engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1140 of 4087

8. INSPECT CHARGING CIRCUIT WITH LOAD(a) With the engine running at 2,000 rpm, turn on the highbeam headlights and place the heater blower switch at

ºHIº.

(b) Check the reading on the ammeter.

Standard amperage: 30 A or more

If the ammeter reading is less than standard amperage, re-

pair the alternator. (See page CH±9)

HINT: With the battery fully charged, the indication will some-

times be less than standard amperage.

9. REINSTALL ENGINE UNDER COVER

CH±8

±

CHARGING SYSTEM On±Vehicle Inspection

WhereEverybodyKnowsYourName

Page 1141 of 4087

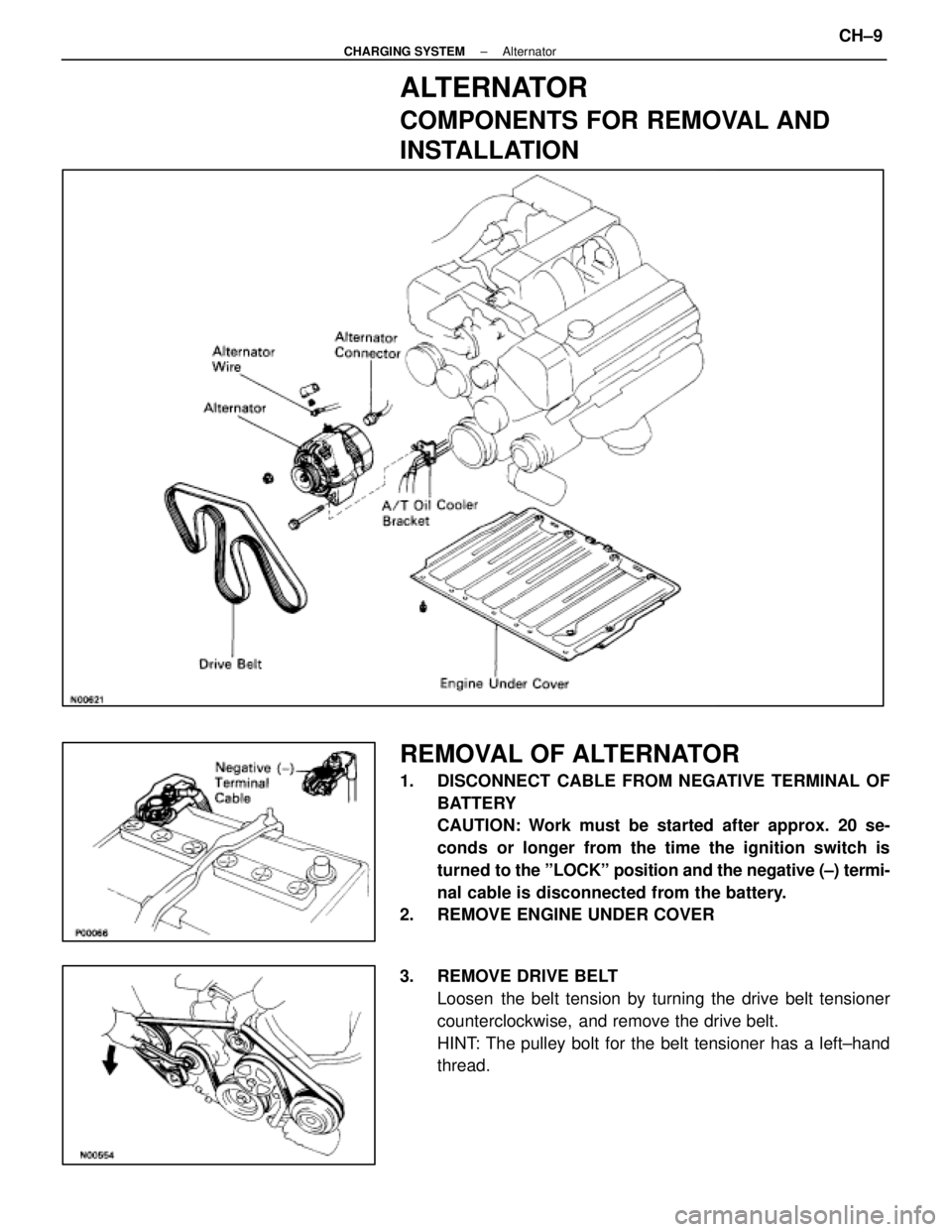

ALTERNATOR

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF ALTERNATOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. REMOVE DRIVE BELT

Loosen the belt tension by turning the drive belt tensioner

counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

±

CHARGING SYSTEM AlternatorCH±9

WhereEverybodyKnowsYourName

Page 1152 of 4087

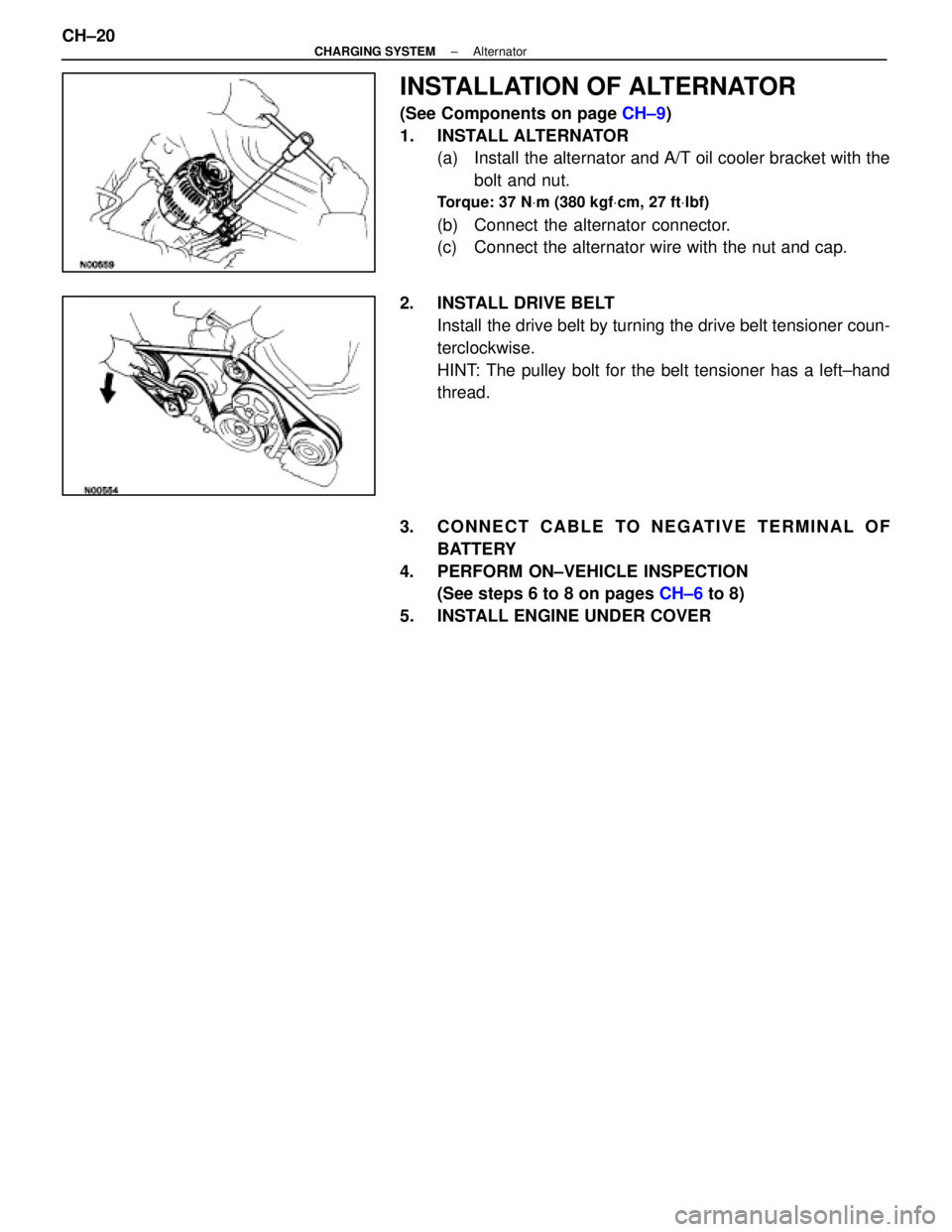

INSTALLATION OF ALTERNATOR

(See Components on page CH±9)

1. INSTALL ALTERNATOR (a) Install the alternator and A/T oil cooler bracket with the

bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the alternator connector.

(c) Connect the alternator wire with the nut and cap.

2. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

3. CONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

4. PERFORM ON±VEHICLE INSPECTION (See steps 6 to 8 on pages CH±6 to 8)

5. INSTALL ENGINE UNDER COVER

CH±20

±

CHARGING SYSTEM Alternator

WhereEverybodyKnowsYourName

Page 1157 of 4087

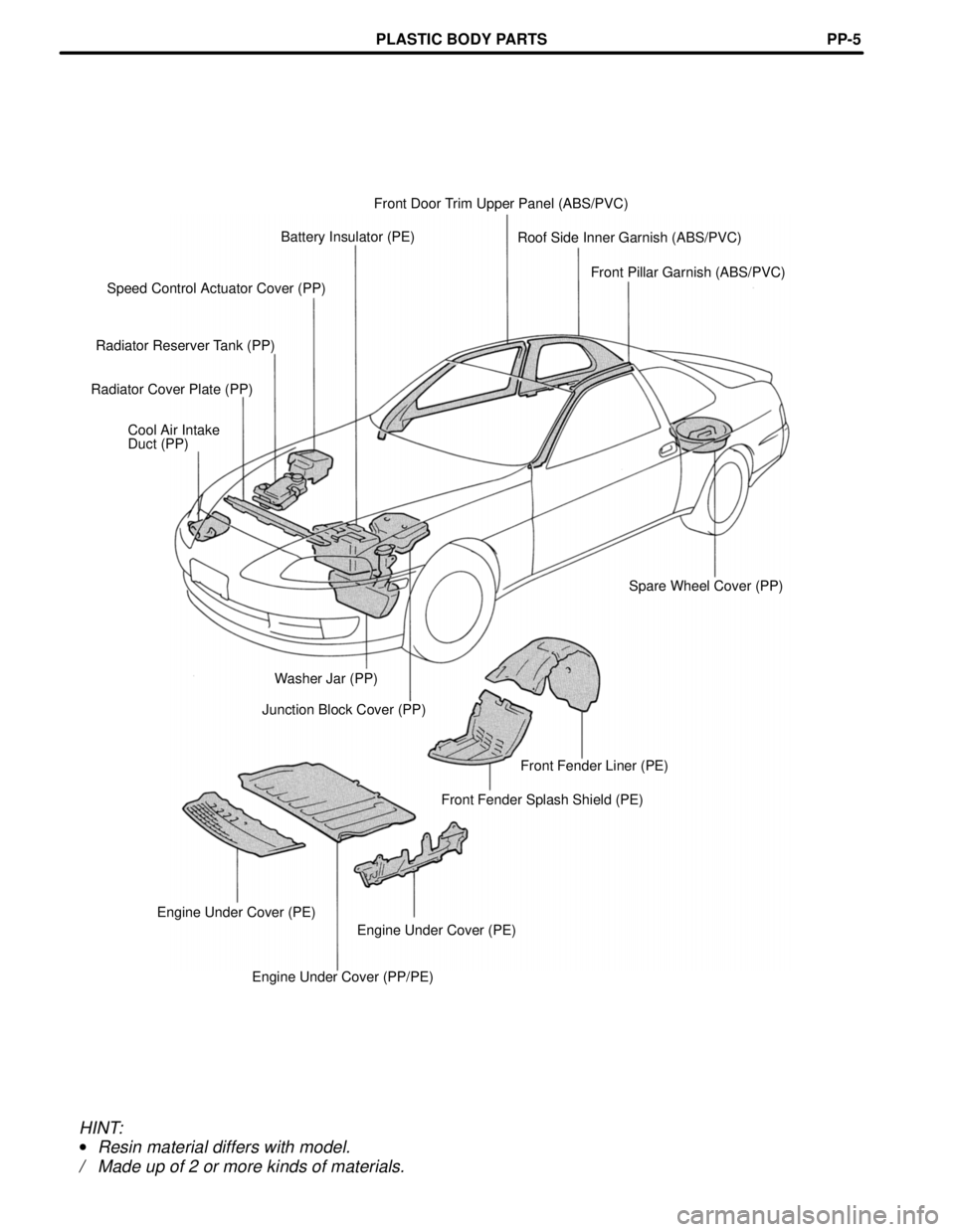

Front Door Trim Upper Panel (ABS/PVC)

Battery Insulator (PE) Roof Side Inner Garnish (ABS/PVC)

Front Pillar Garnish (ABS/PVC)

Speed Control Actuator Cover (PP)

Radiator Reserver Tank (PP)

Radiator Cover Plate (PP) Cool Air Intake

Duct (PP)

Spare Wheel Cover (PP)

Washer Jar (PP)

Junction Block Cover (PP)

Front Fender Liner (PE)

Front Fender Splash Shield (PE)

Engine Under Cover (PE) Engine Under Cover (PE)

Engine Under Cover (PP/PE)

HINT:

wResin material differs with model.

/ Made up of 2 or more kinds of materials.

PLASTIC BODY PARTSPP-5

WhereEverybodyKnowsYourName

Page 1216 of 4087

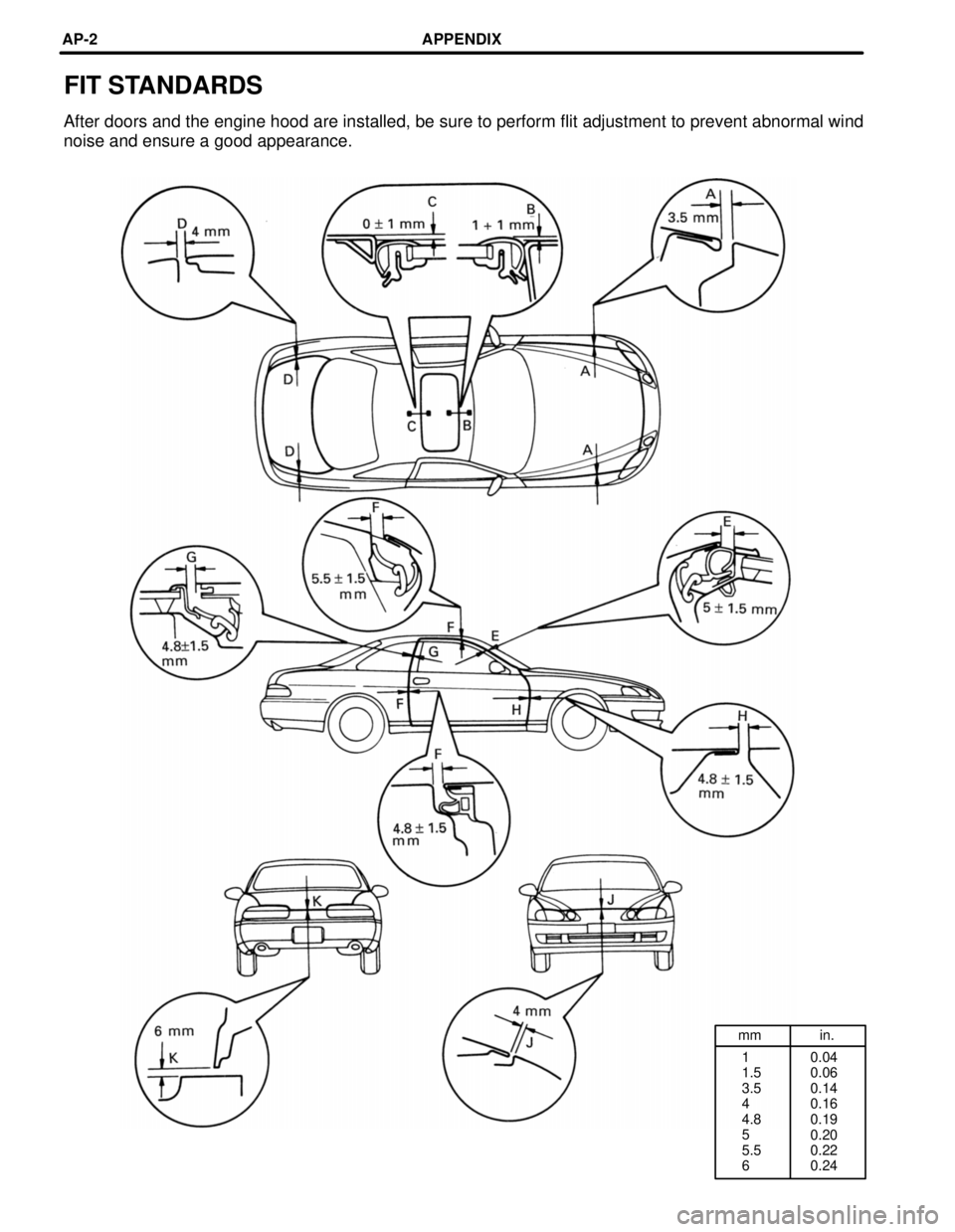

mm in.1

1.5

3.5

4

4.8

5

5.5

6 0.04

0.06

0.14

0.16

0.19

0.20

0.22

0.24

FIT STANDARDS

After doors and the engine hood are installed, be sure to perform flit a\

djustment to prevent abnormal wind

noise and ensure a good appearance.

APPENDIXAP-2

WhereEverybodyKnowsYourName

Page 1232 of 4087

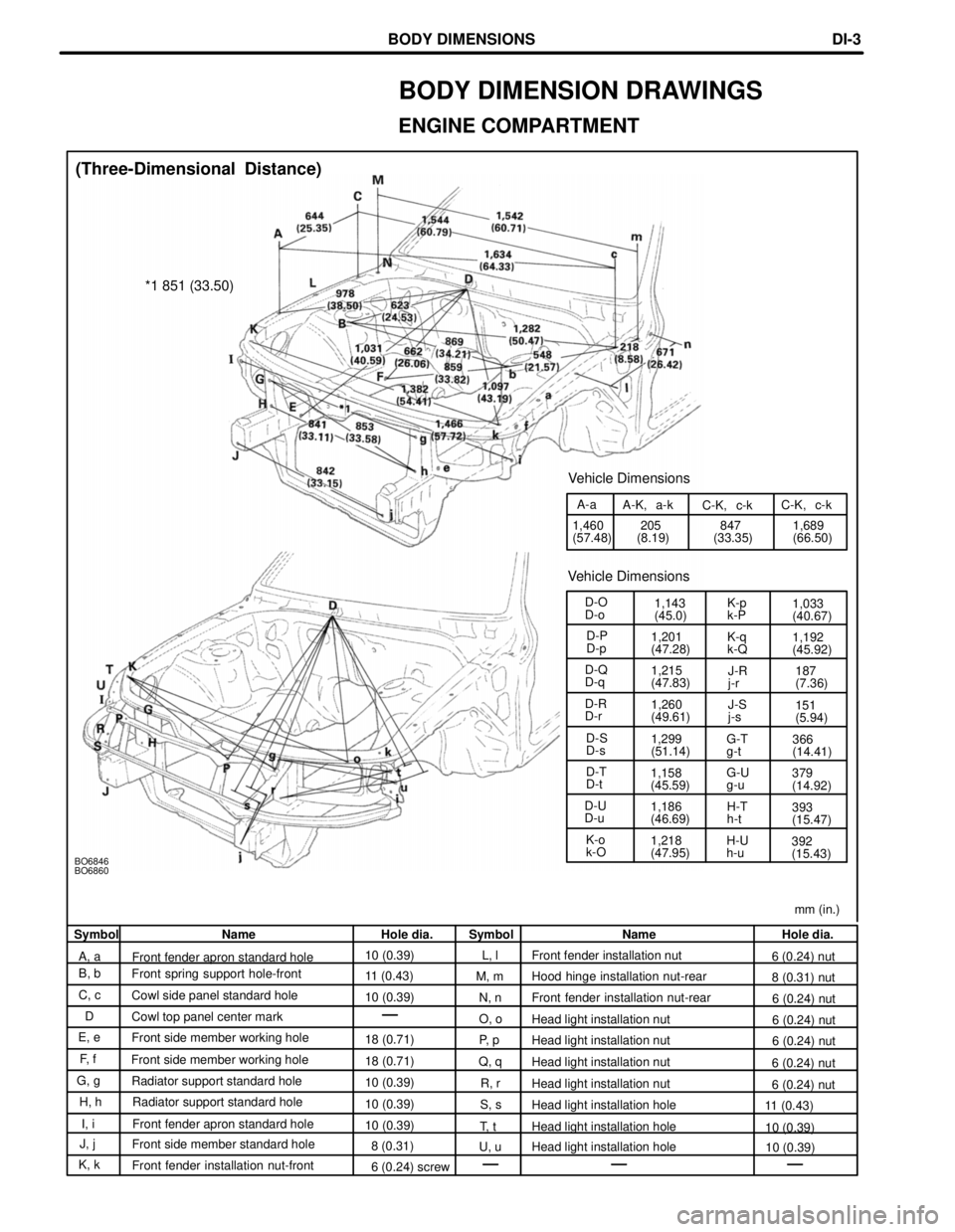

mm (in.)

BO6846

BO6860

1,218

(47.95)392

(15.43)

H-U

h-u

K-o

k-O 1,186

(46.69)

H-T

h-t

393

(15.47)

D-U

D-u 379

(14.92)

G-U

g-u

1,158

(45.59)

D-T

D-t G-T

g-t

366

(14.41)

1,299

(51.14)

D-S

D-s 151

(5.94)

1,260

(49.61)

D-R

D-r

J-S

j-s187

(7.36)

1,215

(47.83)

D-Q

D-q

J-R

j-r1,192

(45.92)

1,201

(47.28)

K-q

k-Q

D-P

D-p 1,033

(40.67)

1,143

(45.0)

K-p

k-P

D-O

D-o

Vehicle Dimensions

1,689

(66.50)

847

(33.35)

205

(8.19)

1,460

(57.48) C-K, c-k

C-K, c-k

A-K, a-k

A-a

Vehicle Dimensions

*1 851 (33.50)

(Three-Dimensional Distance)

Symbol Name Hole dia. Symbol Name Hole dia.

A, a Front fender apron standard hole 10 (0.39)

L, l Front fender installation nut

6 (0.24) nut

B, b Front spring support hole-front

11 (0.43)M, m Hood hinge installation nut-rear

8 (0.31) nut

C, c Cowl side panel standard hole

10 (0.39)N, n Front fender installation nut-rear

6 (0.24) nut

D Cowl top panel center mark

O, oHead light installation nut

6 (0.24) nut

E, e Front side member working hole

18 (0.71)P, pHead light installation nut

6 (0.24) nut

F, f Front side member working hole

18 (0.71)Q, qHead light installation nut

6 (0.24) nut

G, g Radiator support standard hole

10 (0.39)R, rHead light installation nut

6 (0.24) nut

H, h Radiator support standard hole

10 (0.39)S, sHead light installation hole

11 (0.43)

I, i Front fender apron standard hole 10 (0.39)T, t Head light installation hole 10 (0.39)

J, j Front side member standard hole

8 (0.31)U, u Head light installation hole 10 (0.39)

K, k Front fender installation nut-front

6 (0.24) screw

BODY DIMENSION DRAWINGS

ENGINE COMPARTMENT

BODY DIMENSIONSDI-3

WhereEverybodyKnowsYourName

Page 1234 of 4087

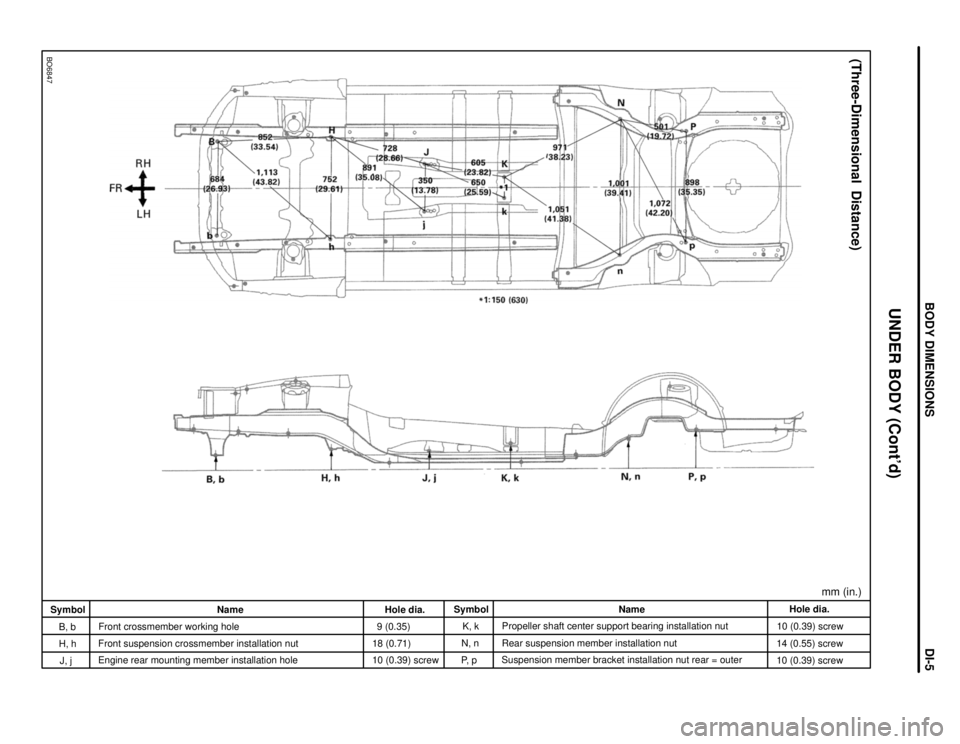

BO6847

mm (in.)

(Three-Dimensional Distance)

Hole dia.

10 (0.39) screw

14 (0.55) screw

10 (0.39) screw

Name

Propeller shaft center support bearing installation nut

Rear suspension member installation nut

Suspension member bracket installation nut rear = outer

Symbol

K, k

N, n

P, p

Hole dia.

9 (0.35)

18 (0.71)

10 (0.39) screw

Name

Front crossmember working hole

Front suspension crossmember installation nut

Engine rear mounting member installation hole

Symbol

B, bH, h J, j

UNDER BODY (Cont'd)

BODY DIMENSIONSDI-5

WhereEverybodyKnowsYourName

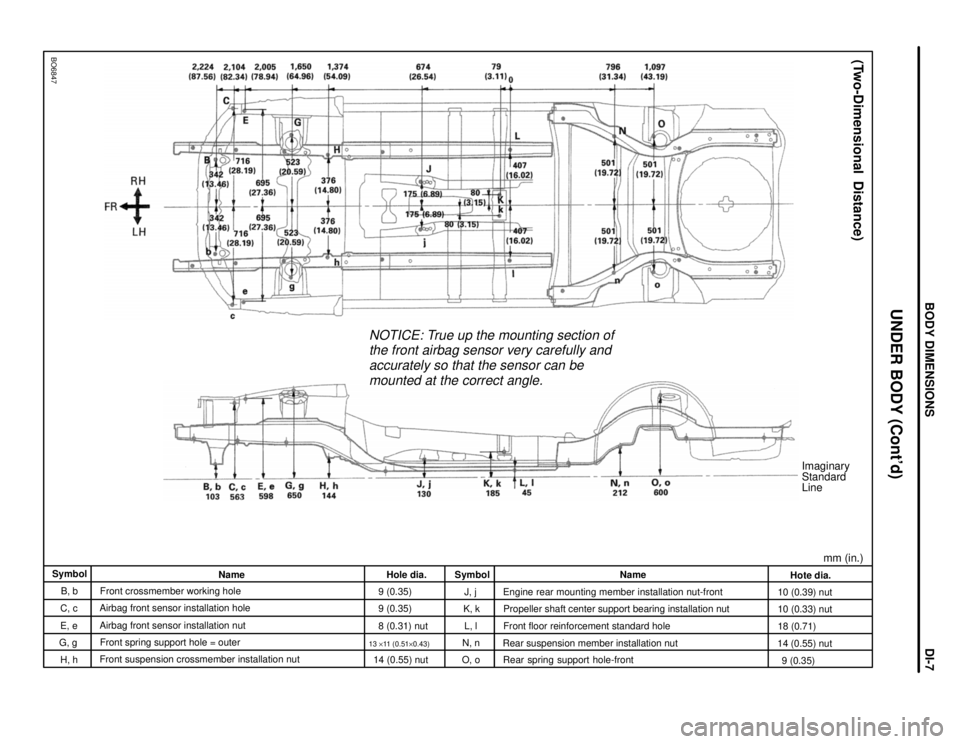

Page 1236 of 4087

BO6847

NOTICE: True up the mounting section ofthe front airbag sensor very carefully and

accurately so that the sensor can bemounted at the correct angle.

Imaginary

Standard

Line

mm (in.)

(Two-Dimensional Distance)

Hote dia.

10 (0.39) nut

10 (0.33) nut

18 (0.71)

14 (0.55) nut 9 (0.35)

Name

Engine rear mounting member installation nut-front Propeller shaft center support bearing installation nut

Front floor reinforcement standard hole

Rear suspension member installation nut Rear spring support hole-front

Symbol

J, j

K, k

L, l

N, n

O, o

Hole dia.

9 (0.35)

9 (0.35)

8 (0.31) nut

13 y11 (0.51 y0.43)14 (0.55) nut

Name

Front crossmember working hole

Airbag front sensor installation hole

Airbag front sensor installation nut Front spring support hole = outer

Front suspension crossmember installation nut

Symbol

B, b

C, c

E, e

G, g H, h

UNDER BODY (Cont'd)

BODY DIMENSIONSDI-7

WhereEverybodyKnowsYourName

Page 1248 of 4087

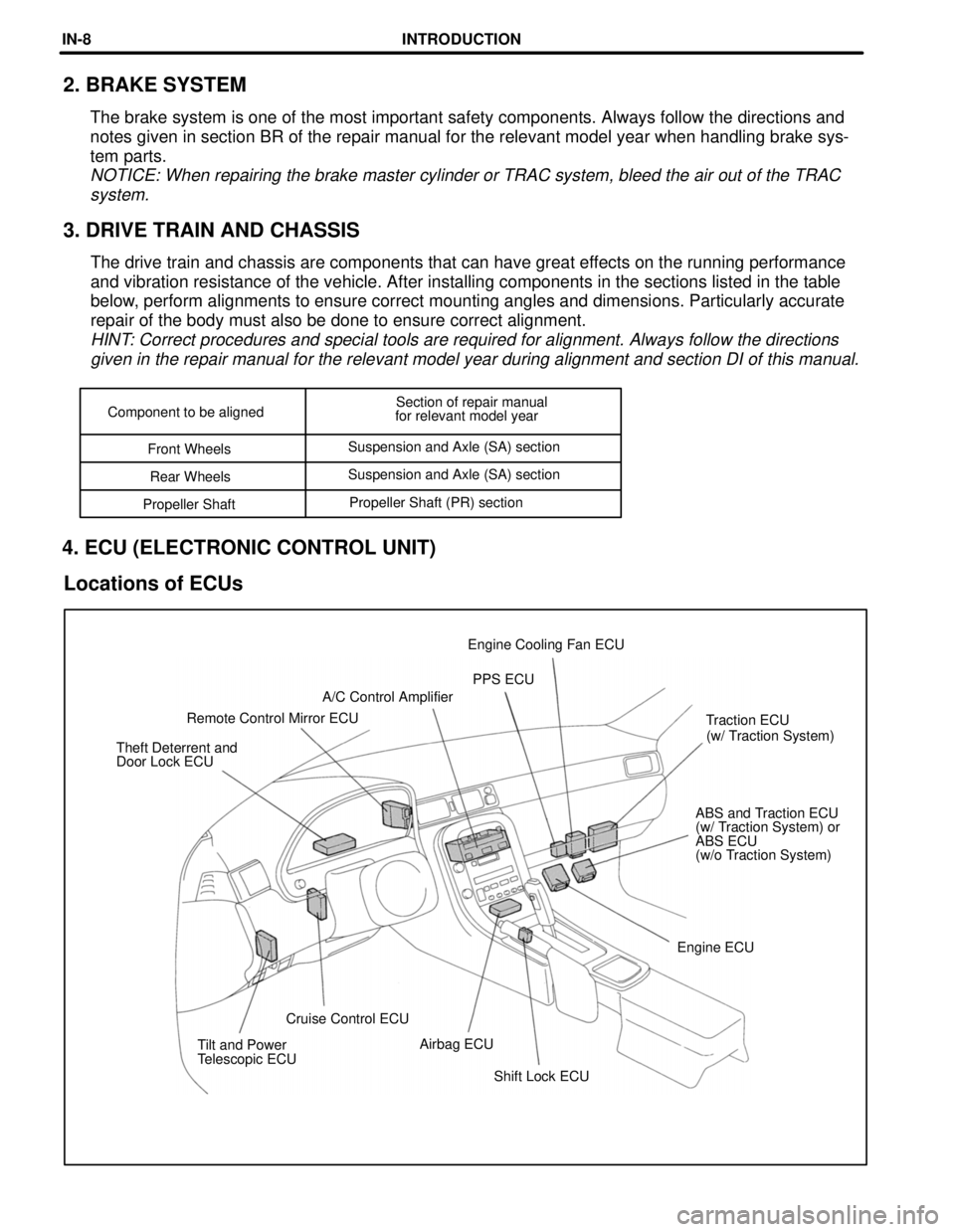

Shift Lock ECU

Tilt and Power

Telescopic ECU

Airbag ECU

Cruise Control ECU Engine ECUABS and Traction ECU

(w/ Traction System) or

ABS ECU

(w/o Traction System)

Theft Deterrent and

Door Lock ECU

(w/ Traction System)

Traction ECU

Remote Control Mirror ECU A/C Control Amplifier

PPS ECU

Engine Cooling Fan ECU

Component to be aligned

Section of repair manual

for relevant model year

Front Wheels Suspension and Axle (SA) section

Rear Wheels Suspension and Axle (SA) section

Propeller Shaft Propeller Shaft (PR) section

2. BRAKE SYSTEM

The brake system is one of the most important safety components. Always \

follow the directions and

notes given in section BR of the repair manual for the relevant model ye\

ar when handling brake sys-

tem parts.

NOTICE: When repairing the brake master cylinder or TRAC system, bleed t\

he air out of the TRAC

system.

3. DRIVE TRAIN AND CHASSIS

The drive train and chassis are components that can have great effects on the running performance

and vibration resistance of the vehicle. After installing components in \

the sections listed in the table

below, perform alignments to ensure correct mounting angles and dimensions. P\

articularly accurate

repair of the body must also be done to ensure correct alignment.

HINT: Correct procedures and special tools are required for alignment. Alway\

s follow the directionsgiven in the repair manual for the relevant model year during alignment \

and section DI of this manual.

4. ECU (ELECTRONIC CONTROL UNIT)

Locations of ECUs

INTRODUCTIONIN-8

WhereEverybodyKnowsYourName

Page 1253 of 4087

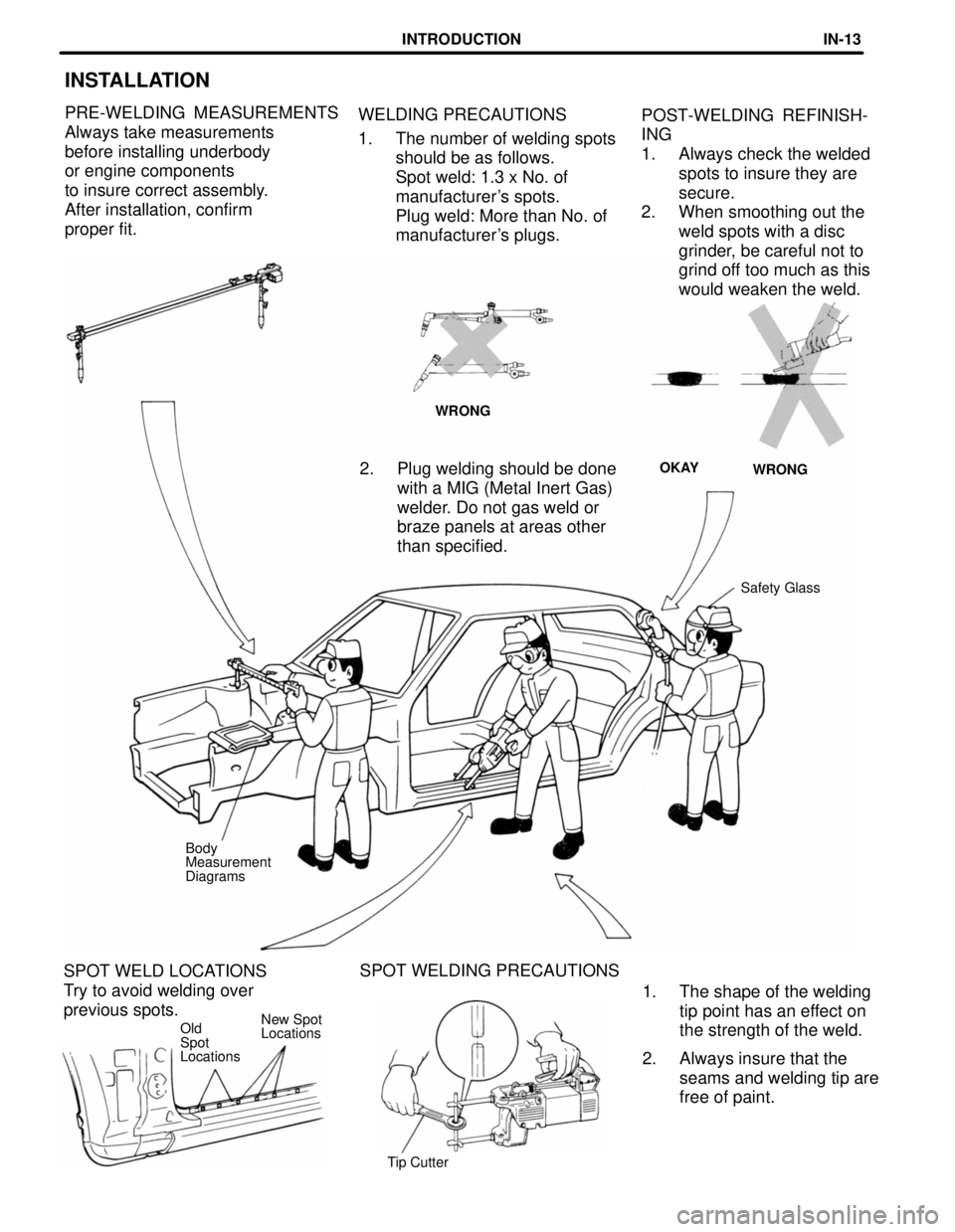

INSTALLATION

PRE-WELDING MEASUREMENTS

Always take measurements

before installing underbody

or engine components

to insure correct assembly.

After installation, confirm

proper fit.POST-WELDING REFINISH-

ING

1. Always check the welded

spots to insure they are

secure.

2. When smoothing out the weld spots with a disc

grinder, be careful not to

grind off too much as this

would weaken the weld.

WELDING PRECAUTIONS

1. The number of welding spots

should be as follows.

Spot weld: 1.3 x No. of

manufacturer's spots.

Plug weld: More than No. of

manufacturer's plugs.

WRONG

OKAYWRONG

2. Plug welding should be done

with a MIG (Metal Inert Gas)

welder. Do not gas weld or

braze panels at areas other

than specified.

Safety Glass

Body

Measurement

Diagrams

SPOT WELDING PRECAUTIONS

SPOT WELD LOCATIONS

Try to avoid welding over

previous spots. 1. The shape of the welding

tip point has an effect on

the strength of the weld.

2. Always insure that the seams and welding tip are

free of paint.

Old

Spot

Locations New Spot

Locations

Tip Cutter

INTRODUCTIONIN-13

WhereEverybodyKnowsYourName