check engine LEXUS LS430 2003 Factory Owner's Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 444 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

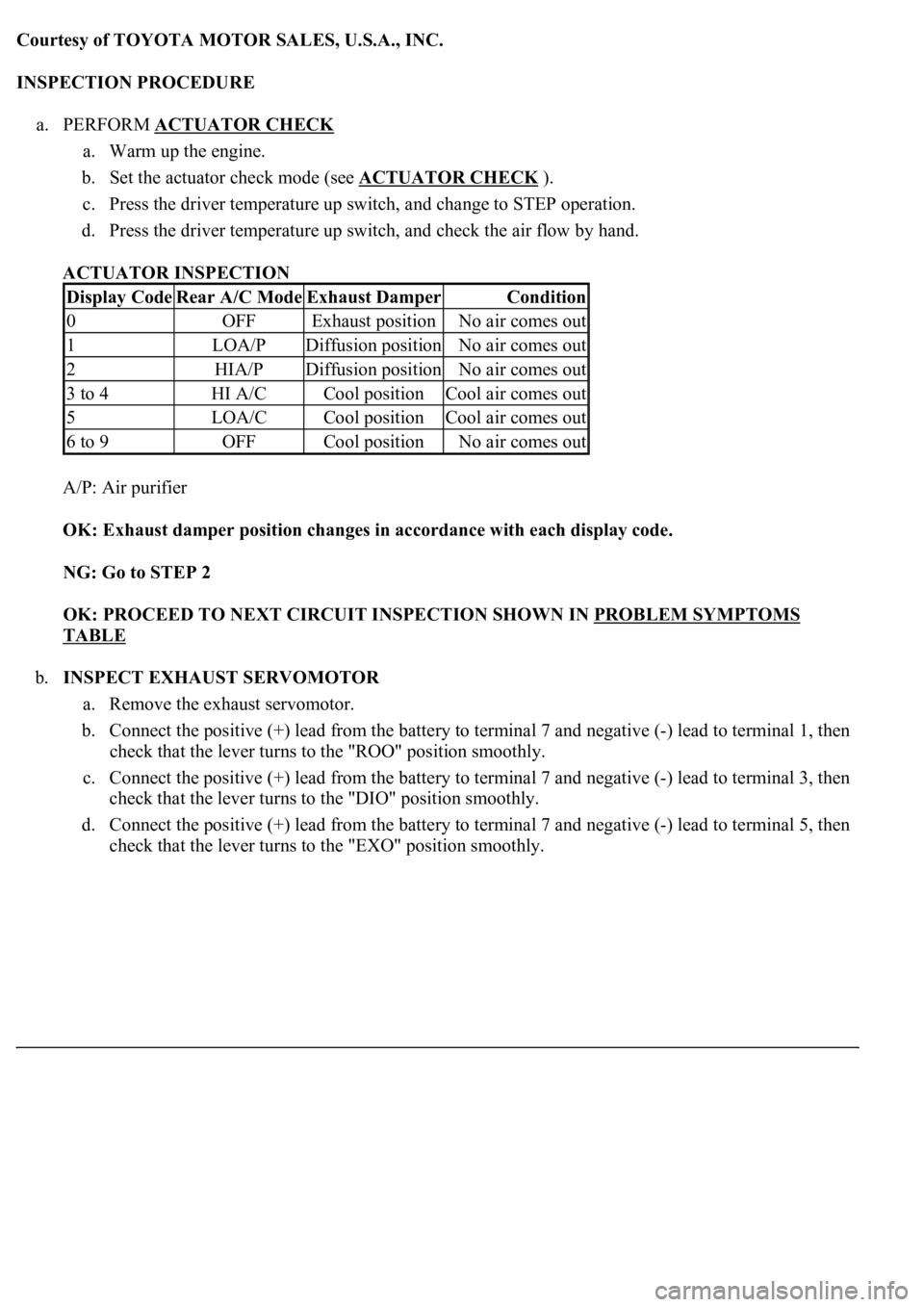

a. PERFORM ACTUATOR CHECK

a. Warm up the engine.

b. Set the actuator check mode (see ACTUATOR CHECK

).

c. Press the driver temperature up switch, and change to STEP operation.

d. Press the driver temperature up switch, and check the air flow by hand.

ACTUATOR INSPECTION

A/P: Air purifier

OK: Exhaust damper position changes in accordance with each display code.

NG: Go to STEP 2

OK: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

b.INSPECT EXHAUST SERVOMOTOR

a. Remove the exhaust servomotor.

b. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 1, then

check that the lever turns to the "ROO" position smoothly.

c. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 3, then

check that the lever turns to the "DIO" position smoothly.

d. Connect the positive (+) lead from the battery to terminal 7 and negative (-) lead to terminal 5, then

check that the lever turns to the "EXO" position smoothl

y.

Display CodeRear A/C ModeExhaust DamperCondition

0OFFExhaust positionNo air comes out

1LOA/PDiffusion positionNo air comes out

2HIA/PDiffusion positionNo air comes out

3 to 4HI A/CCool positionCool air comes out

5LOA/CCool positionCool air comes out

6 to 9OFFCool positionNo air comes out

Page 483 of 4500

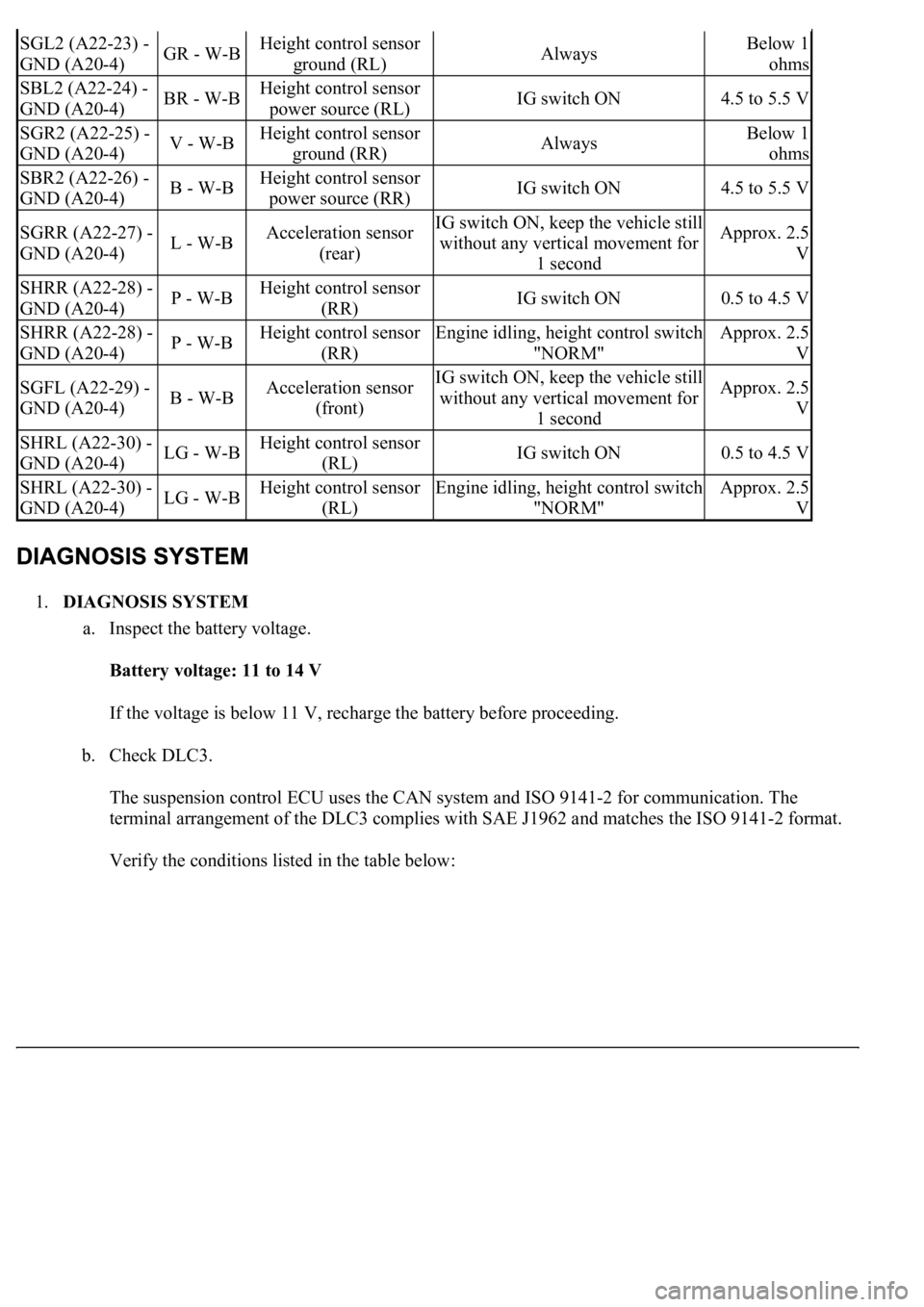

1.DIAGNOSIS SYSTEM

a. Inspect the battery voltage.

Battery voltage: 11 to 14 V

If the voltage is below 11 V, recharge the battery before proceeding.

b. Check DLC3.

The suspension control ECU uses the CAN system and ISO 9141-2 for communication. The

terminal arrangement of the DLC3 complies with SAE J1962 and matches the ISO 9141-2 format.

Verify the conditions listed in the table below:

SGL2 (A22-23) -

GND (A20-4)GR - W-BHeight control sensor

ground (RL)AlwaysBelow 1

ohms

SBL2 (A22-24) -

GND (A20-4)BR - W-BHeight control sensor

power source (RL)IG switch ON4.5 to 5.5 V

SGR2 (A22-25) -

GND (A20-4)V - W-BHeight control sensor

ground (RR)AlwaysBelow 1

ohms

SBR2 (A22-26) -

GND (A20-4)B - W-BHeight control sensor

power source (RR)IG switch ON4.5 to 5.5 V

SGRR (A22-27) -

GND (A20-4)L - W-BAcceleration sensor

(rear)IG switch ON, keep the vehicle still

without any vertical movement for

1 secondApprox. 2.5

V

SHRR (A22-28) -

GND (A20-4)P - W-BHeight control sensor

(RR)IG switch ON0.5 to 4.5 V

SHRR (A22-28) -

GND (A20-4)P - W-BHeight control sensor

(RR)Engine idling, height control switch

"NORM"Approx. 2.5

V

SGFL (A22-29) -

GND (A20-4)B - W-BAcceleration sensor

(front)IG switch ON, keep the vehicle still

without any vertical movement for

1 secondApprox. 2.5

V

SHRL (A22-30) -

GND (A20-4)LG - W-BHeight control sensor

(RL)IG switch ON0.5 to 4.5 V

SHRL (A22-30) -

GND (A20-4)LG - W-BHeight control sensor

(RL)Engine idling, height control switch

"NORM"Approx. 2.5

V

Page 735 of 4500

![LEXUS LS430 2003 Factory Owners Guide Fig. 28: DTC Detecting Condition Chart (Physical address: 17D) [TEL])

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending LEXUS LS430 2003 Factory Owners Guide Fig. 28: DTC Detecting Condition Chart (Physical address: 17D) [TEL])

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending](/img/36/57050/w960_57050-734.png)

Fig. 28: DTC Detecting Condition Chart (Physical address: 17D) [TEL])

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending on the battery

condition or engine start voltage.

*2: If the power connector is disconnected after the engine starts, this code is recorded after

180 seconds.

*3: This code may be stored if the ignition key is turned again after the engine starts.

*4: This code may be stored if the ignition key is held in the START position for one minute

or more before returning to the ON position.

*5: If the device is reported as not existing during verification, check the power source circuit

and AVC-LAN circuit for the device.

b. Logical address: 57 (telephone information drawing): 68 (TEL)

HINT:

Methods used to verify the cause of the problem are listed in order of probability in the verification

column.

Fig. 29: DTC Detecting Condition Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

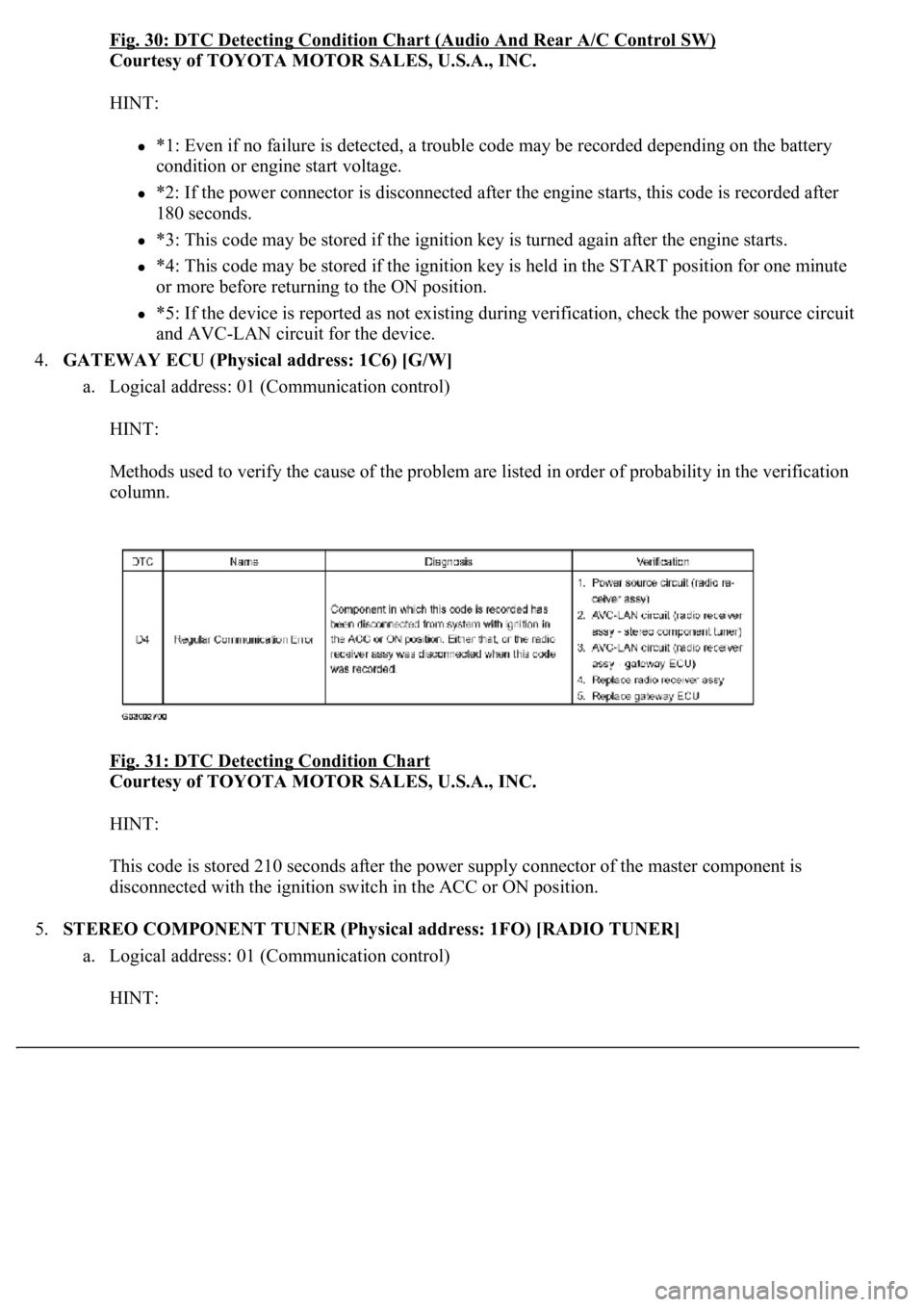

3.AUDIO AND REAR A/C CONTROL SW (Physical address: 1CO) [Rr-CONT]

a. Logical address: 01 (Communication control)

HINT:

Methods used to verify the cause of the problem are listed in order of probability in the verification

column.

Page 737 of 4500

Fig. 30: DTC Detecting Condition Chart (Audio And Rear A/C Control SW)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending on the battery

condition or engine start voltage.

*2: If the power connector is disconnected after the engine starts, this code is recorded after

180 seconds.

*3: This code may be stored if the ignition key is turned again after the engine starts.

*4: This code may be stored if the ignition key is held in the START position for one minute

or more before returning to the ON position.

*5: If the device is reported as not existing during verification, check the power source circuit

and AVC-LAN circuit for the device.

4.GATEWAY ECU (Physical address: 1C6) [G/W]

a. Logical address: 01 (Communication control)

HINT:

Methods used to verify the cause of the problem are listed in order of probability in the verification

column.

Fig. 31: DTC Detecting Condition Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

This code is stored 210 seconds after the power supply connector of the master component is

disconnected with the ignition switch in the ACC or ON position.

5.STEREO COMPONENT TUNER (Physical address: 1FO) [RADIO TUNER]

a. Logical address: 01 (Communication control)

HINT:

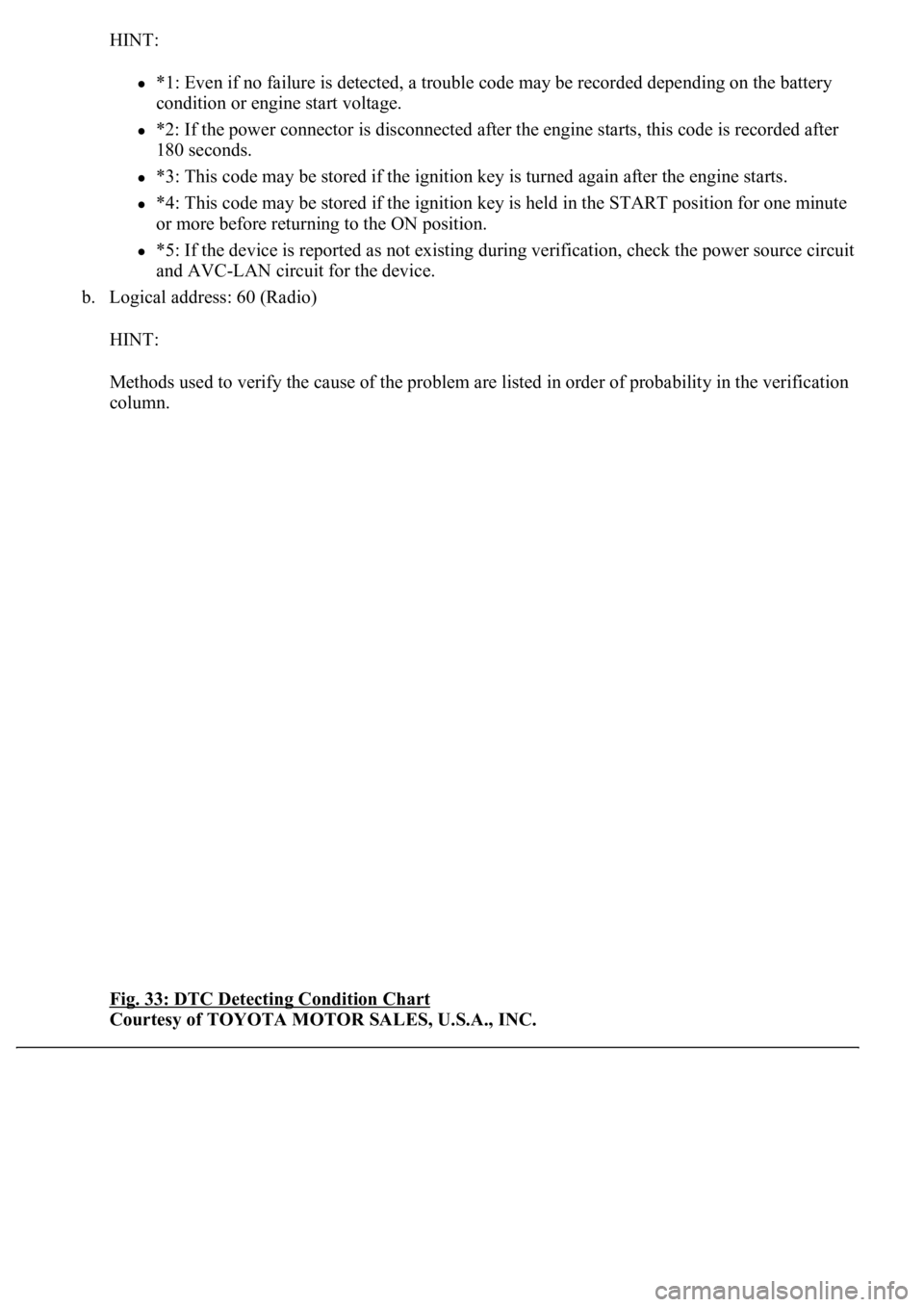

Page 739 of 4500

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending on the battery

condition or engine start voltage.

*2: If the power connector is disconnected after the engine starts, this code is recorded after

180 seconds.

*3: This code may be stored if the ignition key is turned again after the engine starts.

*4: This code may be stored if the ignition key is held in the START position for one minute

or more before returning to the ON position.

*5: If the device is reported as not existing during verification, check the power source circuit

and AVC-LAN circuit for the device.

b. Logical address: 60 (Radio)

HINT:

Methods used to verify the cause of the problem are listed in order of probability in the verification

column.

Fig. 33: DTC Detecting Condition Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 742 of 4500

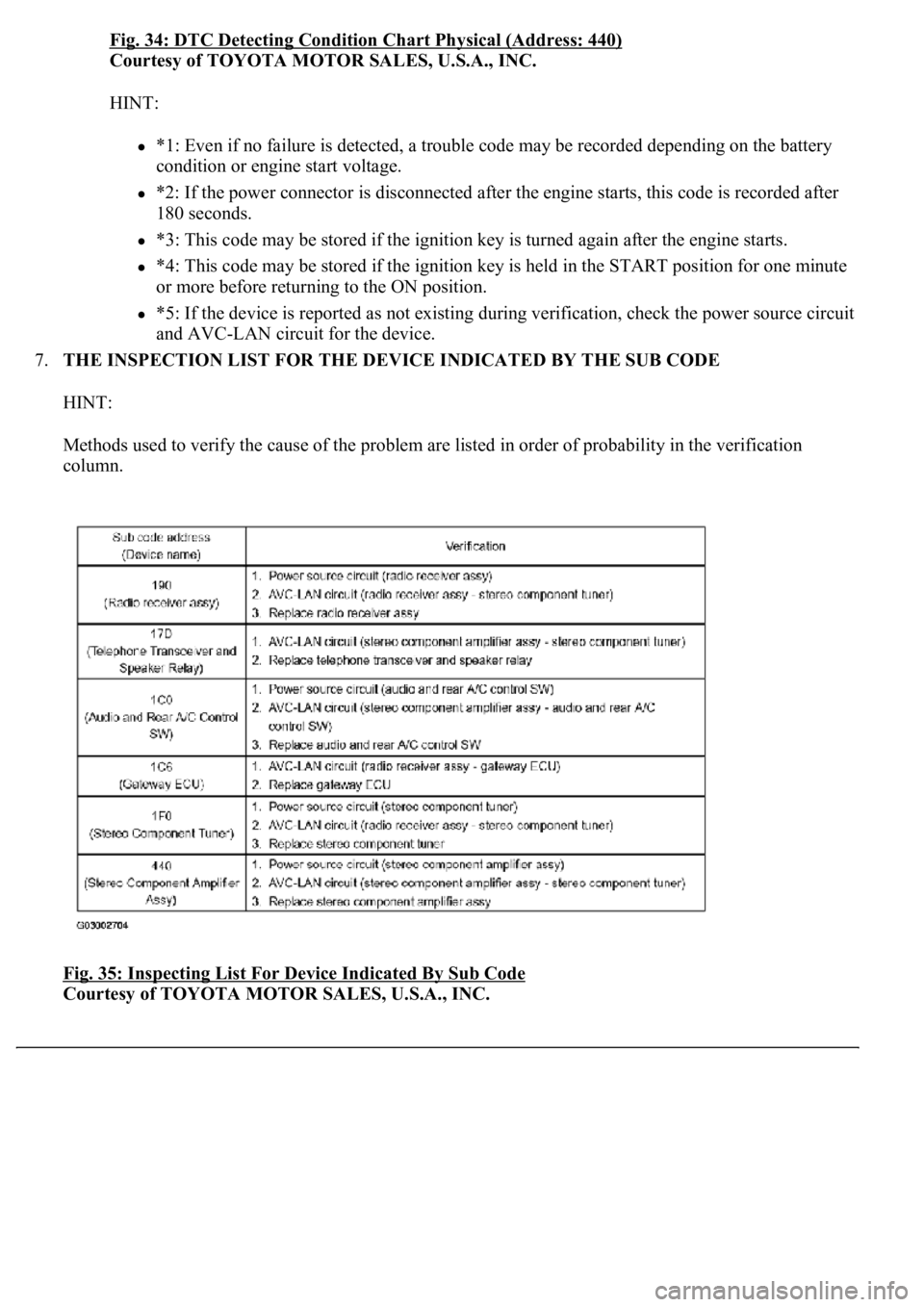

Fig. 34: DTC Detecting Condition Chart Physical (Address: 440)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

*1: Even if no failure is detected, a trouble code may be recorded depending on the battery

condition or engine start voltage.

*2: If the power connector is disconnected after the engine starts, this code is recorded after

180 seconds.

*3: This code may be stored if the ignition key is turned again after the engine starts.

*4: This code may be stored if the ignition key is held in the START position for one minute

or more before returning to the ON position.

*5: If the device is reported as not existing during verification, check the power source circuit

and AVC-LAN circuit for the device.

7.THE INSPECTION LIST FOR THE DEVICE INDICATED BY THE SUB CODE

HINT:

Methods used to verify the cause of the problem are listed in order of probability in the verification

column.

Fig. 35: Inspecting List For Device Indicated By Sub Code

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 749 of 4500

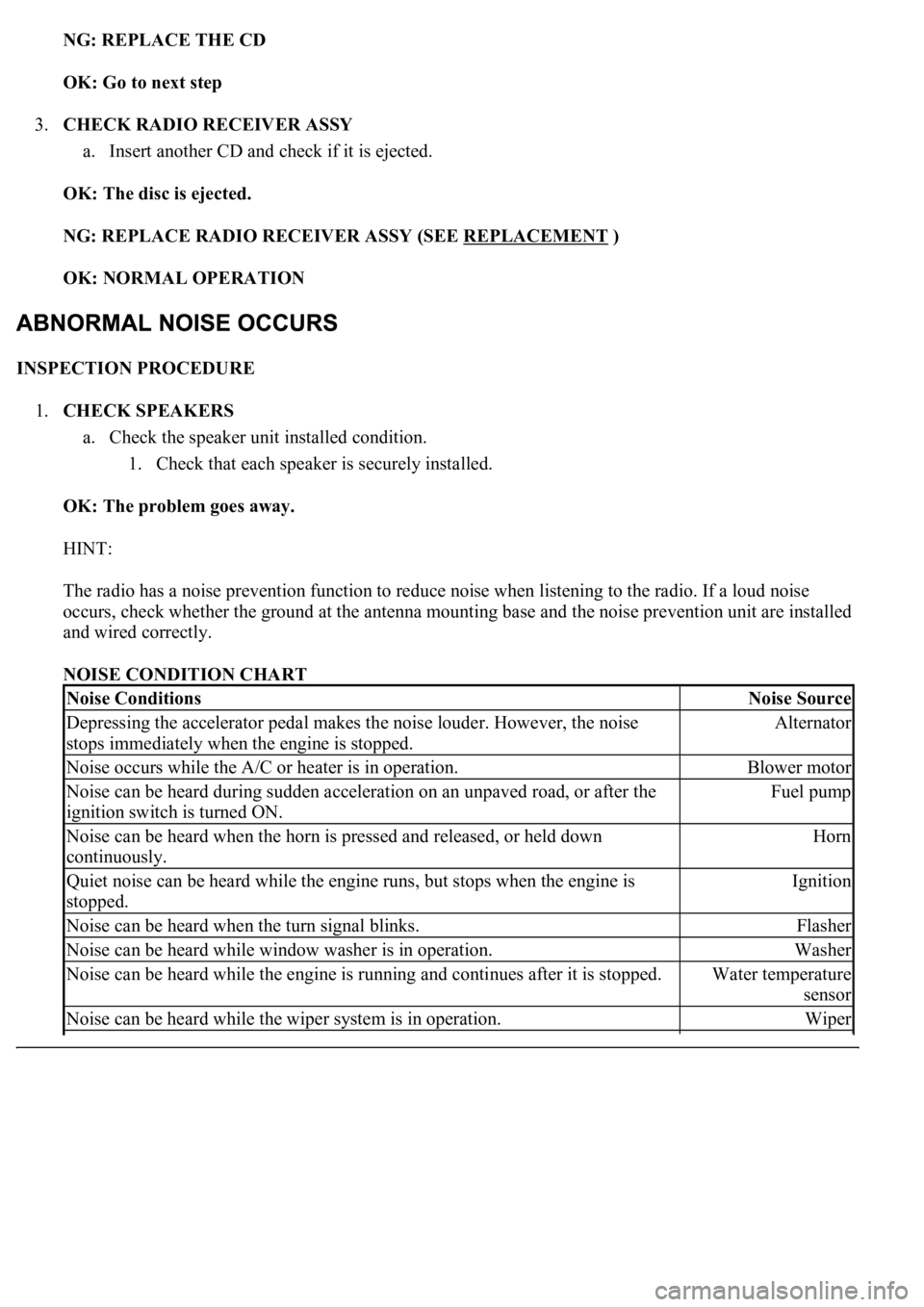

NG: REPLACE THE CD

OK: Go to next step

3.CHECK RADIO RECEIVER ASSY

a. Insert another CD and check if it is ejected.

OK: The disc is ejected.

NG: REPLACE RADIO RECEIVER ASSY (SEE REPLACEMENT

)

OK: NORMAL OPERATION

INSPECTION PROCEDURE

1.CHECK SPEAKERS

a. Check the speaker unit installed condition.

1. Check that each speaker is securely installed.

OK: The problem goes away.

HINT:

The radio has a noise prevention function to reduce noise when listening to the radio. If a loud noise

occurs, check whether the ground at the antenna mounting base and the noise prevention unit are installed

and wired correctly.

NOISE CONDITION CHART

Noise ConditionsNoise Source

Depressing the accelerator pedal makes the noise louder. However, the noise

stops immediately when the engine is stopped.Alternator

Noise occurs while the A/C or heater is in operation.Blower motor

Noise can be heard during sudden acceleration on an unpaved road, or after the

ignition switch is turned ON.Fuel pump

Noise can be heard when the horn is pressed and released, or held down

continuously.Horn

<00340058004c00480057000300510052004c0056004800030046004400510003004500480003004b00480044005500470003005a004b004c004f004800030057004b0048000300480051004a004c0051004800030055005800510056000f00030045005800

570003005600570052005300560003005a004b004800510003[the engine is

stopped.Ignition

Noise can be heard when the turn signal blinks.Flasher

Noise can be heard while window washer is in operation.Washer

Noise can be heard while the engine is running and continues after it is stopped.Water temperature

sensor

Noise can be heard while the wiper system is in operation.Wiper

Page 822 of 4500

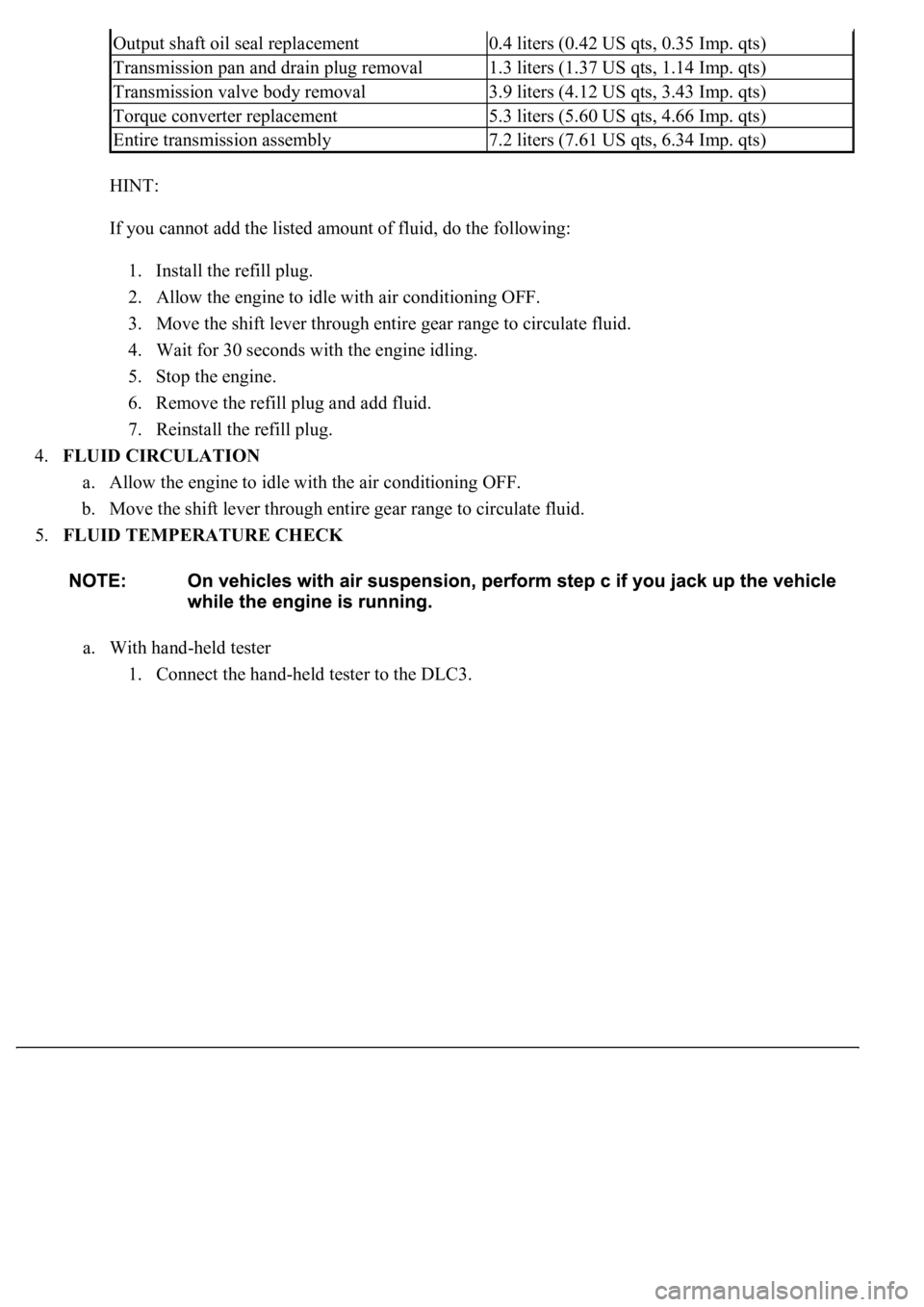

HINT:

If you cannot add the listed amount of fluid, do the following:

1. Install the refill plug.

2. Allow the engine to idle with air conditioning OFF.

3. Move the shift lever through entire gear range to circulate fluid.

4. Wait for 30 seconds with the engine idling.

5. Stop the engine.

6. Remove the refill plug and add fluid.

7. Reinstall the refill plug.

4.FLUID CIRCULATION

a. Allow the engine to idle with the air conditioning OFF.

b. Move the shift lever through entire gear range to circulate fluid.

5.FLUID TEMPERATURE CHECK

a. With hand-held tester

1. Connect the han

d-held tester to the DLC3.

Output shaft oil seal replacement0.4 liters (0.42 US qts, 0.35 Imp. qts)

Transmission pan and drain plug removal1.3 liters (1.37 US qts, 1.14 Imp. qts)

Transmission valve body removal3.9 liters (4.12 US qts, 3.43 Imp. qts)

Torque converter replacement5.3 liters (5.60 US qts, 4.66 Imp. qts)

Entire transmission assembly7.2 liters (7.61 US qts, 6.34 Imp. qts)

Page 823 of 4500

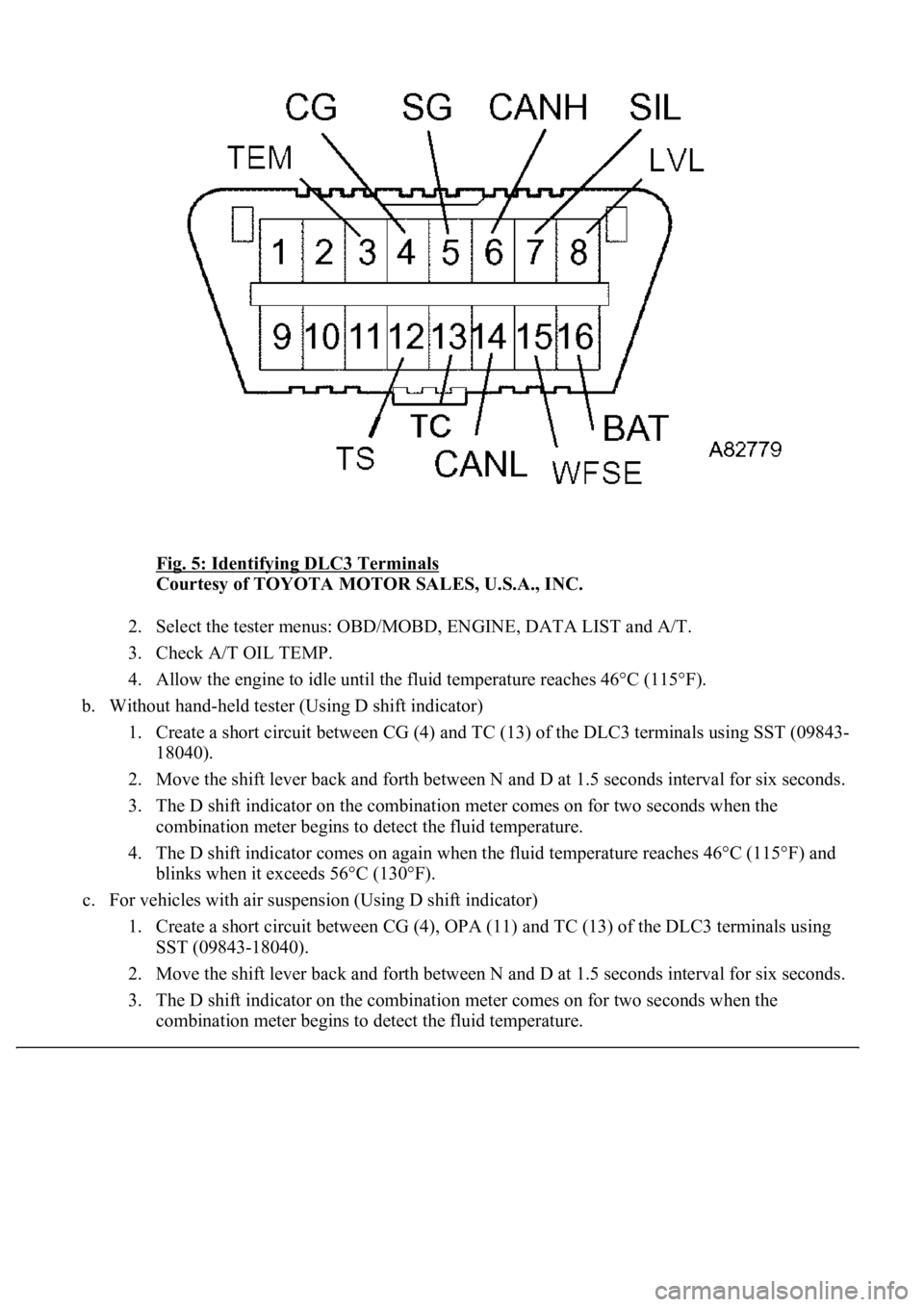

Fig. 5: Identifying DLC3 Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. Select the tester menus: OBD/MOBD, ENGINE, DATA LIST and A/T.

3. Check A/T OIL TEMP.

4. Allow the engine to idle until the fluid temperature reaches 46°C (115°F).

b. Without hand-held tester (Using D shift indicator)

1. Create a short circuit between CG (4) and TC (13) of the DLC3 terminals using SST (09843-

18040).

2. Move the shift lever back and forth between N and D at 1.5 seconds interval for six seconds.

3. The D shift indicator on the combination meter comes on for two seconds when the

combination meter begins to detect the fluid temperature.

4. The D shift indicator comes on again when the fluid temperature reaches 46°C (115°F) and

blinks when it exceeds 56°C (130°F).

c. For vehicles with air suspension (Using D shift indicator)

1. Create a short circuit between CG (4), OPA (11) and TC (13) of the DLC3 terminals using

SST (09843-18040).

2. Move the shift lever back and forth between N and D at 1.5 seconds interval for six seconds.

3. The D shift indicator on the combination meter comes on for two seconds when the

combination meter begins to detect the fluid temperature.

Page 824 of 4500

4. The D shift indicator comes on again when the fluid temperature reaches 46°C (115°F) and

blinks when it exceeds 56°C (130°F).

5. Allow the engine to idle until the fluid temperature reaches 46°C (115°F).

HINT:

The fluid temperature should be less than 30°C (86°F) before check the fluid temperature.

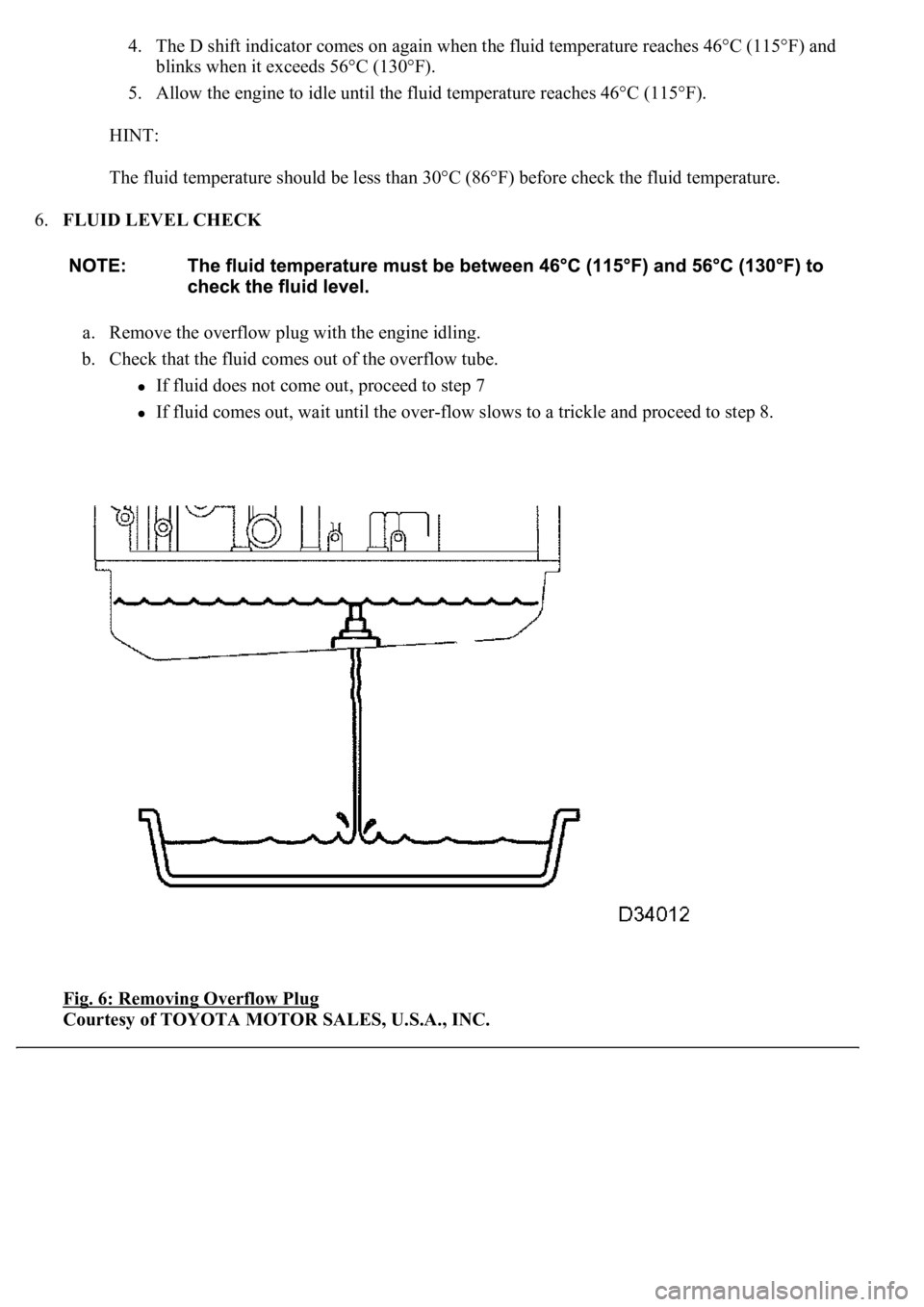

6.FLUID LEVEL CHECK

a. Remove the overflow plug with the engine idling.

b. Check that the fluid comes out of the overflow tube.

If fluid does not come out, proceed to step 7

If fluid comes out, wait until the over-flow slows to a trickle and proceed to step 8.

Fig. 6: Removing Overflow Plug

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.