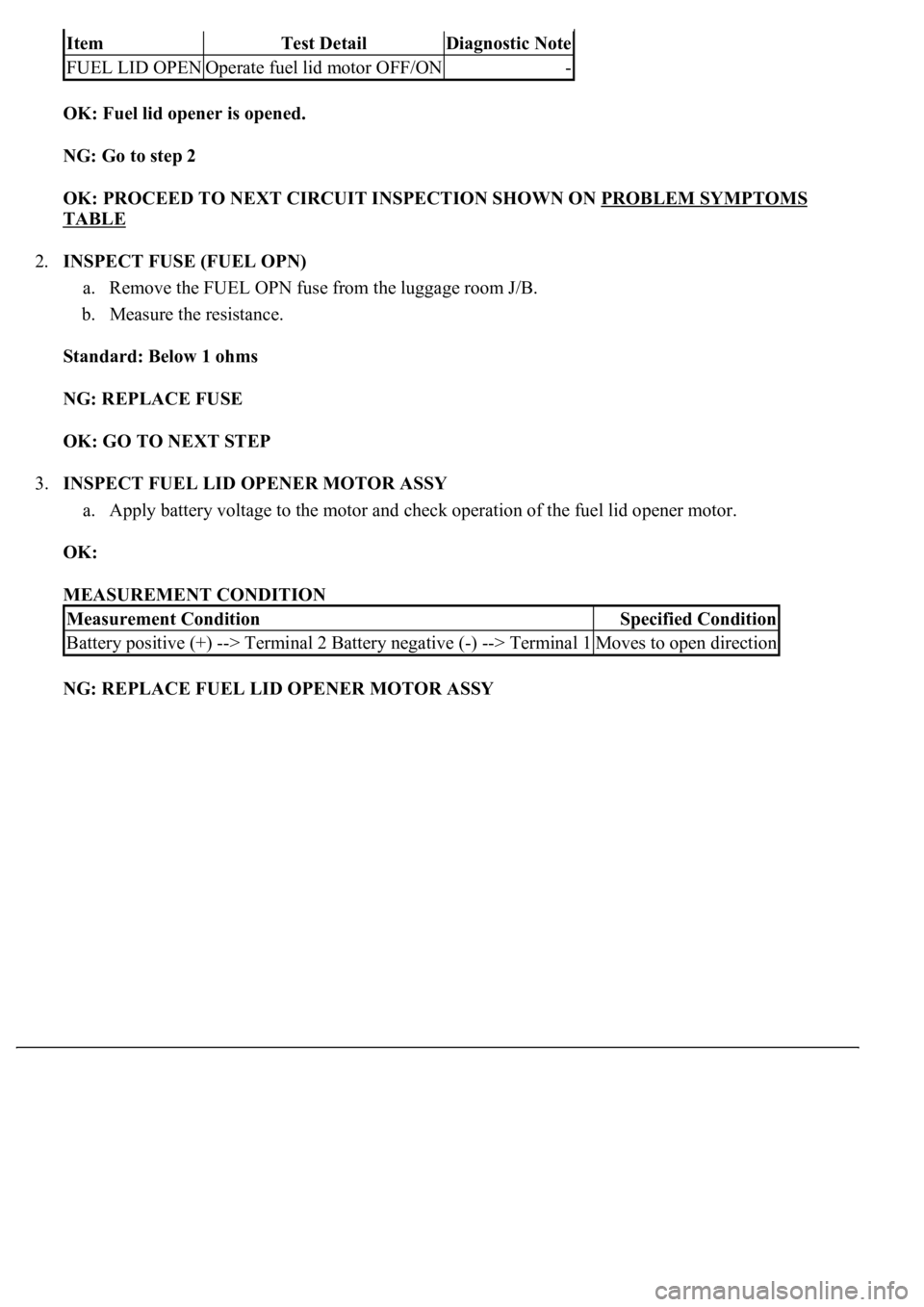

OK: Fuel lid opener is opened.

NG: Go to step 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN ON PROBLEM SYMPTOMS

TABLE

2.INSPECT FUSE (FUEL OPN)

a. Remove the FUEL OPN fuse from the luggage room J/B.

b. Measure the resistance.

Standard: Below 1 ohms

NG: REPLACE FUSE

OK: GO TO NEXT STEP

3.INSPECT FUEL LID OPENER MOTOR ASSY

a. Apply battery voltage to the motor and check operation of the fuel lid opener motor.

OK:

MEASUREMENT CONDITION

NG: REPLACE FUEL LID OPENER MOTOR ASSY

ItemTest DetailDiagnostic Note

FUEL LID OPENOperate fuel lid motor OFF/ON-

Measurement ConditionSpecified Condition

Battery positive (+) --> Terminal 2 Battery negative (-) --> Terminal 1Moves to open direction

Page 4098 of 4500

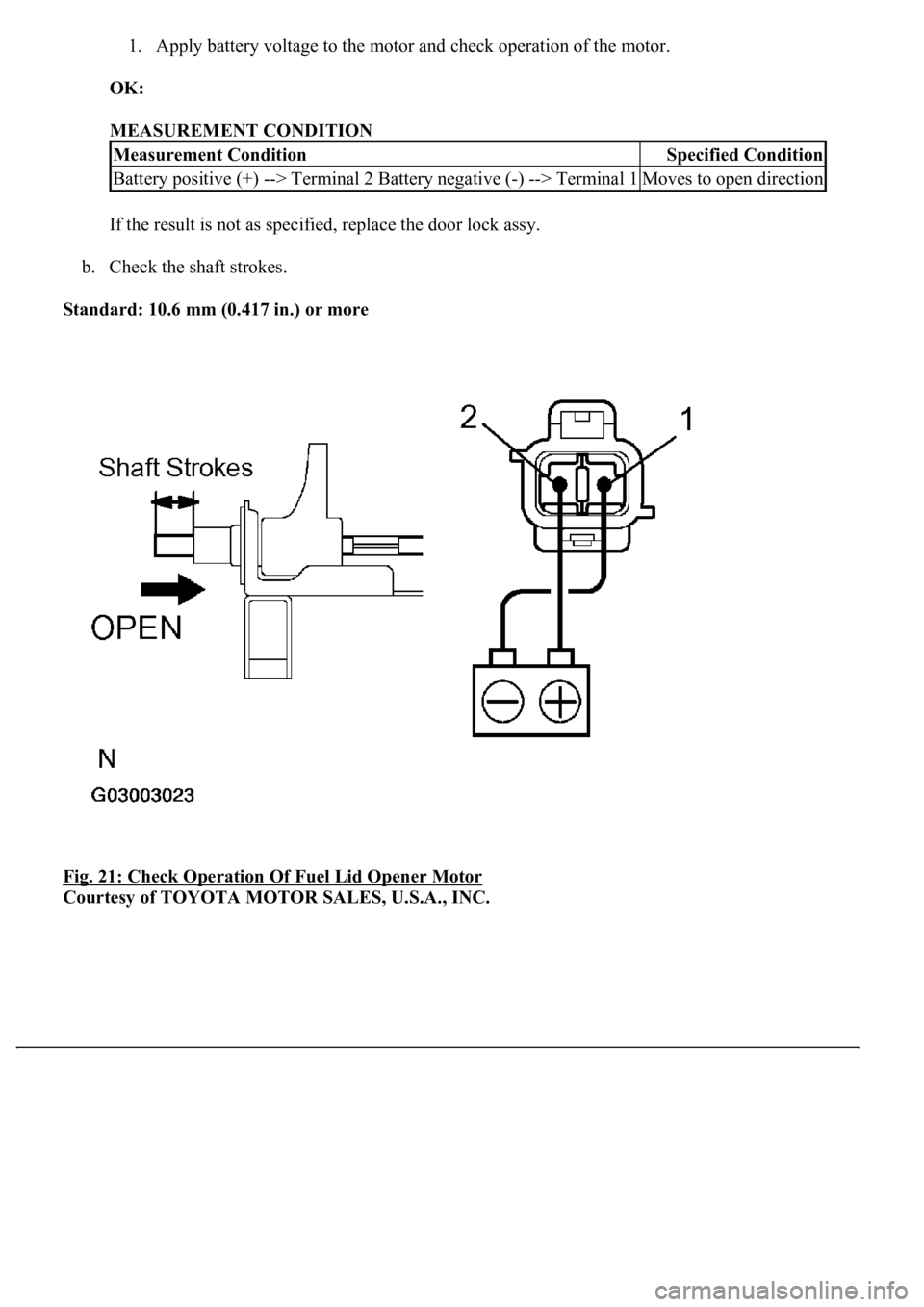

1. Apply battery voltage to the motor and check operation of the motor.

OK:

MEASUREMENT CONDITION

If the result is not as specified, replace the door lock assy.

b. Check the shaft strokes.

Standard: 10.6 mm (0.417 in.) or more

Fig. 21: Check Operation Of Fuel Lid Opener Motor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Measurement ConditionSpecified Condition

Battery positive (+) --> Terminal 2 Battery negative (-) --> Terminal 1Moves to open direction

Page 4102 of 4500

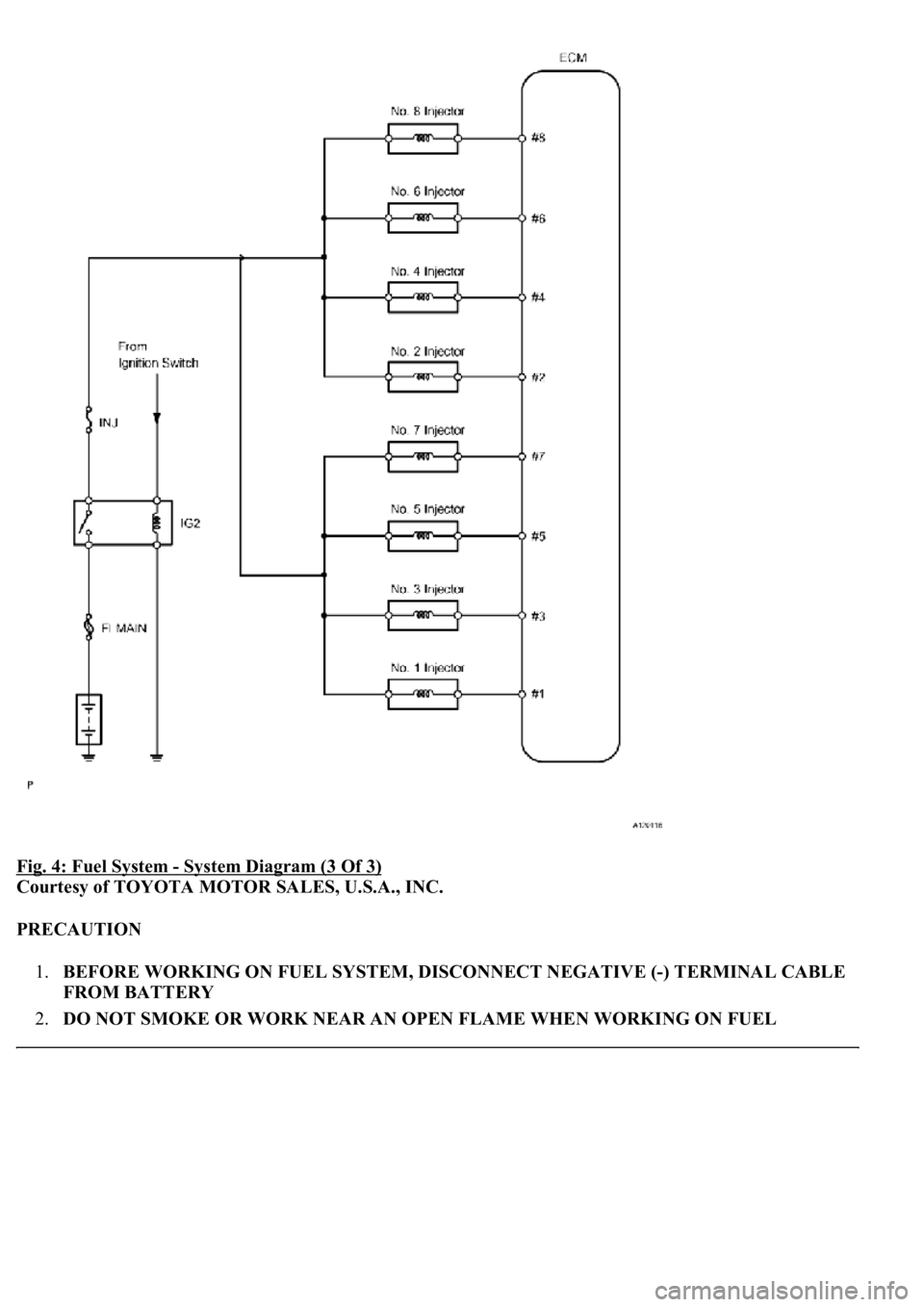

Fig. 4: Fuel System - System Diagram (3 Of 3)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

PRECAUTION

1.BEFORE WORKING ON FUEL SYSTEM, DISCONNECT NEGATIVE (-) TERMINAL CABLE

FROM BATTERY

2.DO NOT SMOKE OR WORK NEAR AN OPEN FLAME WHEN WORKING ON FUEL

Page 4103 of 4500

SYSTEM

3.KEEP GASOLINE AWAY FROM RUBBER AND LEATHER PARTS

4.DISCHARGE FUEL SYSTEM PRESSURE

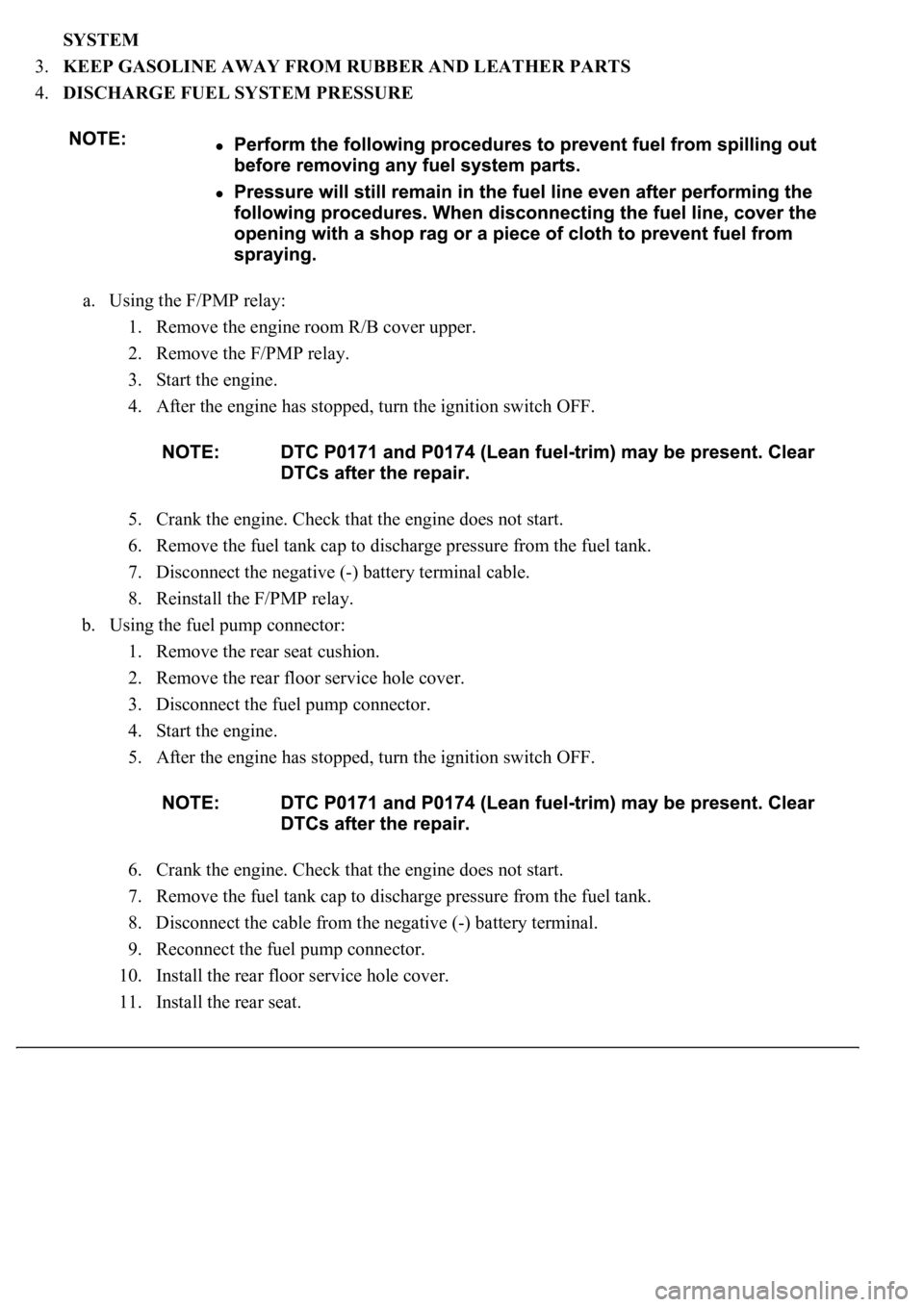

a. Using the F/PMP relay:

1. Remove the engine room R/B cover upper.

2. Remove the F/PMP relay.

3. Start the engine.

4. After the engine has stopped, turn the ignition switch OFF.

5. Crank the engine. Check that the engine does not start.

6. Remove the fuel tank cap to discharge pressure from the fuel tank.

7. Disconnect the negative (-) battery terminal cable.

8. Reinstall the F/PMP relay.

b. Using the fuel pump connector:

1. Remove the rear seat cushion.

2. Remove the rear floor service hole cover.

3. Disconnect the fuel pump connector.

4. Start the engine.

5. After the engine has stopped, turn the ignition switch OFF.

6. Crank the engine. Check that the engine does not start.

7. Remove the fuel tank cap to discharge pressure from the fuel tank.

8. Disconnect the cable from the negative (-) battery terminal.

9. Reconnect the fuel pump connector.

10. Install the rear floor service hole cover.

11. Install the rear seat.

Page 4113 of 4500

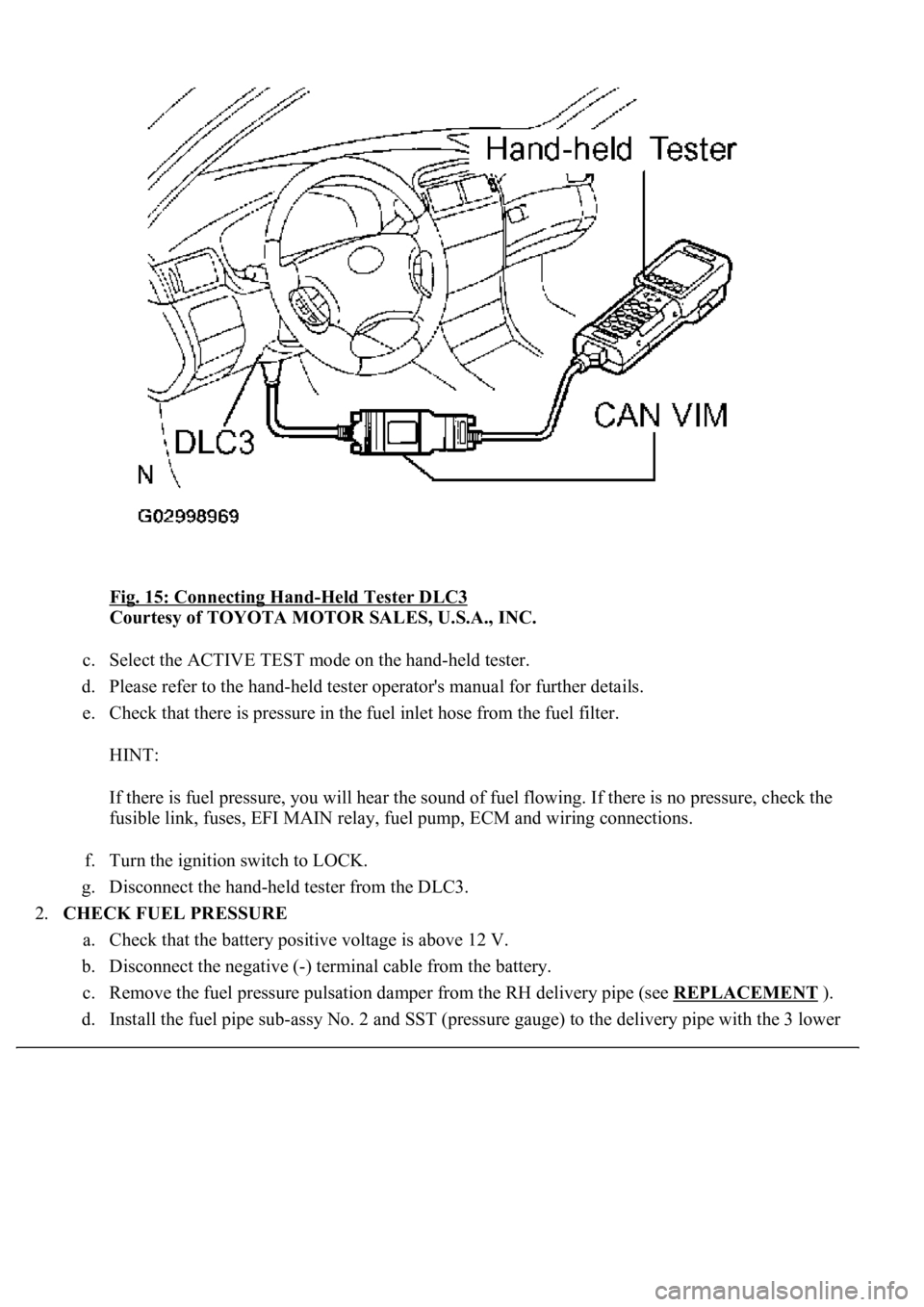

Fig. 15: Connecting Hand-Held Tester DLC3

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Select the ACTIVE TEST mode on the hand-held tester.

d. Please refer to the hand-held tester operator's manual for further details.

e. Check that there is pressure in the fuel inlet hose from the fuel filter.

HINT:

If there is fuel pressure, you will hear the sound of fuel flowing. If there is no pressure, check the

fusible link, fuses, EFI MAIN relay, fuel pump, ECM and wiring connections.

f. Turn the ignition switch to LOCK.

g. Disconnect the hand-held tester from the DLC3.

2.CHECK FUEL PRESSURE

a. Check that the battery positive voltage is above 12 V.

b. Disconnect the negative (-) terminal cable from the battery.

c. Remove the fuel pressure pulsation damper from the RH delivery pipe (see REPLACEMENT

).

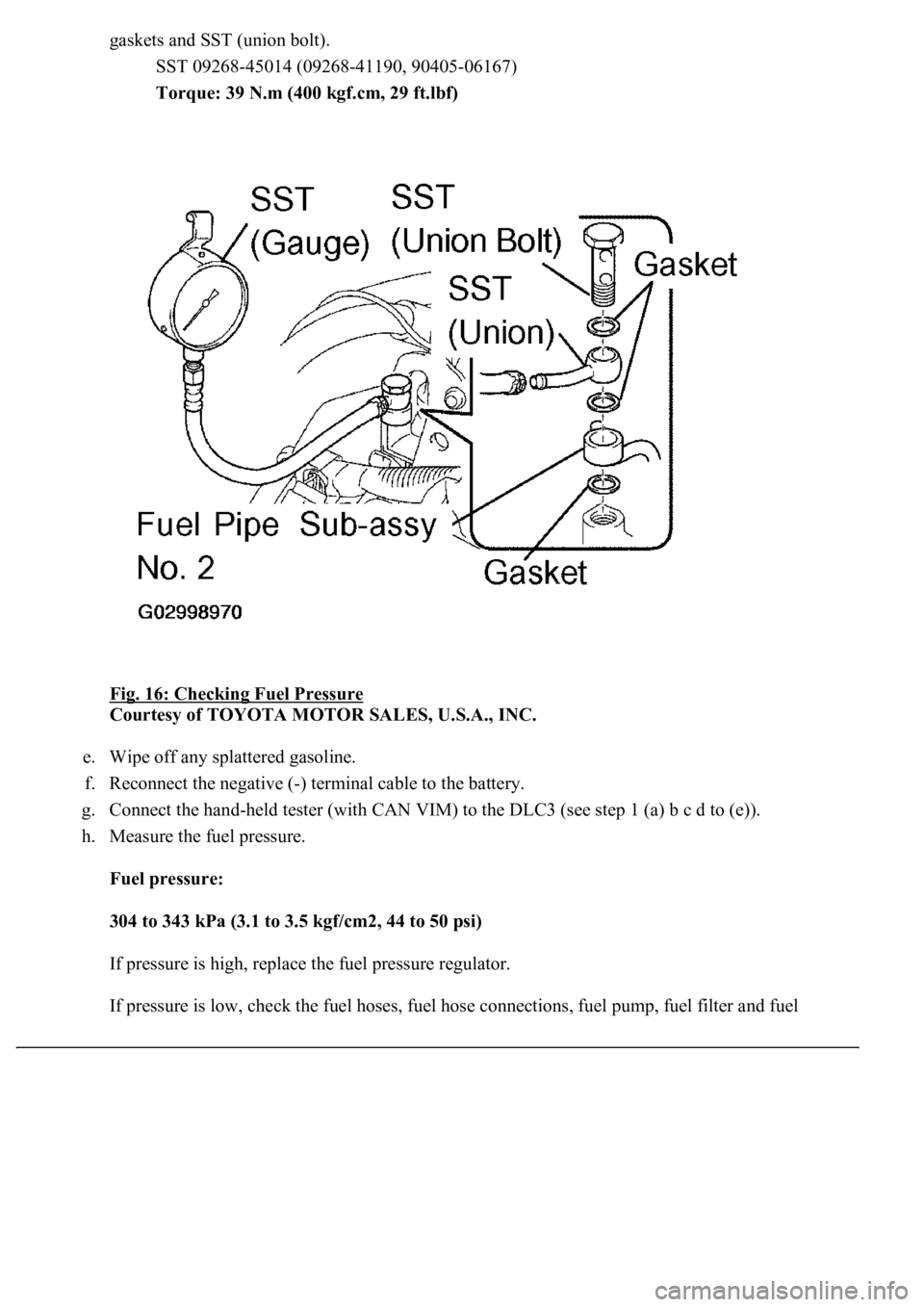

d. Install the fuel pipe sub-ass

y No. 2 and SST (pressure gauge) to the delivery pipe with the 3 lower

Page 4114 of 4500

gaskets and SST (union bolt).

SST 09268-45014 (09268-41190, 90405-06167)

Torque: 39 N.m (400 kgf.cm, 29 ft.lbf)

Fig. 16: Checking Fuel Pressure

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

e. Wipe off any splattered gasoline.

f. Reconnect the negative (-) terminal cable to the battery.

g. Connect the hand-held tester (with CAN VIM) to the DLC3 (see step 1 (a) b c d to (e)).

h. Measure the fuel pressure.

Fuel pressure:

304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the fuel hoses, fuel hose connections, fuel pump, fuel filter and fuel

Page 4115 of 4500

pressure regulator.

i. Disconnect the hand-held tester from the DLC3.

j. Start the engine.

k. Measure the fuel pressure at idle.

Fuel pressure: 304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi)

l. Stop the engine.

m. Check that the fuel pressure remains as specified for 5 minutes after the engine has stopped.

Fuel pressure: 147 kPa (1.5 kgf/cm2, 21 psi) or more

If pressure is not as specified, check the fuel pump, pressure regulator and/or injectors.

n. After checking fuel pressure, disconnect the negative (-) terminal cable from the battery and

carefully remove the SST to prevent gasoline from spilling.

SST 09268-45014

o. Reinstall the fuel pressure pulsation damper to the RH delivery pipe (see REPLACEMENT

).

p. Reconnect the negative (-) terminal cable to the battery.

q. Check for fuel leaks.

3.INSPECT FUEL PUMP