battery LEXUS LS430 2003 Factory Owner's Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 427 of 4500

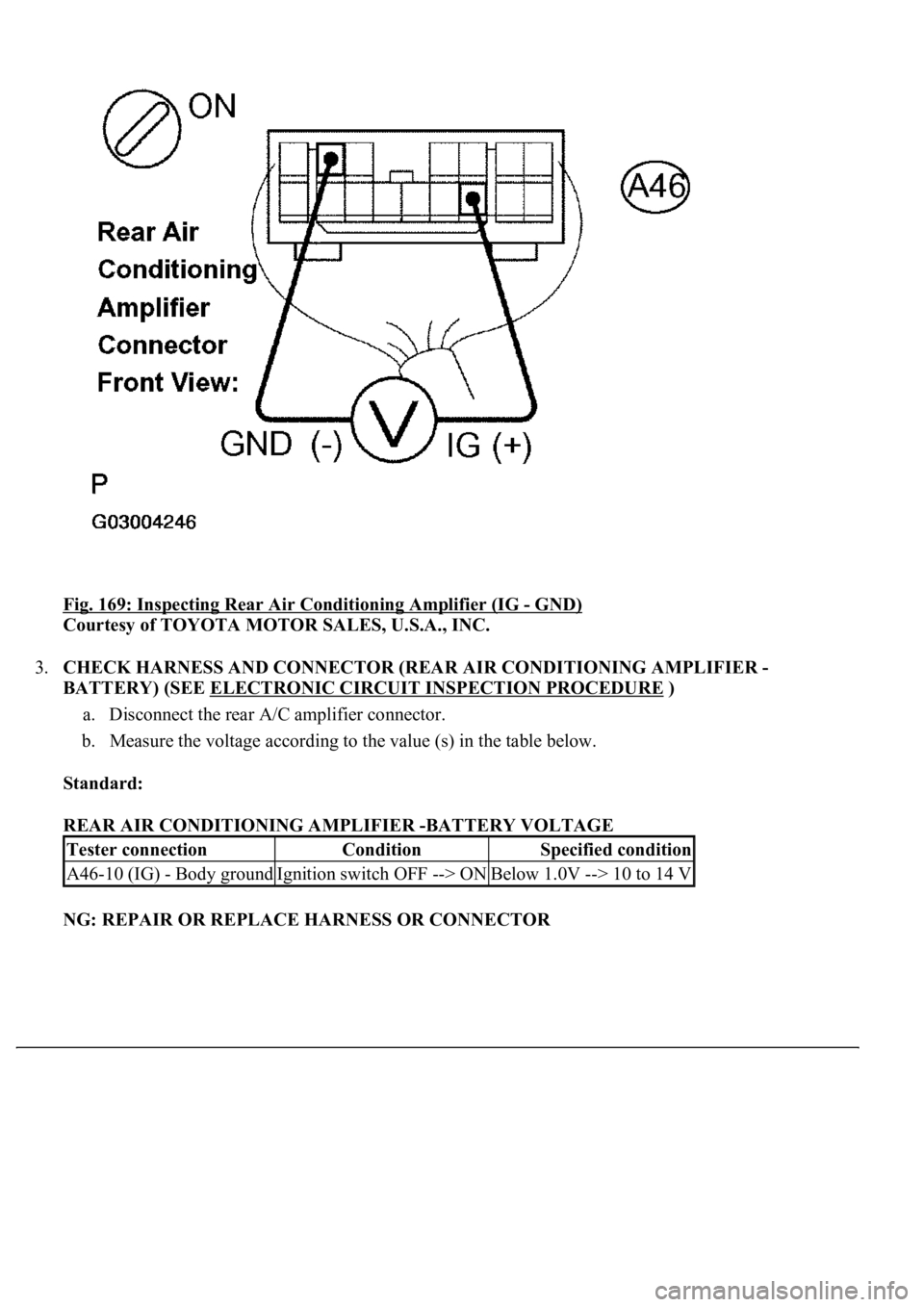

Fig. 169: Inspecting Rear Air Conditioning Amplifier (IG - GND)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3.CHECK HARNESS AND CONNECTOR (REAR AIR CONDITIONING AMPLIFIER -

BATTERY) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Disconnect the rear A/C amplifier connector.

b. Measure the voltage according to the value (s) in the table below.

Standard:

REAR AIR CONDITIONING AMPLIFIER -BATTERY VOLTAGE

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Tester connectionConditionSpecified condition

A46-10 (IG) - Body groundIgnition switch OFF --> ONBelow 1.0V --> 10 to 14 V

Page 428 of 4500

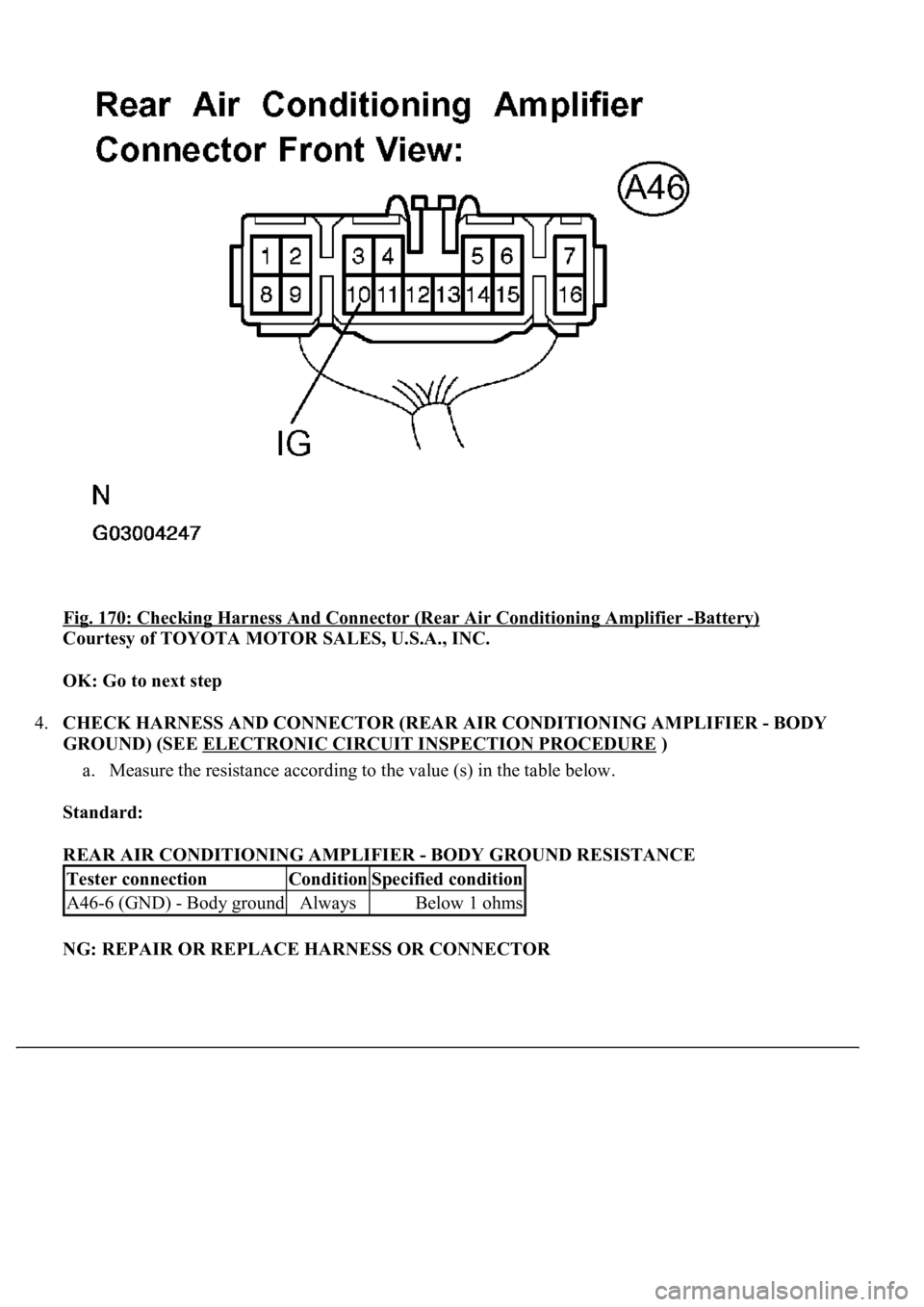

Fig. 170: Checking Harness And Connector (Rear Air Conditioning Amplifier -Battery)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: Go to next step

4.CHECK HARNESS AND CONNECTOR (REAR AIR CONDITIONING AMPLIFIER - BODY

GROUND) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

Standard:

REAR AIR CONDITIONING AMPLIFIER - BODY GROUND RESISTANCE

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Tester connectionConditionSpecified condition

A46-6 (GND) - Body groundAlwaysBelow 1 ohms

Page 444 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

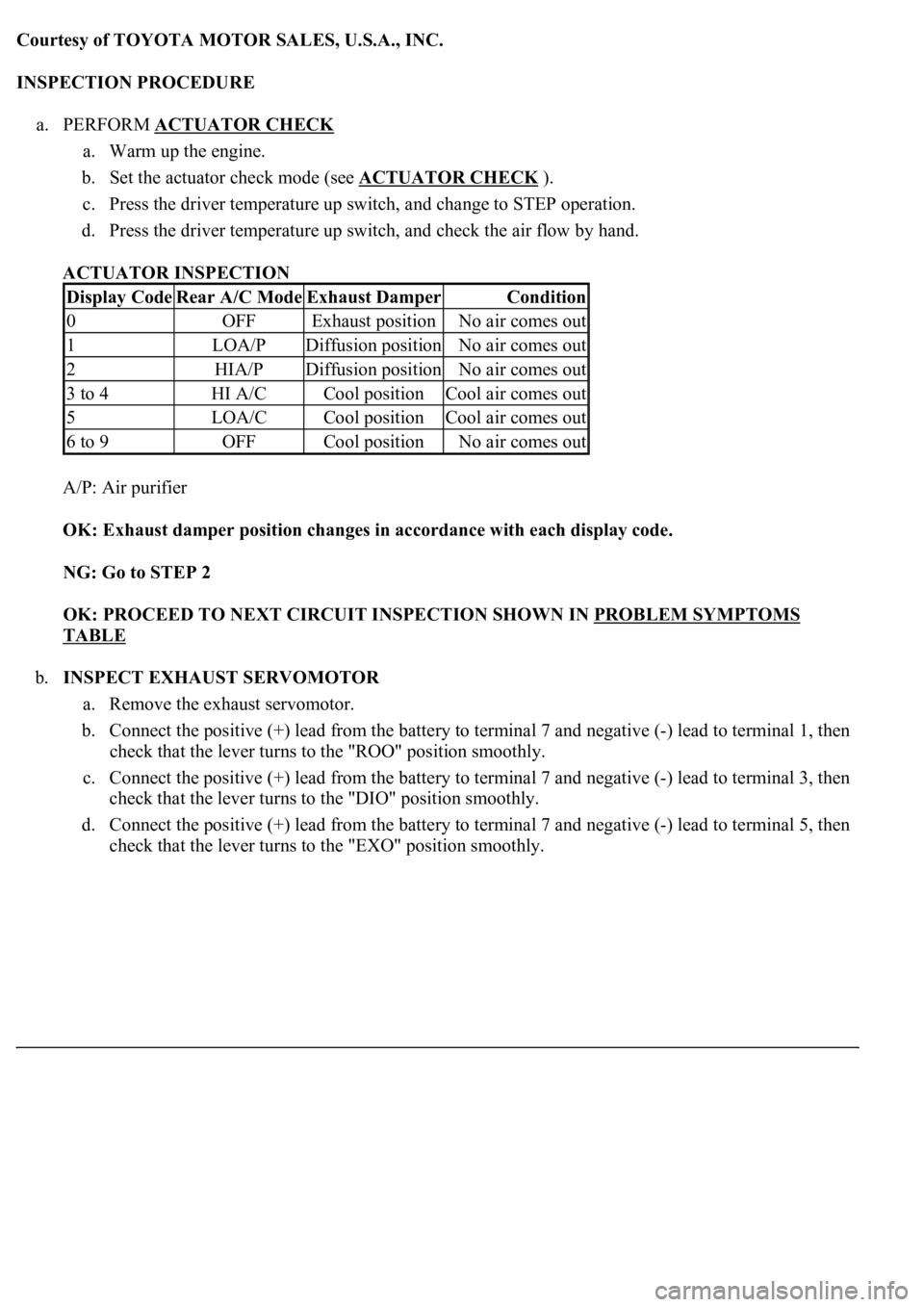

INSPECTION PROCEDURE

a. PERFORM ACTUATOR CHECK

a. Warm up the engine.

b. Set the actuator check mode (see ACTUATOR CHECK

).

c. Press the driver temperature up switch, and change to STEP operation.

d. Press the driver temperature up switch, and check the air flow by hand.

ACTUATOR INSPECTION

A/P: Air purifier

OK: Exhaust damper position changes in accordance with each display code.

NG: Go to STEP 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

b.INSPECT EXHAUST SERVOMOTOR

a. Remove the exhaust servomotor.

b. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 1, then

check that the lever turns to the "ROO" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 3, then

check that the lever turns to the "DIO" position smoothly.

d. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 5, then

check that the lever turns to the "EXO" position smoothl

y.

Display CodeRear A/C ModeExhaust DamperCondition

0OFFExhaust positionNo air comes out

1LOA/PDiffusion positionNo air comes out

2HIA/PDiffusion positionNo air comes out

3 to 4HI A/CCool positionCool air comes out

5LOA/CCool positionCool air comes out

6 to 9OFFCool positionNo air comes out

Page 452 of 4500

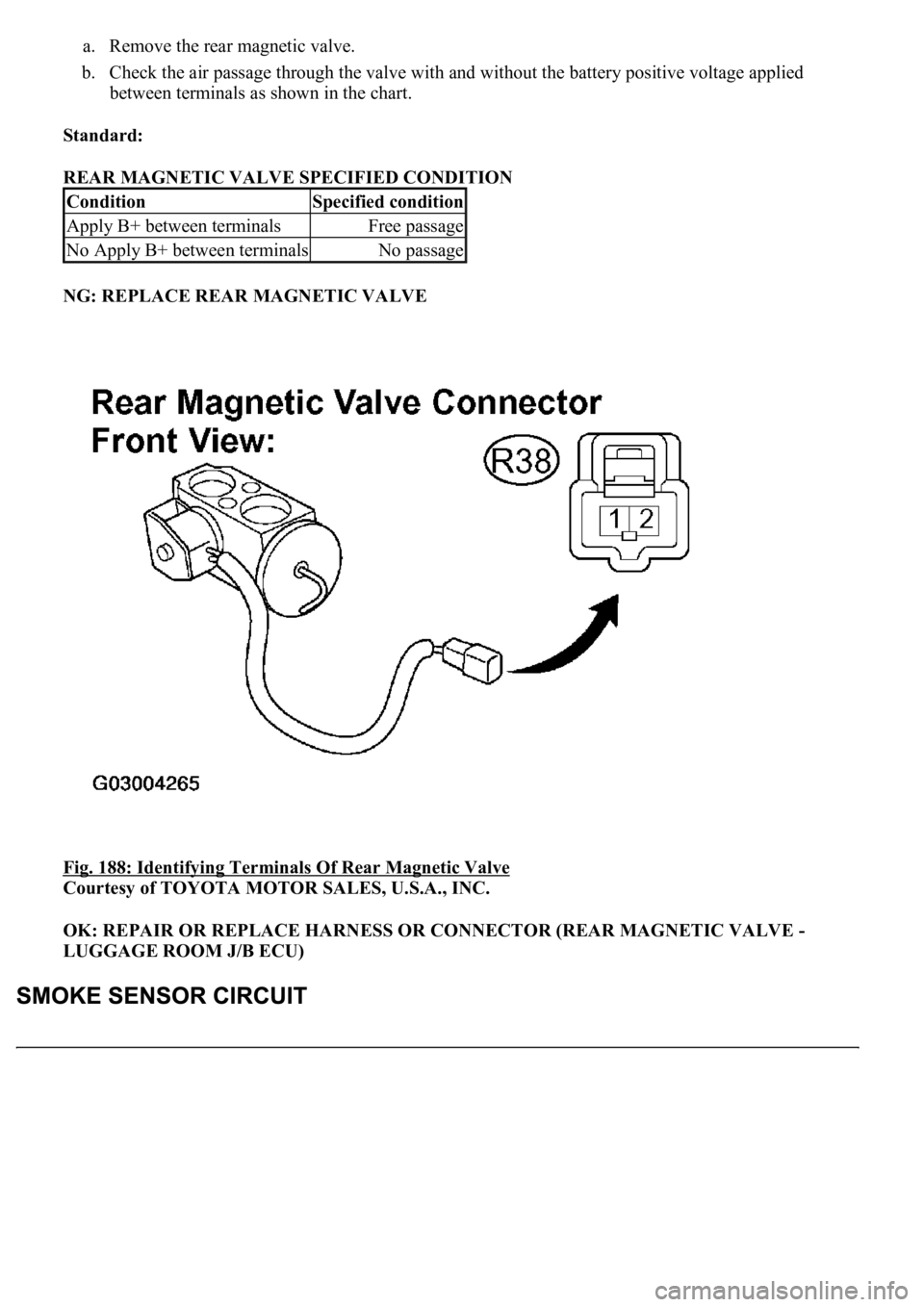

a. Remove the rear magnetic valve.

b. Check the air passage through the valve with and without the battery positive voltage applied

between terminals as shown in the chart.

Standard:

REAR MAGNETIC VALVE SPECIFIED CONDITION

NG: REPLACE REAR MAGNETIC VALVE

Fig. 188: Identifying Terminals Of Rear Magnetic Valve

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPAIR OR REPLACE HARNESS OR CONNECTOR (REAR MAGNETIC VALVE -

LUGGAGE ROOM J/B ECU)

ConditionSpecified condition

Apply B+ between terminalsFree passage

No Apply B+ between terminalsNo passage

Page 456 of 4500

NG: Go to STEP 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

2.INSPECT SMOKE SENSOR

a. Remove the smoke sensor.

b. Connect the positive (+) lead from the battery to terminal S47-1 and negative (-) lead to terminal

S47-3.

c. Measure the voltage according to the value (s) in the table below.

Standard:

SMOKE SENSOR VOLTAGE

Tester connectionConditionSpecified condition

S47-2 - S47-3There is no smokeBelow 1.0 V

S47-2 - S47-3There is smokeAbove 4.0 V

Page 458 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPLACE SMOKE SENSOR

OK: Go to next step

3.CHECK HARNESS AND CONNECTOR (BATTERY - SMOKE SENSOR) (SEE ELECTRONIC

CIRCUIT INSPECTION PROCEDURE )

a. Measure the resistance according to the value (s) in the table below.

Standard:

BATTERY - SMOKE SENSOR RESISTANCE

b. Measure the voltage according to the value (s) in the table below.

Standard:

BATTERY - SMOKE SENSOR VOLTAGE

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Tester connectionConditionSpecified condition

S47-1 (GND) - Body groundAlwaysBelow 1 ohms

Tester connectionConditionSpecified condition

S47-3 (+B) - Body groundIG ON10 to 14 V

Page 469 of 4500

If the vehicle is raised with its engine running, connect terminals OPB and CG of the DLC3 to stop

the vehicle height control operation of the suspension control ECU.

Do not operate the steering wheel if there is no air in the pneumatic cylinder.

HINT:

The pneumatic cylinder could be damaged if twisted without air in the cylinder.

In the case of lifting down the vehicle without air in the cylinder, make sure all the pipes are securely

connected.

HINT:

The pneumatic cylinder could be damaged if any pipe is disconnected while lifting down the vehicle.

Do not apply battery voltage to the compressor motor for more than 60 seconds to prevent damage to the

motor.

HINT:

When it is necessary to perform the operation by charging the battery for more than 60 seconds, for example

height recovery without air in the cylinder, proceed to the operation as follows: after 60 seconds have passed,

turn the ignition switch off once, and then turn the ignition switch to the ON position again for commencement

of operation.

Page 480 of 4500

Fig. 8: Problem Symptoms Table

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

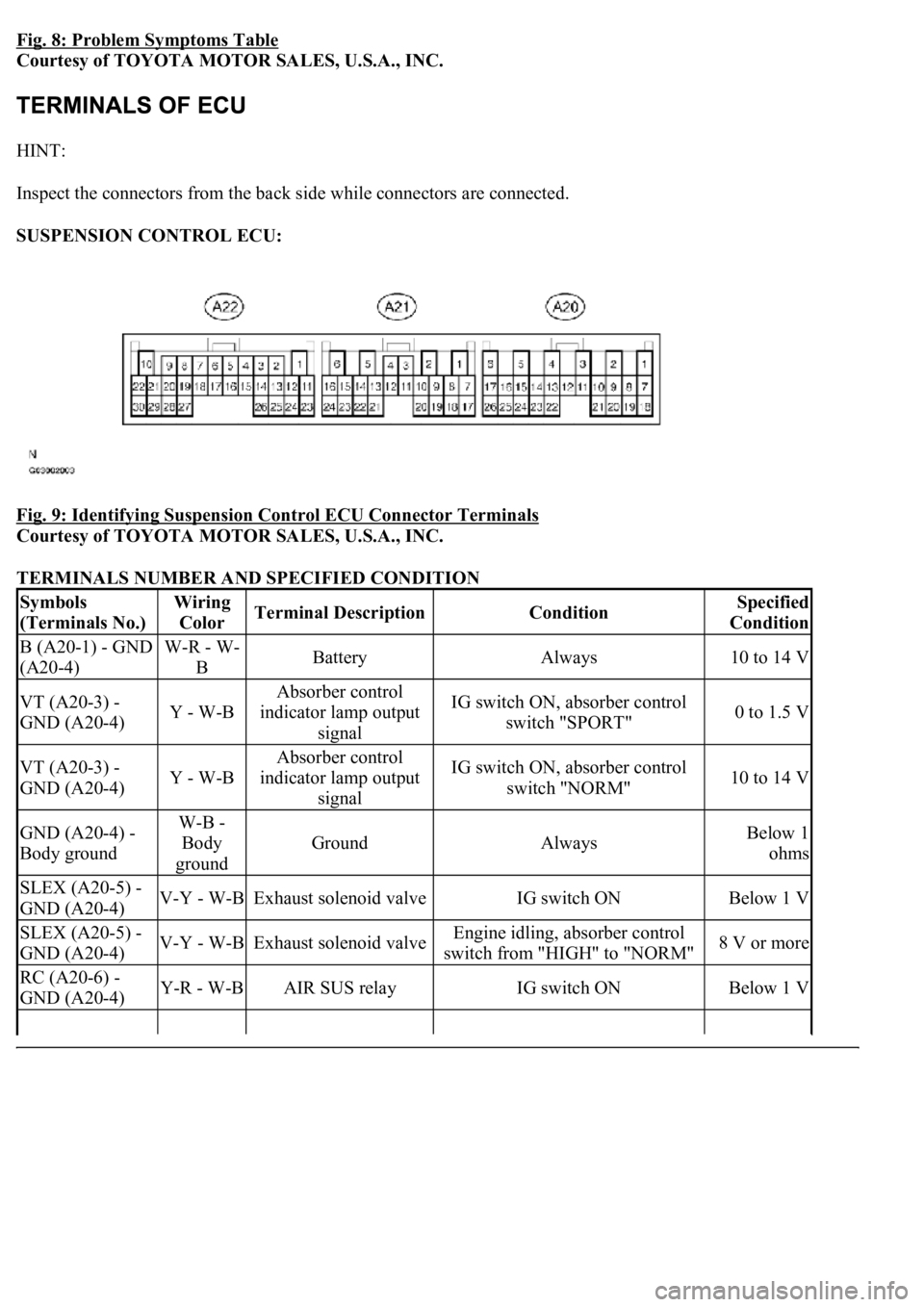

HINT:

Inspect the connectors from the back side while connectors are connected.

SUSPENSION CONTROL ECU:

Fig. 9: Identifying Suspension Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TERMINALS NUMBER AND SPECIFIED CONDITION

Symbols

(Terminals No.)Wiring

ColorTerminal DescriptionConditionSpecified

Condition

B (A20-1) - GND

(A20-4)W-R - W-

BBatteryAlways10 to 14 V

VT (A20-3) -

GND (A20-4)Y - W-B

Absorber control

indicator lamp output

signalIG switch ON, absorber control

switch "SPORT"0 to 1.5 V

VT (A20-3) -

GND (A20-4)Y - W-B

Absorber control

indicator lamp output

signalIG switch ON, absorber control

switch "NORM"10 to 14 V

GND (A20-4) -

Body groundW-B -

Body

ground

GroundAlwaysBelow 1

ohms

SLEX (A20-5) -

GND (A20-4)V-Y - W-BExhaust solenoid valveIG switch ONBelow 1 V

SLEX (A20-5) -

GND (A20-4)V-Y - W-BExhaust solenoid valveEngine idling, absorber control

switch from "HIGH" to "NORM"8 V or more

RC (A20-6) -

GND (A20-4)Y-R - W-BAIR SUS relayIG switch ONBelow 1 V

Page 483 of 4500

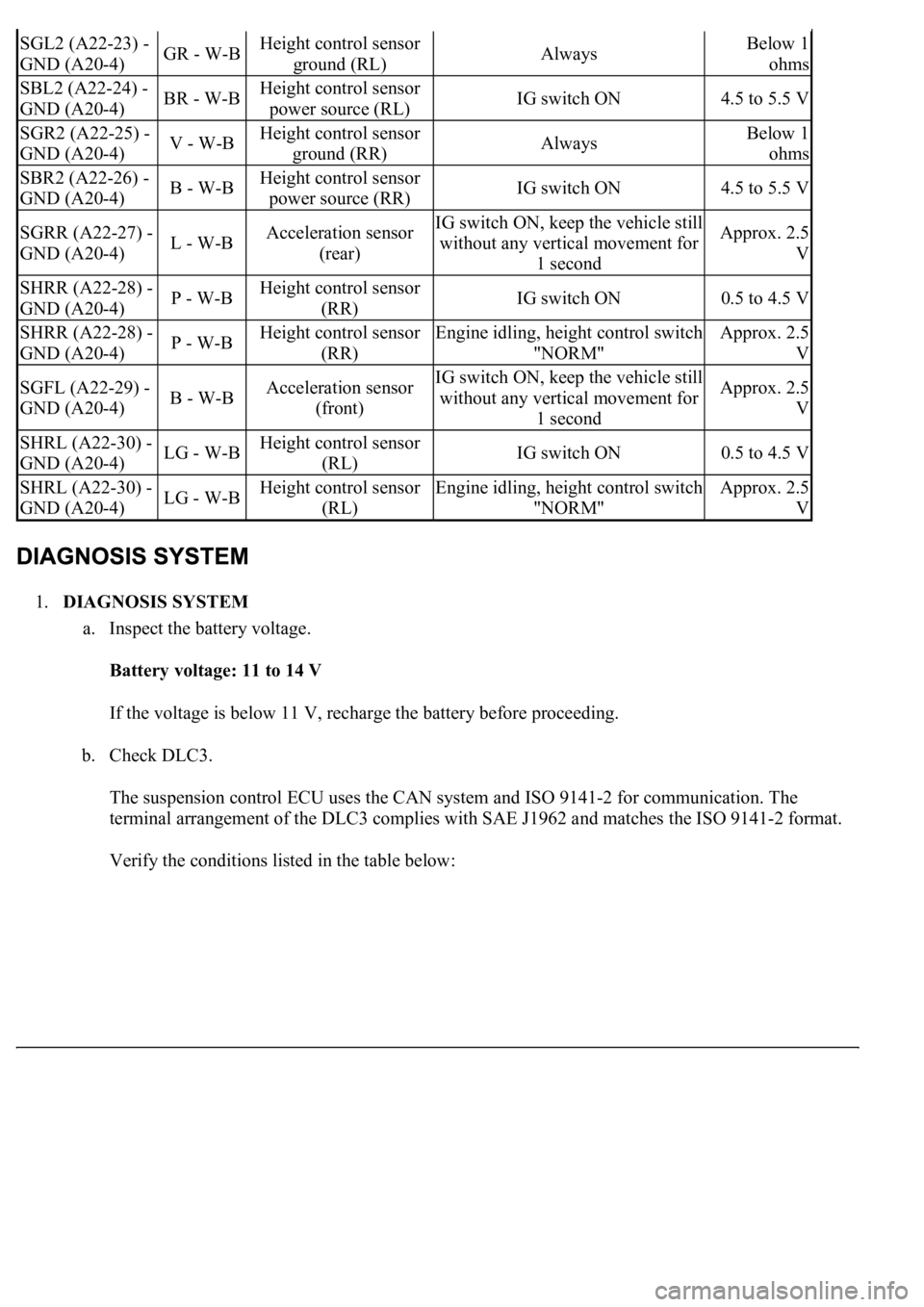

1.DIAGNOSIS SYSTEM

a. Inspect the battery voltage.

Battery voltage: 11 to 14 V

If the voltage is below 11 V, recharge the battery before proceeding.

b. Check DLC3.

The suspension control ECU uses the CAN system and ISO 9141-2 for communication. The

terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO 9141-2 format.

Verify the conditions listed in the table below:

SGL2 (A22-23) -

GND (A20-4)GR - W-BHeight control sensor

ground (RL)AlwaysBelow 1

ohms

SBL2 (A22-24) -

GND (A20-4)BR - W-BHeight control sensor

power source (RL)IG switch ON4.5 to 5.5 V

SGR2 (A22-25) -

GND (A20-4)V - W-BHeight control sensor

ground (RR)AlwaysBelow 1

ohms

SBR2 (A22-26) -

GND (A20-4)B - W-BHeight control sensor

power source (RR)IG switch ON4.5 to 5.5 V

SGRR (A22-27) -

GND (A20-4)L - W-BAcceleration sensor

(rear)IG switch ON, keep the vehicle still

without any vertical movement for

1 secondApprox. 2.5

V

SHRR (A22-28) -

GND (A20-4)P - W-BHeight control sensor

(RR)IG switch ON0.5 to 4.5 V

SHRR (A22-28) -

GND (A20-4)P - W-BHeight control sensor

(RR)Engine idling, height control switch

"NORM"Approx. 2.5

V

SGFL (A22-29) -

GND (A20-4)B - W-BAcceleration sensor

(front)IG switch ON, keep the vehicle still

without any vertical movement for

1 secondApprox. 2.5

V

SHRL (A22-30) -

GND (A20-4)LG - W-BHeight control sensor

(RL)IG switch ON0.5 to 4.5 V

SHRL (A22-30) -

GND (A20-4)LG - W-BHeight control sensor

(RL)Engine idling, height control switch

"NORM"Approx. 2.5

V

Page 484 of 4500

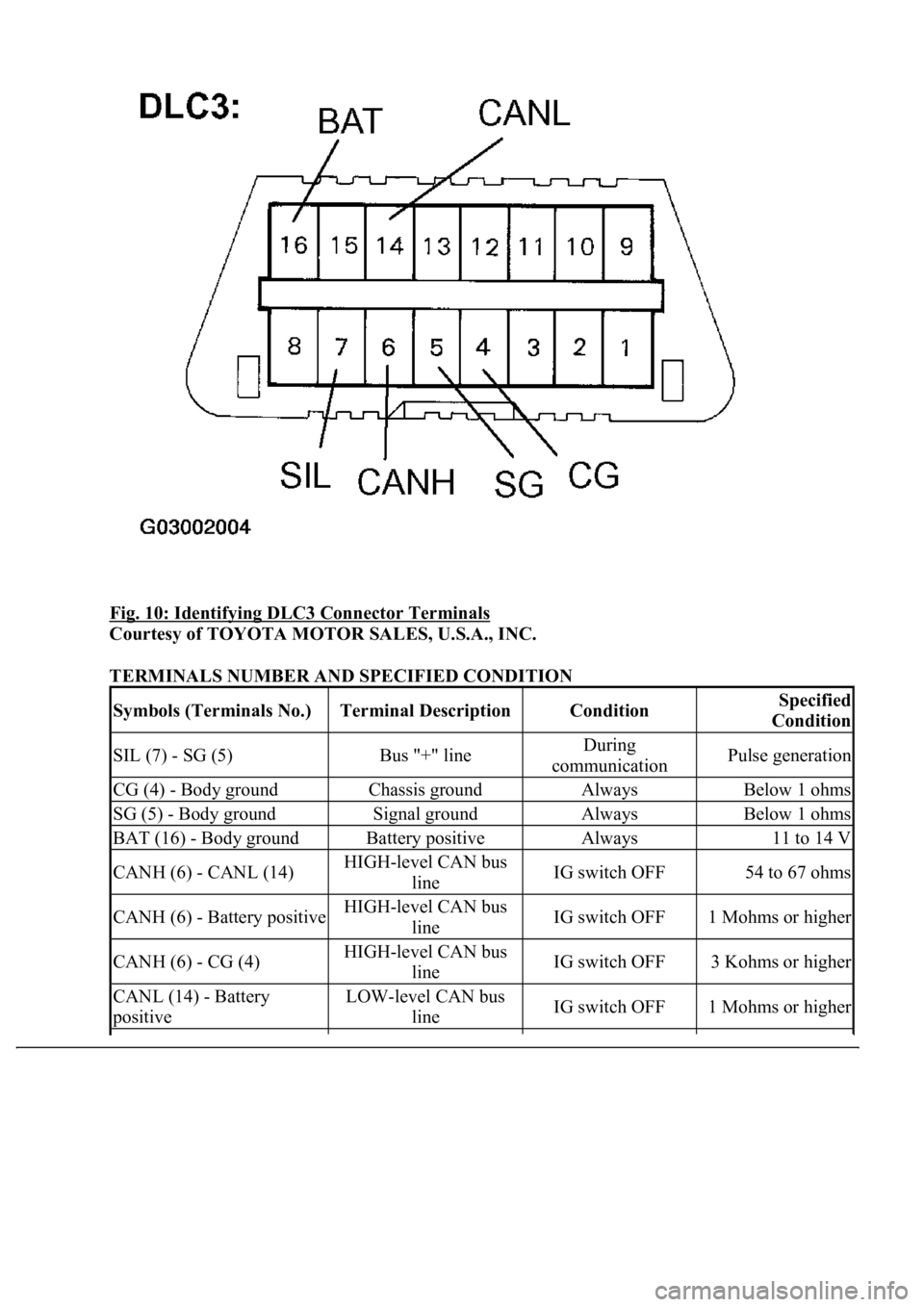

Fig. 10: Identifying DLC3 Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TERMINALS NUMBER AND SPECIFIED CONDITION

Symbols (Terminals No.)Terminal DescriptionConditionSpecified

Condition

SIL (7) - SG (5)Bus "+" lineDuring

communicationPulse generation

CG (4) - Body groundChassis groundAlwaysBelow 1 ohms

SG (5) - Body groundSignal groundAlwaysBelow 1 ohms

BAT (16) - Body groundBattery positiveAlways11 to 14 V

CANH (6) - CANL (14)HIGH-level CAN bus

lineIG switch OFF54 to 67 ohms

CANH (6) - Battery positiveHIGH-level CAN bus

lineIG switch OFF1 Mohms or higher

CANH (6) - CG (4)HIGH-level CAN bus

lineIG switch OFF3 Kohms or higher

CANL (14) - Battery

positiveLOW-level CAN bus

lineIG switch OFF1 Mohms or higher