brake fluid LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 13 of 4500

If a collision (front collision) is determined to be unavoidable, the pre-collision brake assist system

receives the brake assist standby signal from the distance control ECU and enters brake assist standby

mode.

If the STP signal is input, the pre-collision brake assist system improves deceleration performance by

increasing pressure according to the amount of brake pedal effort.

The hand-held tester can be used at step 5, 8, 11, 14

1.Vehicle Brought to Workshop

2.(SEE CUSTOMER PROBLEM ANALYSIS CHECK

)

3.Check MULTIPLEX COMMUNICATION SYSTEM (SEE HOW TO PROCEED WITH

TROUBLESHOOTING )

DTC is output: Check MULTIPLEX COMMUNICATION circuit (SEE HOW TO PROCEED

WITH TROUBLESHOOTING )

There is no output: Go to step 4

4.(SEE CHECK CAN BUS LINE

)

DTC is output: Check CAN COMMUNICATION circuit (SEE SKID CONTROL ECU

COMMUNICATION STOP MODE )

There is no output: Go to step 5

5.Check and Clear DTCs (SEE DTC CHECK/CLEAR

)

6.Problem Symptom Confirmation

Symptom does not occur: Go to step 7

Symptom occurs: Go to step 8

7.Symptom Simulation (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

8.(SEE DTC CHECK/CLEAR

)

There is no output: Go to step 9

There is output: Go to step 10

9.(SEE PROBLEM SYMPTOMS TABLE

)

Check for fluid leakage and Go to step 10

Page 39 of 4500

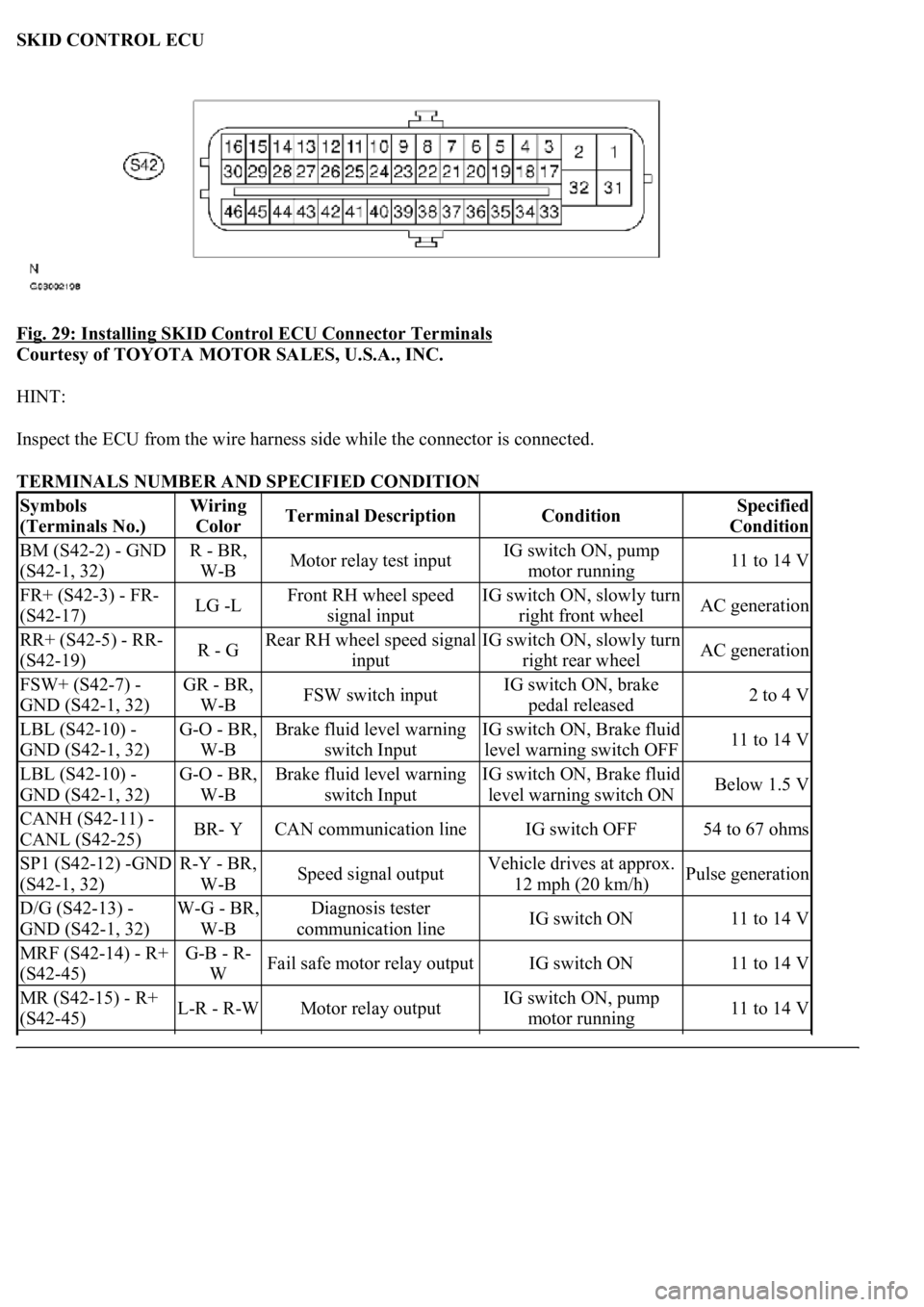

SKID CONTROL ECU

Fig. 29: Installing SKID Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Inspect the ECU from the wire harness side while the connector is connected.

TERMINALS NUMBER AND SPECIFIED CONDITION

Symbols

(Terminals No.)Wiring

ColorTerminal DescriptionConditionSpecified

Condition

BM (S42-2) - GND

(S42-1, 32)R - BR,

W-BMotor relay test inputIG switch ON, pump

motor running11 to 14 V

FR+ (S42-3) - FR-

(S42-17)LG -LFront RH wheel speed

signal inputIG switch ON, slowly turn

right front wheelAC generation

RR+ (S42-5) - RR-

(S42-19)R - GRear RH wheel speed signal

inputIG switch ON, slowly turn

right rear wheelAC generation

FSW+ (S42-7) -

GND (S42-1, 32)GR - BR,

W-BFSW switch inputIG switch ON, brake

pedal released2 to 4 V

LBL (S42-10) -

GND (S42-1, 32)G-O - BR,

W-BBrake fluid level warning

switch InputIG switch ON, Brake fluid

level warning switch OFF11 to 14 V

LBL (S42-10) -

GND (S42-1, 32)G-O - BR,

W-BBrake fluid level warning

switch InputIG switch ON, Brake fluid

level warning switch ONBelow 1.5 V

CANH (S42-11) -

CANL (S42-25)BR- YCAN communication lineIG switch OFF54 to 67 ohms

SP1 (S42-12) -GND

(S42-1, 32)R-Y - BR,

W-BSpeed signal outputVehicle drives at approx.

12 mph (20 km/h)Pulse generation

D/G (S42-13) -

GND (S42-1, 32)W-G - BR,

W-BDiagnosis tester

communication lineIG switch ON11 to 14 V

MRF (S42-14) - R+

(S42-45)G-B - R-

WFail safe motor relay outputIG switch ON11 to 14 V

MR (S42-15) - R+

(S42-45)L-R - R-WMotor relay outputIG switch ON, pump

motor running11 to 14 V

Page 128 of 4500

c. Select the DATA LIST mode on the hand-held tester.

MEASUREMENT ITEM / RANGE (DISPLAY) DESCRIPTION

d. Check that the brake fluid pressure value of the master cylinder pressure sensor observed in the

hand held tester changes when the brake pedal is depressed.

OK: Go to next step

When the pedal is depressed, displayed voltage on the hand-held tester increases.

NG: Go to step 2

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

2.INSPECT SKID CONTROL ECU TERMINAL VOLTAGE (STP TERMINAL)

a. Disconnect the skid control ECU connector.

b. Measure the voltage according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

NG: CHECK AND REPLACE STOP LIGHT SWITCH CIRCUIT

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

ItemMeasurement Item / Range (Display)Normal Condition

MAS CYL PRS

1Master cylinder pressure sensor 1 reading /

min.: 0 V, max.: 5 VWhen brake pedal is released:

0.3 to 0.9V

Tester ConnectionSwitch ConditionSpecified Condition

S42-27 (STP) - Body groundBrake pedal depressed8 to 14V

S42-27 (STP) - Body groundBrake pedal releasedBelow 1 V

Page 162 of 4500

CIRCUIT DESCRIPTION

The BRAKE warning light comes on when the brake fluid is insufficient, the parking brake is applied or the

EBD is defective.

The skid control ECU is connected to the combination meter via CAN and Multiplex communications.

The pad wear indicator is installed to the brake pad (right side).

If the wear indicator wire is open, "Brake Wear" appears on the multi-information display, which indicates that

the pad must be replaced.

WIRING DIAGRAM

Page 165 of 4500

INSPECTION PROCEDURE

HINT:

When releasing the parking brake, set the chocks to hold the vehicle for safety.

Check that "Brake Wear" does not appear on the multi-information display.

If it appears, check that brake pad thickness and replace the pad as necessary.

1.CHECK BRAKE FLUID LEVEL IN RESERVOIR

a. Check that the brake fluid level is proper.

OK: Go to next step

Brake fluid level is proper.

NG: ADD BRAKE FLUID

OK: Go to next step

2.CHECK DTC

a. Are the DTC recorded for ABS, VSC, CAN and/or Multiplex communication system?

OK: Go to next step

DTC OUTPUT DESCRIPTION

B: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

A: Go to next step

3.INSPECT BRAKE WARNING LIGHT

a. Connect the hand-held tester to the DLC3.

b. Start the engine.

c. Select the item "BRAKE WARN LIGHT" in the ACTIVE TEST and operate the BRAKE warning

light on the hand-held tester.

VEHICLE CONDITION / TEST DETAILS

d. Check that "ON" and "OFF" of the BRAKE warning light are indicated on the combination meter

when usin

g the hand-held tester.

DTC is not outputA

DTC is outputB

ItemVehicle Condition / Test DetailsDiagnostic Note

BRAKE WRN LIGHTTurns BRAKE warning light ON / OFFObserve combination meter

Page 168 of 4500

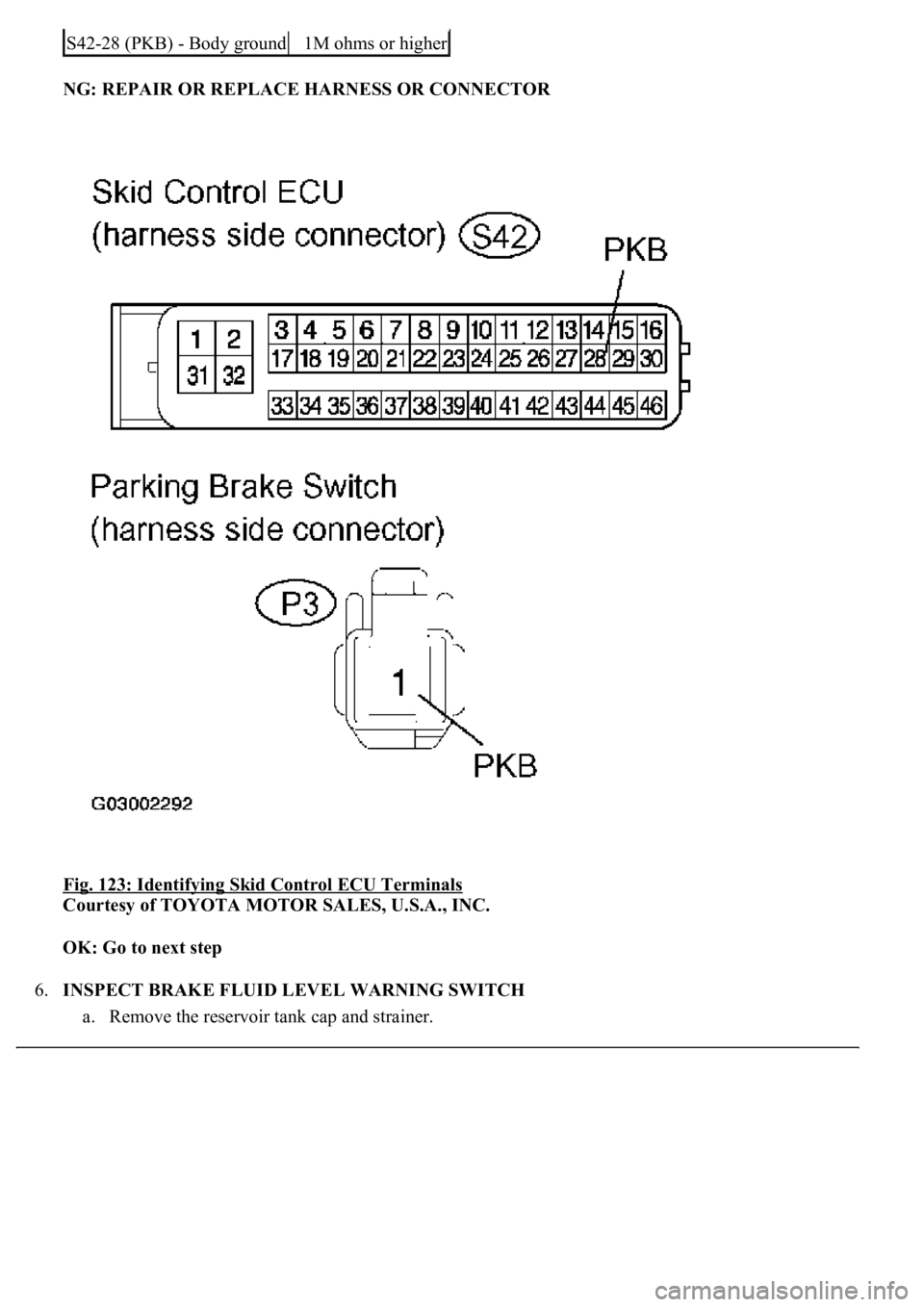

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Fig. 123: Identifying Skid Control ECU Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: Go to next step

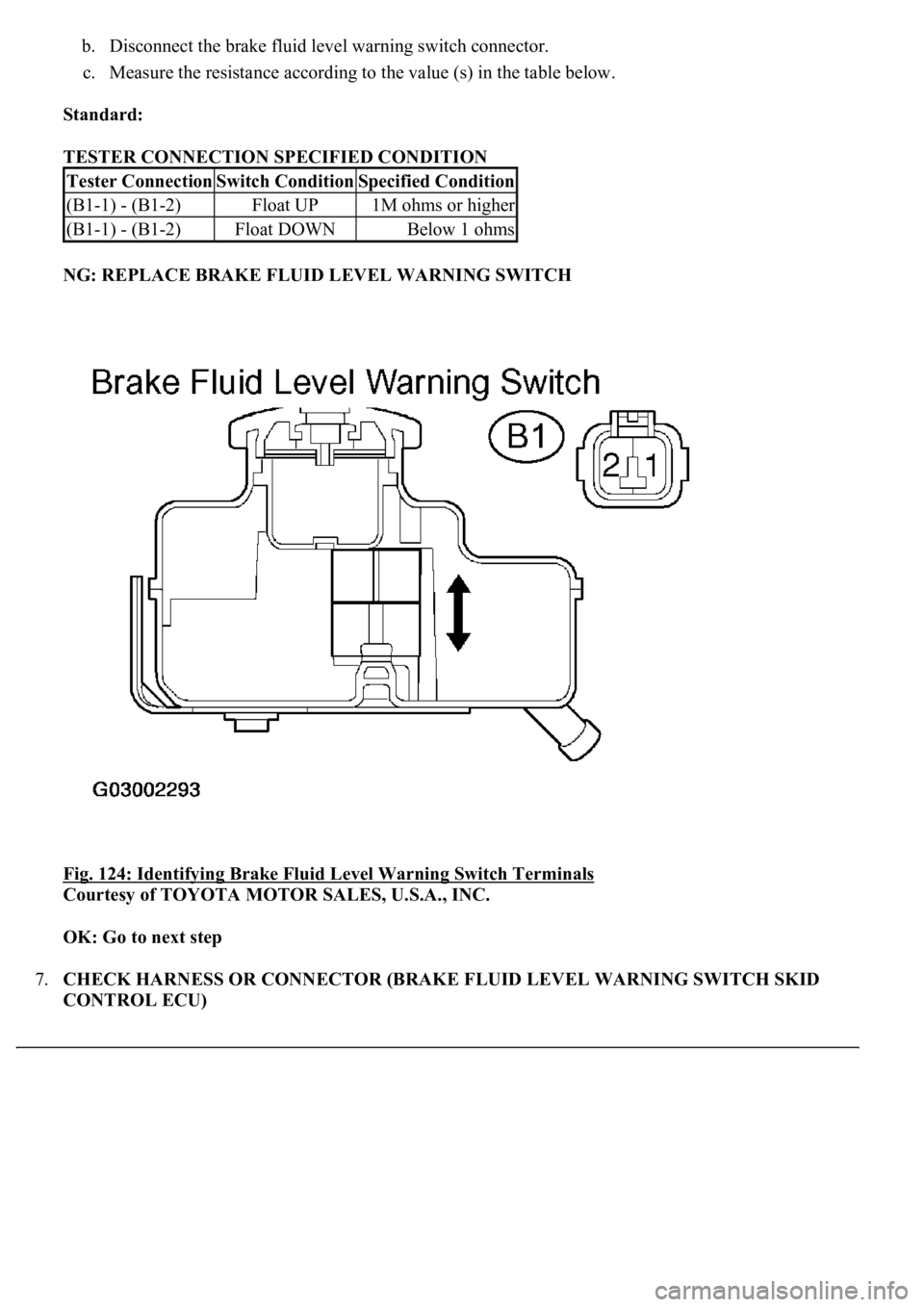

6.INSPECT BRAKE FLUID LEVEL WARNING SWITCH

a. Remove the reservoir tank cap and strainer.

S42-28 (PKB) - Body ground1M ohms or higher

Page 169 of 4500

b. Disconnect the brake fluid level warning switch connector.

c. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

NG: REPLACE BRAKE FLUID LEVEL WARNING SWITCH

Fig. 124: Identifying Brake Fluid Level Warning Switch Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: Go to next step

7.CHECK HARNESS OR CONNECTOR (BRAKE FLUID LEVEL WARNING SWITCH SKID

CONTROL ECU)

Tester ConnectionSwitch ConditionSpecified Condition

(B1-1) - (B1-2)Float UP1M ohms or higher

(B1-1) - (B1-2)Float DOWNBelow 1 ohms

Page 170 of 4500

a. Disconnect the skid control ECU connector and the brake fluid level warning switch connector.

b. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

c. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Tester ConnectionSpecified Condition

S42-10 (LBL) - (B1-1)Below 1 ohms

Tester ConnectionSpecified Condition

S42-10 (LBL) - Body ground1 Mohms or higher

Page 818 of 4500

PRECAUTION

1. The automatic transmission is composed of highly precision-finished parts which need careful inspection

before reassembly because even a small nick could cause fluid leakage or affect performance. The

instructions here are organized so that you work on only one component group at a time. This will help

avoid confusion from similar-looking parts of different sub-assemblies being on your workbench at the

same time. The component groups should be inspected and repaired from the converter housing side.

Inspect, repair and reassemble as much as possible before proceeding to the next component group. If a

defect is found in a certain component group during reassembly, inspect and repair this group

immediately. If a component group cannot be assembled because parts are being ordered, be sure to keep

all parts of the group in a separate container while proceeding with disassembly, inspection, repair and

reassembly of other component groups. Recommended ATF: ATF WS

2. All disassembled parts should be washed clean and any fluid passages and holes should be blown through

with compressed air.

3. Dry all parts with compressed air. Never use shop rags.

4. When using compressed air, be careful not to not aim at yourself to prevent accidentally spraying ATF or

kerosene on your face.

5. Only recommended automatic transaxle fluid or kerosene should be used for cleaning.

6. After cleaning, the parts should be arranged in the correct order for efficient inspection, repairs, and

reassembly.

7. When disassembling a valve body, be sure to match each valve together with the corresponding spring.

8. New discs for the brakes and clutches that are to be used for replacement must be soaked in ATF for at

least 15 minutes before reassembly.

9. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

ATF prior to reassembly.

10. All gaskets and rubber O-rings should be replaced.

11. Do not apply adhesive cements to gaskets or similar parts.

12. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

13. When replacing a worn bushing, the sub-assembly containing the bushing must also be replaced.

14. Check thrust bearings and races for wear or damage. Replace them as necessary.

15. Use petroleum jelly to keep parts in place.

16. When working with FIPG material, perform the following: Using a razor blade and a gasket scraper,

remove all the old packing (FIPG) material from the gasket surface.

Thoroughly clean all components to remove any loose material.

Page 921 of 4500

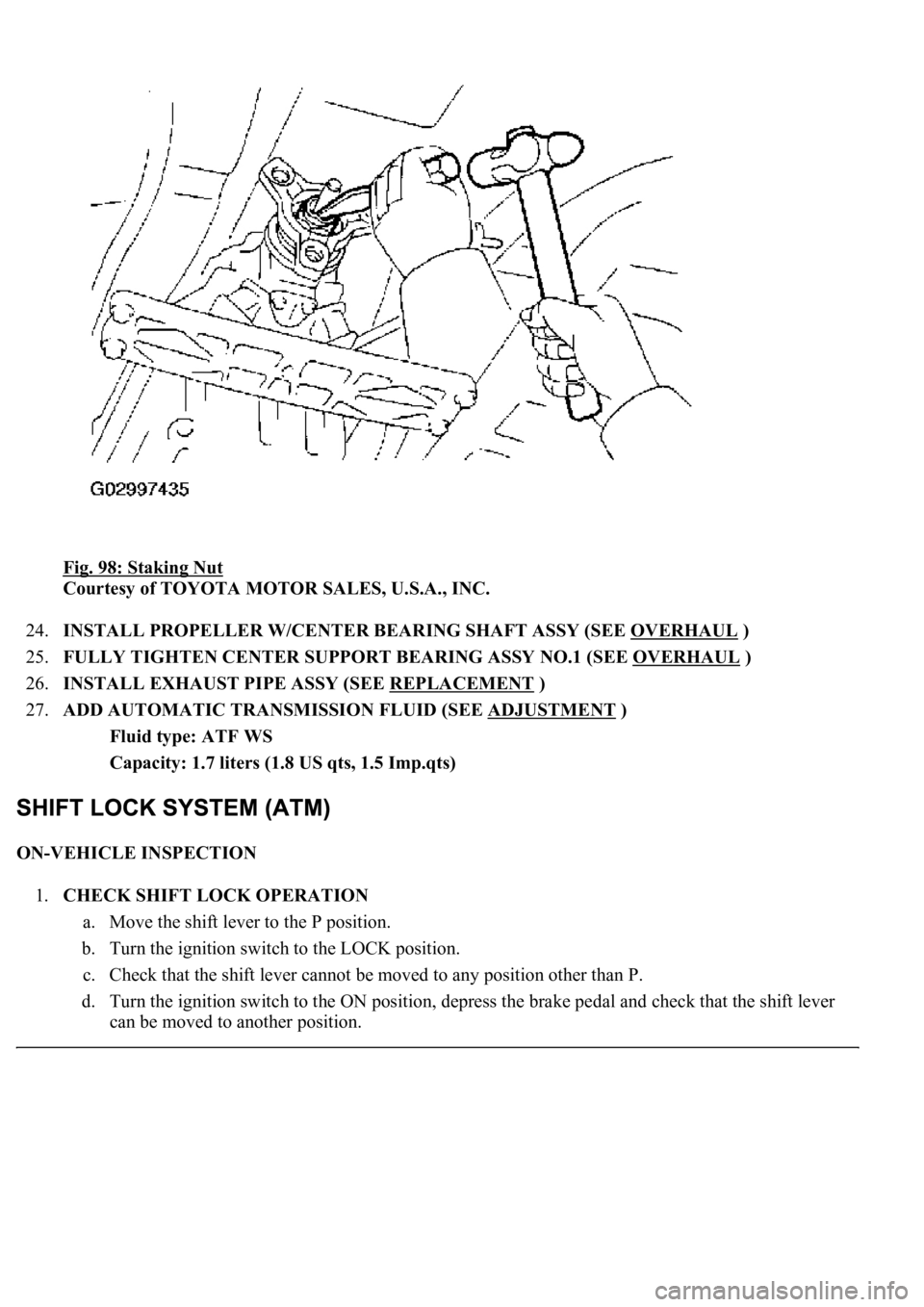

Fig. 98: Staking Nut

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

24.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

25.FULLY TIGHTEN CENTER SUPPORT BEARING ASSY NO.1 (SEE OVERHAUL

)

26.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

27.ADD AUTOMATIC TRANSMISSION FLUID (SEE ADJUSTMENT

)

Fluid type: ATF WS

Capacity: 1.7 liters (1.8 US qts, 1.5 Imp.qts)

ON-VEHICLE INSPECTION

1.CHECK SHIFT LOCK OPERATION

a. Move the shift lever to the P position.

b. Turn the ignition switch to the LOCK position.

c. Check that the shift lever cannot be moved to any position other than P.

d. Turn the ignition switch to the ON position, depress the brake pedal and check that the shift lever

can be moved to another position.