torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1726 of 4087

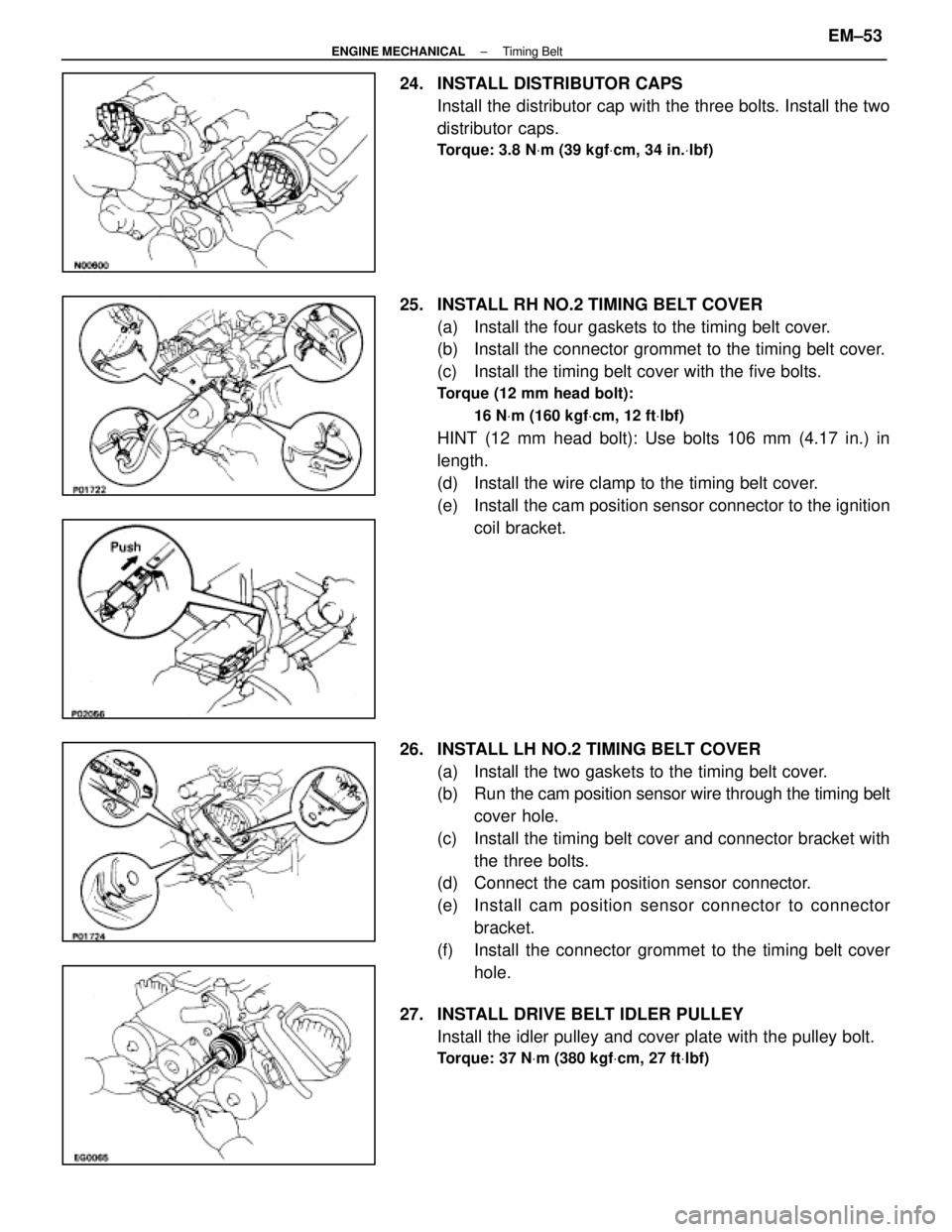

24. INSTALL DISTRIBUTOR CAPSInstall the distributor cap with the three bolts. Install the two

distributor caps.

Torque: 3.8 N Vm (39 kgf Vcm, 34 in. Vlbf)

25. INSTALL RH NO.2 TIMING BELT COVER

(a) Install the four gaskets to the timing belt cover.

(b) Install the connector grommet to the timing belt cover.

(c) Install the timing belt cover with the five bolts.

Torque (12 mm head bolt):

16 NVm (160 kgf Vcm, 12 ft Vlbf)

HINT (12 mm head bolt): Use bolts 106 mm (4.17 in.) in

length.

(d) Install the wire clamp to the timing belt cover.

(e) Install the cam position sensor connector to the ignition

coil bracket.

26. INSTALL LH NO.2 TIMING BELT COVER (a) Install the two gaskets to the timing belt cover.

(b) Run the cam po sition sensor wire through the timing belt

cover hole.

(c) Install the timing belt cover and connector bracket with the three bolts.

(d) Connect the cam position sensor connector.

(e) Install cam position sensor c onnector to connector

bracket.

(f) Install the connector grommet to the timing belt cover hole.

27. INSTALL DRIVE BELT IDLER PULLEY Install the idler pulley and cover plate with the pulley bolt.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

±

ENGINE MECHANICAL Timing BeltEM±53

WhereEverybodyKnowsYourName

Page 1730 of 4087

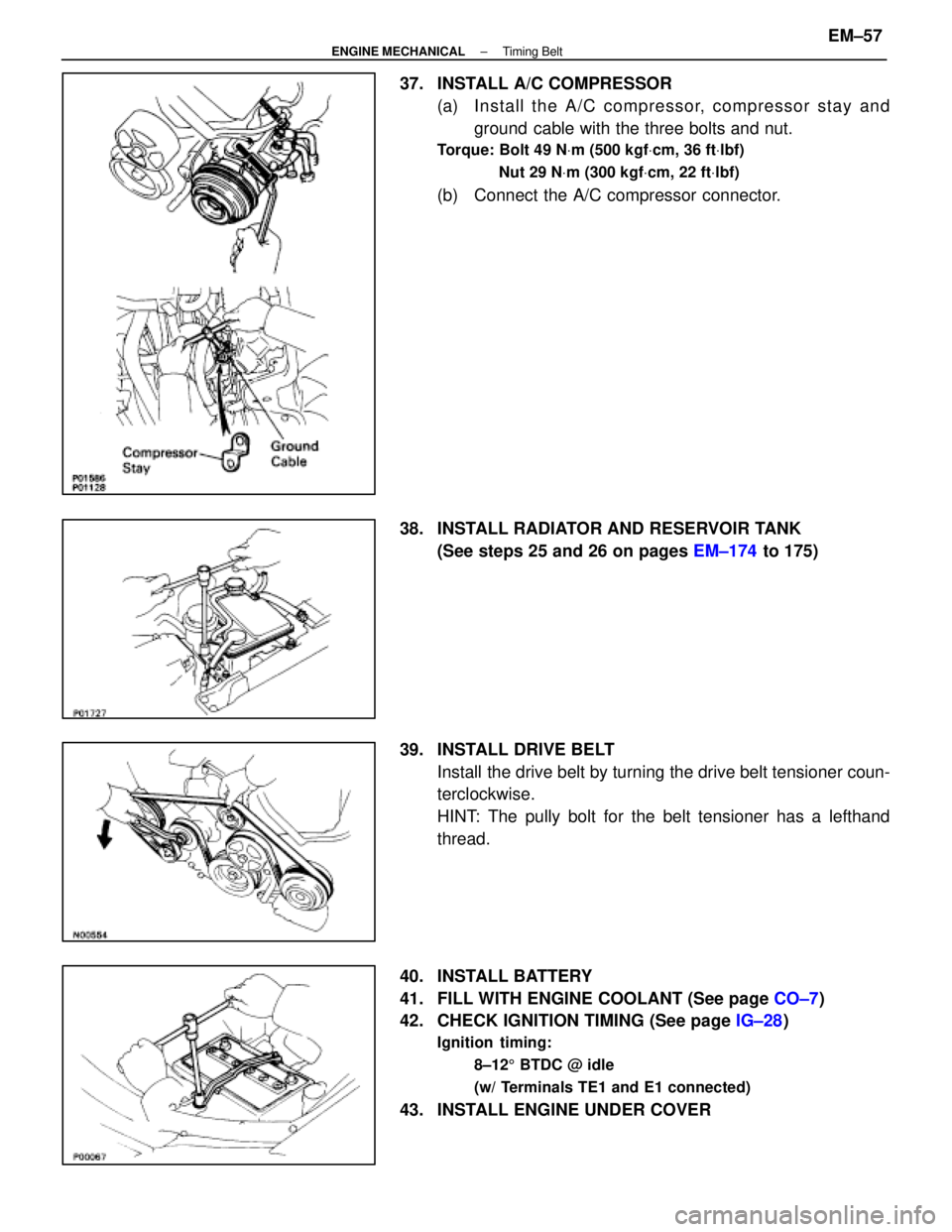

37. INSTALL A/C COMPRESSOR(a) In sta ll th e A/C co mp re sso r, co mp re sso r sta y an dground cable with the three bolts and nut.

Torque: Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

Nut 29 N Vm (300 kgf Vcm, 22 ft Vlbf)

(b) Connect the A/C compressor connector.

38. INSTALL RADIATOR AND RESERVOIR TANK (See steps 25 and 26 on pages EM±174 to 175)

39. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pully bolt for the belt tensioner has a lefthand

thread.

40. INSTALL BATTERY

41. FILL WITH ENGINE COOLANT (See page CO±7)

42. CHECK IGNITION TIMING (See page IG±28)

Ignition timing:

8±125 BTDC @ idle

(w/ Terminals TE1 and E1 connected)

43. INSTALL ENGINE UNDER COVER

±

ENGINE MECHANICAL Timing BeltEM±57

WhereEverybodyKnowsYourName

Page 1746 of 4087

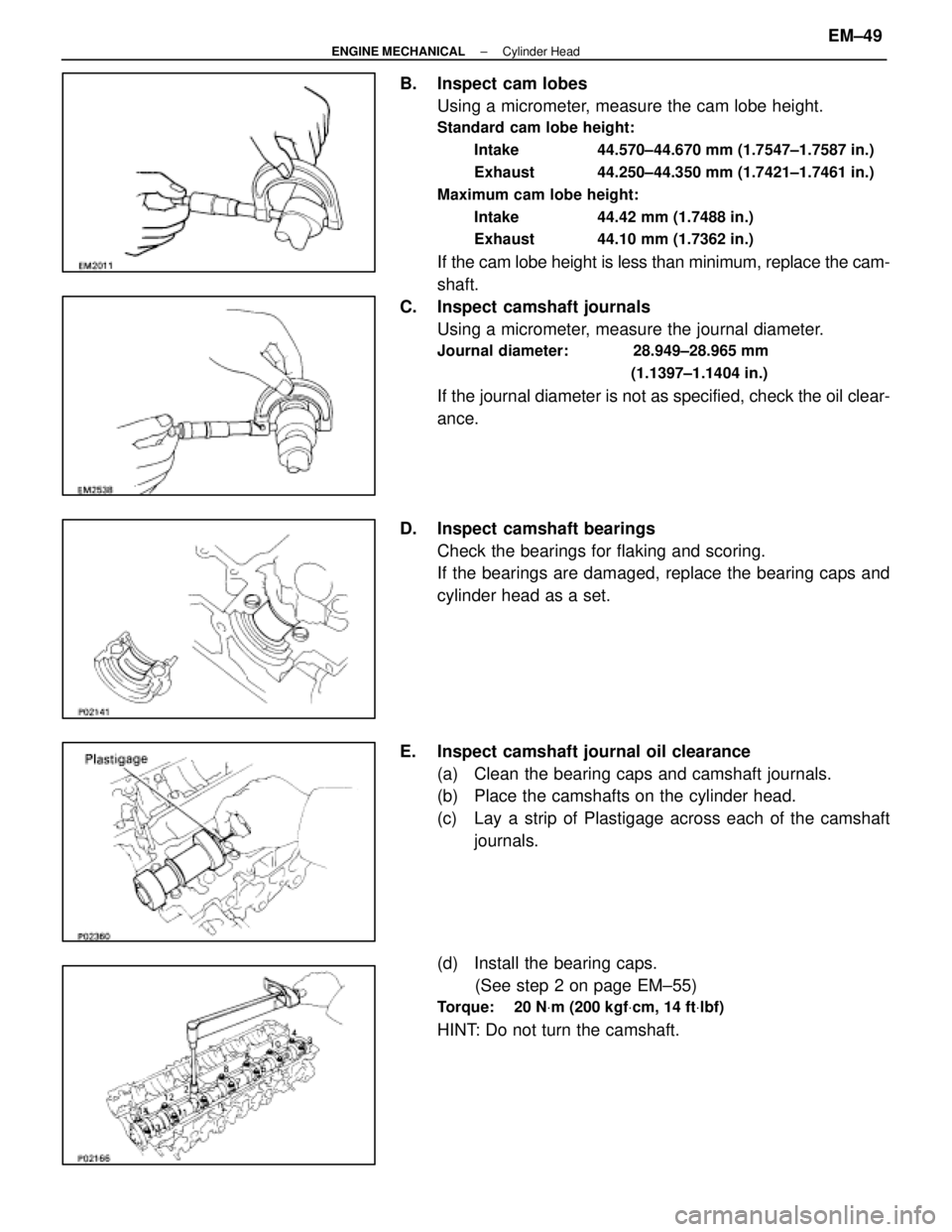

B. Inspect cam lobesUsing a micrometer, measure the cam lobe height.

Standard cam lobe height:

Intake 44.570±44.670 mm (1.7547±1.7587 in.)

Exhaust 44.250±44.350 mm (1.7421±1.7461 in.)

Maximum cam lobe height: Intake 44.42 mm (1.7488 in.)

Exhaust 44.10 mm (1.7362 in.)

If the cam lobe height is less than minimum, replace the cam-

shaft.

C. Inspect camshaft journals Using a micrometer, measure the journal diameter.

Journal diameter: 28.949±28.965 mm

(1.1397±1.1404 in.)

If the journal diameter is not as specified, check the oil clear-

ance.

D. Inspect camshaft bearings Check the bearings for flaking and scoring.

If the bearings are damaged, replace the bearing caps and

cylinder head as a set.

E. Inspect camshaft journal oil clearance (a) Clean the bearing caps and camshaft journals.

(b) Place the camshafts on the cylinder head.

(c) Lay a strip of Plastigage across each of the camshaftjournals.

(d) Install the bearing caps. (See step 2 on page EM±55)

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

HINT: Do not turn the camshaft.

±

ENGINE MECHANICAL Cylinder HeadEM±49

WhereEverybodyKnowsYourName

Page 1749 of 4087

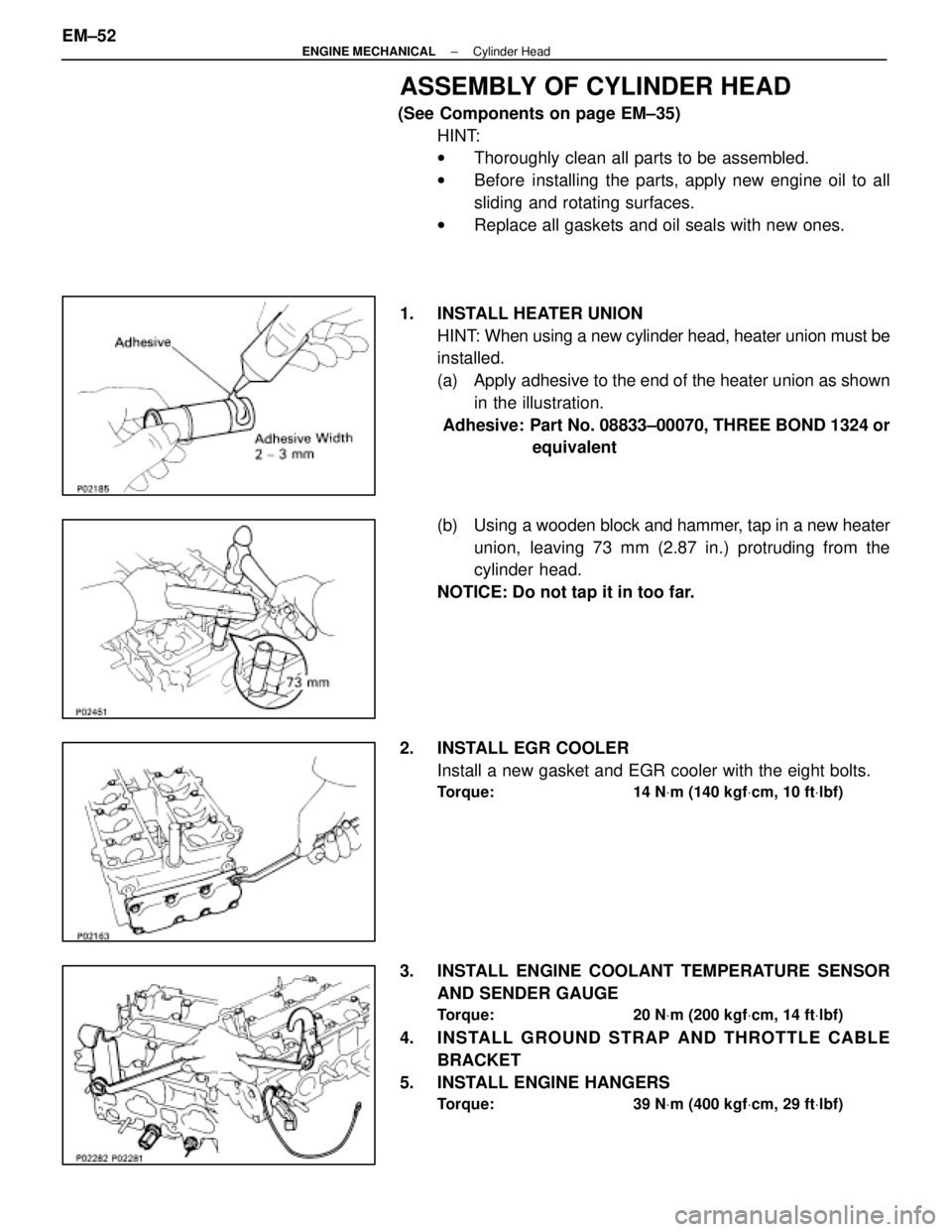

ASSEMBLY OF CYLINDER HEAD

(See Components on page EM±35)HINT:

wThoroughly clean all parts to be assembled.

w Before installing the parts, apply new engine oil to all

sliding and rotating surfaces.

w Replace all gaskets and oil seals with new ones.

1. INSTALL HEATER UNION HINT: When using a new cylinder head, heater union must be

installed.

(a) Apply adhesive to the end of the heater union as shownin the illustration.

Adhesive: Part No. 08833±00070, THREE BOND 1324 or equivalent

(b) Using a wooden block and hammer, tap in a new heater

union, leaving 73 mm (2.87 in.) protruding from the

cylinder head.

NOTICE: Do not tap it in too far.

2. INSTALL EGR COOLER Install a new gasket and EGR cooler with the eight bolts.

Torque: 14 N Vm (140 kgf Vcm, 10 ft Vlbf)

3. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

AND SENDER GAUGE

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

4. INSTALL GROUND STRAP AND THROTTLE CABLE

BRACKET

5. INSTALL ENGINE HANGERS

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

EM±52±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1751 of 4087

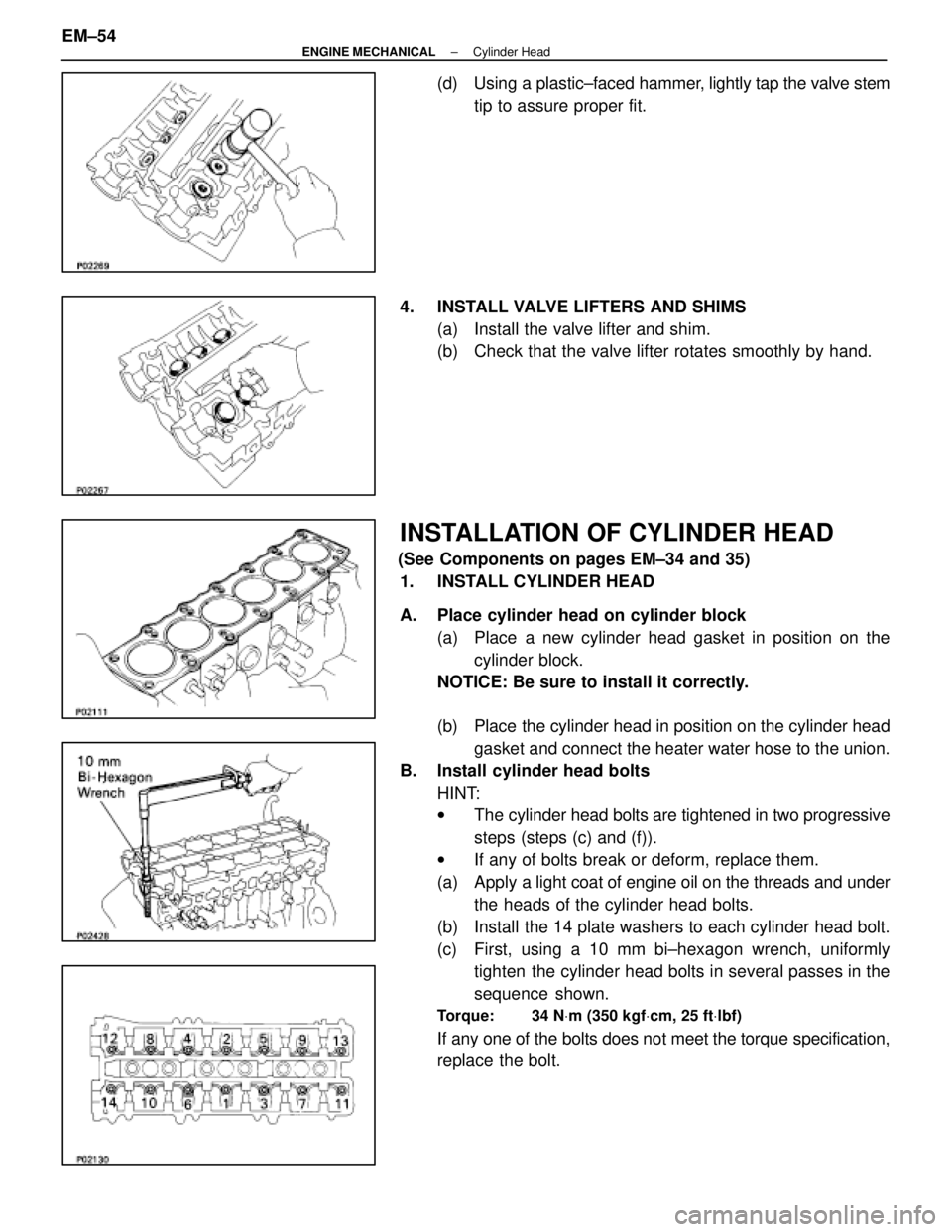

(d) Using a plastic±faced hammer, lightly tap the valve stem

tip to assure proper fit.

4. INSTALL VALVE LIFTERS AND SHIMS (a) Install the valve lifter and shim.

(b) Check that the valve lifter rotates smoothly by hand.

INSTALLATION OF CYLINDER HEAD

(See Components on pages EM±34 and 35)1. INSTALL CYLINDER HEAD

A. Place cylinder head on cylinder block (a) Place a new cylinder head gasket in position on thecylinder block.

NOTICE: Be sure to install it correctly.

(b) Place the cylinder head in position on the cylinder head

gasket and connect the heater water hose to the union.

B. Install cylinder head bolts

HINT:

wThe cylinder head bolts are tightened in two progressive

steps (steps (c) and (f)).

w If any of bolts break or deform, replace them.

(a) Apply a light coat of engine oil on the threads and under

the heads of the cylinder head bolts.

(b) Install the 14 plate washers to each cylinder head bolt.

(c) First, using a 10 mm bi±hexagon wrench, uniformly tighten the cylinder head bolts in several passes in the

sequence shown.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

If any one of the bolts does not meet the torque specification,

replace the bolt.

EM±54

±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1753 of 4087

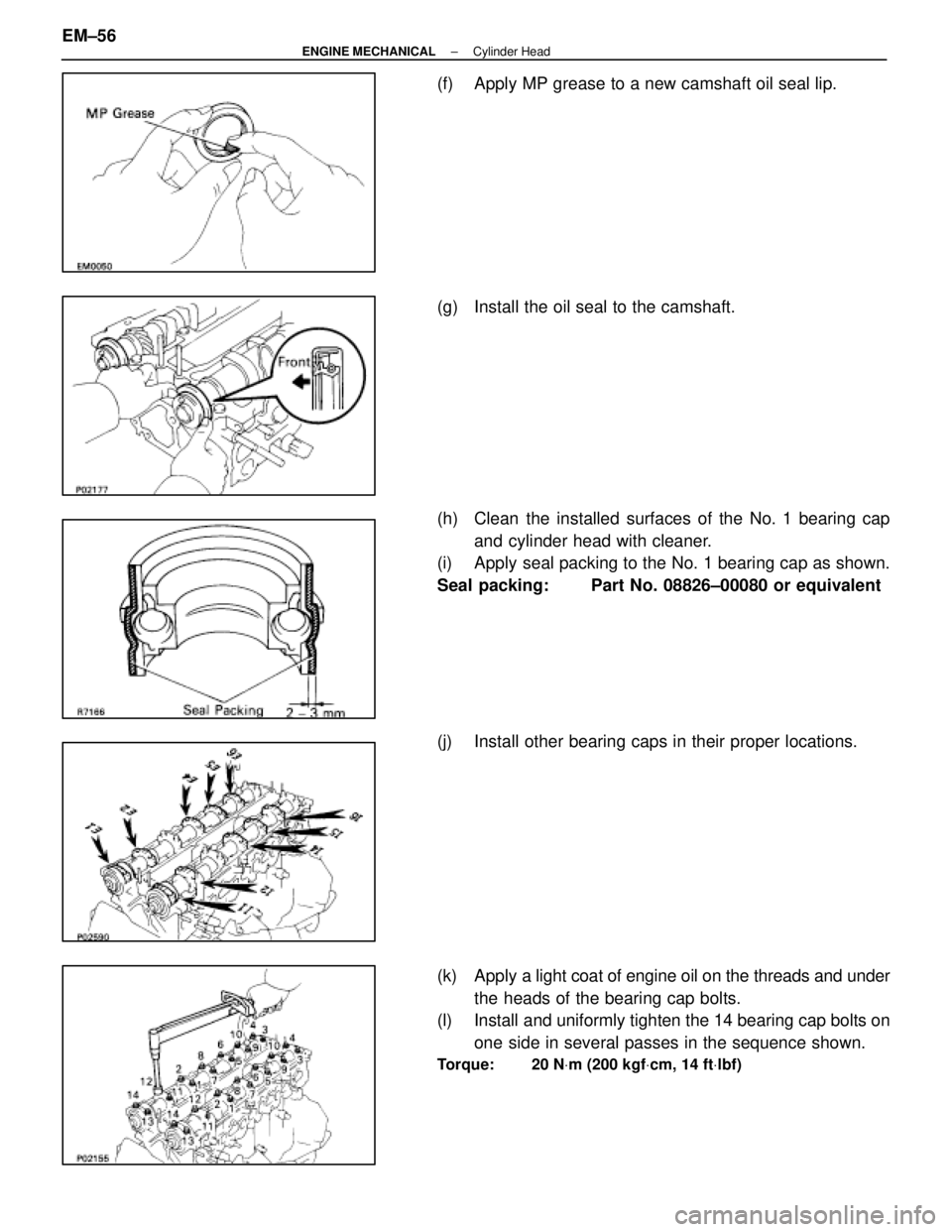

(f) Apply MP grease to a new camshaft oil seal lip.

(g) Install the oil seal to the camshaft.

(h) Clean the installed surfaces of the No. 1 bearing capand cylinder head with cleaner.

(i) Apply seal packing to the No. 1 bearing cap as shown.

Seal packing: Part No. 08826±00080 or equivalent

(j) Install other bearing caps in their proper locations.

(k) Apply a light coat of engine oil on the threads and under

the heads of the bearing cap bolts.

(l) Install and uniformly tighten the 14 bearing cap bolts on

one side in several passes in the sequence shown.

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

EM±56±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1754 of 4087

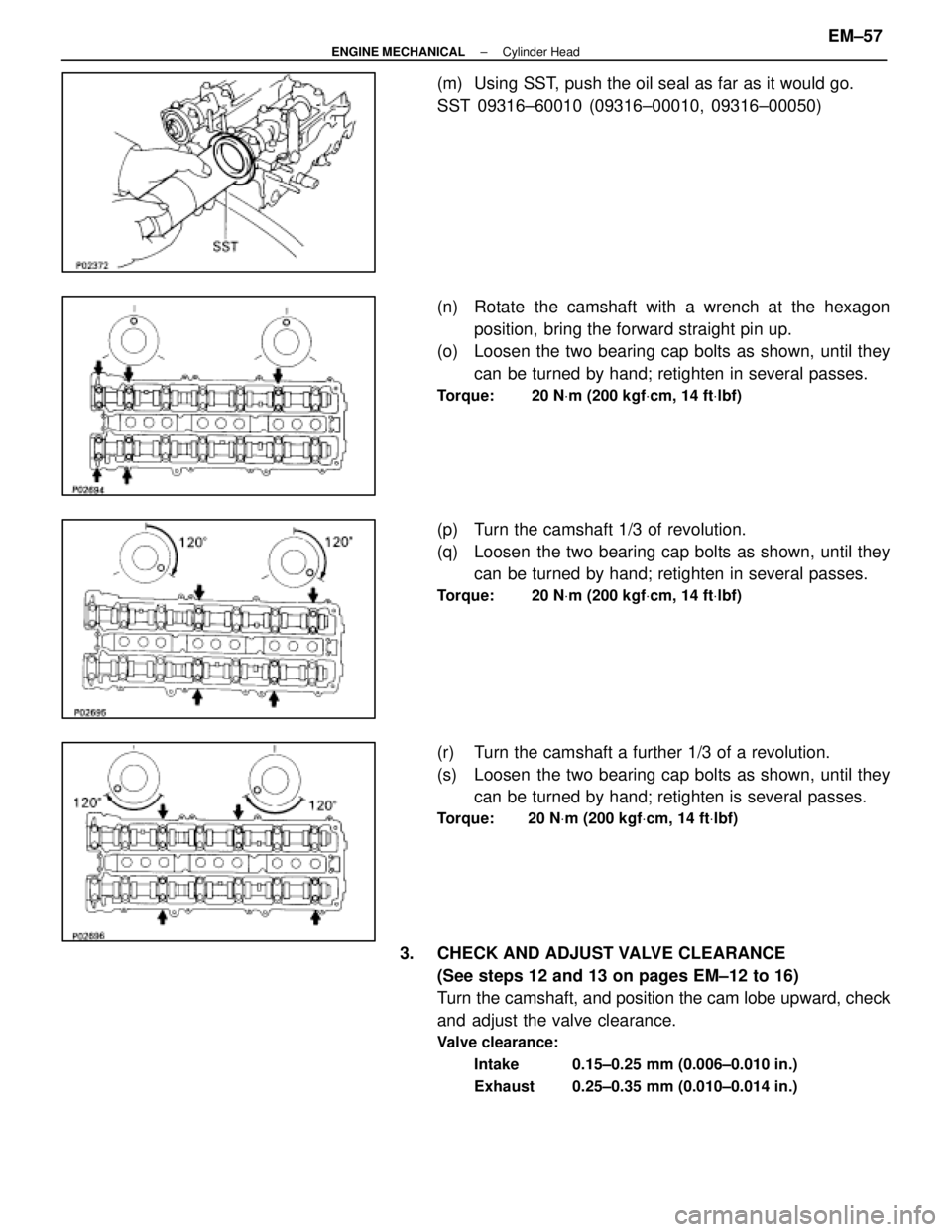

(m) Using SST, push the oil seal as far as it would go.

SST 09316±60010 (09316±00010, 09316±00050)

(n) Rotate the camshaft with a wrench at the hexagonposition, bring the forward straight pin up.

(o) Loosen the two bearing cap bolts as shown, until they

can be turned by hand; retighten in several passes.

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

(p) Turn the camshaft 1/3 of revolution.

(q) Loosen the two bearing cap bolts as shown, until they

can be turned by hand; retighten in several passes.

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

(r) Turn the camshaft a further 1/3 of a revolution.

(s) Loosen the two bearing cap bolts as shown, until they

can be turned by hand; retighten is several passes.

Torque: 20 N Vm (200 kgf Vcm, 14 ft Vlbf)

3. CHECK AND ADJUST VALVE CLEARANCE

(See steps 12 and 13 on pages EM±12 to 16)

Turn the camshaft, and position the cam lobe upward, check

and adjust the valve clearance.

Valve clearance:

Intake 0.15±0.25 mm (0.006±0.010 in.)

Exhaust 0.25±0.35 mm (0.010±0.014 in.)

±

ENGINE MECHANICAL Cylinder HeadEM±57

WhereEverybodyKnowsYourName

Page 1755 of 4087

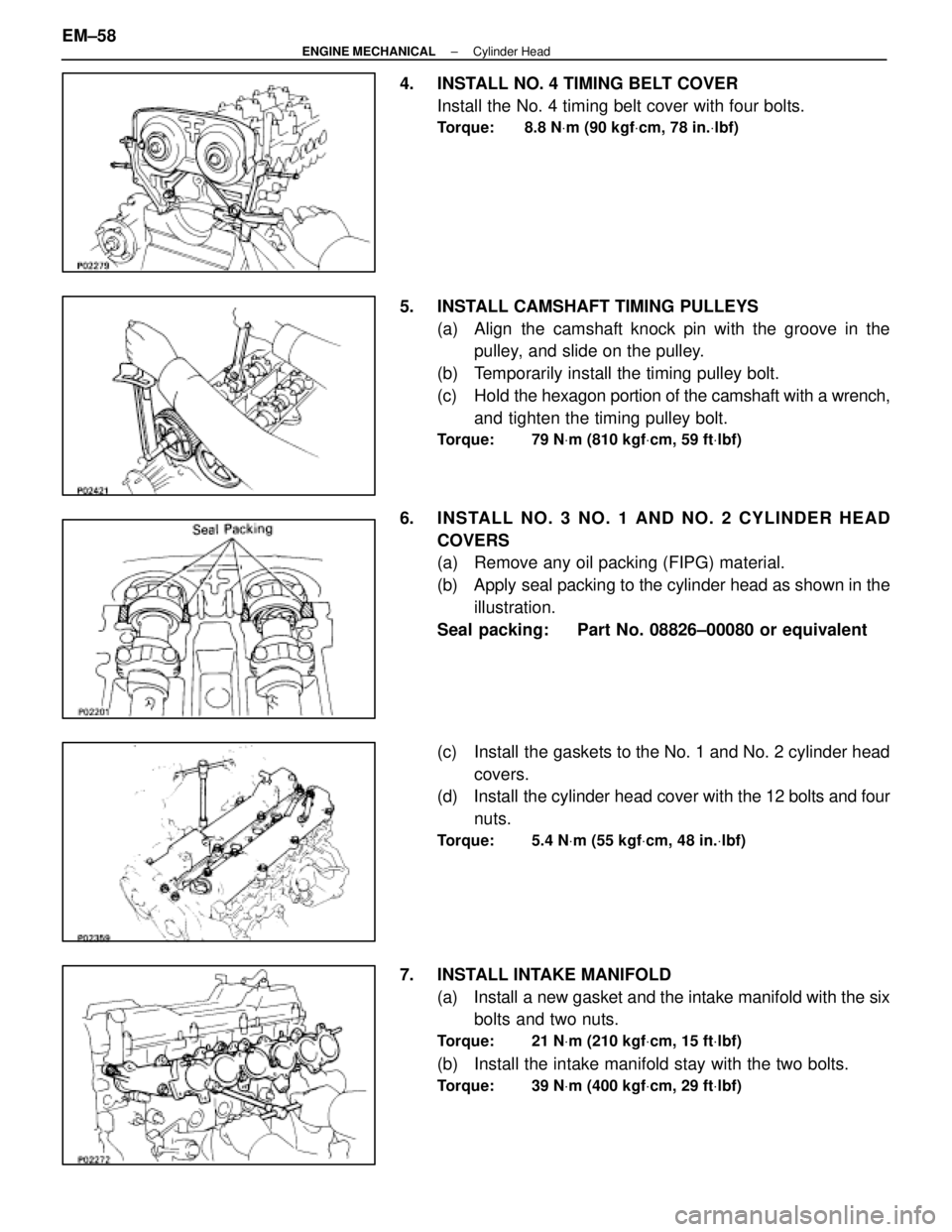

4. INSTALL NO. 4 TIMING BELT COVERInstall the No. 4 timing belt cover with four bolts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

5. INSTALL CAMSHAFT TIMING PULLEYS

(a) Align the camshaft knock pin with the groove in thepulley, and slide on the pulley.

(b) Temporarily install the timing pulley bolt.

(c) Hold the hexagon portion of the camshaft with a wrench,

and tighten the timing pulley bolt.

Torque: 79 N Vm (810 kgf Vcm, 59 ft Vlbf)

6. INS TALL NO . 3 NO . 1 AND NO . 2 CY LINDE R HE AD

COVERS

(a) Remove any oil packing (FIPG) material.

(b) Apply seal packing to the cylinder head as shown in theillustration.

Seal packing: Part No. 08826±00080 or equivalent

(c) Install the gaskets to the No. 1 and No. 2 cylinder head covers.

(d) Install the cylinder head cover with the 12 bolts and four

nuts.

Torque: 5.4 N Vm (55 kgf Vcm, 48 in. Vlbf)

7. INSTALL INTAKE MANIFOLD

(a) Install a new gasket and the intake manifold with the sixbolts and two nuts.

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

(b) Install the intake manifold stay with the two bolts.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

EM±58±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName

Page 1756 of 4087

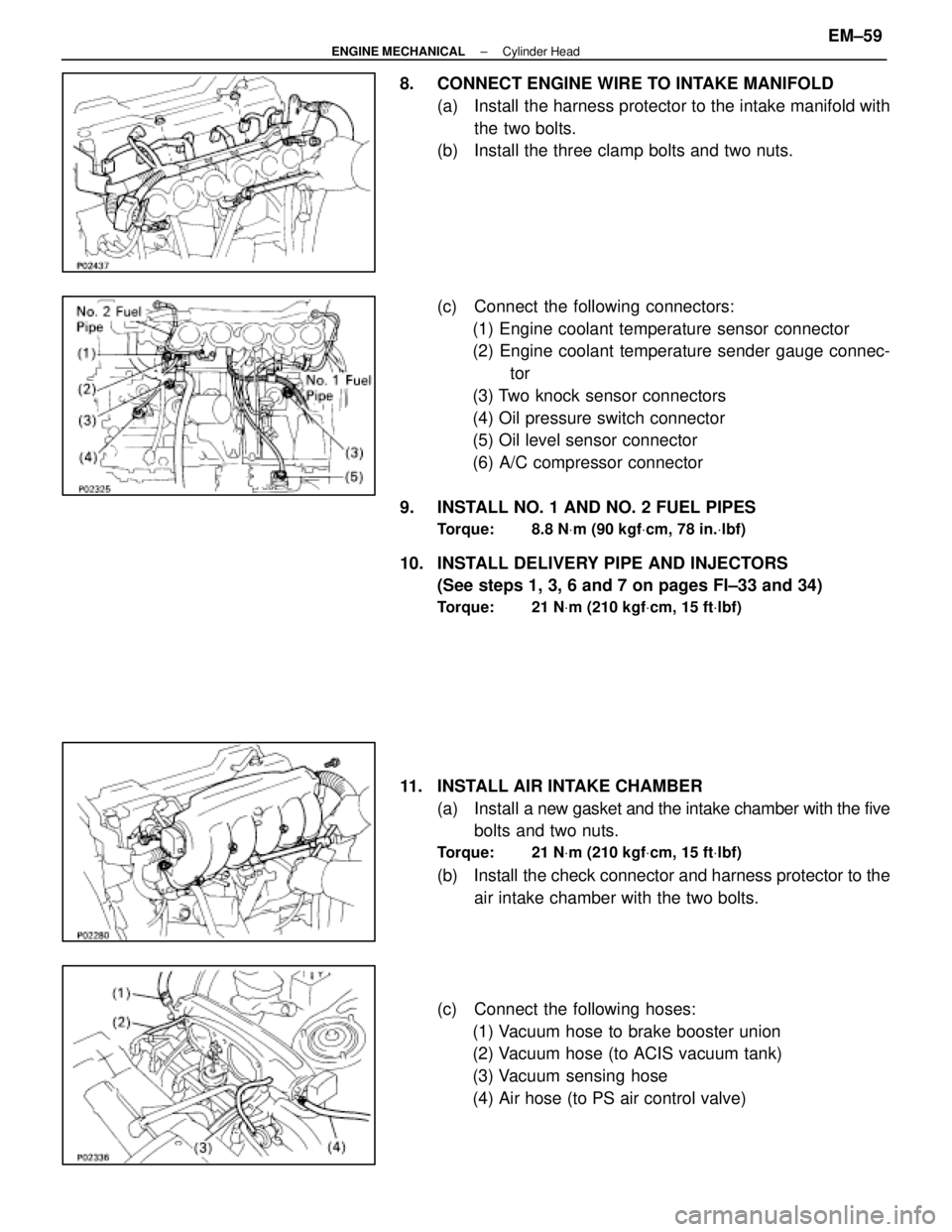

8. CONNECT ENGINE WIRE TO INTAKE MANIFOLD(a) Install the harness protector to the intake manifold withthe two bolts.

(b) Install the three clamp bolts and two nuts.

(c) Connect the following connectors:

(1) Engine coolant temperature sensor connector

(2) Engine coolant temperature sender gauge connec- tor

(3) Two knock sensor connectors

(4) Oil pressure switch connector

(5) Oil level sensor connector

(6) A/C compressor connector

9. INSTALL NO. 1 AND NO. 2 FUEL PIPES

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

10. INSTALL DELIVERY PIPE AND INJECTORS

(See steps 1, 3, 6 and 7 on pages FI±33 and 34)

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

11. INSTALL AIR INTAKE CHAMBER

(a) Install a new gasket and the intake chamber with the five

bolts and two nuts.

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

(b) Install the check connector and harness protector to the

air intake chamber with the two bolts.

(c) Connect the following hoses: (1) Vacuum hose to brake booster union

(2) Vacuum hose (to ACIS vacuum tank)

(3) Vacuum sensing hose

(4) Air hose (to PS air control valve)

±

ENGINE MECHANICAL Cylinder HeadEM±59

WhereEverybodyKnowsYourName

Page 1757 of 4087

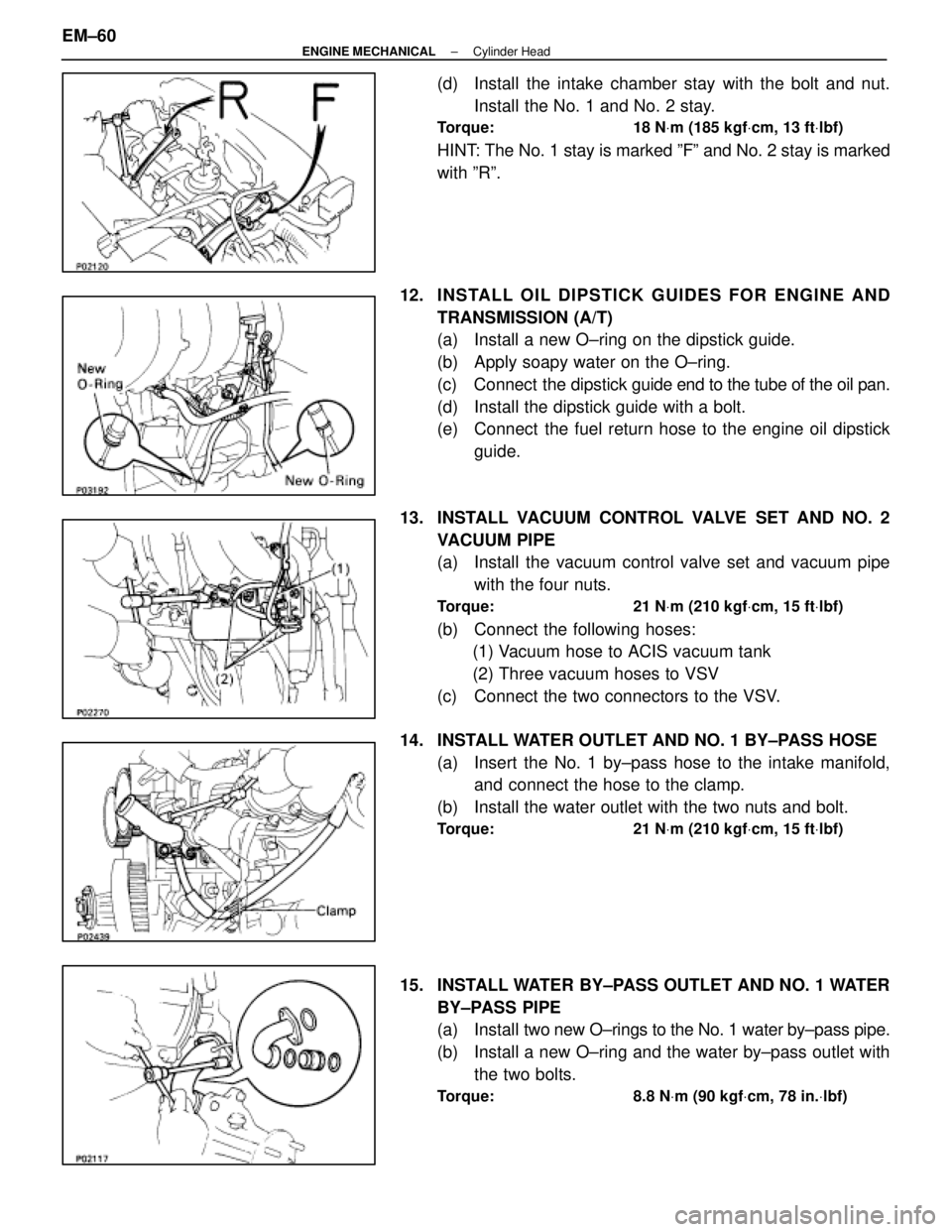

(d) Install the intake chamber stay with the bolt and nut.Install the No. 1 and No. 2 stay.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: The No. 1 stay is marked ºFº and No. 2 stay is marked

with ºRº.

12. INS TALL OIL DIP S TICK GUIDE S FO R ENG INE AND TRANSMISSION (A/T)

(a) Install a new O±ring on the dipstick guide.

(b) Apply soapy water on the O±ring.

(c) Connect the dipstick guide end to the tube of the oil pan.

(d) Install the dipstick guide with a bolt.

(e) Connect the fuel return hose to the engine oil dipstick guide.

13. INSTALL VACUUM CONTROL VALVE SET AND NO. 2 VACUUM PIPE

(a) Install the vacuum control valve set and vacuum pipewith the four nuts.

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

(b) Connect the following hoses:

(1) Vacuum hose to ACIS vacuum tank

(2) Three vacuum hoses to VSV

(c) Connect the two connectors to the VSV.

14. INSTALL WATER OUTLET AND NO. 1 BY±PASS HOSE (a) Insert the No. 1 by±pass hose to the intake manifold,and connect the hose to the clamp.

(b) Install the water outlet with the two nuts and bolt.

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

15. INSTALL WATER BY±PASS OUTLET AND NO. 1 WATER

BY±PASS PIPE

(a) Install two new O±rings to the No. 1 water by±pass pipe.

(b) Install a new O±ring and the water by±pass outlet with the two bolts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

EM±60±

ENGINE MECHANICAL Cylinder Head

WhereEverybodyKnowsYourName