LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: air filter, belt, stop start, reset, oil pressure, fuel pressure, heater

Page 1141 of 4087

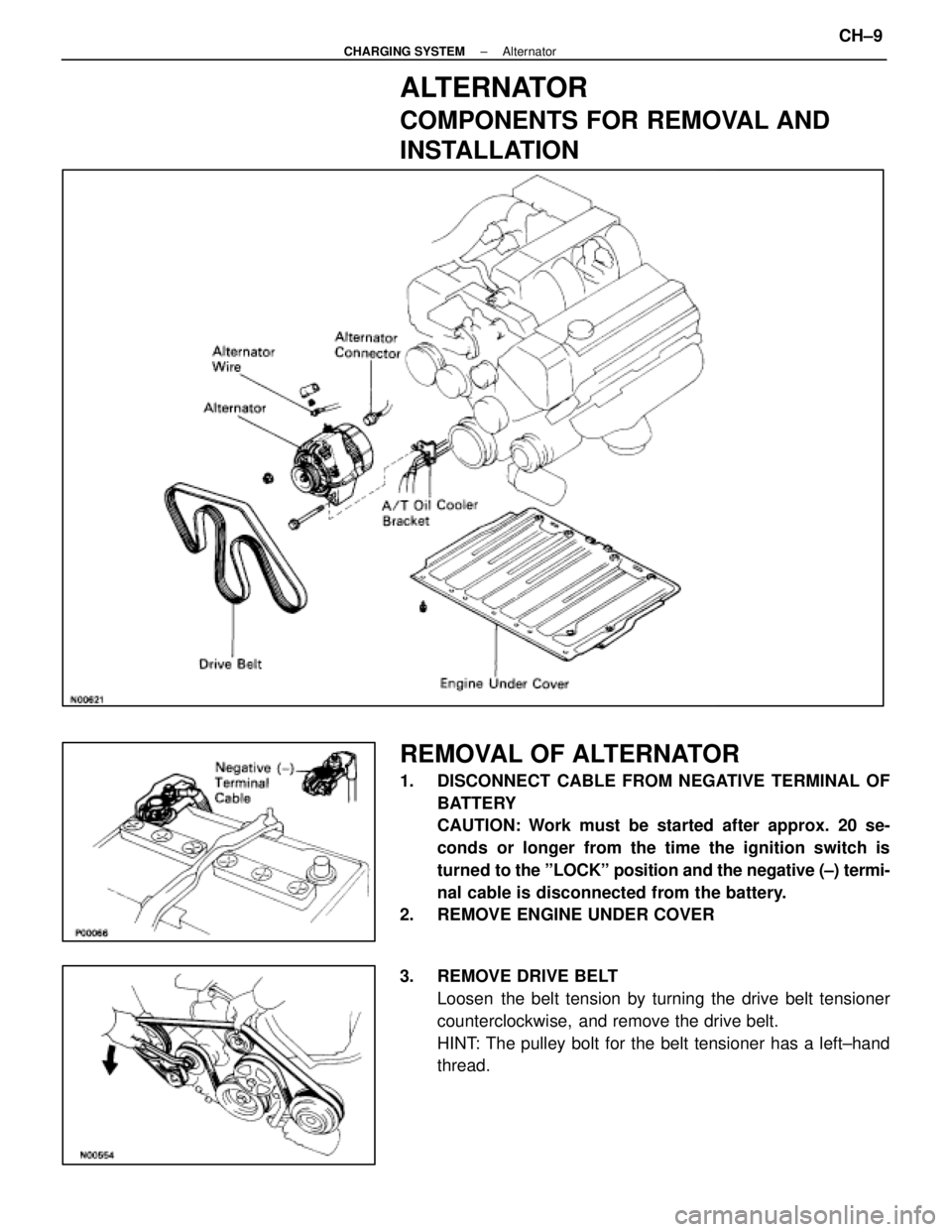

ALTERNATOR

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF ALTERNATOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. REMOVE DRIVE BELT

Loosen the belt tension by turning the drive belt tensioner

counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

±

CHARGING SYSTEM AlternatorCH±9

WhereEverybodyKnowsYourName

Page 1142 of 4087

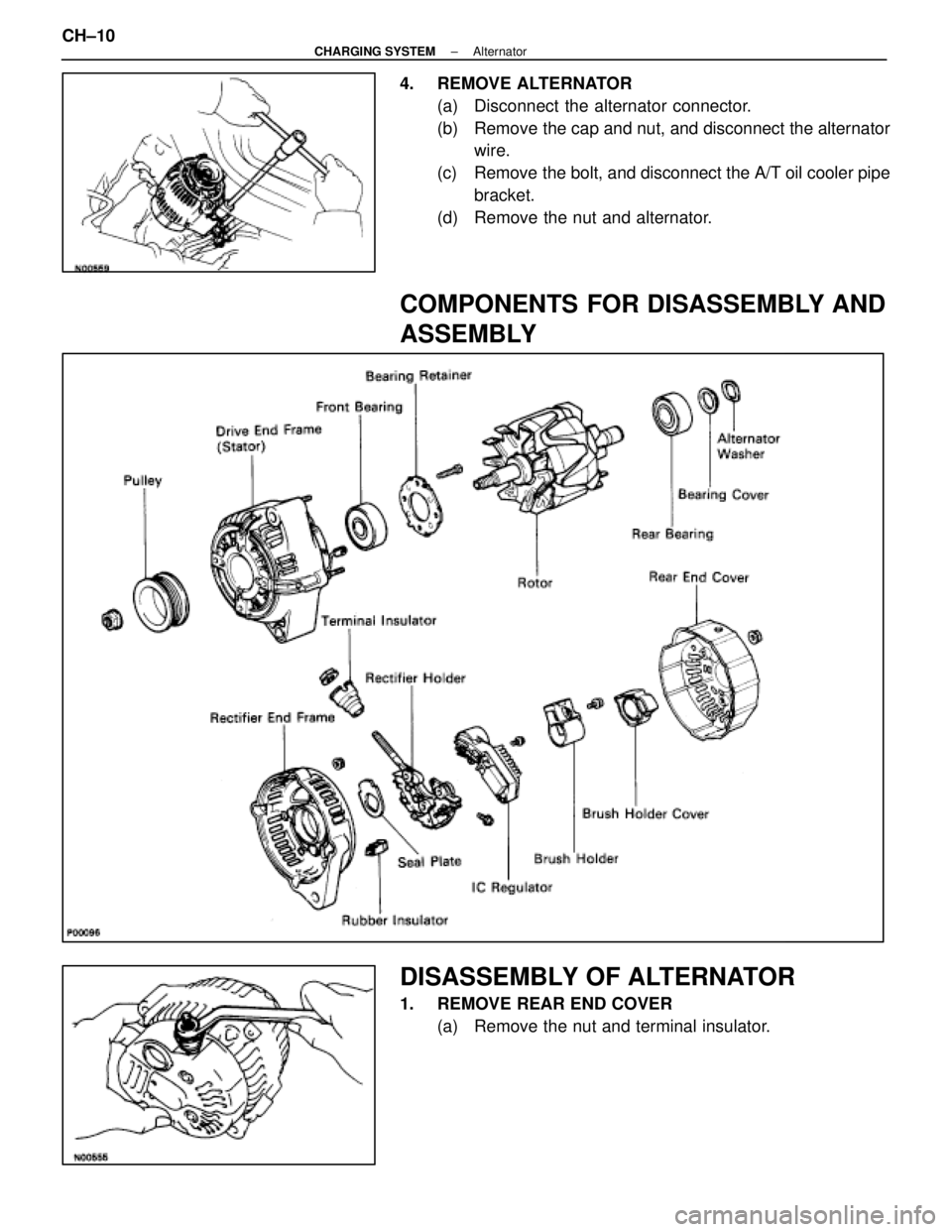

4. REMOVE ALTERNATOR(a) Disconnect the alternator connector.

(b) Remove the cap and nut, and disconnect the alternatorwire.

(c) Remove the bolt, and disconnect the A/T oil cooler pipe bracket.

(d) Remove the nut and alternator.

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY

DISASSEMBLY OF ALTERNATOR

1. REMOVE REAR END COVER (a) Remove the nut and terminal insulator.

CH±10

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1143 of 4087

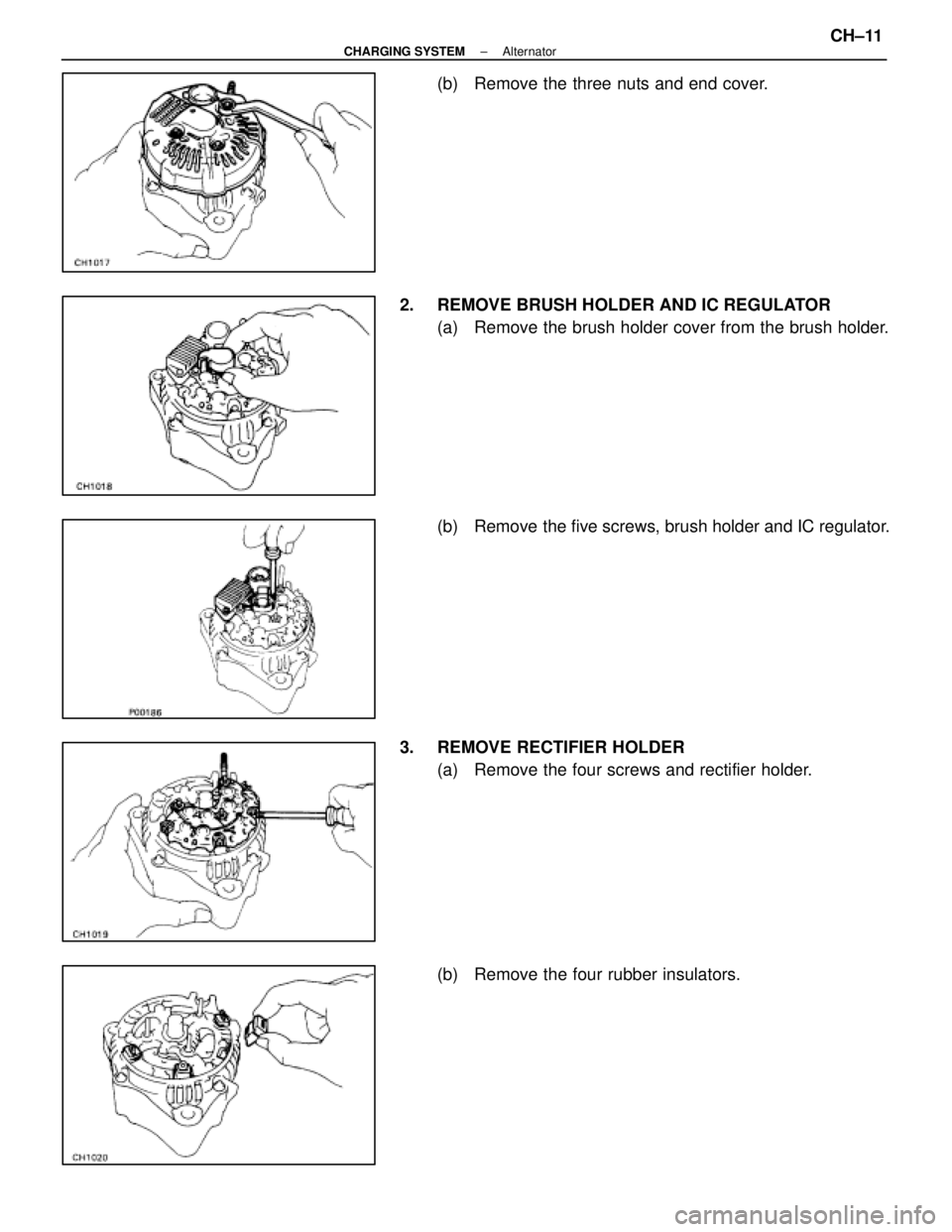

(b) Remove the three nuts and end cover.

2. REMOVE BRUSH HOLDER AND IC REGULATOR (a) Remove the brush holder cover from the brush holder.

(b) Remove the five screws, brush holder and IC regulator.

3. REMOVE RECTIFIER HOLDER (a) Remove the four screws and rectifier holder.

(b) Remove the four rubber insulators.

±

CHARGING SYSTEM AlternatorCH±11

WhereEverybodyKnowsYourName

Page 1144 of 4087

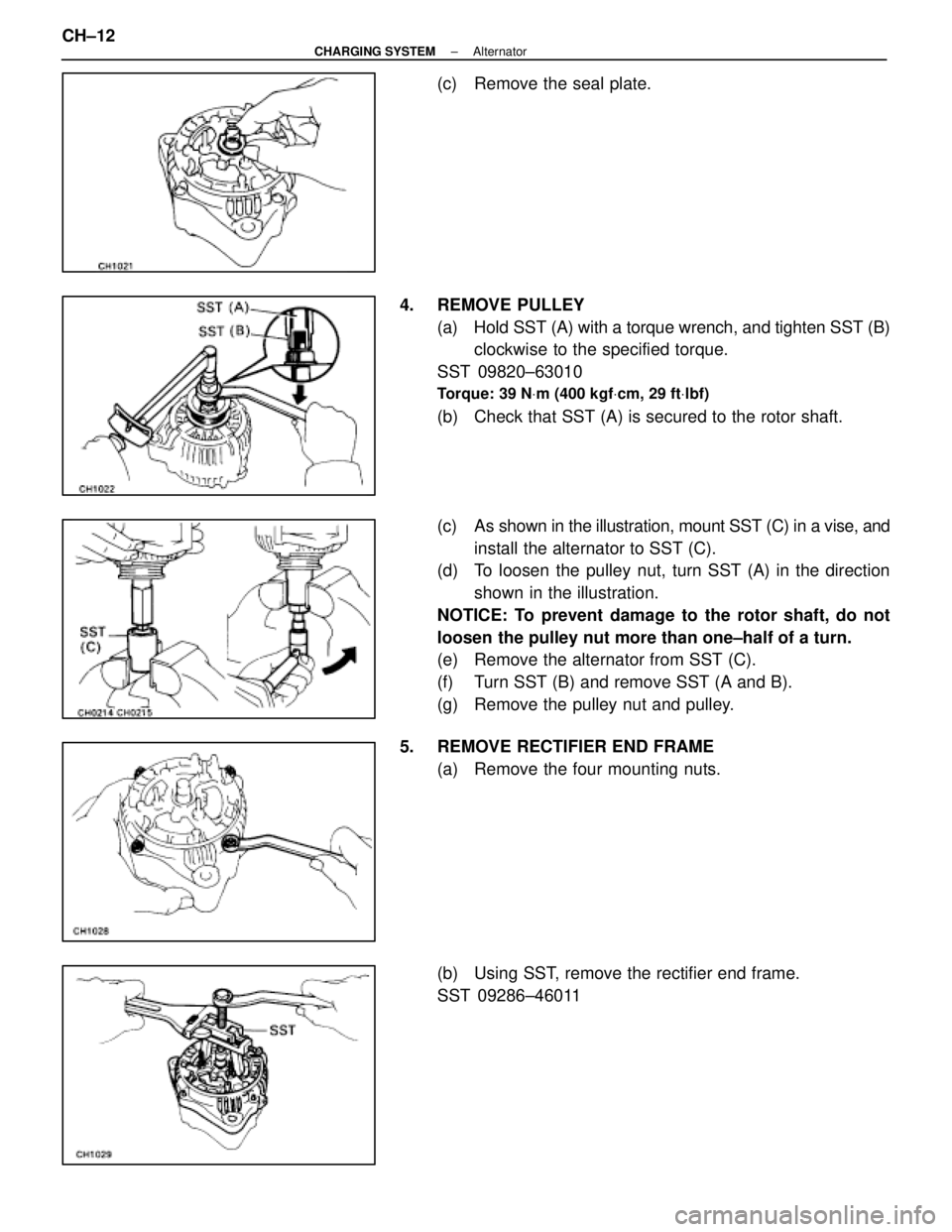

(c) Remove the seal plate.

4. REMOVE PULLEY (a) Hold SST (A) with a torque wrench, and tighten SST (B)clockwise to the specified torque.

SST 09820±63010

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(b) Check that SST (A) is secured to the rotor shaft.

(c) As shown in the illustration, mount SST (C) in a vise, and

install the alternator to SST (C).

(d) To loosen the pulley nut, turn SST (A) in the direction

shown in the illustration.

NOTICE: To prevent damage to the rotor shaft, do not

loosen the pulley nut more than one±half of a turn.

(e) Remove the alternator from SST (C).

(f) Turn SST (B) and remove SST (A and B).

(g) Remove the pulley nut and pulley.

5. REMOVE RECTIFIER END FRAME (a) Remove the four mounting nuts.

(b) Using SST, remove the rectifier end frame.

SST 09286±46011

CH±12

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1145 of 4087

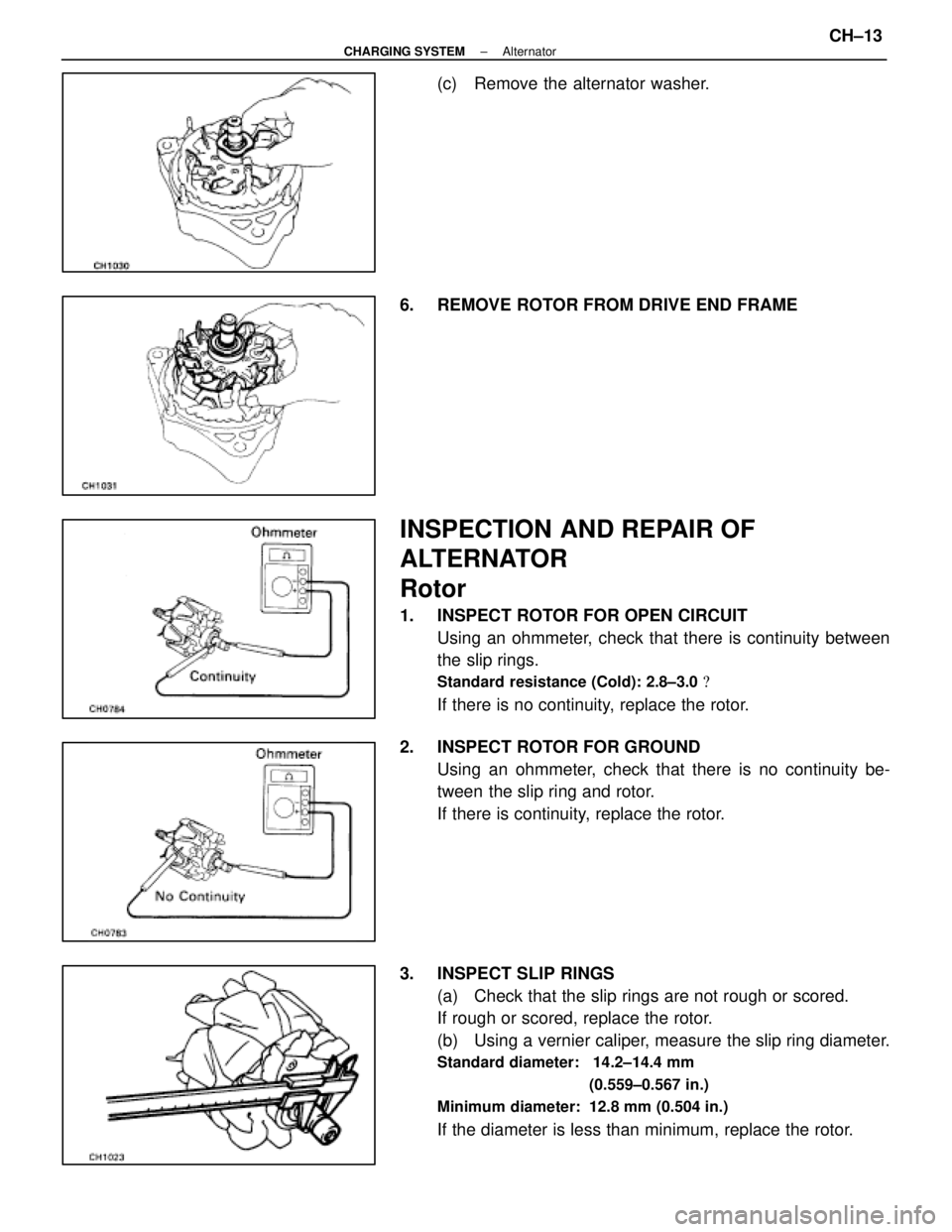

(c) Remove the alternator washer.

6. REMOVE ROTOR FROM DRIVE END FRAME

INSPECTION AND REPAIR OF

ALTERNATOR

Rotor

1. INSPECT ROTOR FOR OPEN CIRCUIT Using an ohmmeter, check that there is continuity between

the slip rings.

Standard resistance (Cold): 2.8±3.0 �

If there is no continuity, replace the rotor.

2. INSPECT ROTOR FOR GROUND Using an ohmmeter, check that there is no continuity be-

tween the slip ring and rotor.

If there is continuity, replace the rotor.

3. INSPECT SLIP RINGS (a) Check that the slip rings are not rough or scored.

If rough or scored, replace the rotor.

(b) Using a vernier caliper, measure the slip ring diameter.

Standard diameter: 14.2±14.4 mm

(0.559±0.567 in.)

Minimum diameter: 12.8 mm (0.504 in.)

If the diameter is less than minimum, replace the rotor.

±

CHARGING SYSTEM AlternatorCH±13

WhereEverybodyKnowsYourName

Page 1146 of 4087

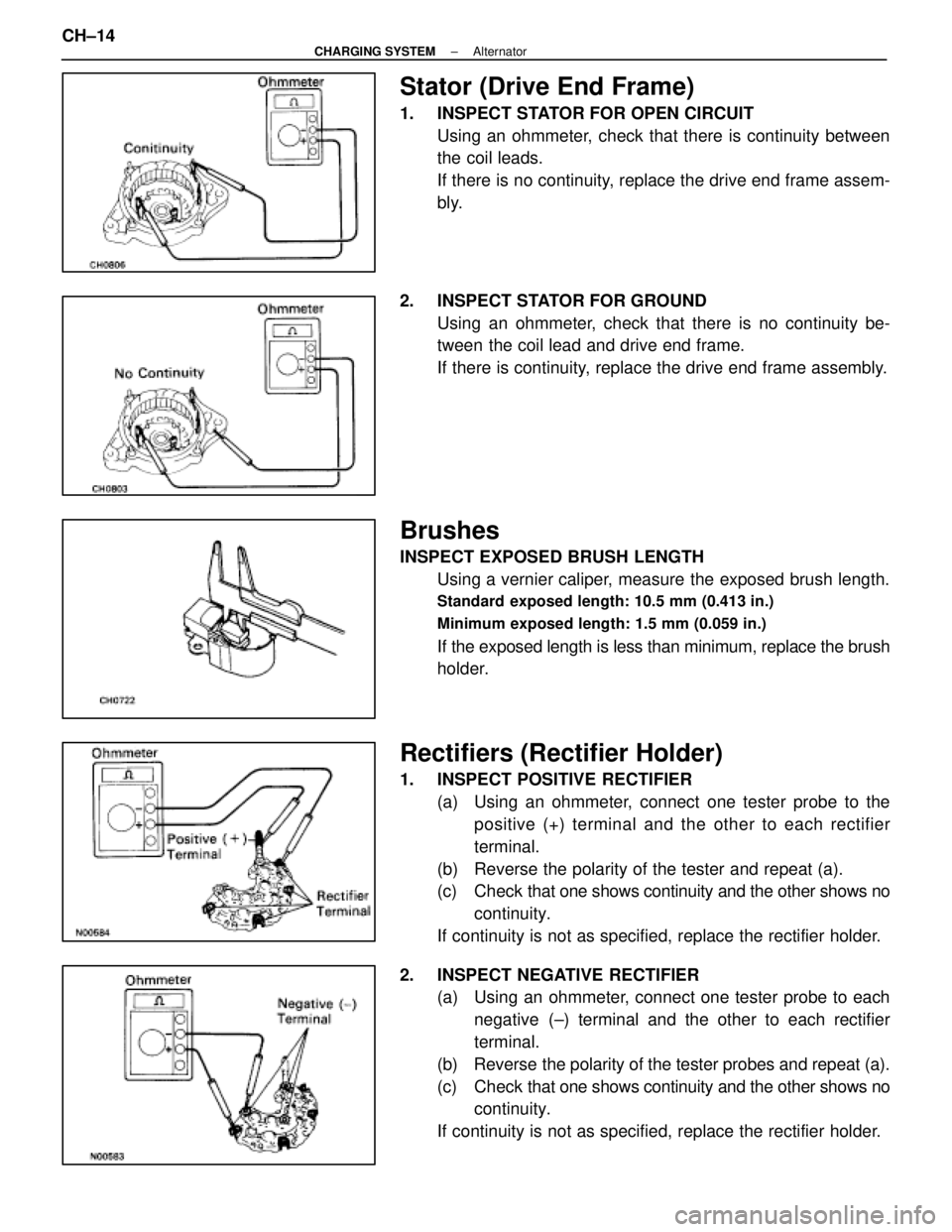

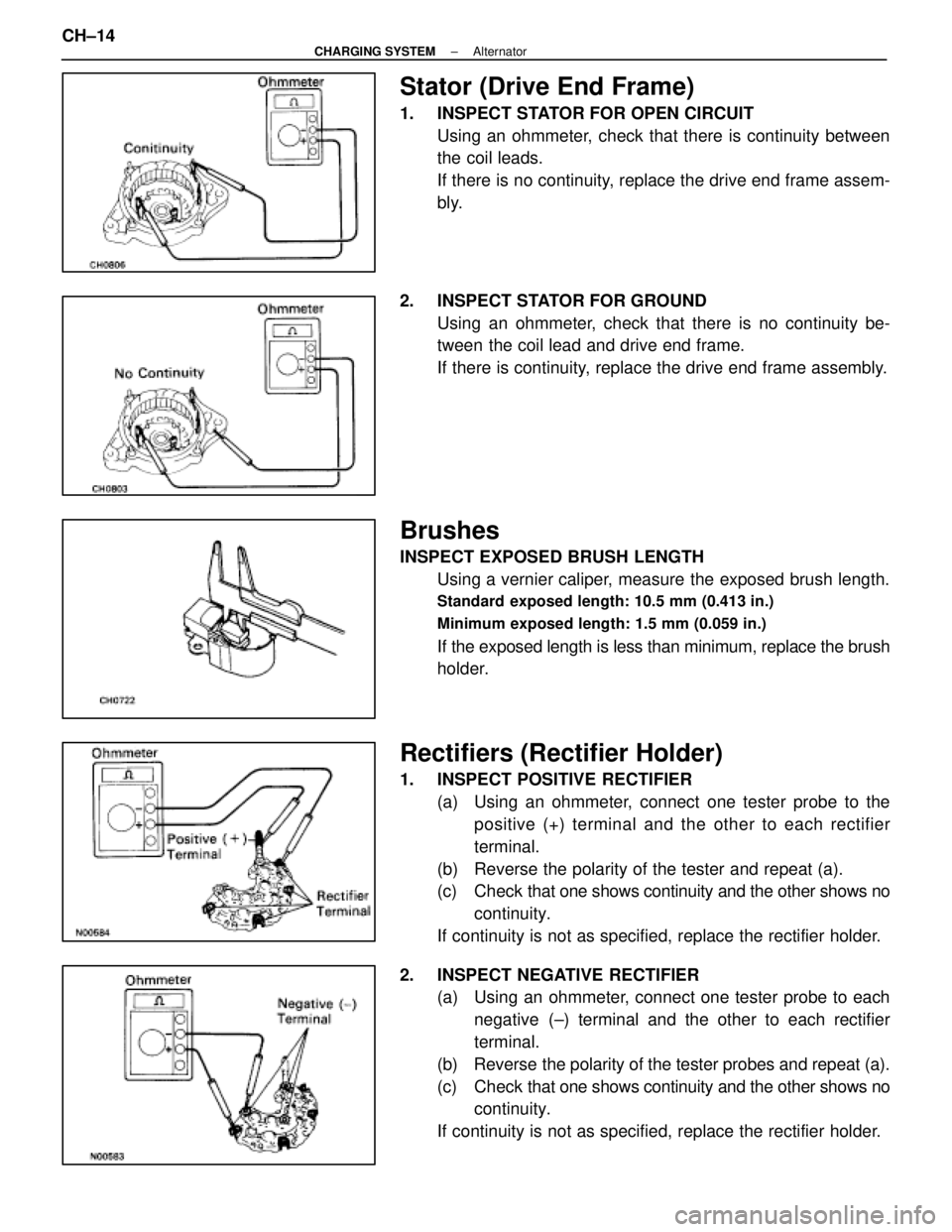

Stator (Drive End Frame)

1. INSPECT STATOR FOR OPEN CIRCUITUsing an ohmmeter, check that there is continuity between

the coil leads.

If there is no continuity, replace the drive end frame assem-

bly.

2. INSPECT STATOR FOR GROUND Using an ohmmeter, check that there is no continuity be-

tween the coil lead and drive end frame.

If there is continuity, replace the drive end frame assembly.

Brushes

INSPECT EXPOSED BRUSH LENGTHUsing a vernier caliper, measure the exposed brush length.

Standard exposed length: 10.5 mm (0.413 in.)

Minimum exposed length: 1.5 mm (0.059 in.)

If the exposed length is less than minimum, replace the brush

holder.

Rectifiers (Rectifier Holder)

1. INSPECT POSITIVE RECTIFIER(a) Using an ohmmeter, connect one tester probe to thepositive (+) terminal and the other to each rectifier

terminal.

(b) Reverse the polarity of the tester and repeat (a).

(c) Check that one shows continuity and the other shows no

continuity.

If continuity is not as specified, replace the rectifier holder.

2. INSPECT NEGATIVE RECTIFIER (a) Using an ohmmeter, connect one tester probe to each

negative (±) terminal and the other to each rectifier

terminal.

(b) Reverse the polarity of the tester probes and repeat (a).

(c) Check that one shows continuity and the other shows no

continuity.

If continuity is not as specified, replace the rectifier holder.

CH±14

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1147 of 4087

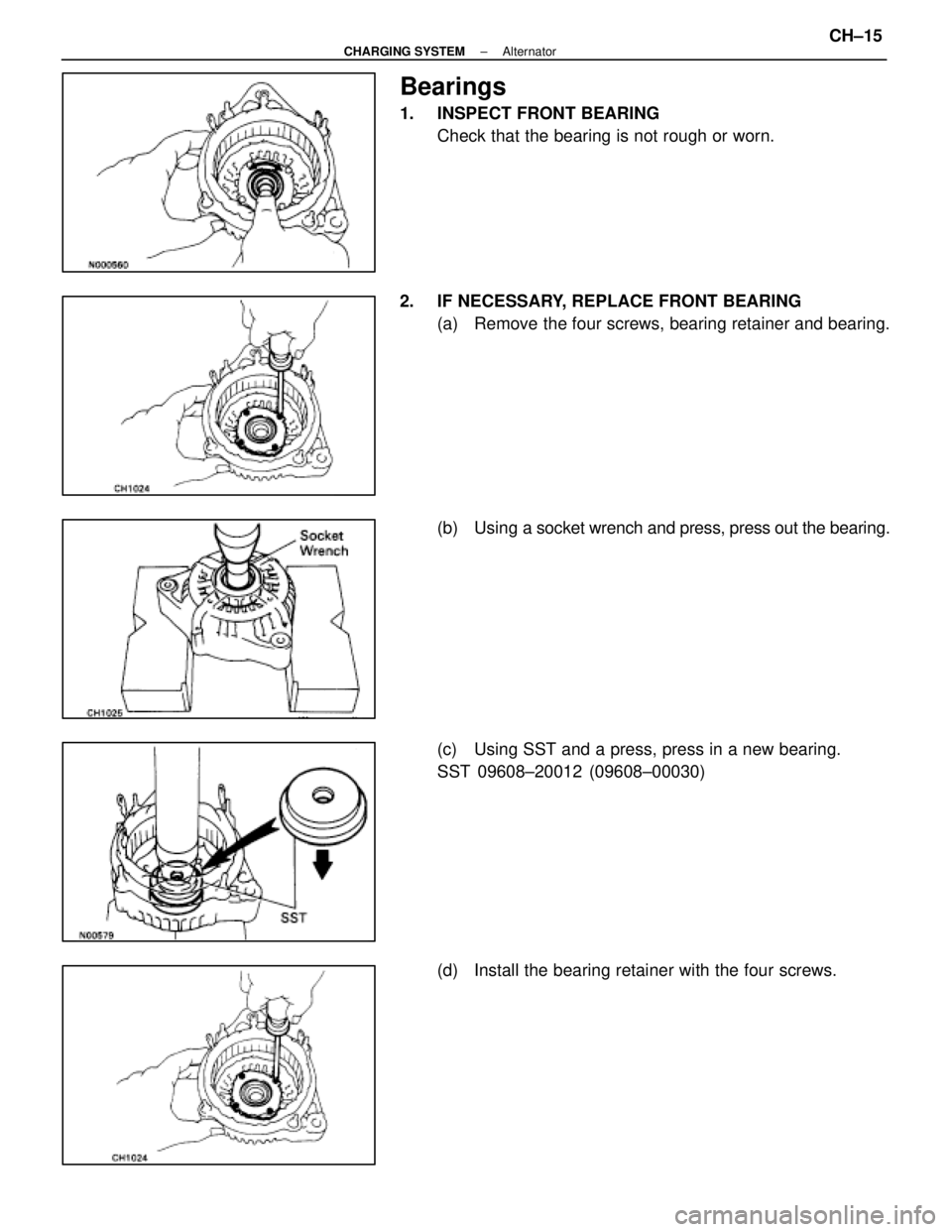

Bearings

1. INSPECT FRONT BEARINGCheck that the bearing is not rough or worn.

2. IF NECESSARY, REPLACE FRONT BEARING (a) Remove the four screws, bearing retainer and bearing.

(b) Using a socket wrench and press, press out the bearing.

(c) Using SST and a press, press in a new bearing.

SST 09608±20012 (09608±00030)

(d) Install the bearing retainer with the four screws.

±

CHARGING SYSTEM AlternatorCH±15

WhereEverybodyKnowsYourName

Page 1148 of 4087

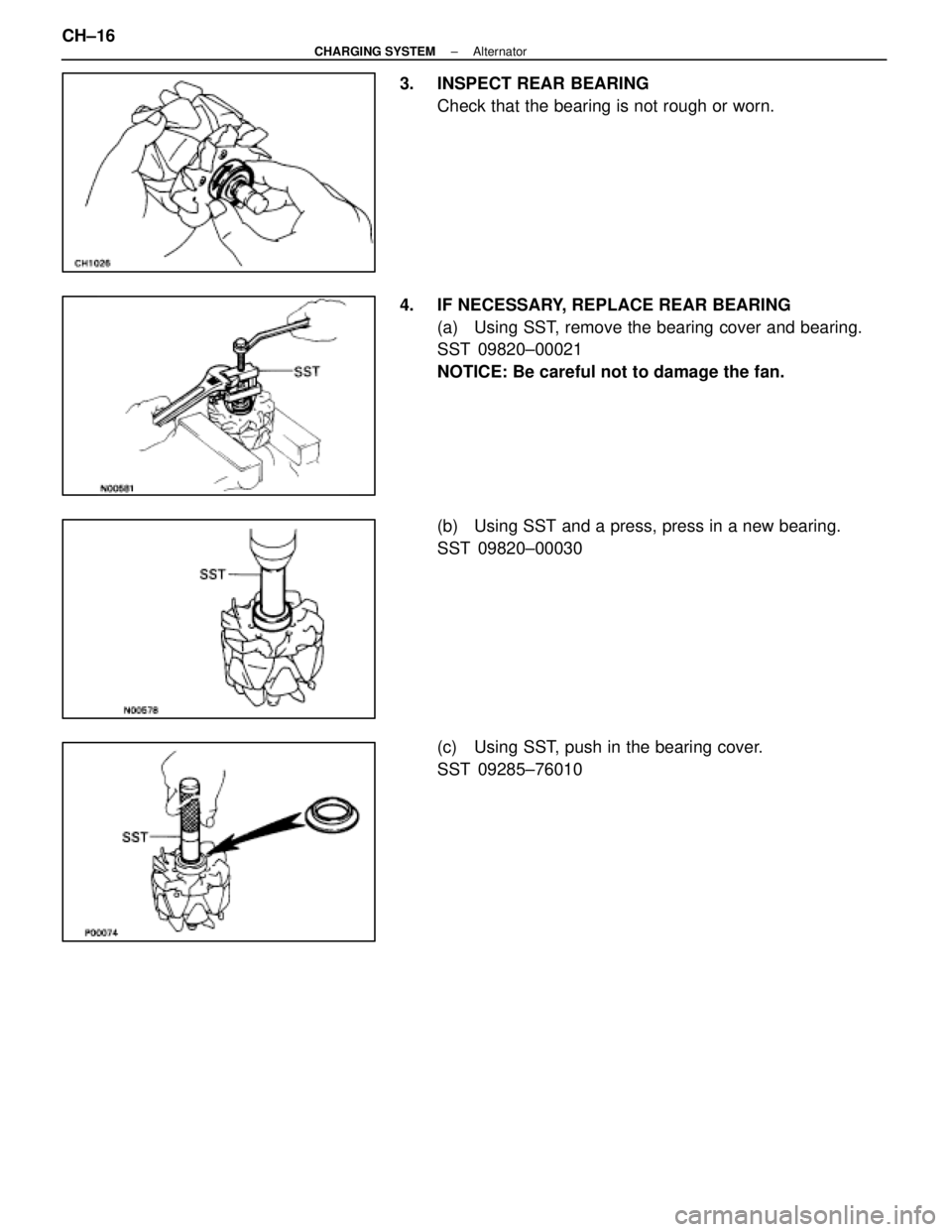

3. INSPECT REAR BEARINGCheck that the bearing is not rough or worn.

4. IF NECESSARY, REPLACE REAR BEARING (a) Using SST, remove the bearing cover and bearing.

SST 09820±00021

NOTICE: Be careful not to damage the fan.

(b) Using SST and a press, press in a new bearing.

SST 09820±00030

(c) Using SST, push in the bearing cover.

SST 09285±76010

CH±16

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1149 of 4087

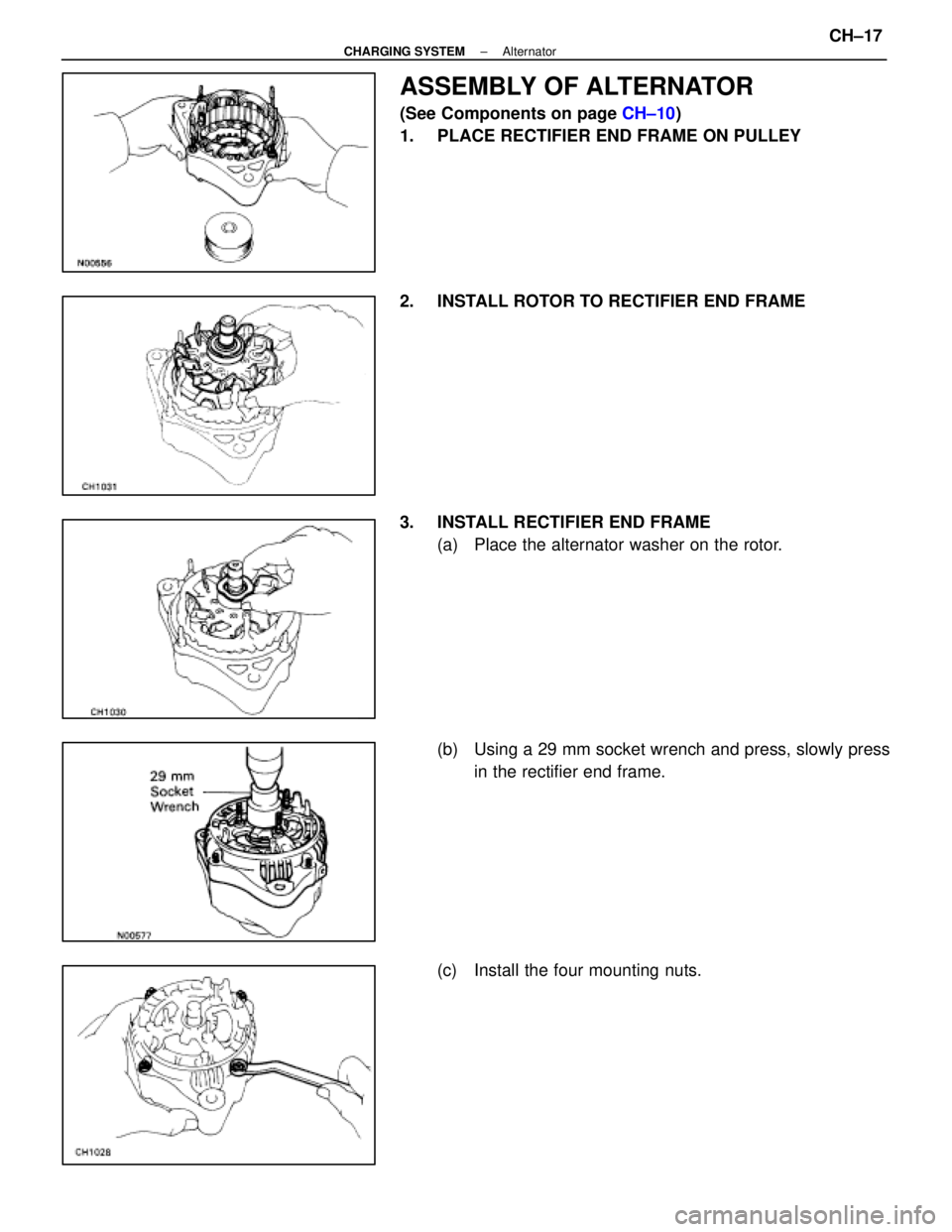

ASSEMBLY OF ALTERNATOR

(See Components on page CH±10)

1. PLACE RECTIFIER END FRAME ON PULLEY

2. INSTALL ROTOR TO RECTIFIER END FRAME

3. INSTALL RECTIFIER END FRAME (a) Place the alternator washer on the rotor.

(b) Using a 29 mm socket wrench and press, slowly pressin the rectifier end frame.

(c) Install the four mounting nuts.

±

CHARGING SYSTEM AlternatorCH±17

WhereEverybodyKnowsYourName

Page 1150 of 4087

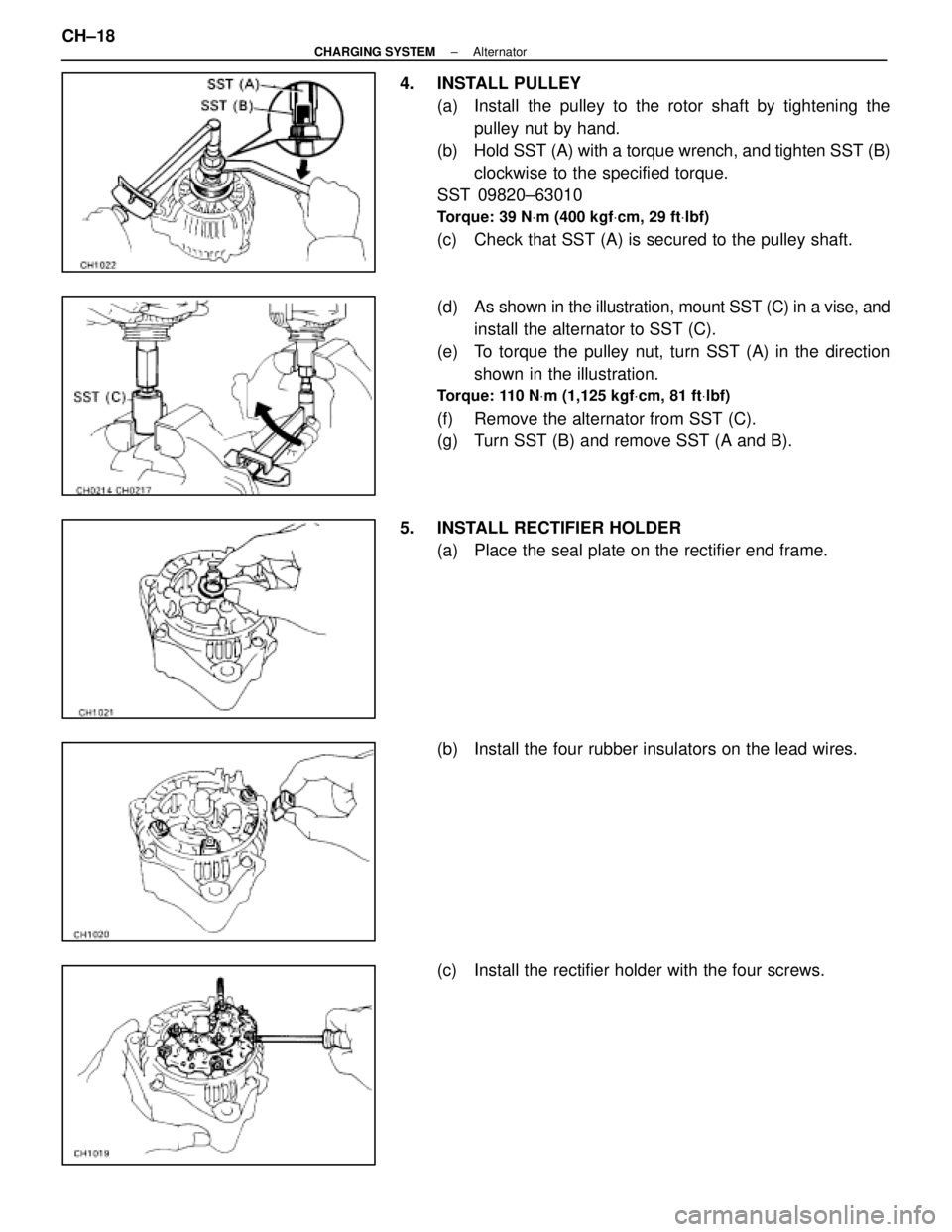

4. INSTALL PULLEY(a) Install the pulley to the rotor shaft by tightening thepulley nut by hand.

(b) Hold SST (A) with a torque wrench, and tighten SST (B)

clockwise to the specified torque.

SST 09820±63010

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(c) Check that SST (A) is secured to the pulley shaft.

(d) As shown in the illustration, mount SST (C) in a vise, and

install the alternator to SST (C).

(e) To torque the pulley nut, turn SST (A) in the direction shown in the illustration.

Torque: 110 N Vm (1,125 kgf Vcm, 81 ft Vlbf)

(f) Remove the alternator from SST (C).

(g) Turn SST (B) and remove SST (A and B).

5. INSTALL RECTIFIER HOLDER (a) Place the seal plate on the rectifier end frame.

(b) Install the four rubber insulators on the lead wires.

(c) Install the rectifier holder with the four screws.

CH±18

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Trending: oil temperature, brake light, drain bolt, engine oil capacity, check oil, change wheel, service indicator