ignition switch LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2040 of 4087

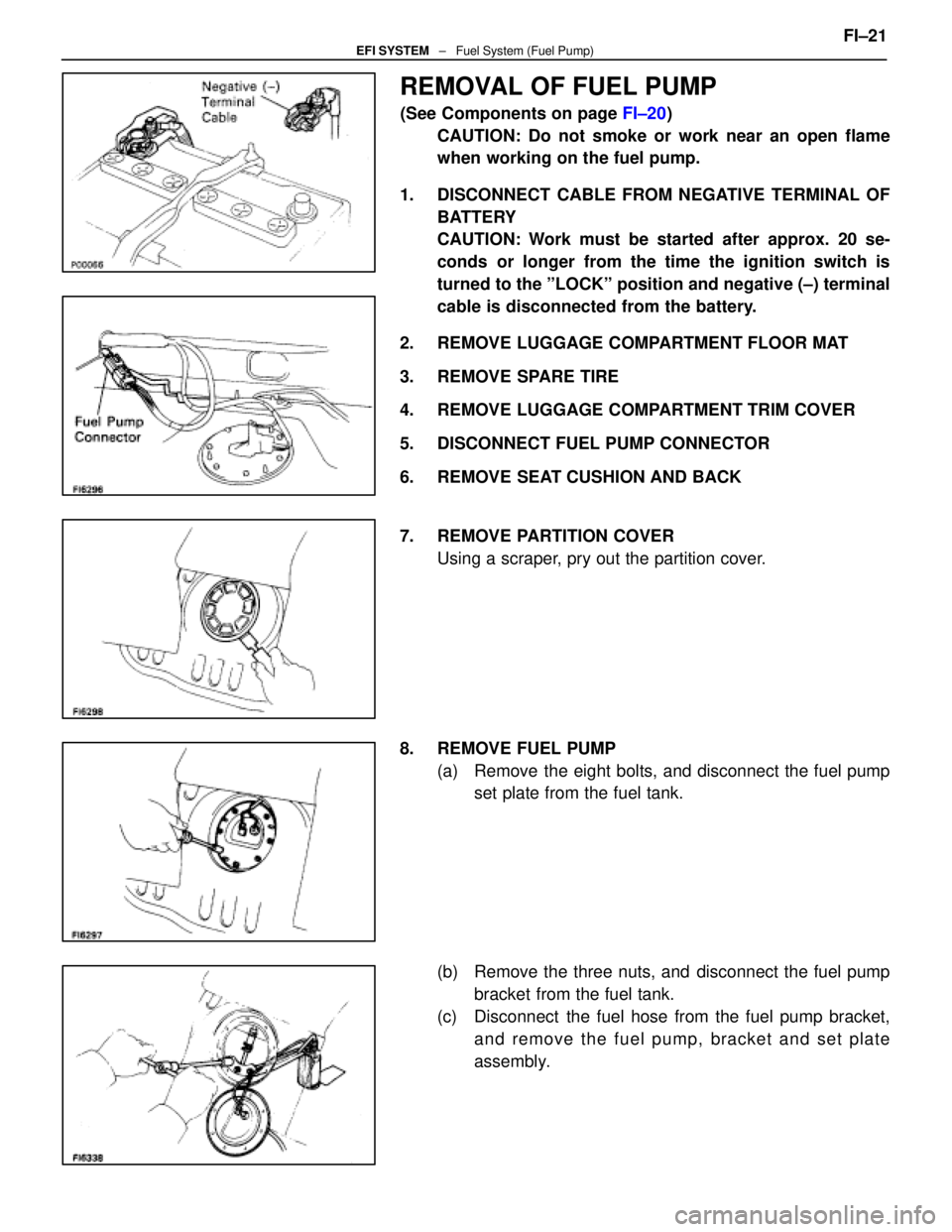

REMOVAL OF FUEL PUMP

(See Components on page FI±20)

CAUTION: Do not smoke or work near an open flame

when working on the fuel pump.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. REMOVE LUGGAGE COMPARTMENT FLOOR MAT

3. REMOVE SPARE TIRE

4. REMOVE LUGGAGE COMPARTMENT TRIM COVER

5. DISCONNECT FUEL PUMP CONNECTOR

6. REMOVE SEAT CUSHION AND BACK

7. REMOVE PARTITION COVER Using a scraper, pry out the partition cover.

8. REMOVE FUEL PUMP (a) Remove the eight bolts, and disconnect the fuel pumpset plate from the fuel tank.

(b) Remove the three nuts, and disconnect the fuel pump bracket from the fuel tank.

(c) Disconnect the fuel hose from the fuel pump bracket, and remove the fuel pump, bracket and set plate

assembly. FI±21

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2048 of 4087

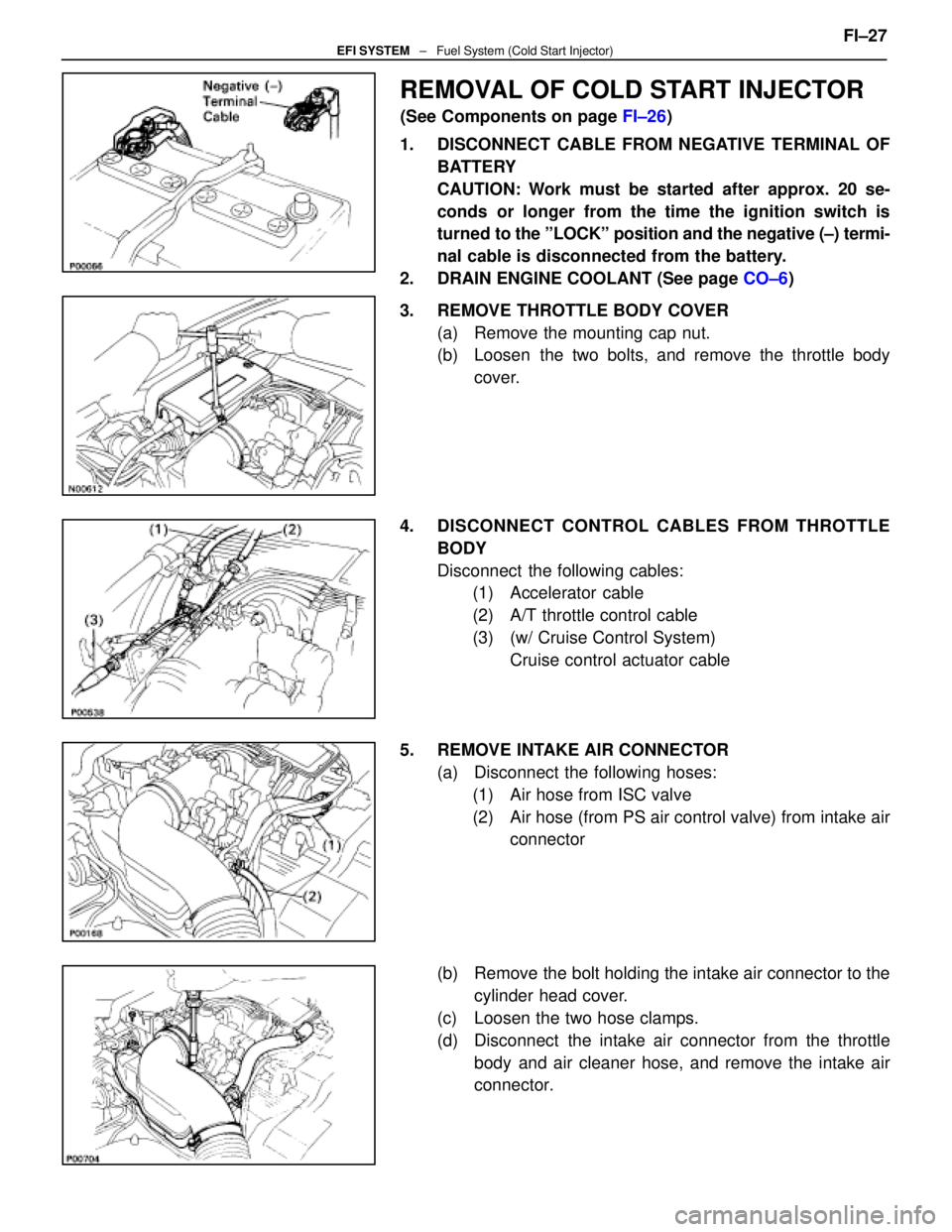

REMOVAL OF COLD START INJECTOR

(See Components on page FI±26)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. DRAIN ENGINE COOLANT (See page CO±6)

3. REMOVE THROTTLE BODY COVER (a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

5. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the two hose clamps.

(d) Disconnect the intake air connector from the throttle body and air cleaner hose, and remove the intake air

connector. FI±27

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2055 of 4087

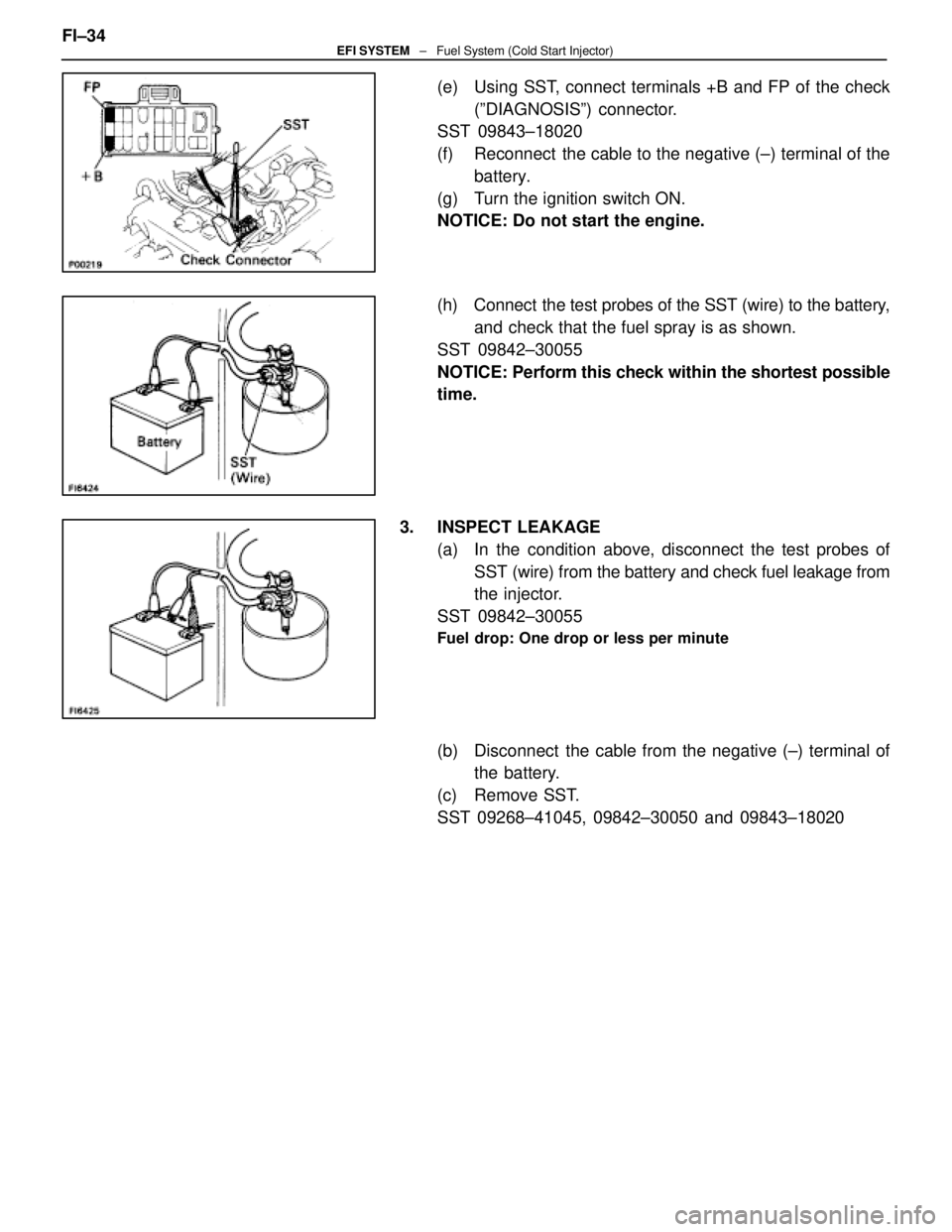

(e) Using SST, connect terminals +B and FP of the check(ºDIAGNOSISº) connector.

SST 09843±18020

(f) Reconnect the cable to the negative (±) terminal of the

battery.

(g) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(h) Connect the test probes of the SST (wire) to the battery, and check that the fuel spray is as shown.

SST 09842±30055

NOTICE: Perform this check within the shortest possible

time.

3. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check fuel leakage from

the injector.

SST 09842±30055

Fuel drop: One drop or less per minute

(b) Disconnect the cable from the negative (±) terminal of the battery.

(c) Remove SST.

SST 09268±41045, 09842±30050 and 09843±18020

FI±34

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2065 of 4087

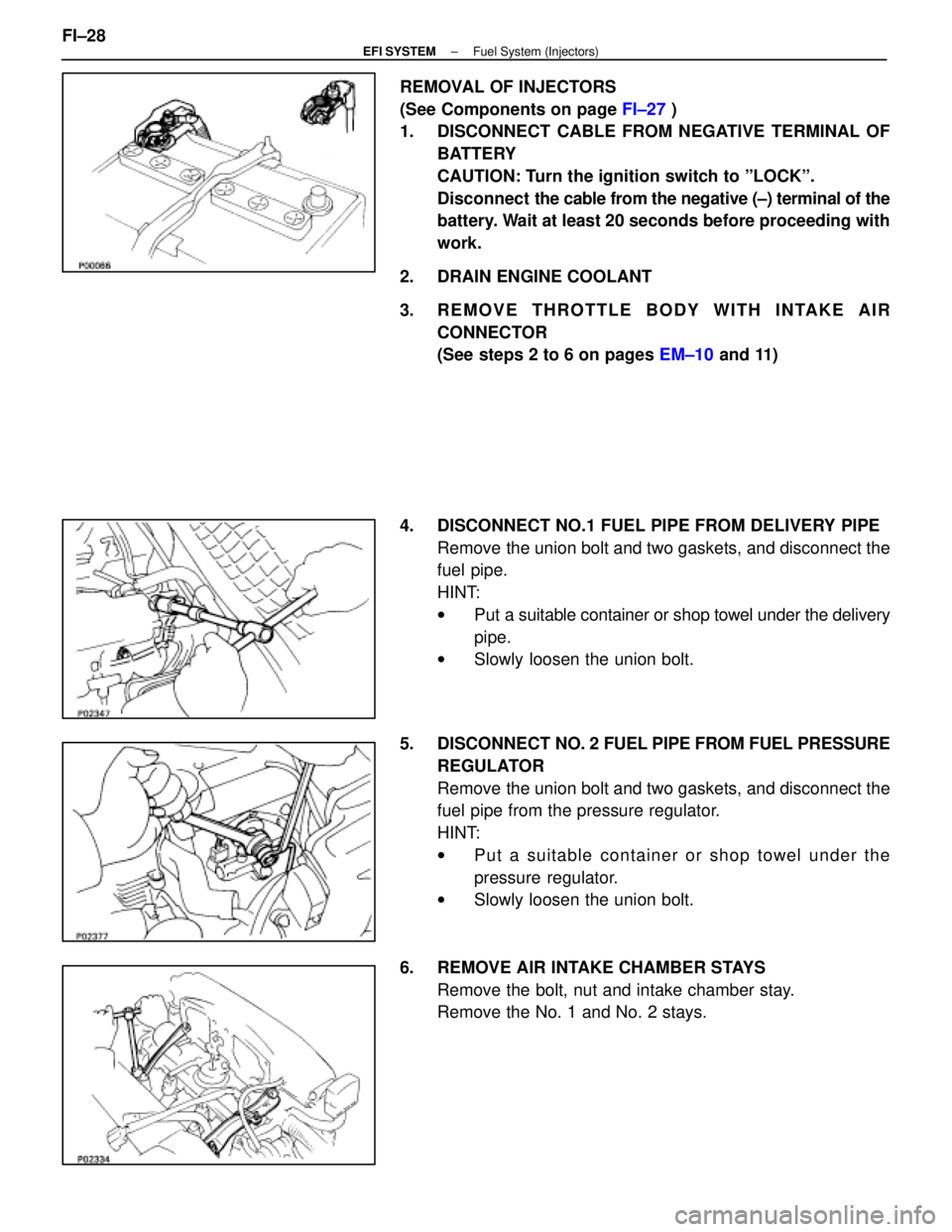

REMOVAL OF INJECTORS

(See Components on page FI±27 )

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF

BATTERY

CAUTION: Turn the ignition switch to ºLOCKº.

Disconnect the cable from the negative (±) terminal of the

battery. Wait at least 20 seconds before proceeding with

work.

2. DRAIN ENGINE COOLANT

3. REMOVE THROTTLE BODY WITH INTAKE AIR CONNECTOR

(See steps 2 to 6 on pages EM±10 and 11)

4. DISCONNECT NO.1 FUEL PIPE FROM DELIVERY PIPE Remove the union bolt and two gaskets, and disconnect the

fuel pipe.

HINT:

wPut a suitable container or shop towel under the delivery

pipe.

w Slowly loosen the union bolt.

5. DISCONNECT NO. 2 FUEL PIPE FROM FUEL PRESSURE

REGULATOR

Remove the union bolt and two gaskets, and disconnect the

fuel pipe from the pressure regulator.

HINT:

w Put a suitable container or shop towel under the

pressure regulator.

w Slowly loosen the union bolt.

6. REMOVE AIR INTAKE CHAMBER STAYS Remove the bolt, nut and intake chamber stay.

Remove the No. 1 and No. 2 stays.

FI±28

±

EFI SYSTEM Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 2068 of 4087

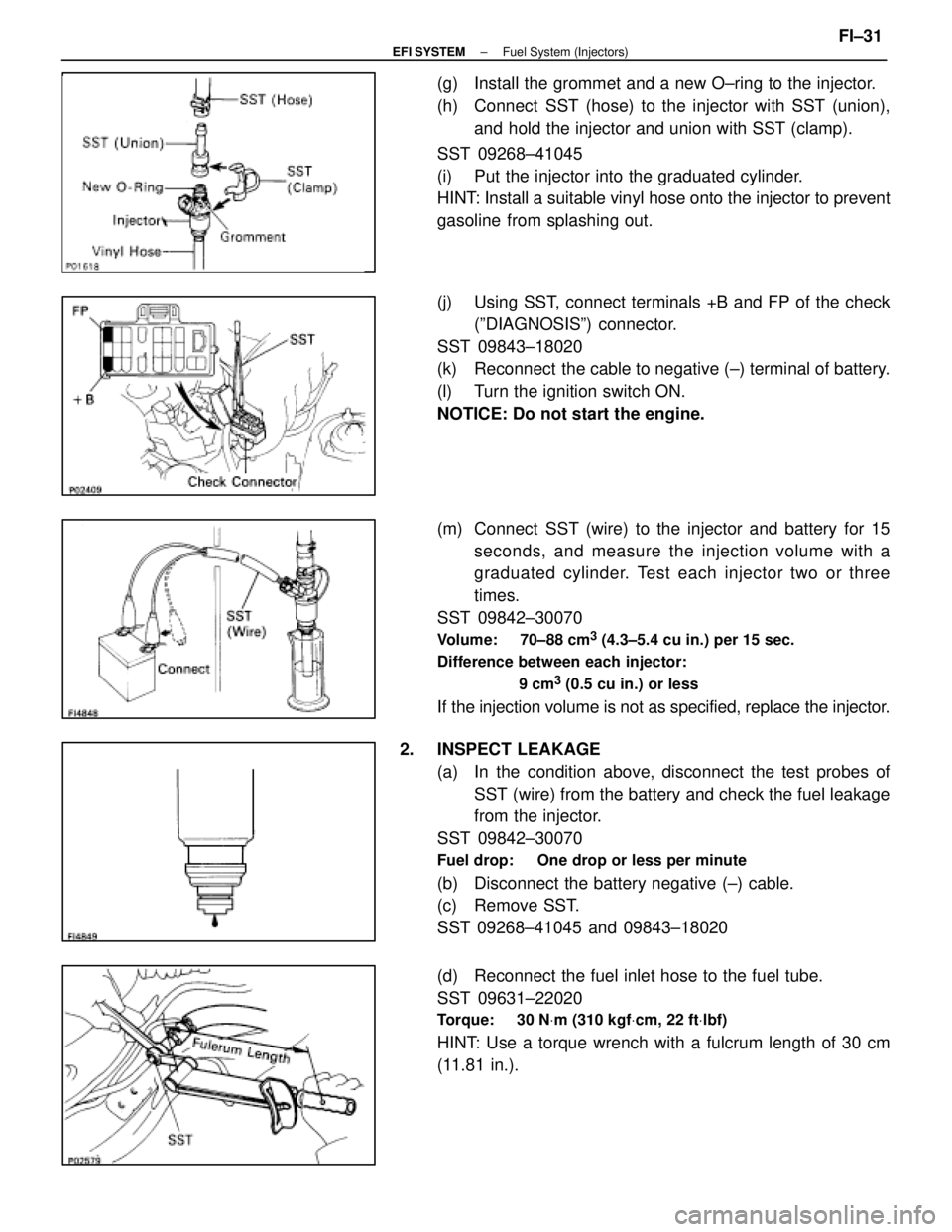

(g) Install the grommet and a new O±ring to the injector.

(h) Connect SST (hose) to the injector with SST (union),and hold the injector and union with SST (clamp).

SST 09268±41045

(i) Put the injector into the graduated cylinder.

HINT: Install a suitable vinyl hose onto the injector to prevent

gasoline from splashing out.

(j) Using SST, connect terminals +B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(k) Reconnect the cable to negative (±) terminal of battery.

(l) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(m) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a

graduated cylinder. Test each injector two or three

times.

SST 09842±30070

Volume: 70±88 cm3 (4.3±5.4 cu in.) per 15 sec.

Difference between each injector:

9 cm

3 (0.5 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check the fuel leakage

from the injector.

SST 09842±30070

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (±) cable.

(c) Remove SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel tube.

SST 09631±22020

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

±

EFI SYSTEM Fuel System (Injectors)FI±31

WhereEverybodyKnowsYourName

Page 2077 of 4087

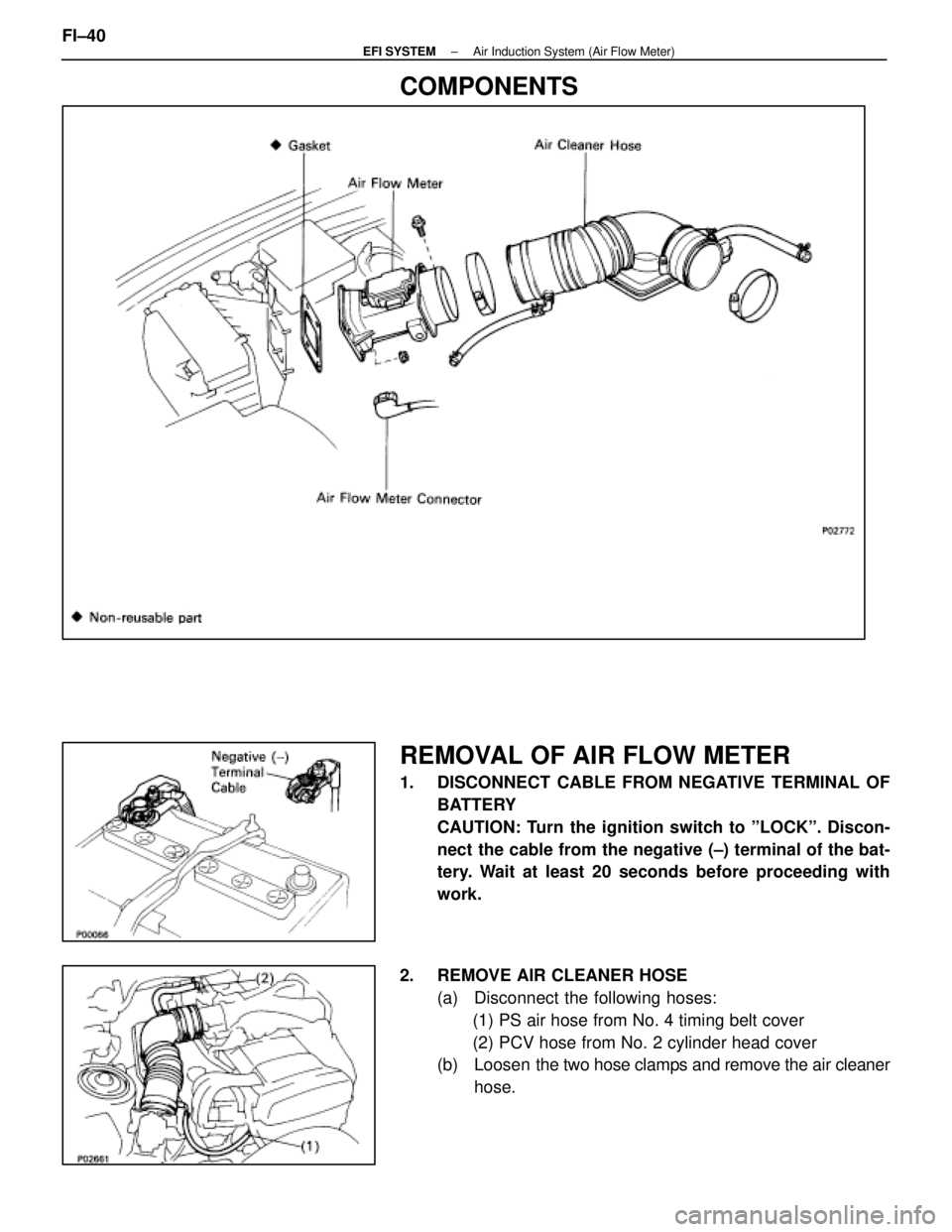

COMPONENTS

REMOVAL OF AIR FLOW METER

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

2. REMOVE AIR CLEANER HOSE (a) Disconnect the following hoses:(1) PS air hose from No. 4 timing belt cover

(2) PCV hose from No. 2 cylinder head cover

(b) Loosen the two hose clamps and remove the air cleaner

hose.

FI±40

±

EFI SYSTEM Air Induction System (Air Flow Meter)

WhereEverybodyKnowsYourName

Page 2080 of 4087

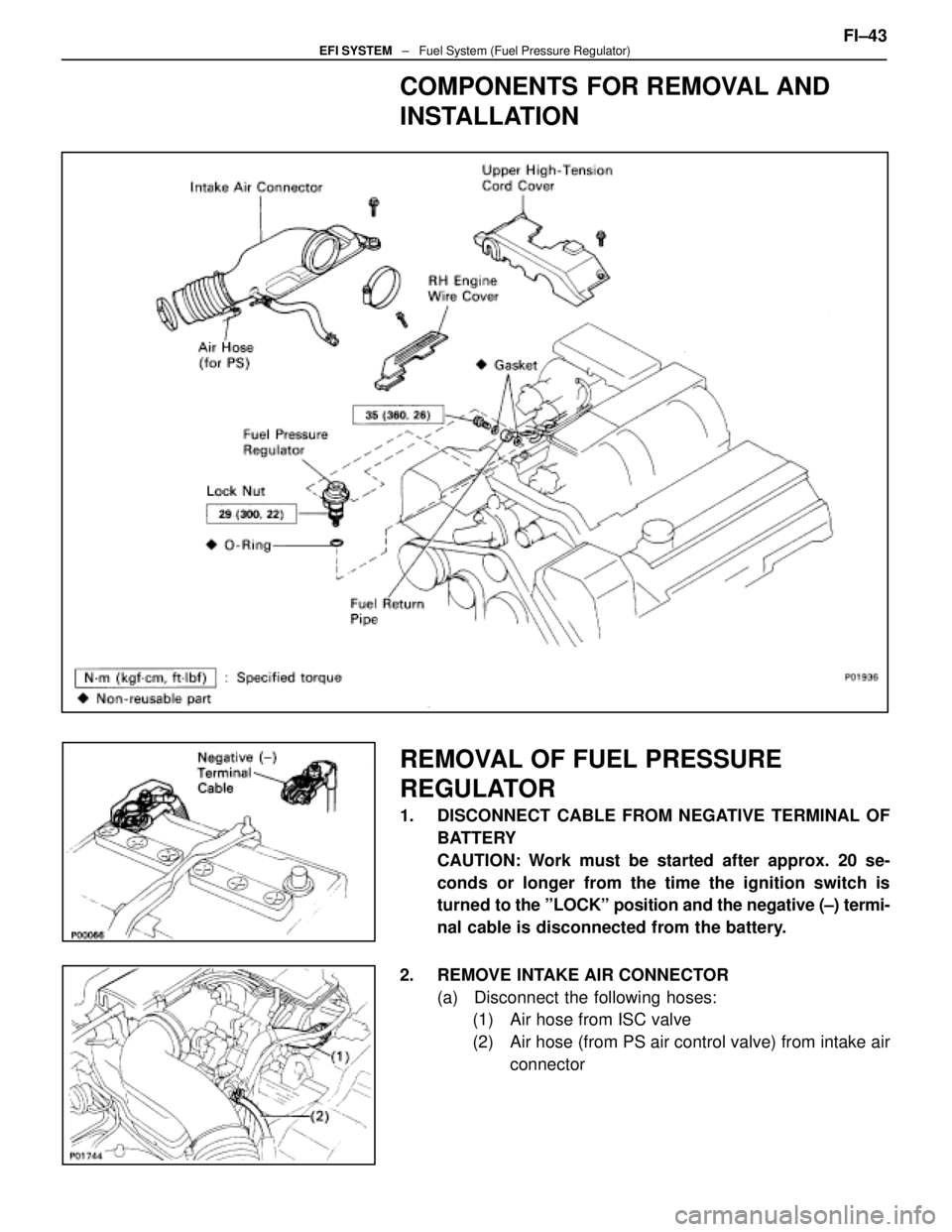

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF FUEL PRESSURE

REGULATOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air

connector FI±43

EFI SYSTEM

± Fuel System (Fuel Pressure Regulator)

WhereEverybodyKnowsYourName

Page 2085 of 4087

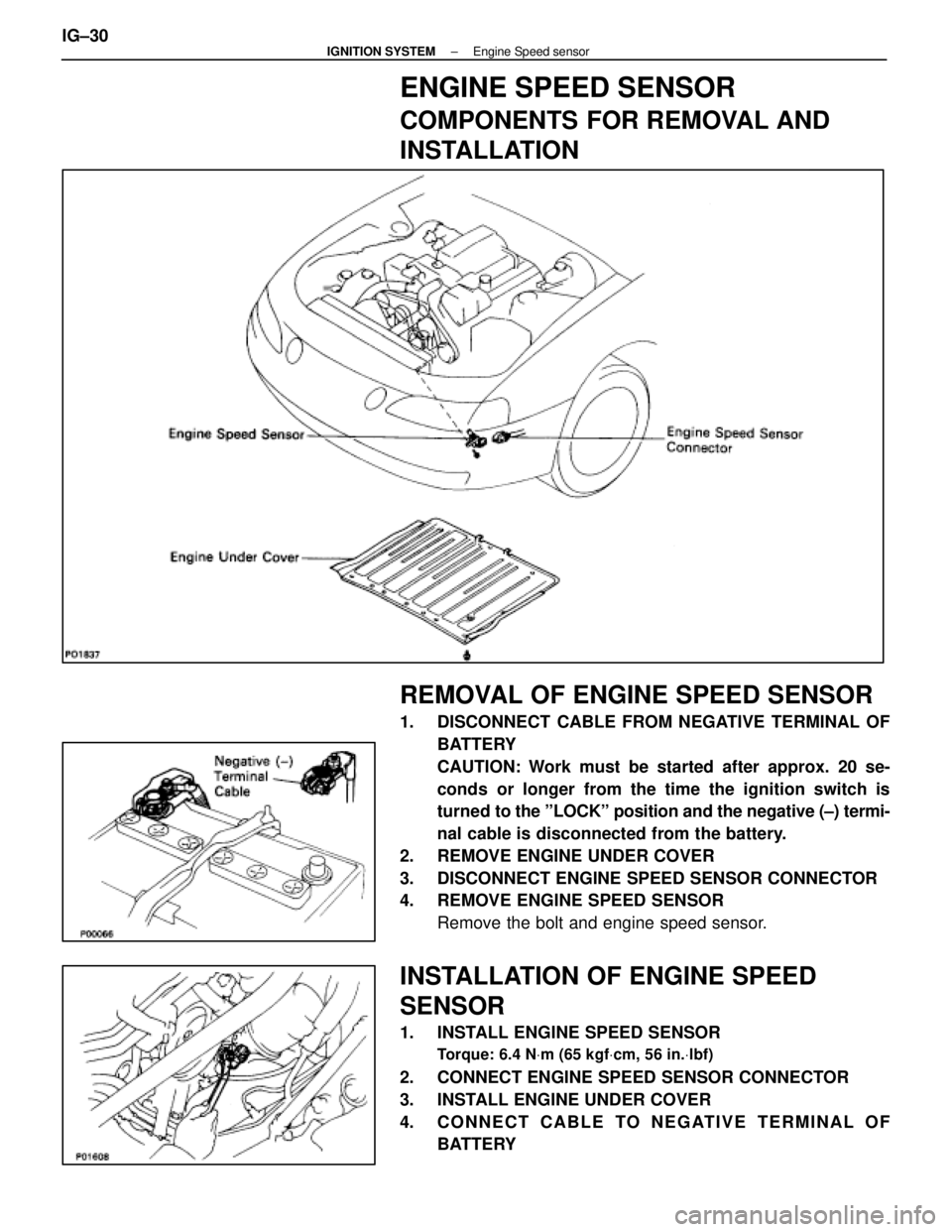

ENGINE SPEED SENSOR

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF ENGINE SPEED SENSOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DISCONNECT ENGINE SPEED SENSOR CONNECTOR

4. REMOVE ENGINE SPEED SENSOR Remove the bolt and engine speed sensor.

INSTALLATION OF ENGINE SPEED

SENSOR

1. INSTALL ENGINE SPEED SENSOR

Torque: 6.4 N Vm (65 kgf Vcm, 56 in. Vlbf)

2. CONNECT ENGINE SPEED SENSOR CONNECTOR

3. INSTALL ENGINE UNDER COVER

4. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

IG±30

±

IGNITION SYSTEM Engine Speed sensor

WhereEverybodyKnowsYourName

Page 2086 of 4087

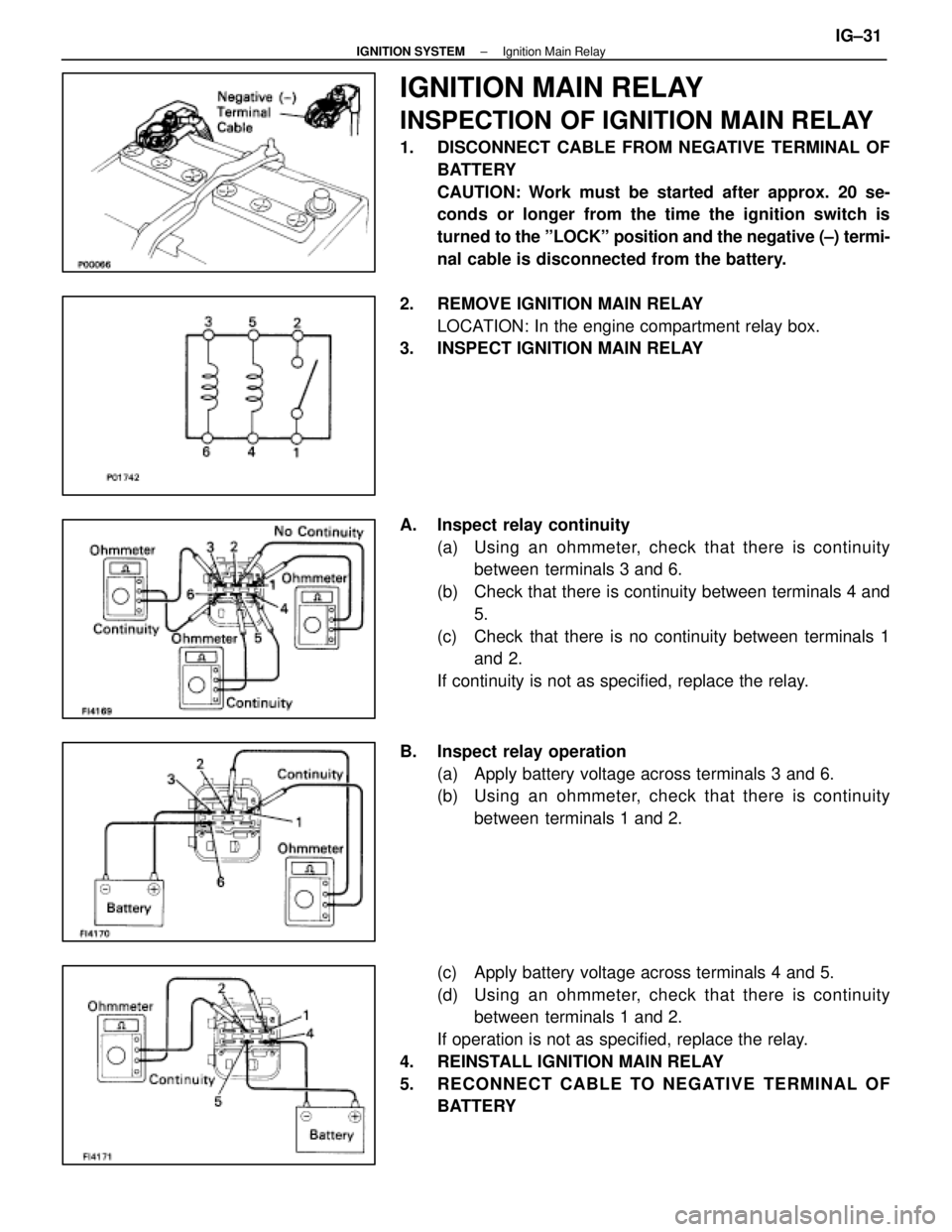

IGNITION MAIN RELAY

INSPECTION OF IGNITION MAIN RELAY

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE IGNITION MAIN RELAY LOCATION: In the engine compartment relay box.

3. INSPECT IGNITION MAIN RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuitybetween terminals 3 and 6.

(b) Check that there is continuity between terminals 4 and 5.

(c) Check that there is no continuity between terminals 1 and 2.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 3 and 6.

(b) Using an ohmmeter, check that there is continuitybetween terminals 1 and 2.

(c) Apply battery voltage across terminals 4 and 5.

(d) Using an ohmmeter, check that there is continuity between terminals 1 and 2.

If operation is not as specified, replace the relay.

4. REINSTALL IGNITION MAIN RELAY

5. RECONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

±

IGNITION SYSTEM Ignition Main RelayIG±31

WhereEverybodyKnowsYourName

Page 2090 of 4087

PRECAUTIONS

1. Do not leave the ignition switch on for more than 10minutes if the engine will not start.

2. With a tachometer connected to the system, connect the tester probe of the tachometer to terminal IG

of the

check (ºDIAGNOSISº) connector.

HINT:

wAllow the engine to warm up to normal operation

temperature.

w Set the tachometer to the 4±cylinder range.

3. As some tachometers are not compatible with this ignition system, we recommend that you confirm the

compatibility of your unit before use.

4. Never allow the tachometer terminal to touch ground as this could damage the igniter and/or ignition coil.

5. Do not disconnect the battery when the engine is running.

6. Check that the igniter is properly grounded to the body.

±

IGNITION SYSTEM PrecautionsIG±3

WhereEverybodyKnowsYourName