LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1151 of 4087

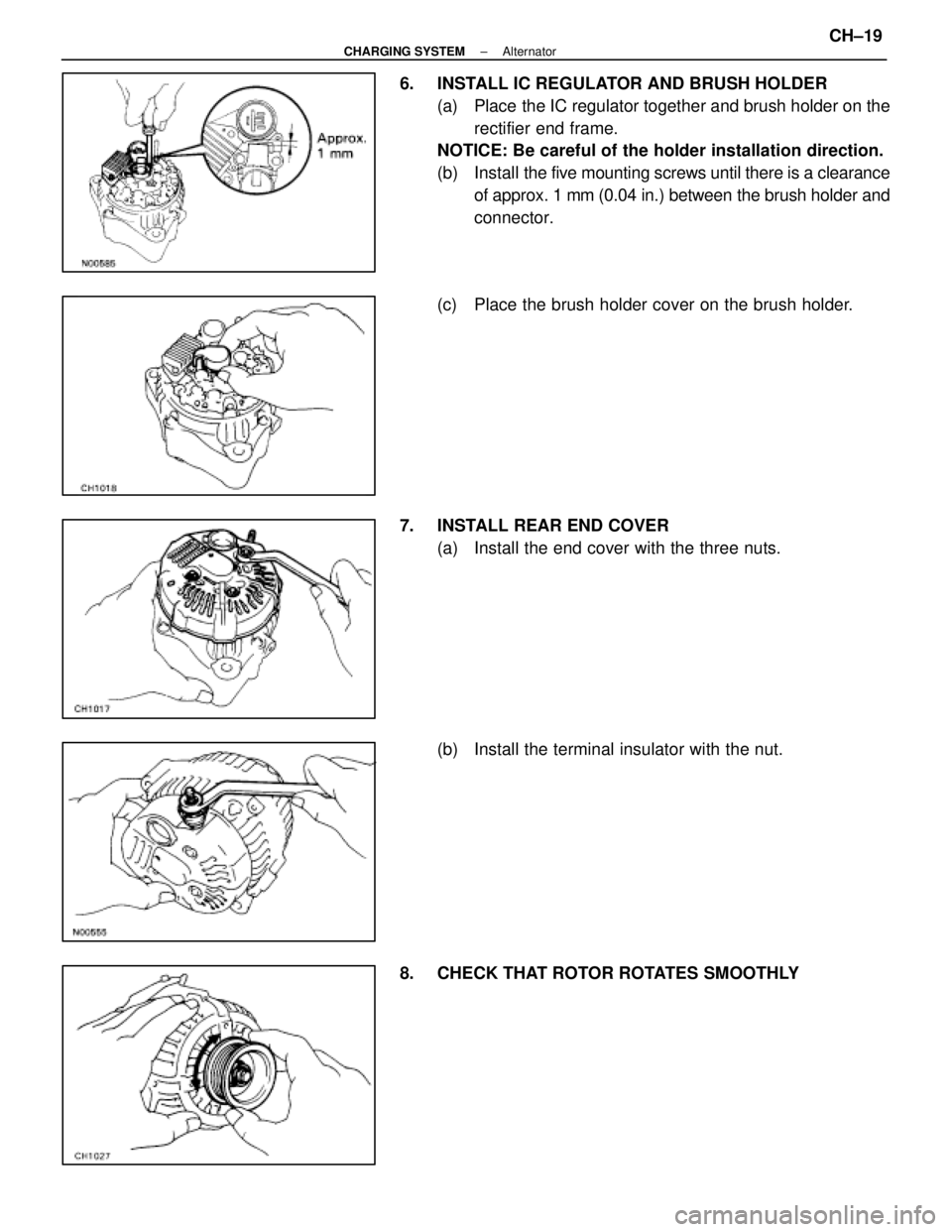

6. INSTALL IC REGULATOR AND BRUSH HOLDER(a) Place the IC regulator together and brush holder on therectifier end frame.

NOTICE: Be careful of the holder installation direction.

(b) Install the five mounting screws until there is a clearance

of approx. 1 mm (0.04 in.) between the brush holder and

connector.

(c) Place the brush holder cover on the brush holder.

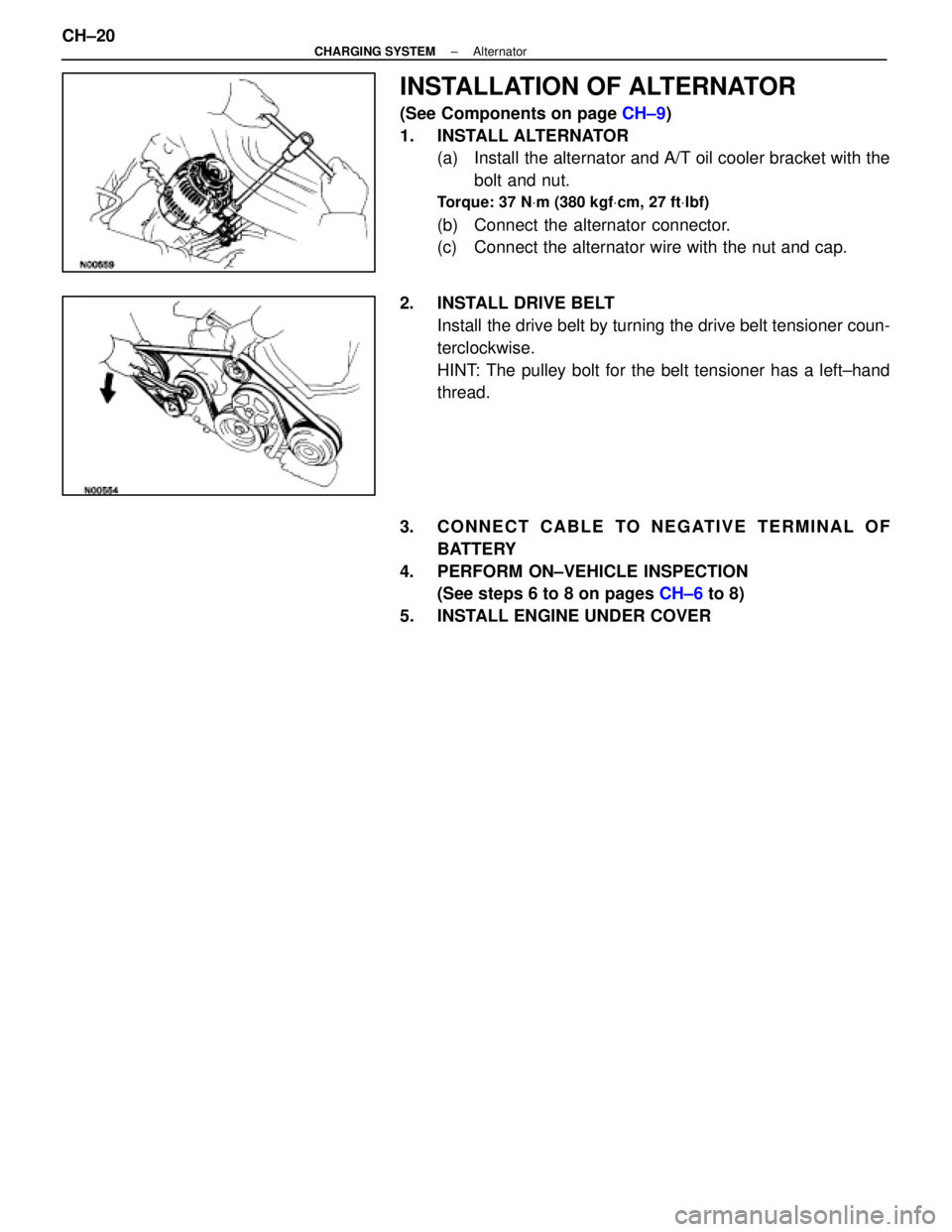

7. INSTALL REAR END COVER (a) Install the end cover with the three nuts.

(b) Install the terminal insulator with the nut.

8. CHECK THAT ROTOR ROTATES SMOOTHLY

±

CHARGING SYSTEM AlternatorCH±19

WhereEverybodyKnowsYourName

Page 1152 of 4087

INSTALLATION OF ALTERNATOR

(See Components on page CH±9)

1. INSTALL ALTERNATOR (a) Install the alternator and A/T oil cooler bracket with the

bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the alternator connector.

(c) Connect the alternator wire with the nut and cap.

2. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

3. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

4. PERFORM ON±VEHICLE INSPECTION (See steps 6 to 8 on pages CH±6 to 8)

5. INSTALL ENGINE UNDER COVER

CH±20

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1153 of 4087

ABBREVIATIONS USED IN THIS MANUAL

For convenience, the following abbreviations are used in this

manual.

ABS Antilock Brake System

assy assembly

ECT Electronic Controlled Transmission

ECU Electronic Control Unit

e.g. Exempi Gratia (For Example)

Ex. Except

in. inch

LH Left-hand

MIG Metal Inert Gas

M/Y Model Year

PPS Progressive Power Steering

RH Right-hand

w/ with

w/o without

INTRODUCTIONIN-16

WhereEverybodyKnowsYourName

Page 1154 of 4087

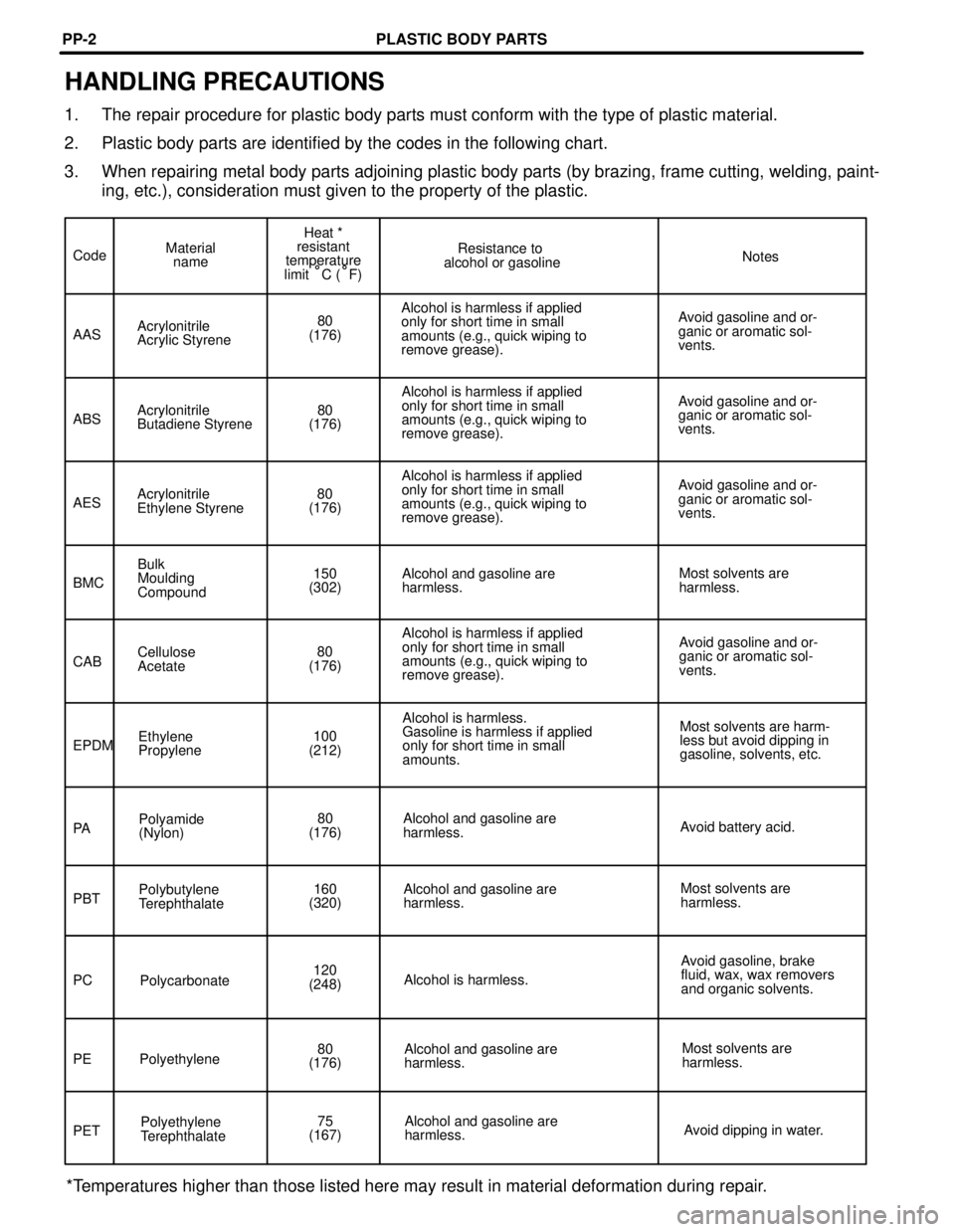

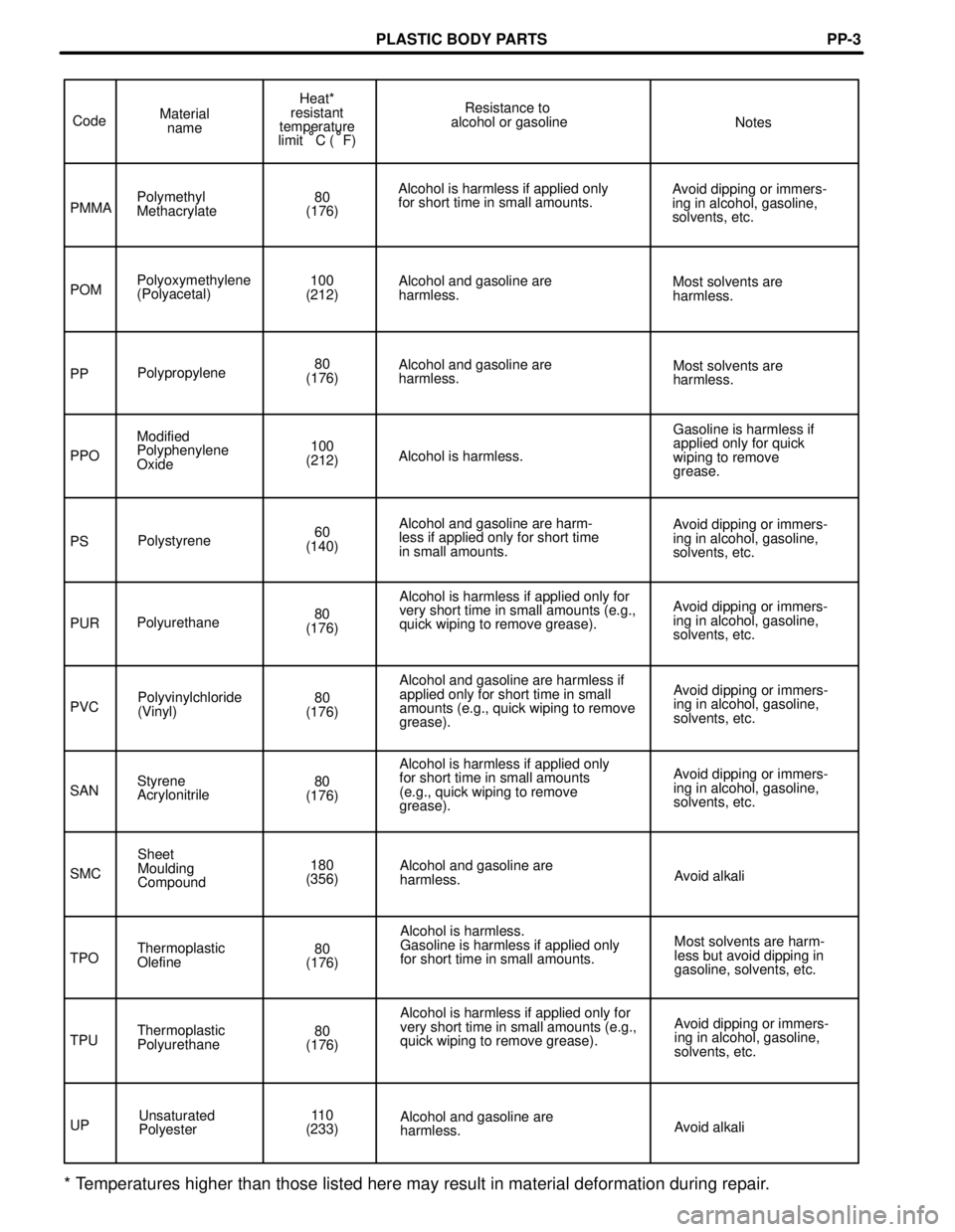

CodeMaterial

name Heat *

resistant

temperature

limit

°C (°F) Resistance to

alcohol or gasoline Notes

AAS Acrylonitrile

Acrylic Styrene 80

(176) Alcohol is harmless if applied

only for short time in small

amounts (e.g., quick wiping to

remove grease). Avoid gasoline and or-

ganic or aromatic sol-

vents.

ABS Acrylonitrile

Butadiene Styrene 80

(176) Alcohol is harmless if applied

only for short time in small

amounts (e.g., quick wiping to

remove grease).

Avoid gasoline and or-

ganic or aromatic sol-

vents.

AES Acrylonitrile

Ethylene Styrene 80

(176) Alcohol is harmless if applied

only for short time in small

amounts (e.g., quick wiping to

remove grease). Avoid gasoline and or-

ganic or aromatic sol-

vents.

BMC Bulk

Moulding

Compound

150

(302) Alcohol and gasoline are

harmless. Most solvents are

harmless.

CAB Cellulose

Acetate 80

(176) Alcohol is harmless if applied

only for short time in small

amounts (e.g., quick wiping to

remove grease). Avoid gasoline and or-

ganic or aromatic sol-

vents.

EPDM Ethylene

Propylene 100

(212) Alcohol is harmless.

Gasoline is harmless if applied

only for short time in small

amounts. Most solvents are harm-

less but avoid dipping in

gasoline, solvents, etc.

PA Polyamide

(Nylon) 80

(176) Alcohol and gasoline are

harmless.

Avoid battery acid.

PBT Polybutylene

Terephthalate 160

(320) Alcohol and gasoline are

harmless. Most solvents are

harmless.

PC Polycarbonate 120

(248) Alcohol is harmless. Avoid gasoline, brake

fluid, wax, wax removers

and organic solvents.

PE Polyethylene 80

(176) Alcohol and gasoline are

harmless. Most solvents are

harmless.

PET Polyethylene

Terephthalate 75

(167) Alcohol and gasoline are

harmless.

Avoid dipping in water.

HANDLING PRECAUTIONS

1. The repair procedure for plastic body parts must conform with the type o\

f plastic material.

2. Plastic body parts are identified by the codes in the following chart.

3. When repairing metal body parts adjoining plastic body parts (by brazin\

g, frame cutting, welding, paint-

ing, etc.), consideration must given to the property of the plastic.

*Temperatures higher than those listed here may result in material deforma\

tion during repair.

PLASTIC BODY PARTSPP-2

WhereEverybodyKnowsYourName

Page 1155 of 4087

CodeMaterial

name Heat*

resistant

temperature

limit

°C (°F) Resistance to

alcohol or gasoline Notes

PMMA Polymethyl

Methacrylate 80

(176) Alcohol is harmless if applied only

for short time in small amounts.

Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

POM Polyoxymethylene

(Polyacetal) 100

(212) Alcohol and gasoline are

harmless.

Most solvents are

harmless.

PP Polypropylene 80

(176) Alcohol and gasoline are

harmless.

Most solvents are

harmless.

PPO Modified

Polyphenylene

Oxide

100

(212) Alcohol is harmless. Gasoline is harmless if

applied only for quick

wiping to remove

grease.

PS Polystyrene 60

(140) Alcohol and gasoline are harm-

less if applied only for short time

in small amounts. Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

PUR Polyurethane 80

(176) Alcohol is harmless if applied only for

very short time in small amounts (e.g.,

quick wiping to remove grease).

Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

PVC Polyvinylchloride

(Vinyl) 80

(176) Alcohol and gasoline are harmless if

applied only for short time in small

amounts (e.g., quick wiping to remove

grease). Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

SAN Styrene

Acrylonitrile 80

(176) Alcohol is harmless if applied only

for short time in small amounts

(e.g., quick wiping to remove

grease).

Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

SMC Sheet

Moulding

Compound

180

(356) Alcohol and gasoline are

harmless.

Avoid alkali

TPO Thermoplastic

Olefine 80

(176) Alcohol is harmless.

Gasoline is harmless if applied only

for short time in small amounts.

Most solvents are harm-

less but avoid dipping in

gasoline, solvents, etc.

TPU Thermoplastic

Polyurethane 80

(176) Alcohol is harmless if applied only for

very short time in small amounts (e.g.,

quick wiping to remove grease).

Avoid dipping or immers-

ing in alcohol, gasoline,

solvents, etc.

UP Unsaturated

Polyester 11 0

(233) Alcohol and gasoline are

harmless.

Avoid alkali

* Temperatures higher than those listed here may result in material deforma\

tion during repair.

PLASTIC BODY PARTSPP-3

WhereEverybodyKnowsYourName

Page 1156 of 4087

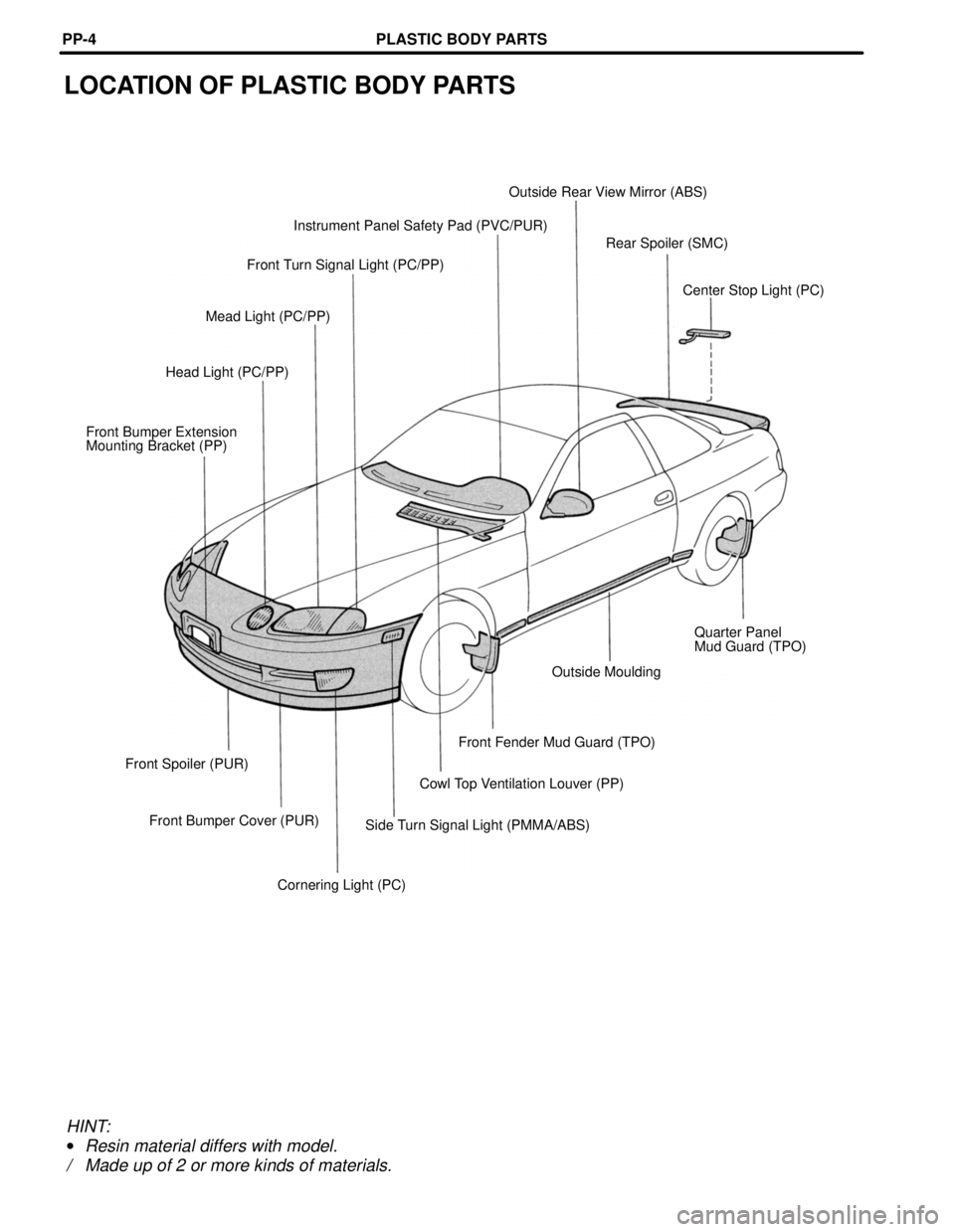

LOCATION OF PLASTIC BODY PARTS

Outside Rear View Mirror (ABS)

Instrument Panel Safety Pad (PVC/PUR) Rear Spoiler (SMC)

Front Turn Signal Light (PC/PP)

Center Stop Light (PC)

Mead Light (PC/PP)

Head Light (PC/PP)

Front Bumper Extension

Mounting Bracket (PP)

Quarter Panel

Mud Guard (TPO)

Outside Moulding

Front Fender Mud Guard (TPO)

Front Spoiler (PUR) Cowl Top Ventilation Louver (PP)

Front Bumper Cover (PUR) Side Turn Signal Light (PMMA/ABS)

Cornering Light (PC)

HINT:

wResin material differs with model.

/ Made up of 2 or more kinds of materials.

PLASTIC BODY PARTSPP-4

WhereEverybodyKnowsYourName

Page 1157 of 4087

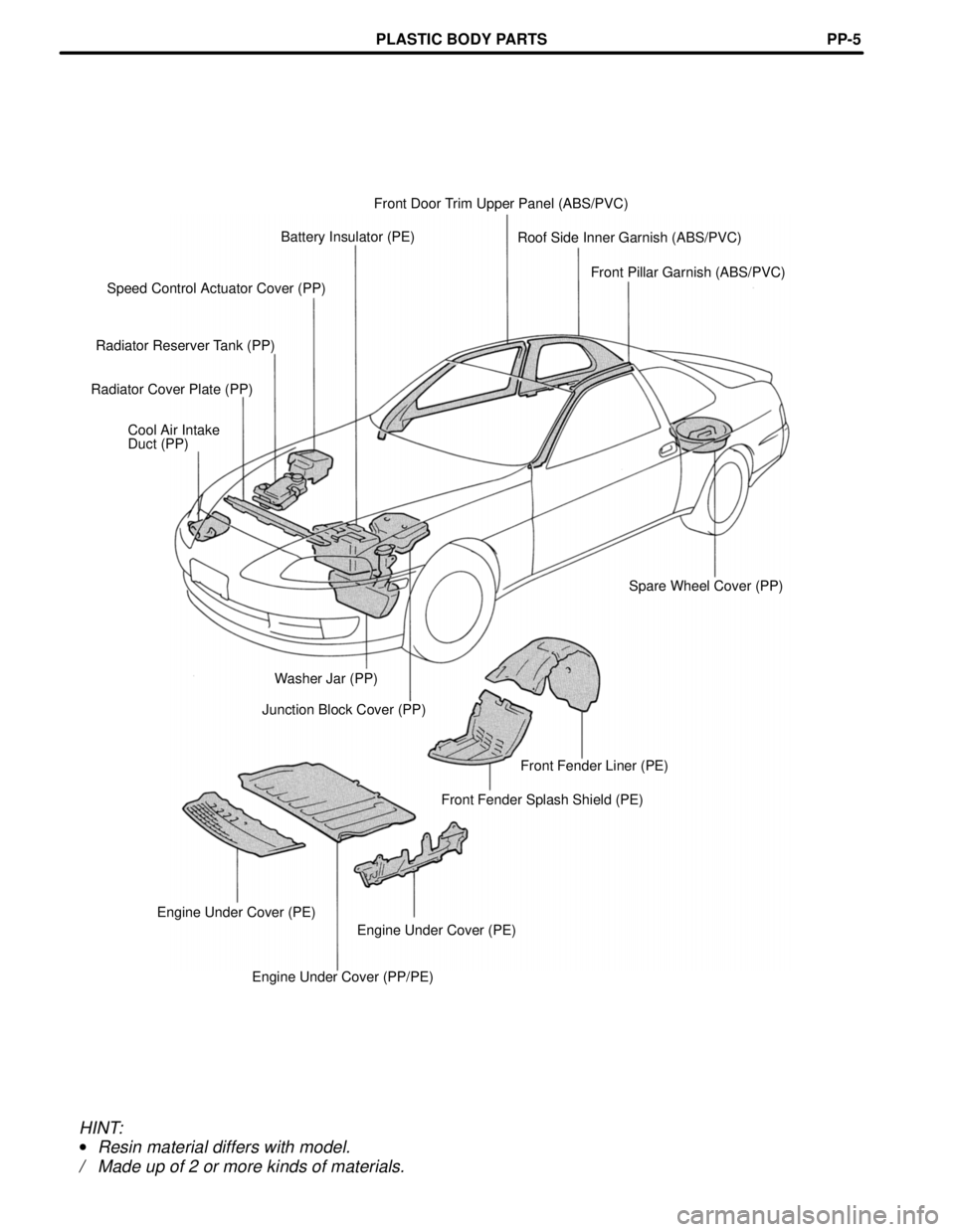

Front Door Trim Upper Panel (ABS/PVC)

Battery Insulator (PE) Roof Side Inner Garnish (ABS/PVC)

Front Pillar Garnish (ABS/PVC)

Speed Control Actuator Cover (PP)

Radiator Reserver Tank (PP)

Radiator Cover Plate (PP) Cool Air Intake

Duct (PP)

Spare Wheel Cover (PP)

Washer Jar (PP)

Junction Block Cover (PP)

Front Fender Liner (PE)

Front Fender Splash Shield (PE)

Engine Under Cover (PE) Engine Under Cover (PE)

Engine Under Cover (PP/PE)

HINT:

wResin material differs with model.

/ Made up of 2 or more kinds of materials.

PLASTIC BODY PARTSPP-5

WhereEverybodyKnowsYourName

Page 1158 of 4087

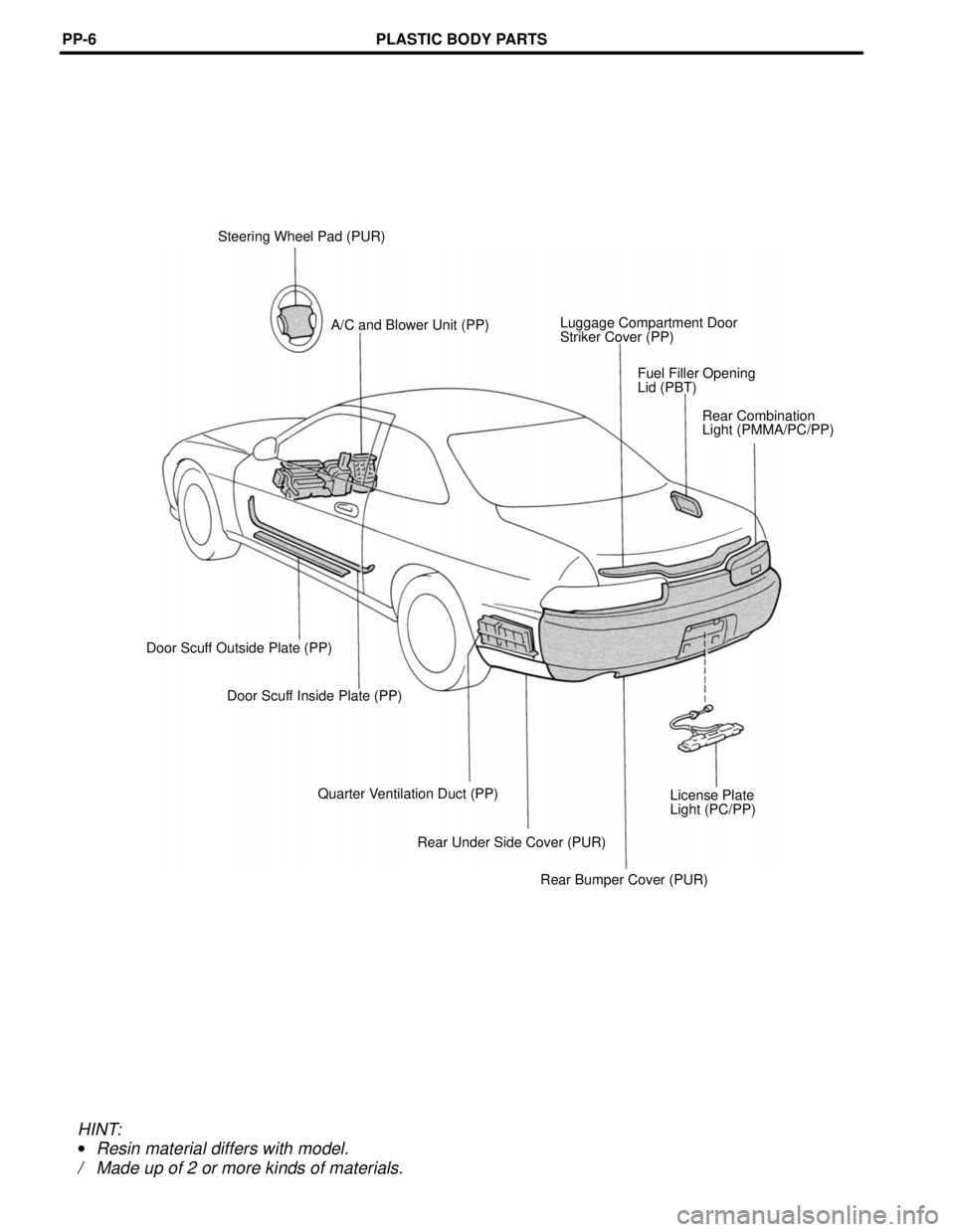

Steering Wheel Pad (PUR)A/C and Blower Unit (PP) Luggage Compartment Door

Striker Cover (PP)

Fuel Filler Opening

Lid (PBT)Rear Combination

Light (PMMA/PC/PP)

Door Scuff Outside Plate (PP) Door Scuff Inside Plate (PP)

Quarter Ventilation Duct (PP) License Plate

Light (PC/PP)

Rear Under Side Cover (PUR)

Rear Bumper Cover (PUR)

HINT:

wResin material differs with model.

/ Made up of 2 or more kinds of materials.

PLASTIC BODY PARTSPP-6

WhereEverybodyKnowsYourName

Page 1159 of 4087

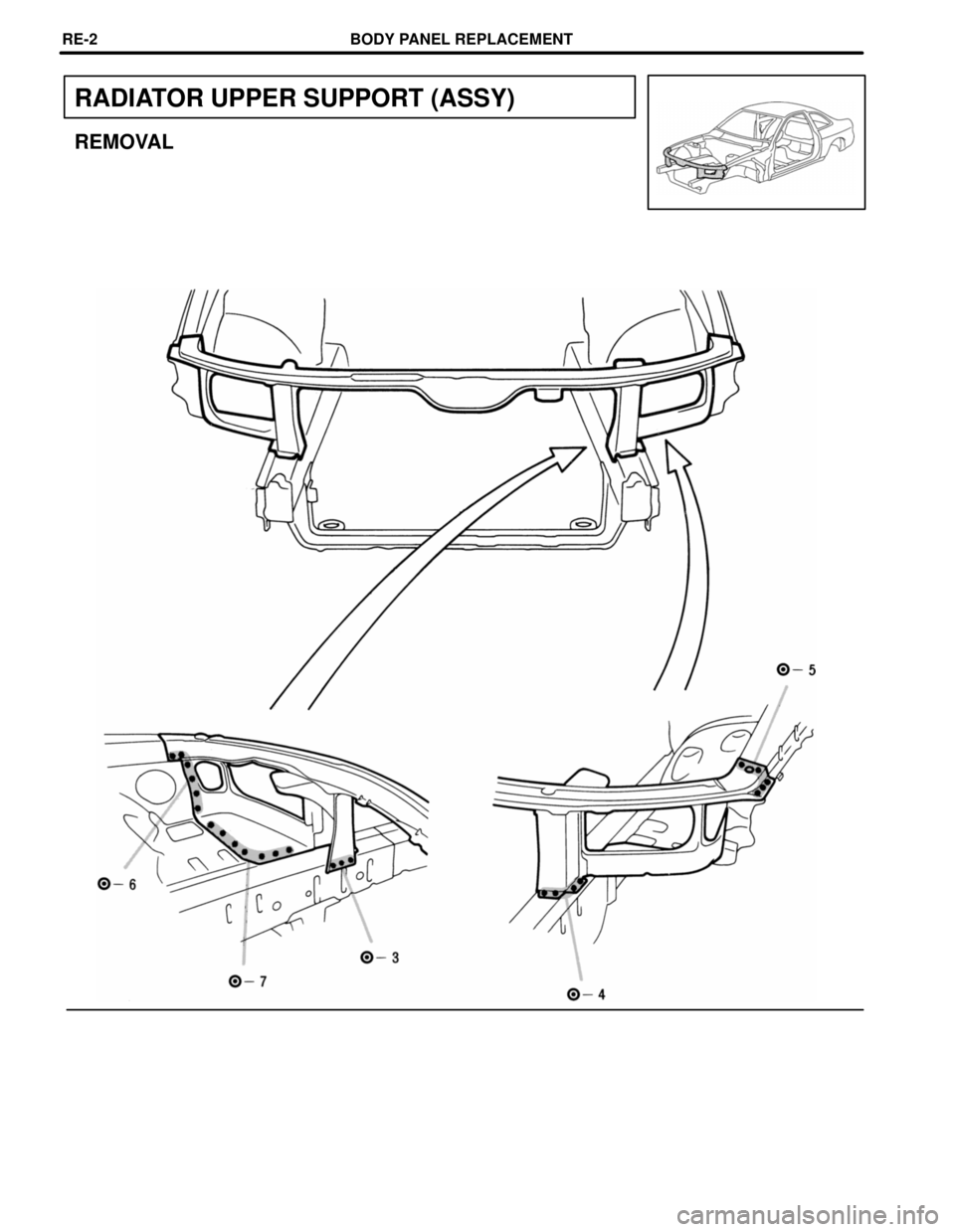

RADIATOR UPPER SUPPORT (ASSY)

REMOVAL

BODY PANEL REPLACEMENTRE-2

WhereEverybodyKnowsYourName

Page 1160 of 4087

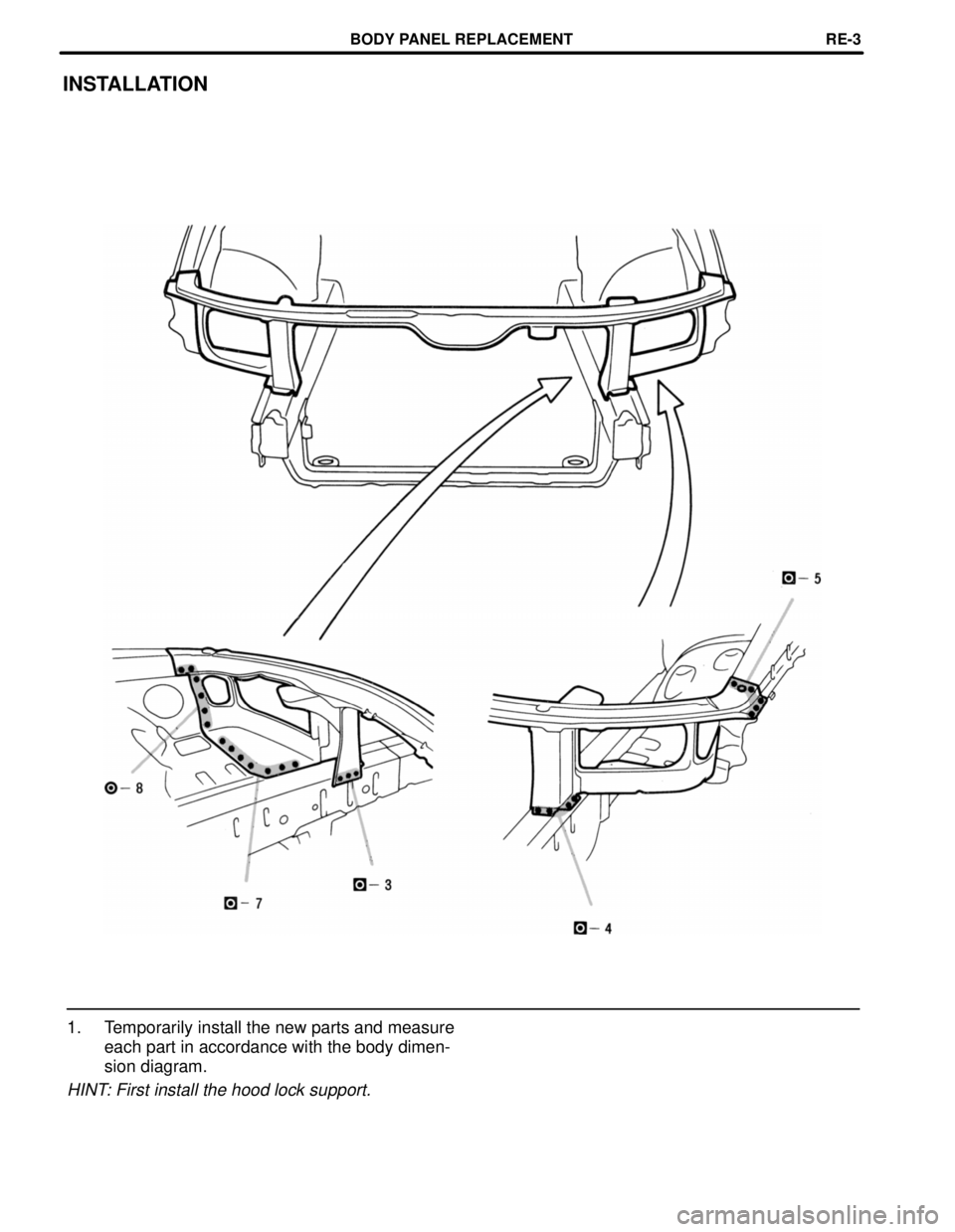

INSTALLATION

1. Temporarily install the new parts and measureeach part in accordance with the body dimen-

sion diagram.

HINT: First install the hood lock support.

BODY PANEL REPLACEMENTRE-3

WhereEverybodyKnowsYourName