ignition switch LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2023 of 4087

PRECAUTIONS

1. Before working on the fuel system, disconnect the cablefrom negative (±) terminal of the battery.

HINT: Any diagnostic code retained by the computer will be

erased when the battery terminal is removed. Therefore, if

necessary, read the diagnosis before removing the battery

terminal.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. Do not smoke or work on open flame when working on the fuel system.

3. Keep gasoline away from rubber or leather parts.

INSPECTION PRECAUTIONS

MAINTENANCE PRECAUTIONS

1. CHECK CORRECT ENGINE TUNE±UP (See page EM±8)

2. PRECAUTIONS WHEN CONNECTING GAUGE (a) Use the battery as the power source for the timing light,tachometer, etc.

(b) Connect the test probe of a tachometer to the terminal IG of the check connector.

3. IN EVENT OF ENGINE MISFIRE, FOLLOWING PRECAUTIONS SHOULD BE TAKEN

(a) Check proper connection of battery terminals, etc.

(b) Handle high±tension cords carefully.

(c) After repair work, check that the ignition coil terminalsand all other ignition system lines are reconnected

securely.

(d) When cleaning the engine compartment, be especially careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR (a) Do not allow oxygen sensor to drop or hit against anobject.

(b) Do not allow the sensor to come into contact with water.

FI±12

± Precautions, Inspection PrecautionsEFI SYSTEM

WhereEverybodyKnowsYourName

Page 2024 of 4087

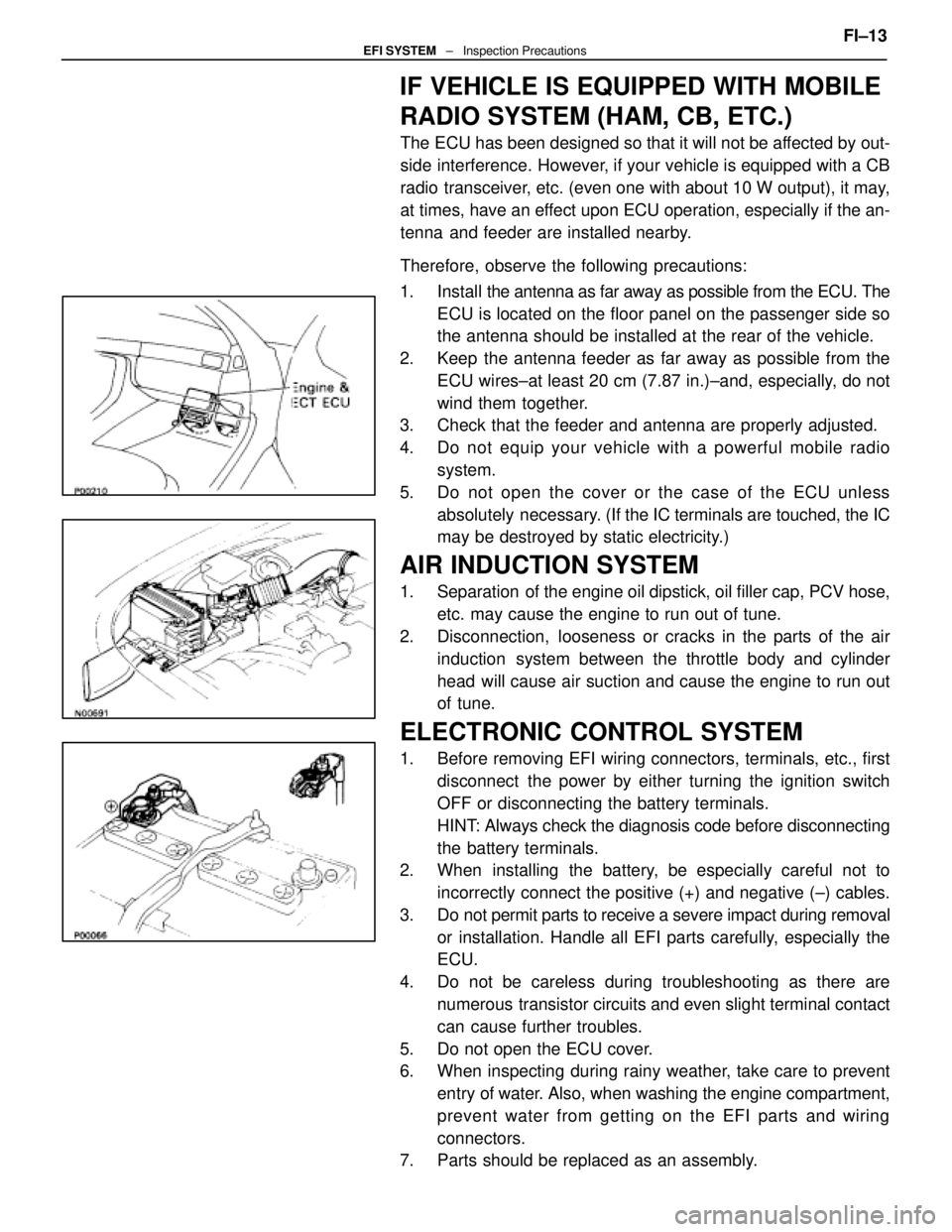

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC.)

The ECU has been designed so that it will not be affected by out-

side interference. However, if your vehicle is equipped with a CB

radio transceiver, etc. (even one with about 10 W output), it may,

at times, have an effect upon ECU operation, especially if the an-

tenna and feeder are installed nearby.

Therefore, observe the following precautions:

1. Install the antenna as far away as possible from the ECU. The

ECU is located on the floor panel on the passenger side so

the antenna should be installed at the rear of the vehicle.

2. Keep the antenna feeder as far away as possible from the ECU wires±at least 20 cm (7.87 in.)±and, especially, do not

wind them together.

3. Check that the feeder and antenna are properly adjusted.

4. Do not equip your vehicle with a powerful mobile radio

system.

5. Do not open the cover or the case of the ECU unless absolutely necessary. (If the IC terminals are touched, the IC

may be destroyed by static electricity.)

AIR INDUCTION SYSTEM

1. Separation of the engine oil dipstick, oil filler cap, PCV hose,

etc. may cause the engine to run out of tune.

2. Disconnection, looseness or cracks in the parts of the air induction system between the throttle body and cylinder

head will cause air suction and cause the engine to run out

of tune.

ELECTRONIC CONTROL SYSTEM

1. Before removing EFI wiring connectors, terminals, etc., firstdisconnect the power by either turning the ignition switch

OFF or disconnecting the battery terminals.

HINT: Always check the diagnosis code before disconnecting

the battery terminals.

2. When installing the battery, be especially careful not to

incorrectly connect the positive (+) and negative (±) cables.

3. Do not permit parts to receive a severe impact during removal or installation. Handle all EFI parts carefully, especially the

ECU.

4. Do not be careless during troubleshooting as there are numerous transistor circuits and even slight terminal contact

can cause further troubles.

5. Do not open the ECU cover.

6. When inspecting during rainy weather, take care to prevent entry of water. Also, when washing the engine compartment,

prevent water from getting on the EFI parts and wiring

connectors.

7. Parts should be replaced as an assembly. FI±13

EFI SYSTEM

± Inspection Precautions

WhereEverybodyKnowsYourName

Page 2027 of 4087

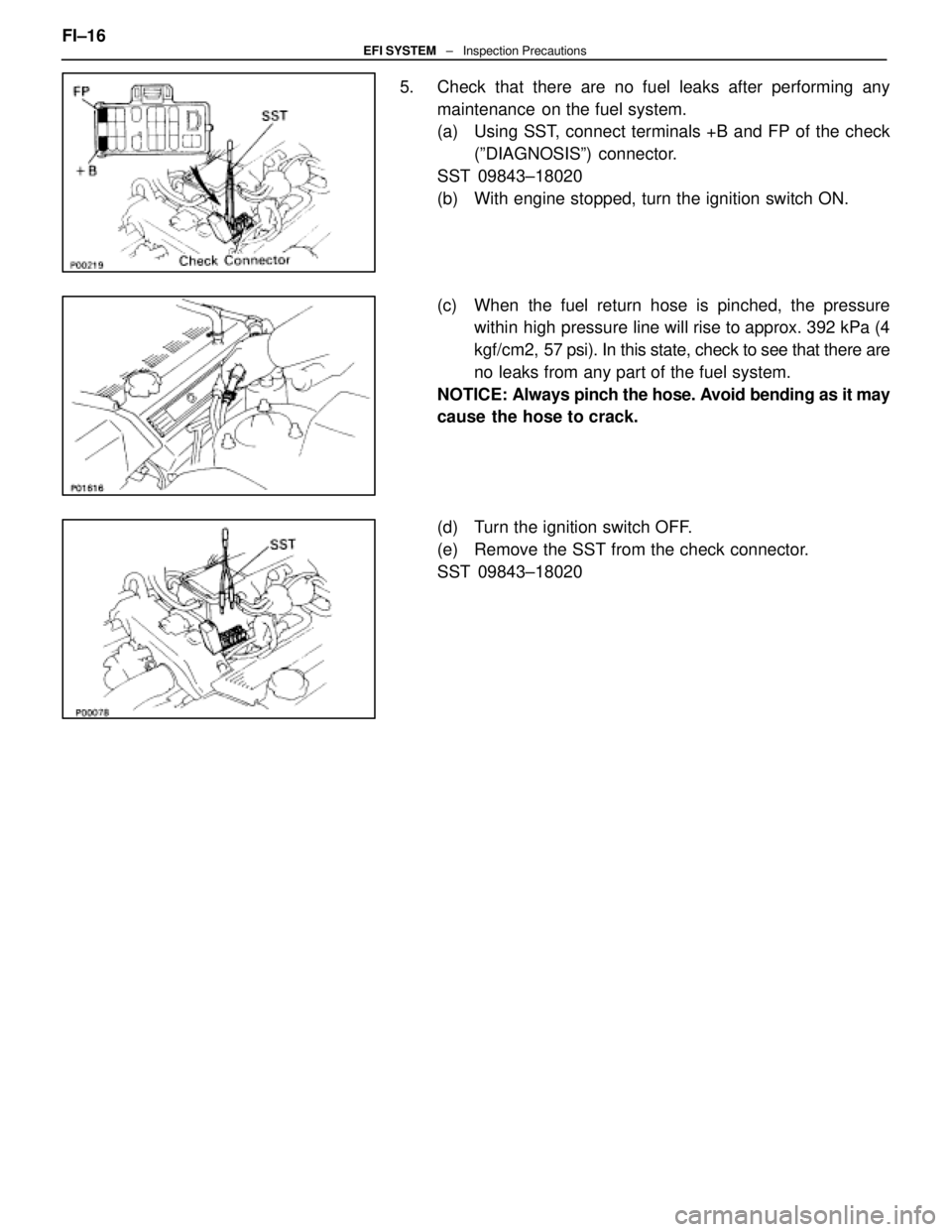

5. Check that there are no fuel leaks after performing anymaintenance on the fuel system.

(a) Using SST, connect terminals +B and FP of the check(ºDIAGNOSISº) connector.

SST 09843±18020

(b) With engine stopped, turn the ignition switch ON.

(c) When the fuel return hose is pinched, the pressure within high pressure line will rise to approx. 392 kPa (4

kgf/cm2, 57 psi). In this state, check to see that there are

no leaks from any part of the fuel system.

NOTICE: Always pinch the hose. Avoid bending as it may

cause the hose to crack.

(d) Turn the ignition switch OFF.

(e) Remove the SST from the check connector.

SST 09843±18020

FI±16

EFI SYSTEM

± Inspection Precautions

WhereEverybodyKnowsYourName

Page 2028 of 4087

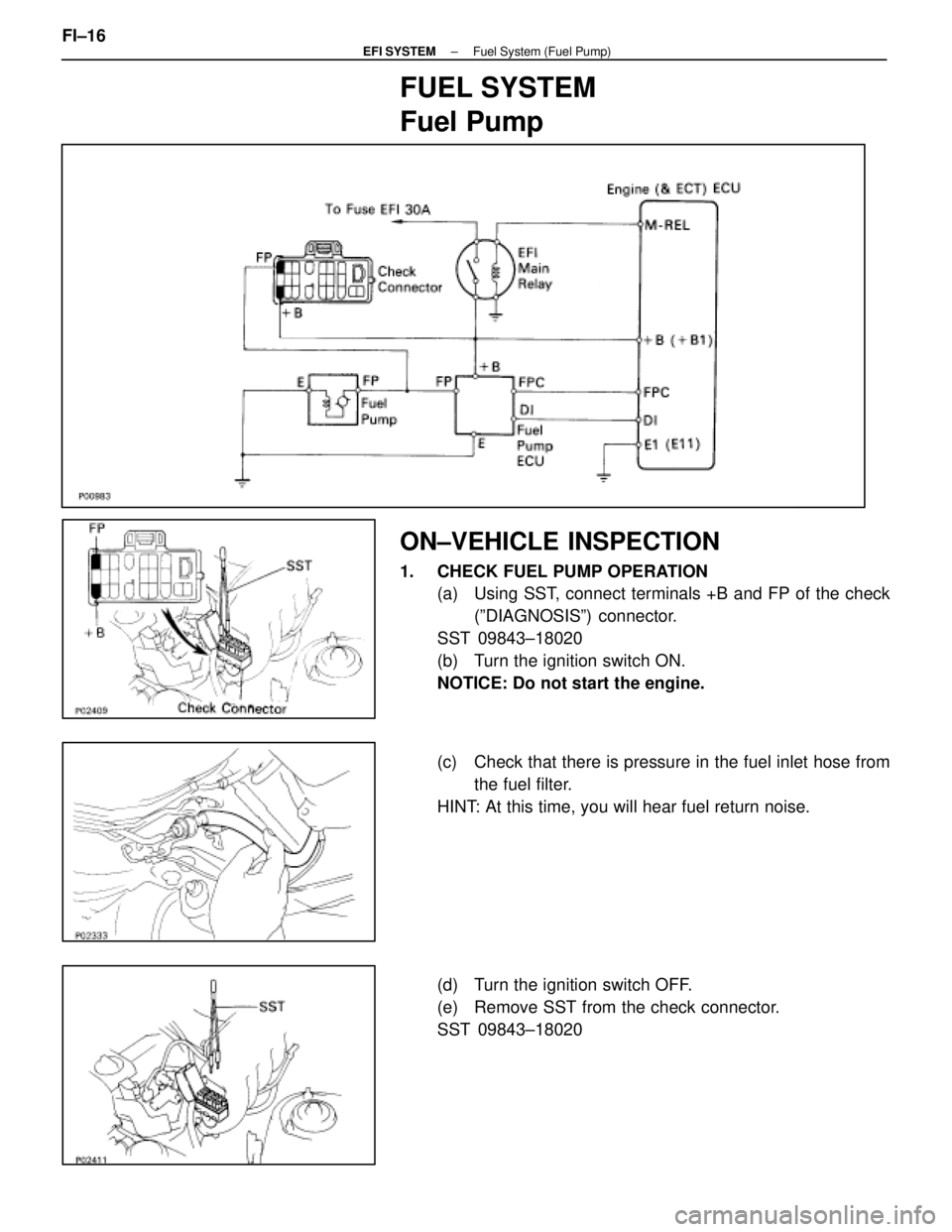

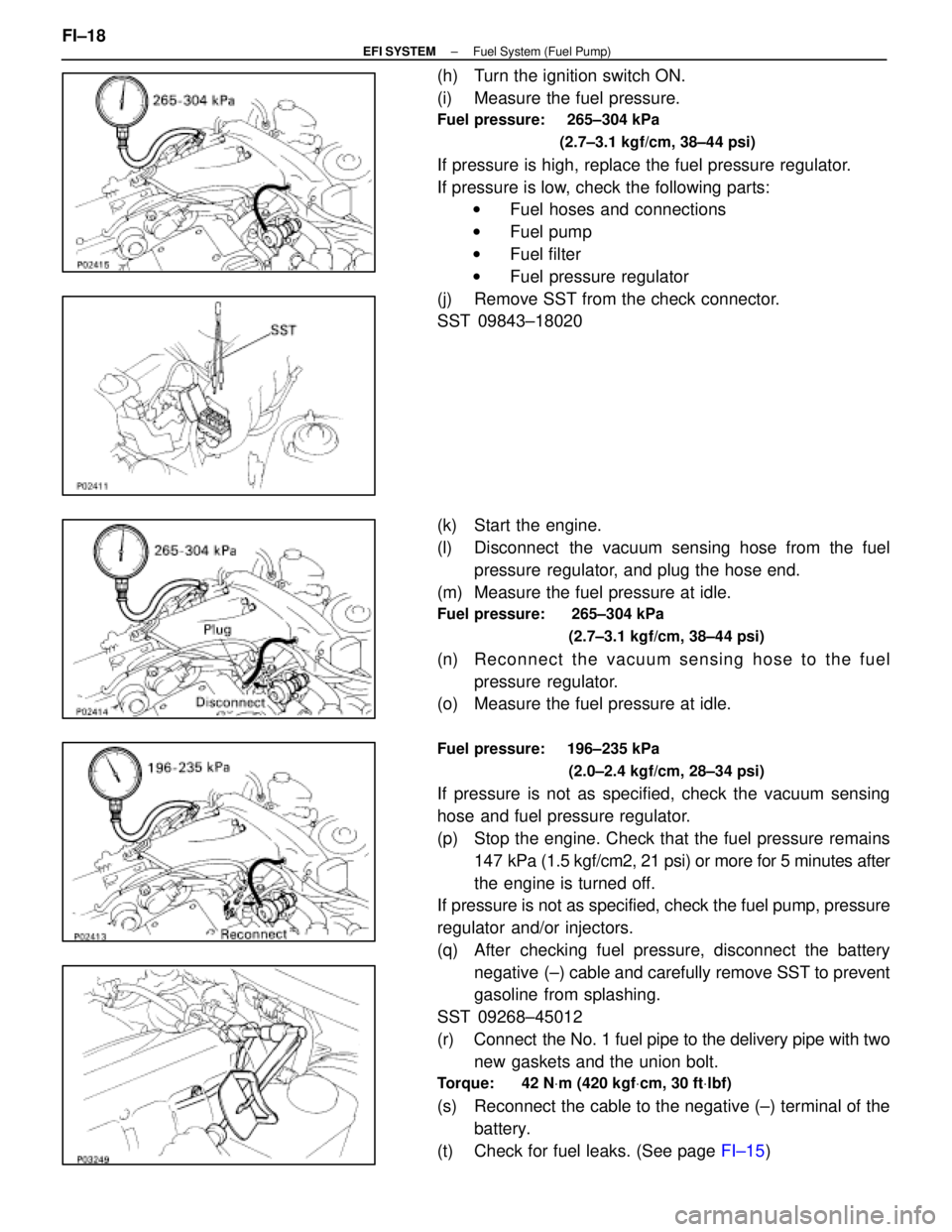

FUEL SYSTEM

Fuel Pump

ON±VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION(a) Using SST, connect terminals +B and FP of the check

(ºDIAGNOSISº) connector.

SST 09843±18020

(b) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(c) Check that there is pressure in the fuel inlet hose from the fuel filter.

HINT: At this time, you will hear fuel return noise.

(d) Turn the ignition switch OFF.

(e) Remove SST from the check connector.

SST 09843±18020

FI±16

±

EFI SYSTEM Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2029 of 4087

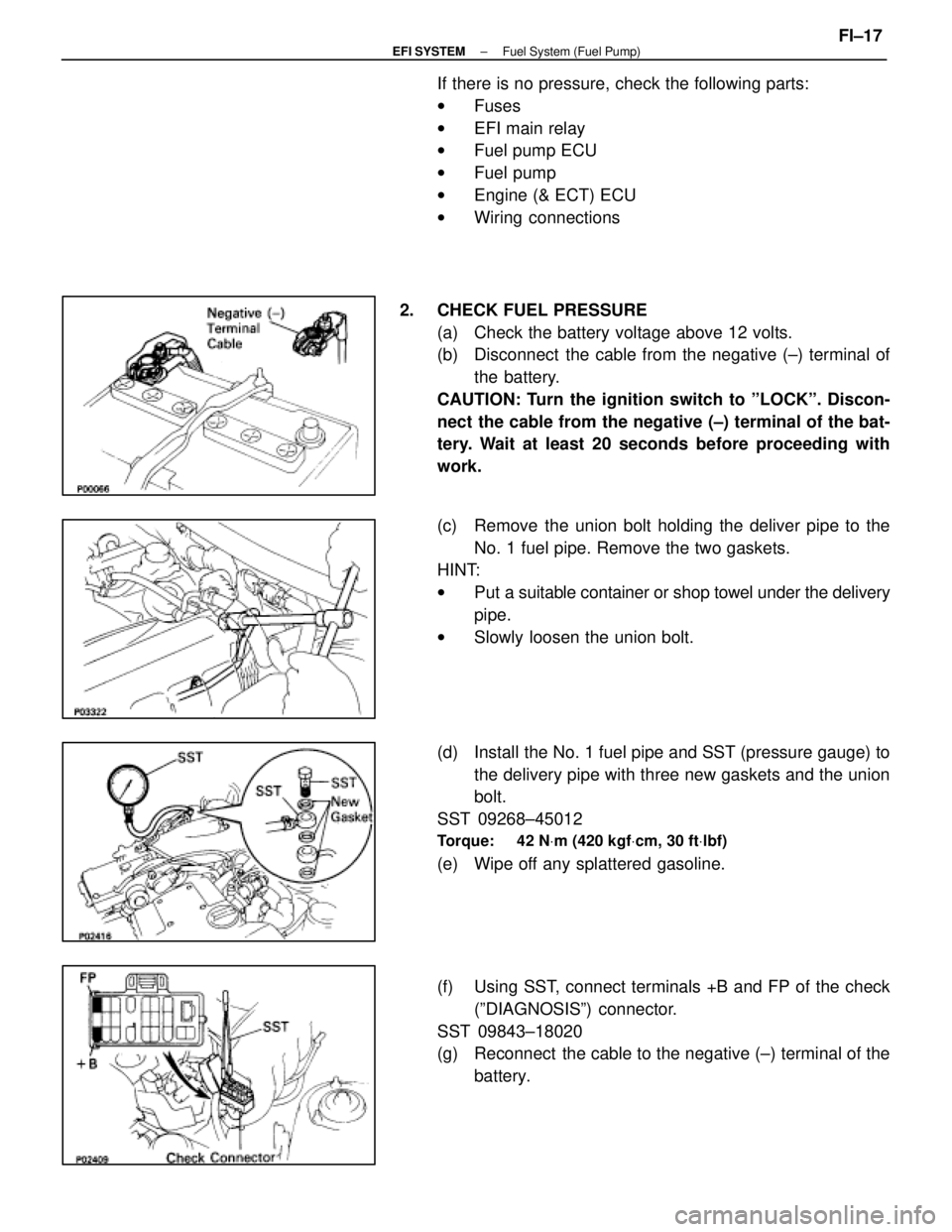

If there is no pressure, check the following parts:

wFuses

w EFI main relay

w Fuel pump ECU

w Fuel pump

w Engine (& ECT) ECU

w Wiring connections

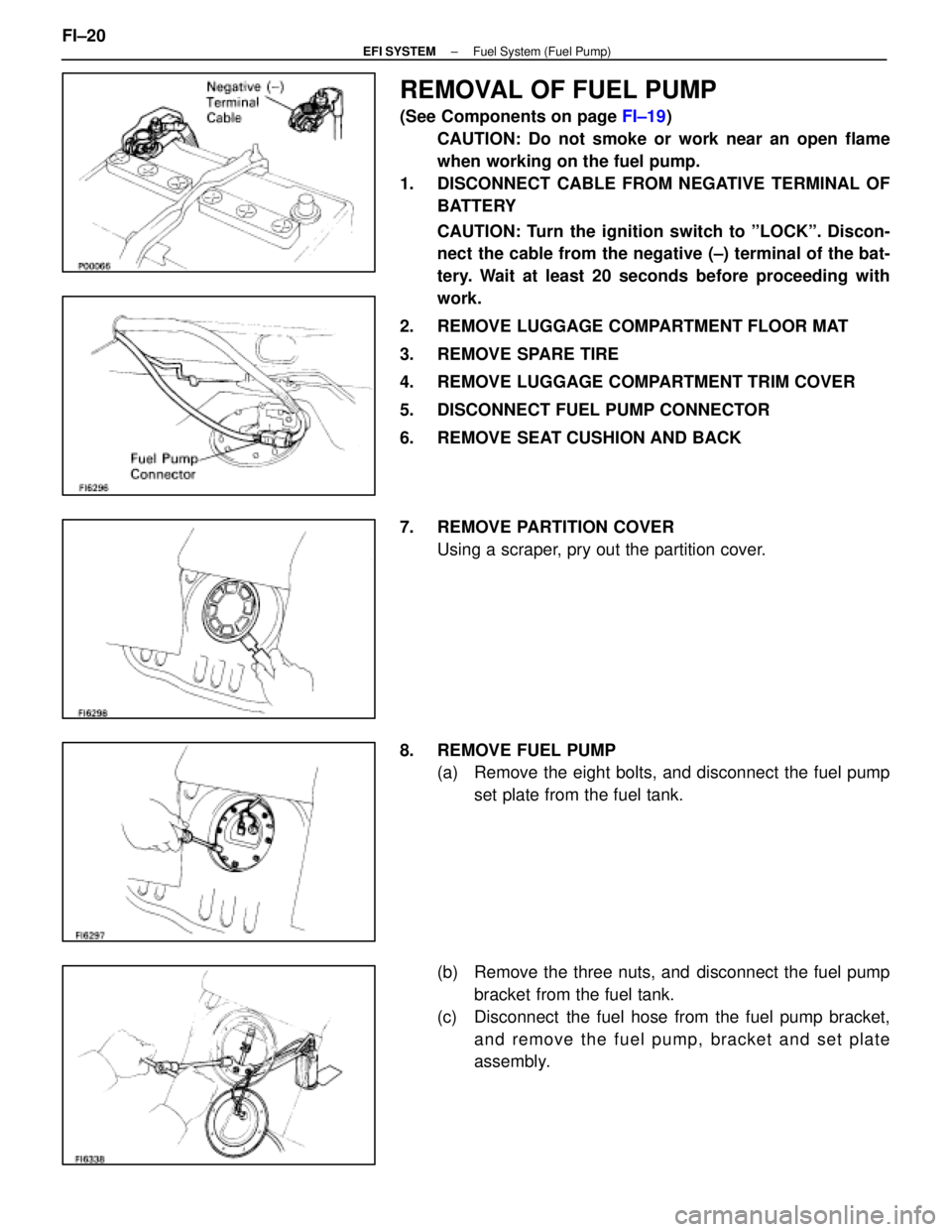

2. CHECK FUEL PRESSURE (a) Check the battery voltage above 12 volts.

(b) Disconnect the cable from the negative (±) terminal ofthe battery.

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

(c) Remove the union bolt holding the deliver pipe to the No. 1 fuel pipe. Remove the two gaskets.

HINT:

w Put a suitable container or shop towel under the delivery

pipe.

w Slowly loosen the union bolt.

(d) Install the No. 1 fuel pipe and SST (pressure gauge) to the delivery pipe with three new gaskets and the union

bolt.

SST 09268±45012

Torque: 42 N Vm (420 kgf Vcm, 30 ft Vlbf)

(e) Wipe off any splattered gasoline.

(f) Using SST, connect terminals +B and FP of the check

(ºDIAGNOSISº) connector.

SST 09843±18020

(g) Reconnect the cable to the negative (±) terminal of the battery.

±

EFI SYSTEM Fuel System (Fuel Pump)FI±17

WhereEverybodyKnowsYourName

Page 2030 of 4087

(h) Turn the ignition switch ON.

(i) Measure the fuel pressure.

Fuel pressure: 265±304 kPa (2.7±3.1 kgf/cm, 38±44 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:w Fuel hoses and connections

w Fuel pump

w Fuel filter

w Fuel pressure regulator

(j) Remove SST from the check connector.

SST 09843±18020

(k) Start the engine.

(l) Disconnect the vacuum sensing hose from the fuel pressure regulator, and plug the hose end.

(m) Measure the fuel pressure at idle.

Fuel pressure: 265±304 kPa

(2.7±3.1 kgf/cm, 38±44 psi)

(n) Re c onnect the vacuum sensing hose to the fuel

pressure regulator.

(o) Measure the fuel pressure at idle.

Fuel pressure: 196±235 kPa

(2.0±2.4 kgf/cm, 28±34 psi)

If pressure is not as specified, check the vacuum sensing

hose and fuel pressure regulator.

(p) Stop the engine. Check that the fuel pressure remains147 kPa (1.5 kgf/cm2, 21 psi) or more for 5 minutes after

the engine is turned off.

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(q) After checking fuel pressure, disconnect the battery

negative (±) cable and carefully remove SST to prevent

gasoline from splashing.

SST 09268±45012

(r) Connect the No. 1 fuel pipe to the delivery pipe with two new gaskets and the union bolt.

Torque: 42 N Vm (420 kgf Vcm, 30 ft Vlbf)

(s) Reconnect the cable to the negative (±) terminal of the

battery.

(t) Check for fuel leaks. (See page FI±15)

FI±18

±

EFI SYSTEM Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2032 of 4087

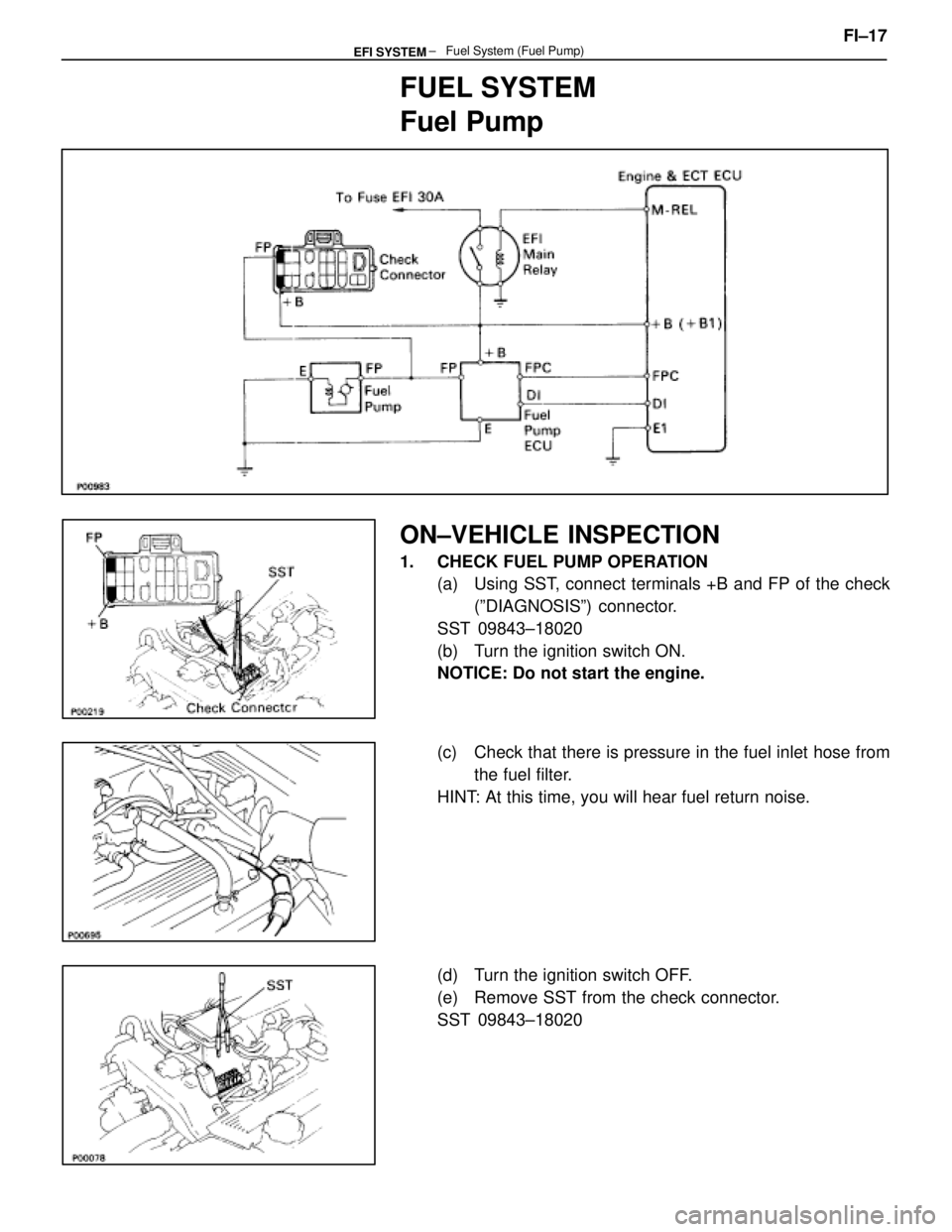

REMOVAL OF FUEL PUMP

(See Components on page FI±19)

CAUTION: Do not smoke or work near an open flame

when working on the fuel pump.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

2. REMOVE LUGGAGE COMPARTMENT FLOOR MAT

3. REMOVE SPARE TIRE

4. REMOVE LUGGAGE COMPARTMENT TRIM COVER

5. DISCONNECT FUEL PUMP CONNECTOR

6. REMOVE SEAT CUSHION AND BACK

7. REMOVE PARTITION COVER Using a scraper, pry out the partition cover.

8. REMOVE FUEL PUMP (a) Remove the eight bolts, and disconnect the fuel pump

set plate from the fuel tank.

(b) Remove the three nuts, and disconnect the fuel pump bracket from the fuel tank.

(c) Disconnect the fuel hose from the fuel pump bracket, and remove the fuel pump, bracket and set plate

assembly.

FI±20

±

EFI SYSTEM Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2036 of 4087

FUEL SYSTEM

Fuel Pump

ON±VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION(a) Using SST, connect terminals +B and FP of the check

(ºDIAGNOSISº) connector.

SST 09843±18020

(b) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(c) Check that there is pressure in the fuel inlet hose from the fuel filter.

HINT: At this time, you will hear fuel return noise.

(d) Turn the ignition switch OFF.

(e) Remove SST from the check connector.

SST 09843±18020 FI±17

± Fuel System (Fuel Pump)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2037 of 4087

If there is no pressure, check the following parts:w Fuses

w EFI main relay

w Fuel pump ECU

w Fuel pump

w Engine & ECT ECU

w Wiring connections

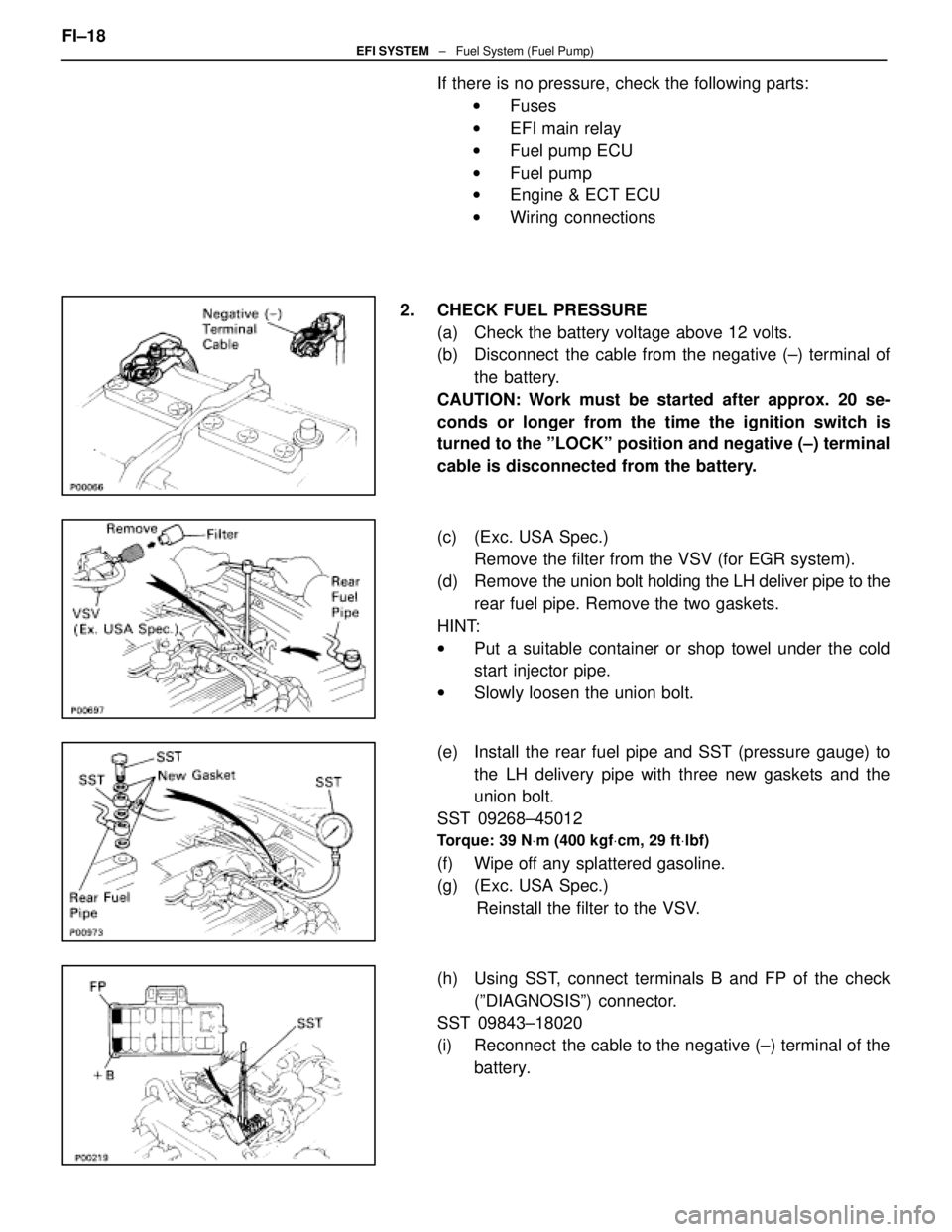

2. CHECK FUEL PRESSURE (a) Check the battery voltage above 12 volts.

(b) Disconnect the cable from the negative (±) terminal ofthe battery.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

(c) (Exc. USA Spec.) Remove the filter from the VSV (for EGR system).

(d) Remove the union bolt holding the LH deliver pipe to the

rear fuel pipe. Remove the two gaskets.

HINT:

w Put a suitable container or shop towel under the cold

start injector pipe.

w Slowly loosen the union bolt.

(e) Install the rear fuel pipe and SST (pressure gauge) to the LH delivery pipe with three new gaskets and the

union bolt.

SST 09268±45012

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(f) Wipe off any splattered gasoline.

(g) (Exc. USA Spec.)

Reinstall the filter to the VSV.

(h) Using SST, connect terminals B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(i) Reconnect the cable to the negative (±) terminal of the

battery.

FI±18

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2038 of 4087

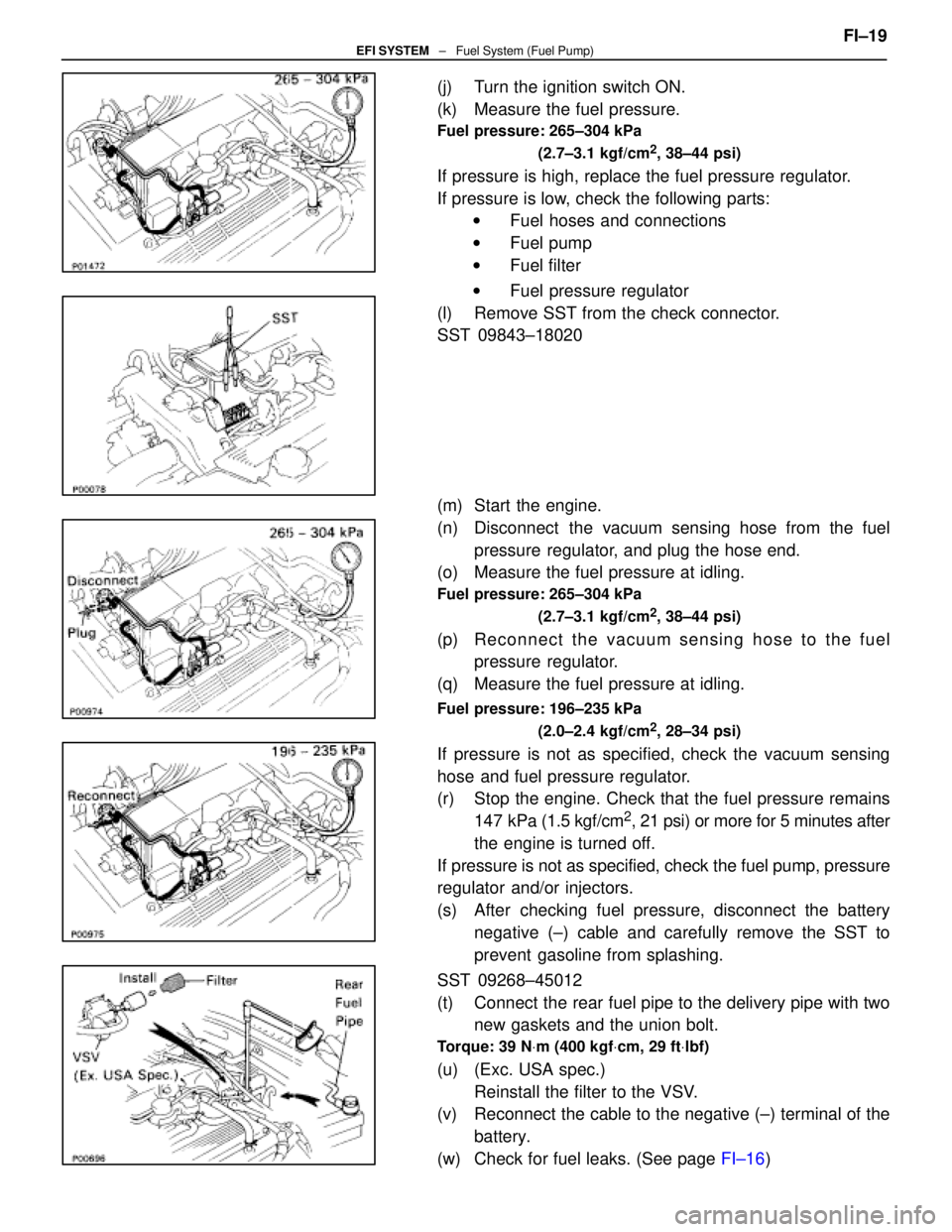

(j) Turn the ignition switch ON.

(k) Measure the fuel pressure.

Fuel pressure: 265±304 kPa(2.7±3.1 kgf/cm

2, 38±44 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:w Fuel hoses and connections

w Fuel pump

w Fuel filter

w Fuel pressure regulator

(l) Remove SST from the check connector.

SST 09843±18020

(m) Start the engine.

(n) Disconnect the vacuum sensing hose from the fuel pressure regulator, and plug the hose end.

(o) Measure the fuel pressure at idling.

Fuel pressure: 265±304 kPa

(2.7±3.1 kgf/cm

2, 38±44 psi)

(p) Re connect the vacuum sensing hose to the fuel

pressure regulator.

(q) Measure the fuel pressure at idling.

Fuel pressure: 196±235 kPa

(2.0±2.4 kgf/cm

2, 28±34 psi)

If pressure is not as specified, check the vacuum sensing

hose and fuel pressure regulator.

(r) Stop the engine. Check that the fuel pressure remains147 kPa (1.5 kgf/cm

2, 21 psi) or more for 5 minutes after

the engine is turned off.

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(s) After checking fuel pressure, disconnect the battery negative (±) cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268±45012

(t) Connect the rear fuel pipe to the delivery pipe with two new gaskets and the union bolt.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(u) (Exc. USA spec.)

Reinstall the filter to the VSV.

(v) Reconnect the cable to the negative (±) terminal of the

battery.

(w) Check for fuel leaks. (See page FI±16) FI±19

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName