transmission oil LEXUS LS430 2003 Factory Owner's Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2635 of 4500

MISCELLANEOUS LOCATION

Rear LHIn left rear door. See Fig. 19 .

Door Lock Motor & Door Unlock Detection SW

Rear RHIn right rear door. See Fig. 19 .

Engine Hood Courtesy SWNear hood latch, on front center of engine

compartment. See Fig. 12

.

Head Rest Limit SW Rear LHIn rear seat assembly. See Fig. 32 .

Head Rest Limit SW Rear RHIn rear seat assembly. See Fig. 32 .

Luggage Compartment Door Key Unlock SWIn luggage compartment. See Fig. 28 .

Luggage Electrical Key SWIn luggage compartment decklid. See Fig. 28 .

Oil Pressure SwitchOn lower left front of engine. See Fig. 15 .

Parking Brake SwitchBehind left end of dash, on parking brake

mechanism. See Fig. 17

.

Park/Neutral Position SwitchOn right side of transmission. See Fig. 15 .

Power Seat Control SW (Rear Seat)Left side of rear seat. See Fig. 32 .

Pressure SwitchLower left side of dash. See Fig. 17 .

Rear Armrest Courtesy SWIn rear seat. See Fig. 32 .

Rear Sunshade SW (Rear)In center of rear seat. See Fig. 32 .

Stoplight SwitchAbove brake pedal, on bracket. See Fig. 18 .

ComponentLocation

A/C AmplifierIn luggage compartment. See Fig. 4 .

Airbag Squib (Front Passenger Airbag Assembly)Right side of dash. See Fig. 2 .

Airbag Squib (Steering Wheel Pad)In steering wheel. See Fig. 2 .

Curtain Shield Airbag Squib LHLeft "C" pillar. See Fig. 19 .

Curtain Shield Airbag Squib RHRight "C" pillar. See Fig. 19 .

Data Link Connector 3Below left side of dash. See Fig. 16 .

Door Oscillator Front LHIn left front door. See Fig. 19 .

Door Oscillator Front RHIn right front door. See Fig. 19 .

Door Oscillator Rear LHIn left rear door. See Fig. 19 .

Door Oscillator Rear RHIn right rear door. See Fig. 19 .

GeneratorRight front of engine. See Fig. 13 .

Horn (High)On center radiator support. See Fig. 13 .

Horn (Low)On center radiator support. See Fig. 13 .

Ignition Coil & Ignitor No. 1Above No. 1 spark plug. See Fig. 14 .

Ignition Coil & Ignitor No. 2Above No. 2 spark plug. See Fig. 14 .

Ignition Coil & Ignitor No. 3Above No. 3 spark plug. See Fig. 14 .

Ignition Coil & Ignitor No. 4Above No. 4 spark plug. See Fig. 14 .

Ignition Coil & Ignitor No. 5Above No. 5 spark plug. See Fig. 14 .

Ignition Coil & Ignitor No. 6Above No. 6 spark plug. See Fig. 14 .

Page 2740 of 4500

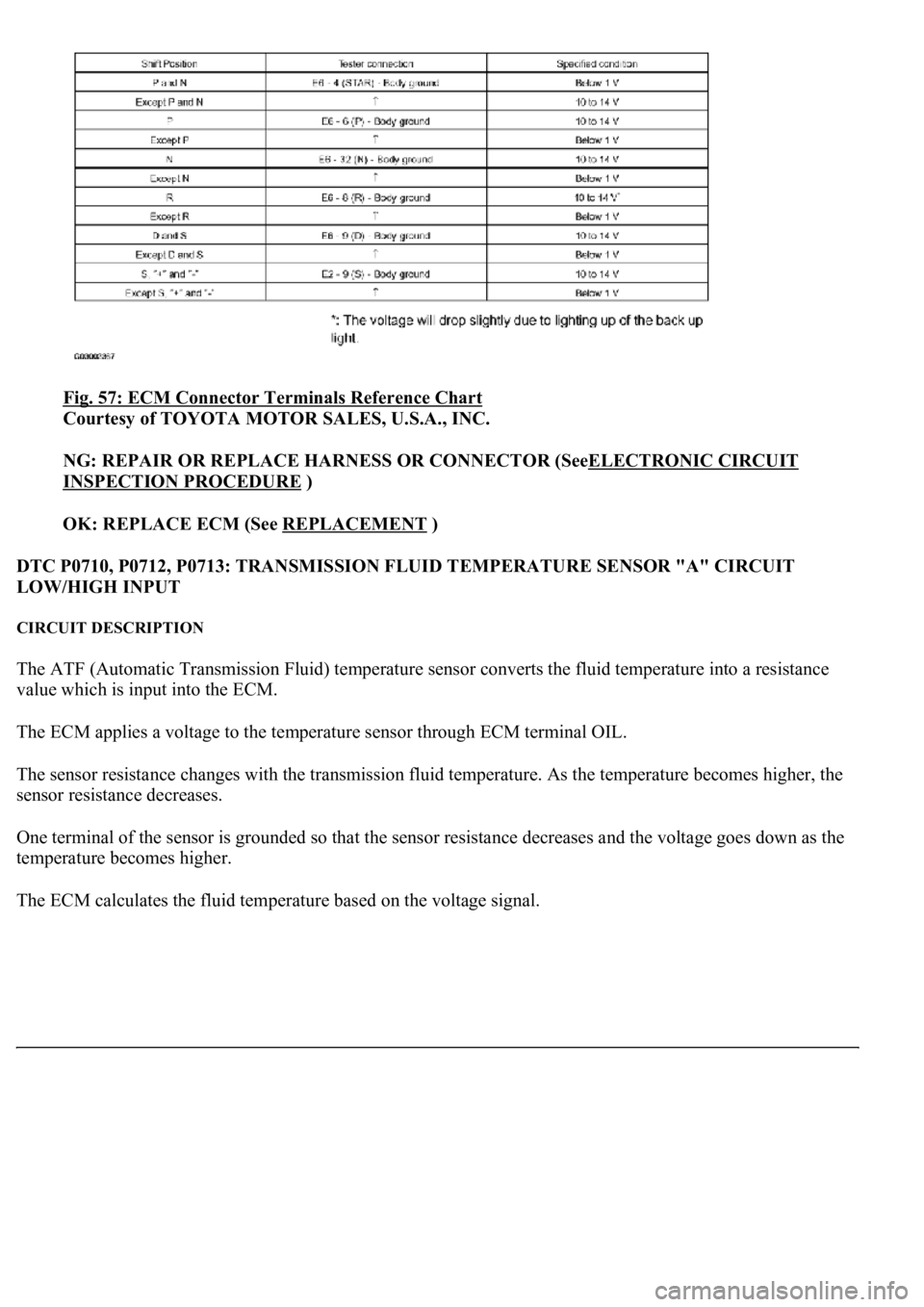

Fig. 57: ECM Connector Terminals Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (SeeELECTRONIC CIRCUIT

INSPECTION PROCEDURE )

OK: REPLACE ECM (See REPLACEMENT

)

DTC P0710, P0712, P0713: TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT

LOW/HIGH INPUT

CIRCUIT DESCRIPTION

The ATF (Automatic Transmission Fluid) temperature sensor converts the fluid temperature into a resistance

value which is input into the ECM.

The ECM applies a voltage to the temperature sensor through ECM terminal OIL.

The sensor resistance changes with the transmission fluid temperature. As the temperature becomes higher, the

sensor resistance decreases.

One terminal of the sensor is grounded so that the sensor resistance decreases and the voltage goes down as the

temperature becomes higher.

The ECM calculates the fluid temperature based on the volta

ge signal.

Page 2745 of 4500

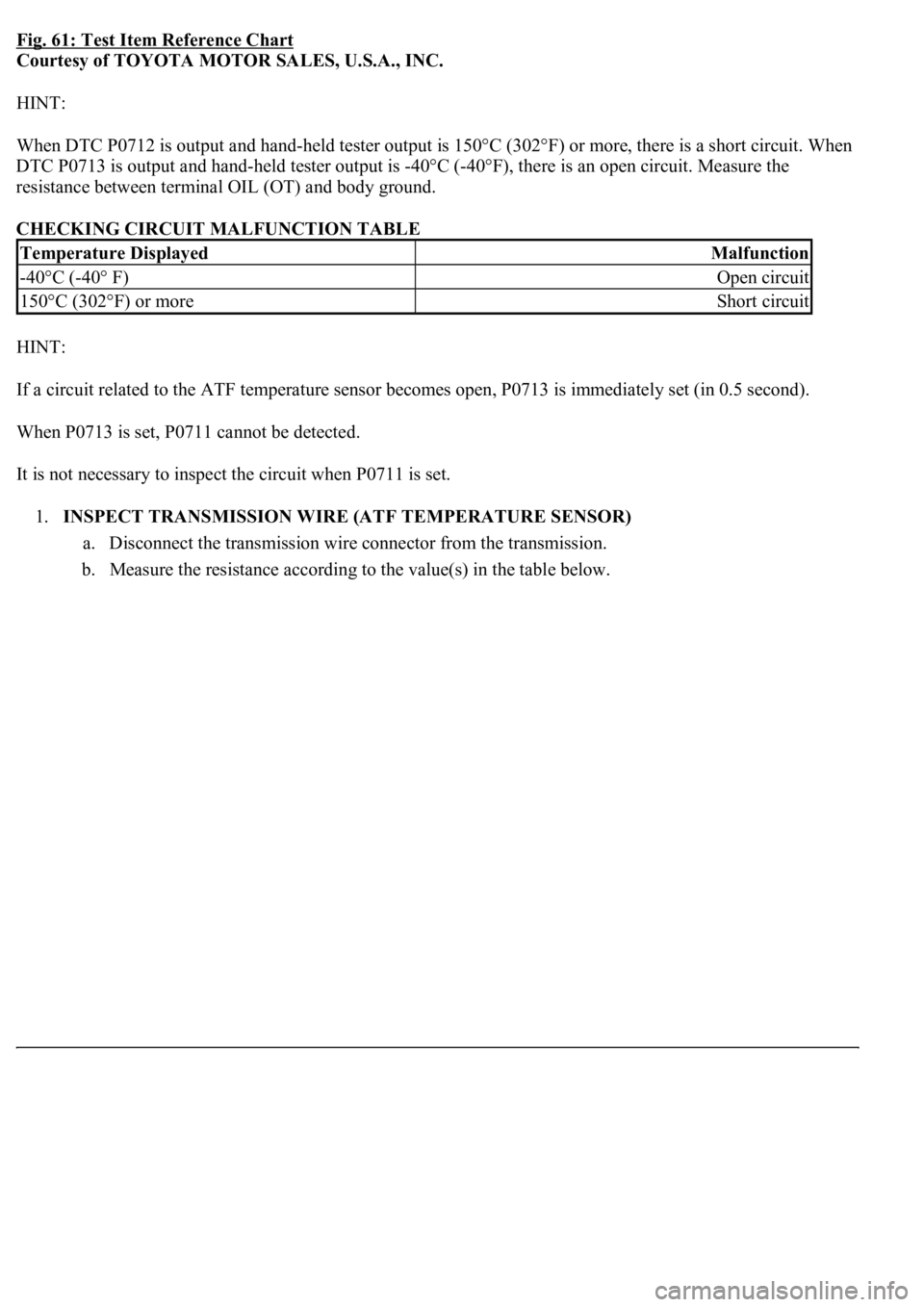

Fig. 61: Test Item Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

<003a004b004800510003002700370026000300330013001a001400150003004c0056000300520058005700530058005700030044005100470003004b0044005100470010004b0048004f004700030057004800560057004800550003005200580057005300

5800570003004c00560003001400180013008300260003000b[302°F) or more, there is a short circuit. When

DTC P0713 is output and hand-held tester output is -40°C (-40°F), there is an open circuit. Measure the

resistance between terminal OIL (OT) and body ground.

CHECKING CIRCUIT MALFUNCTION TABLE

HINT:

If a circuit related to the ATF temperature sensor becomes open, P0713 is immediately set (in 0.5 second).

When P0713 is set, P0711 cannot be detected.

It is not necessary to inspect the circuit when P0711 is set.

1.INSPECT TRANSMISSION WIRE (ATF TEMPERATURE SENSOR)

a. Disconnect the transmission wire connector from the transmission.

b. Measure the resistance according to the value(s) in the table below.

Temperature DisplayedMalfunction

-40°C (-40° F)Open circuit

150°C (302°F) or moreShort circuit

Page 2747 of 4500

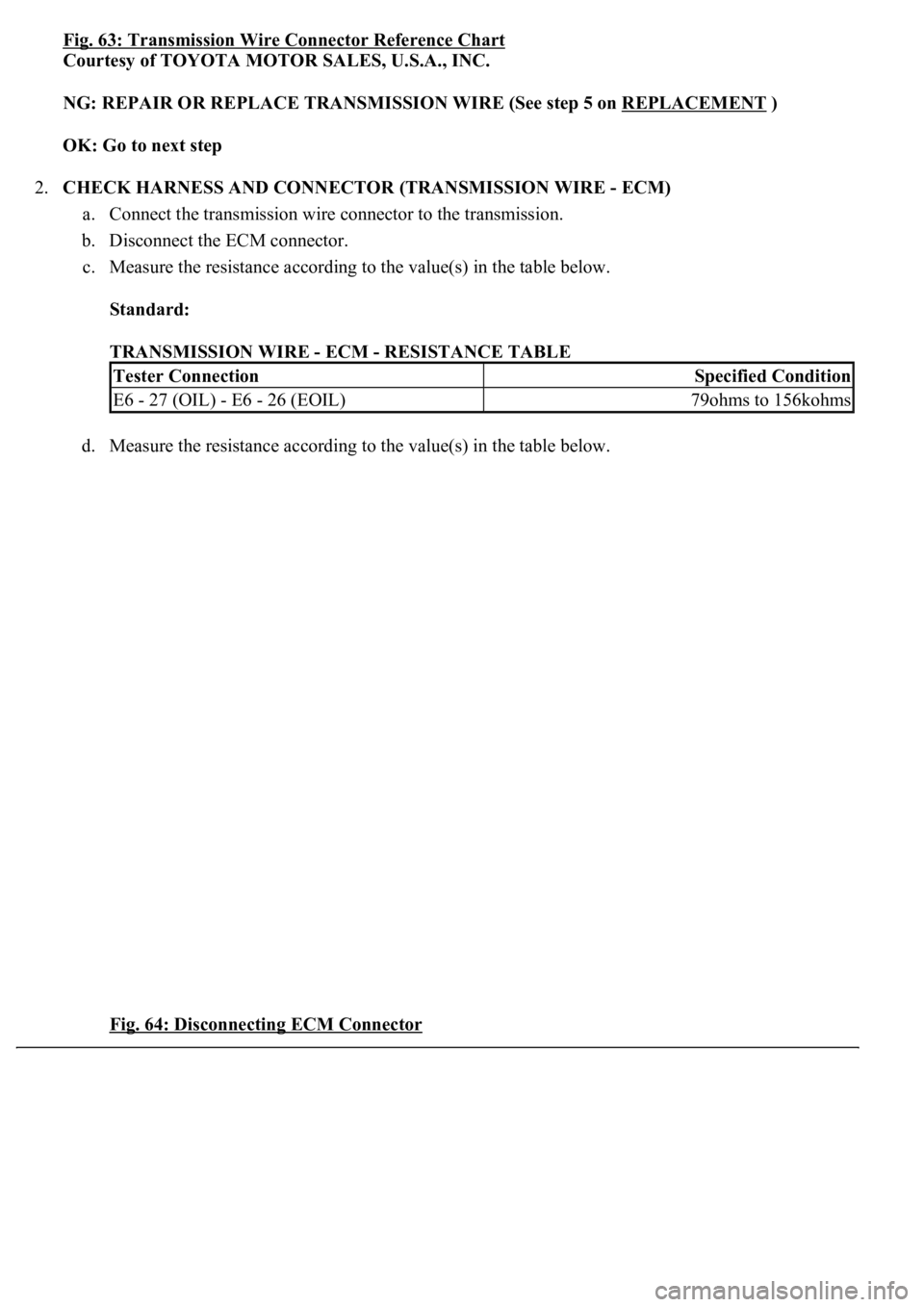

Fig. 63: Transmission Wire Connector Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE TRANSMISSION WIRE (See step 5 on REPLACEMENT

)

OK: Go to next step

2.CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

a. Connect the transmission wire connector to the transmission.

b. Disconnect the ECM connector.

c. Measure the resistance according to the value(s) in the table below.

Standard:

TRANSMISSION WIRE - ECM - RESISTANCE TABLE

d. Measure the resistance according to the value(s) in the table below.

Fig. 64: Disconnecting ECM Connector

Tester ConnectionSpecified Condition

E6 - 27 (OIL) - E6 - 26 (EOIL)79ohms to 156kohms

Page 2820 of 4500

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF" and switching oil pressure to

the valves in the valve body.

The ECM calculates the "actual" transmission gear by comparing the signals from the input speed sensor (NT)

and the output speed sensor (SP2). The ECM can detect many mechanical problems in the shift solenoids, valve

body, and the transmission clutches, brakes, and gears. If the ECM detects that the actual gear position and the

commanded gear position are different, it will illuminate the MIL and store the DTC.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below.

TYPICAL ENABLING CONDITIONS TABLE

Related DTCsP0781: Valve body/Rationality check

Required sensors/ComponentsValve body, Automatic transmission assembly

Frequency of operationContinuous

Duration<0026005200510047004c0057004c005200510003000b0024000c00030044005100470003000b0025000c00030013001100170003005600480046001100030026005200510047004c0057004c005200510003000b0026000c00030016000300560048004600

110003[

Condition (C) 1 sec.

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Turbine speed sensor circuitNot circuit malfunction

Output speed sensor circuitNot circuit malfunction

Shift solenoid valve S1 circuitNot circuit malfunction

Shift solenoid valve S2 circuitNot circuit malfunction

Shift solenoid valve S3 circuitNot circuit malfunction

Shift solenoid valve S4 circuitNot circuit malfunction

Shift solenoid valve SR circuitNot circuit malfunction

Shift solenoid valve SL1 circuitNot circuit malfunction

Shift solenoid valve SL2 circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

KCS sensor circuitNot circuit malfunction

ETCS (Electric throttle control system)Not system down

Transmission range"D"

ECT40°C (104°F) or more

Spark advance from Max. retard timing by KCS

control0° CA or more

EngineStarting

Page 3313 of 4500

13.DRAIN AUTOMATIC TRANSMISSION FLUID

14.REMOVE RADIATOR ASSY (See REPLACEMENT

)

15.DISCONNECT FUEL PIPE SUB-ASSY NO.2 (See REPLACEMENT

)

16.REMOVE FAN AND GENERATOR V BELT (See REPLACEMENT

)

17.DISCONNECT ENGINE WIRE

a. Disconnect the engine wire from the ECM box.

b. Remove the nut, and disconnect the generator wire from the generator.

c. Disconnect the wire for generator wire from the wire clamp on generator.

d. Remove the bolt, and disconnect the ground cable from the stay on the generator.

e. Remove the 2 bolts, and disconnect the PS oil hose from the No. 1 oil pan.

f. Remove the bolt, and disconnect the ground strap from the body.

18.DISCONNECT AIR HOSE NO.5

19.DISCONNECT FUEL VAPOR FEED HOSE NO.2

20.DISCONNECT HEATER WATER INLET HOSE A

21.DISCONNECT HEATER WATER OUTLET HOSE A (FROM HEATER UNIT)

22.DISCONNECT VANE PUMP OIL RESERVOIR ASSY

23.DISCONNECT VANE PUMP ASSY

a. Disconnect the 2 PS air hoses.

b. Remove the 2 screws and RH engine under cover.

c. Disconnect the PS oil pressure switch connector.

d. Remove the 2 bolts and nut, and disconnect the pump from the engine.

e. Support the pump securely.

24.DISCONNECT COOLER COMPRESSOR ASSY

a. Disconnect the compressor connector.

b. Disconnect the wire clamp from the wire bracket on the compressor.

c. Remove the bolt, nut and stay.

d. Remove the bolt, and disconnect the wire bracket from the compressor.

e. Remove the bolt, and disconnect the compressor from the engine.

f. Support the cooler compressor securely.

25.REMOVE FRONT FLOOR BRACE CENTER

a. Remove the 4 bolts and brace center.

26.REMOVE EXHAUST PIPE ASSY (See REPLACEMENT

)

27.REMOVE W/ CATALYST CONVERTER ASSY

28.REMOVE FRONT FLOOR HEAT INSULATOR NO.1

29.REMOVE PARKING BRAKE CABLE HEAT INSULATOR

30.REMOVE PROPELLER W/ CENTER BEARING SHAFT ASSY (See OVERHAUL

)

31.REMOVE FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSY

32.REMOVE STEERING SLIDING W/ SHAFT YOKE SUB-ASSY

Page 3318 of 4500

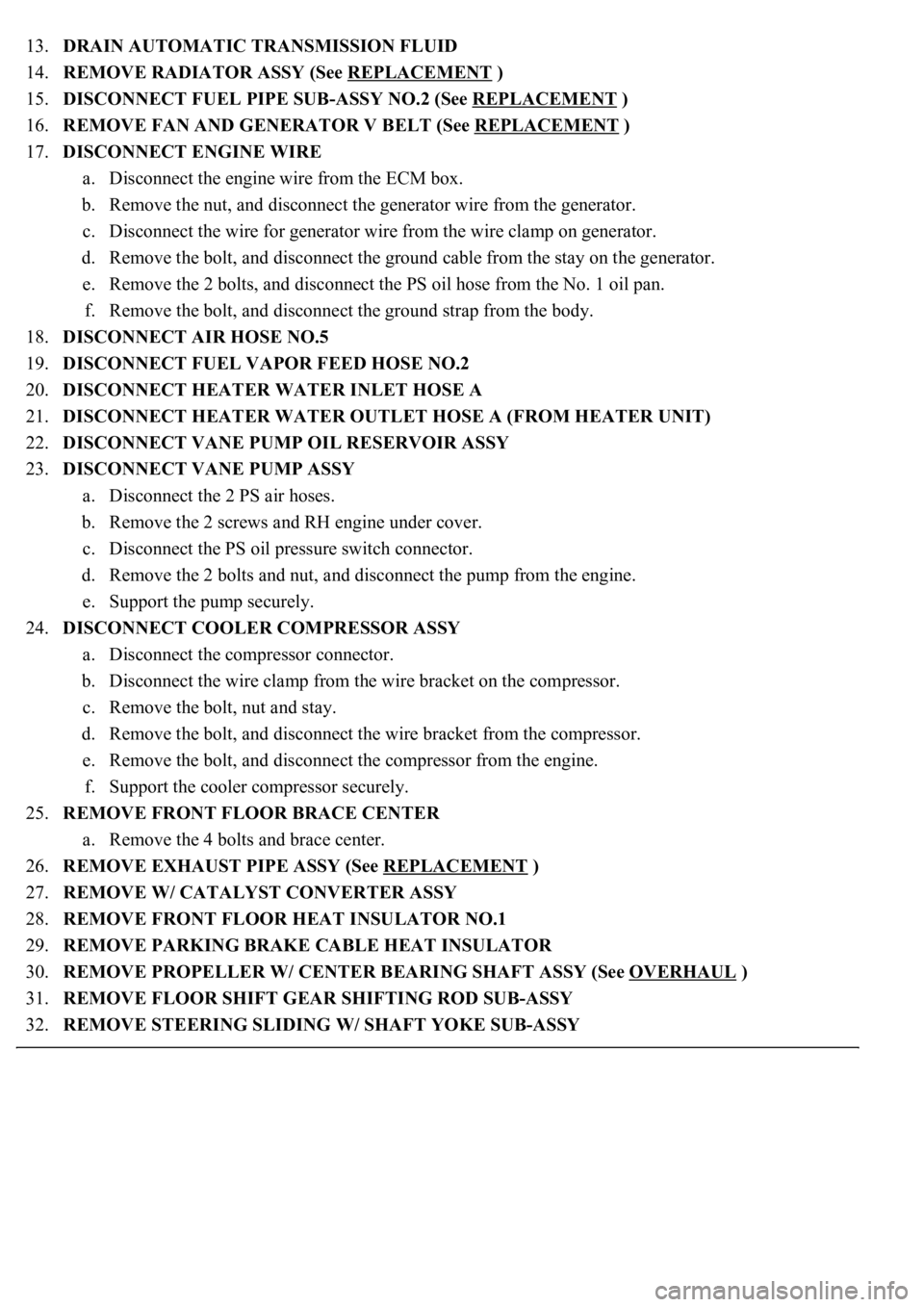

Fig. 38: Lifting Engine Out Of Vehicle

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

43.DISCONNECT ENGINE WIRE

a. Disconnect the engine wire from the transmission.

1. Disconnect the VSV connector.

2. Disconnect the PNP switch connector.

3. Disconnect the solenoid connector.

4. Disconnect the direct clutch speed sensor connector.

5. Disconnect the engine wire from the 3 wire clamps.

6. Disconnect the oil level sensor connector.

44.REMOVE TRANSMISSION OIL FILTER TUBE SUB-ASSY

45.REMOVE OIL COOLER OUTLET TUBE NO.1

46.REMOVE OIL COOLER INLET TUBE NO.1

47.REMOVE AUTOMATIC TRANSMISSION ASSY

a. Remove the torque converter clutch bolts.

1. Remove the 2 bolts and fl

ywheel housing under cover.

Page 3352 of 4500

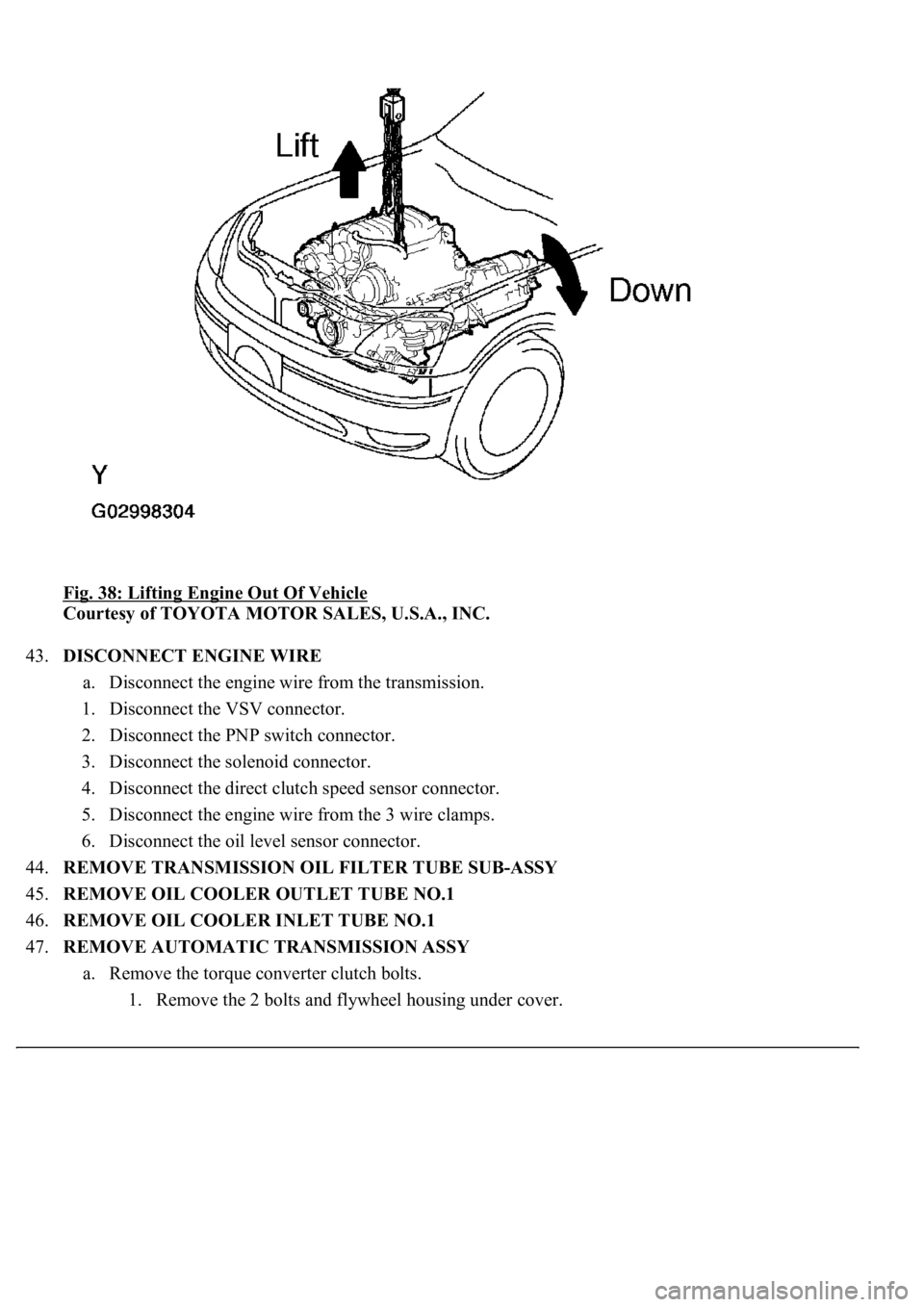

Fig. 72: Identifying Torque Converter Clutch Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

108.INSTALL OIL COOLER INLET TUBE NO.1

109.INSTALL OIL COOLER OUTLET TUBE NO.1

110.INSTALL TRANSMISSION OIL FILTER TUBE SUB-ASSY

111.CONNECT ENGINE WIRE

a. Connect the engine wire to the transmission.

1. Connect the VSV connector.

2. Connect the PNP switch connector.

3. Connect the solenoid connector.

4. Connect the direct clutch speed sensor connector.

5. Connect the engine wire from the 3 wire clamps.

6. Connect the oil level sensor connector.

112.INSTALL ENGINE W/ TRANSMISSION ASSEMBLY

a. Attach the engine chain hoist to the engine hangers.

b. Slowly lower the engine and transmission assembly into the engine compartment.

c. Insert the stud bolts of the front en

gine mounting brackets into the stud bolt holes of the front

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.