torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1574 of 4087

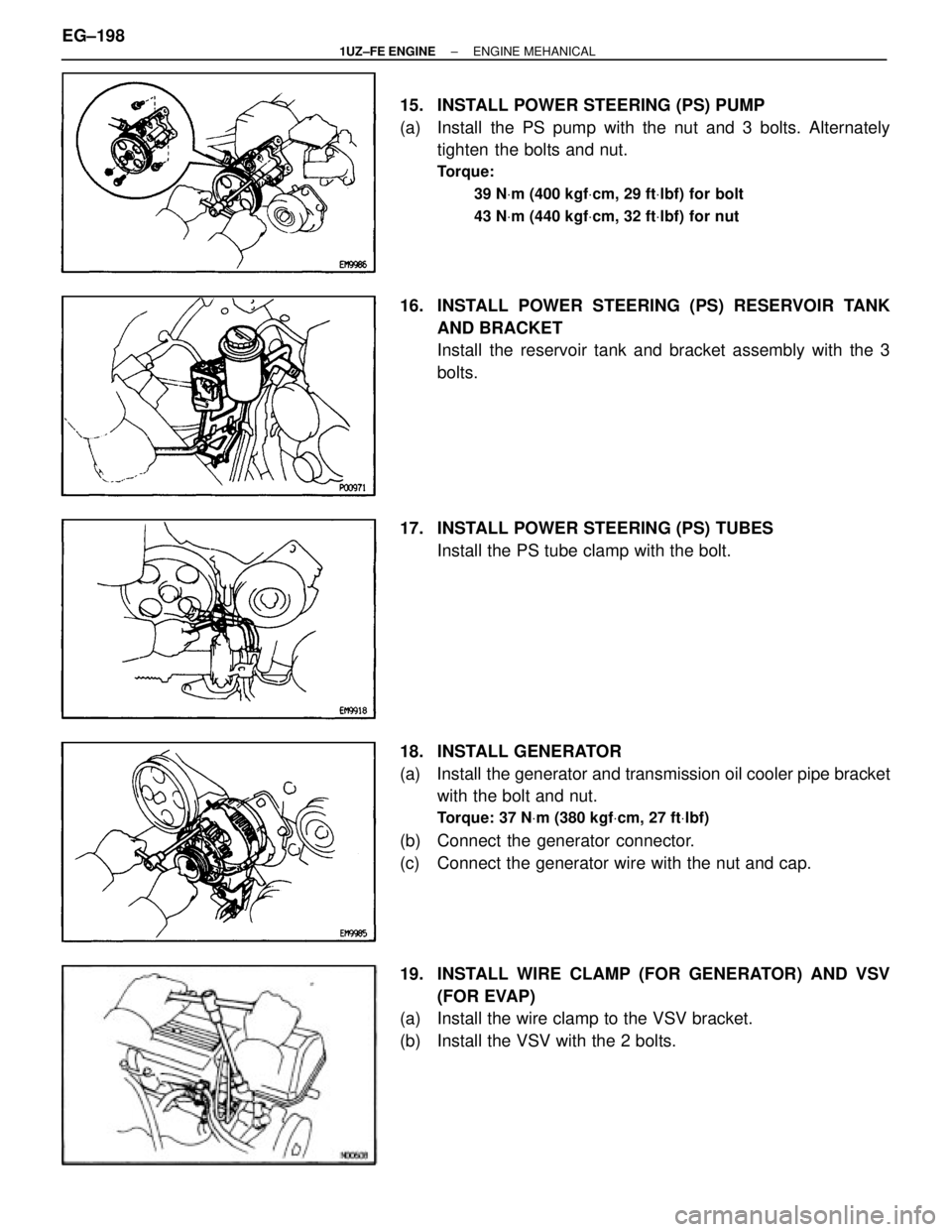

15. INSTALL POWER STEERING (PS) PUMP

(a) Install the PS pump with the nut and 3 bolts. Alternatelytighten the bolts and nut.

Torque:

39 NVm (400 kgf Vcm, 29 ft Vlbf) for bolt

43 N Vm (440 kgf Vcm, 32 ft Vlbf) for nut

16. INSTALL POWER STEERING (PS) RESERVOIR TANK

AND BRACKET

Install the reservoir tank and bracket assembly with the 3

bolts.

17. INSTALL POWER STEERING (PS) TUBES Install the PS tube clamp with the bolt.

18. INSTALL GENERATOR

(a) Install the generator and transmission oil cooler pipe bracket with the bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the generator connector.

(c) Connect the generator wire with the nut and cap.

19. INSTALL WIRE CLAMP (FOR GENERATOR) AND VSV

(FOR EVAP)

(a) Install the wire clamp to the VSV bracket.

(b) Install the VSV with the 2 bolts.

EG±198

±

1UZ±FE ENGINE ENGINE MEHANICAL

WhereEverybodyKnowsYourName

Page 1576 of 4087

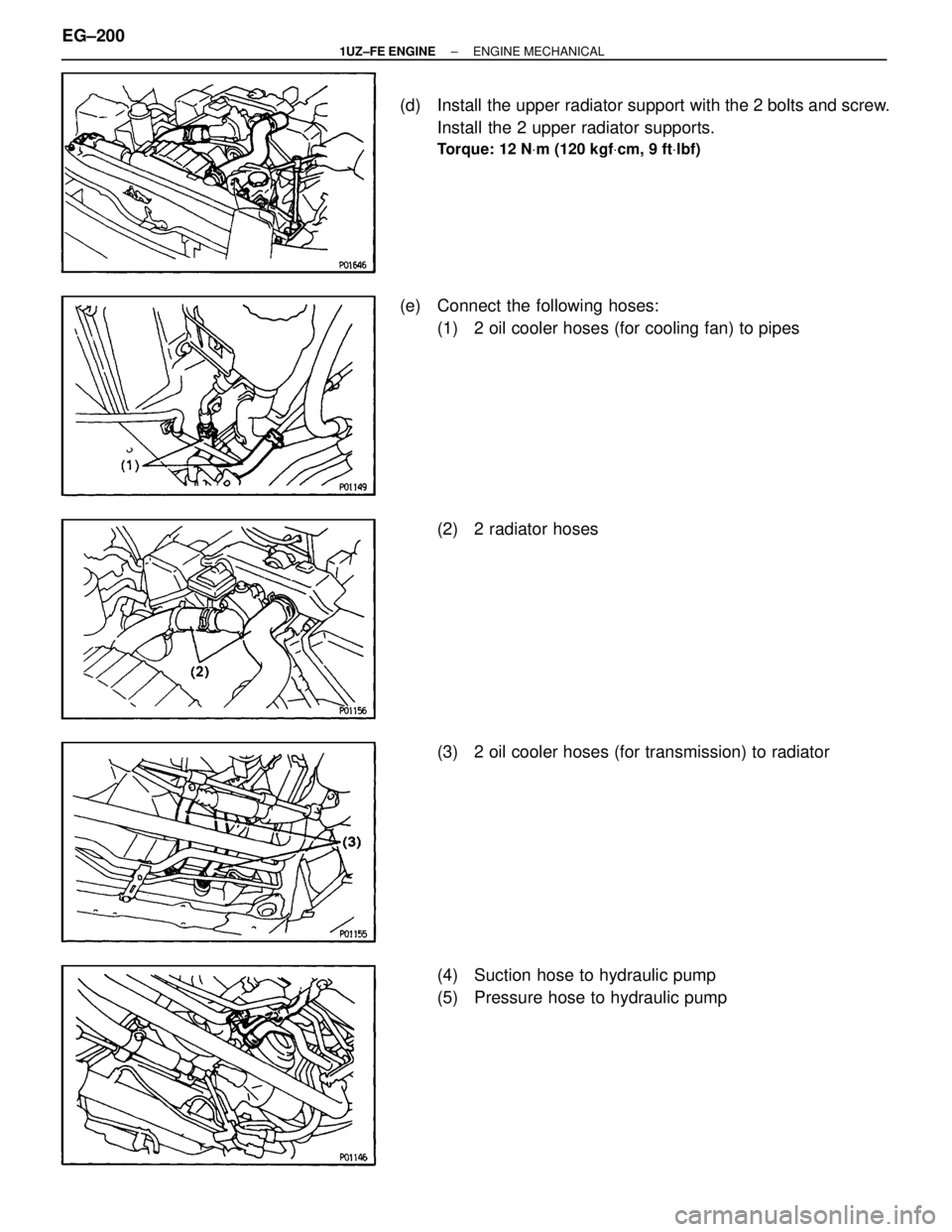

(d) Install the upper radiator support with the 2 bolts and screw.Install the 2 upper radiator supports.

Torque: 12 N Vm (120 kgf Vcm, 9 ft Vlbf)

(e) Connect the following hoses:

(1) 2 oil cooler hoses (for cooling fan) to pipes

(2) 2 radiator hoses

(3) 2 oil cooler hoses (for transmission) to radiator

(4) Suction hose to hydraulic pump

(5) Pressure hose to hydraulic pump

EG±200

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1577 of 4087

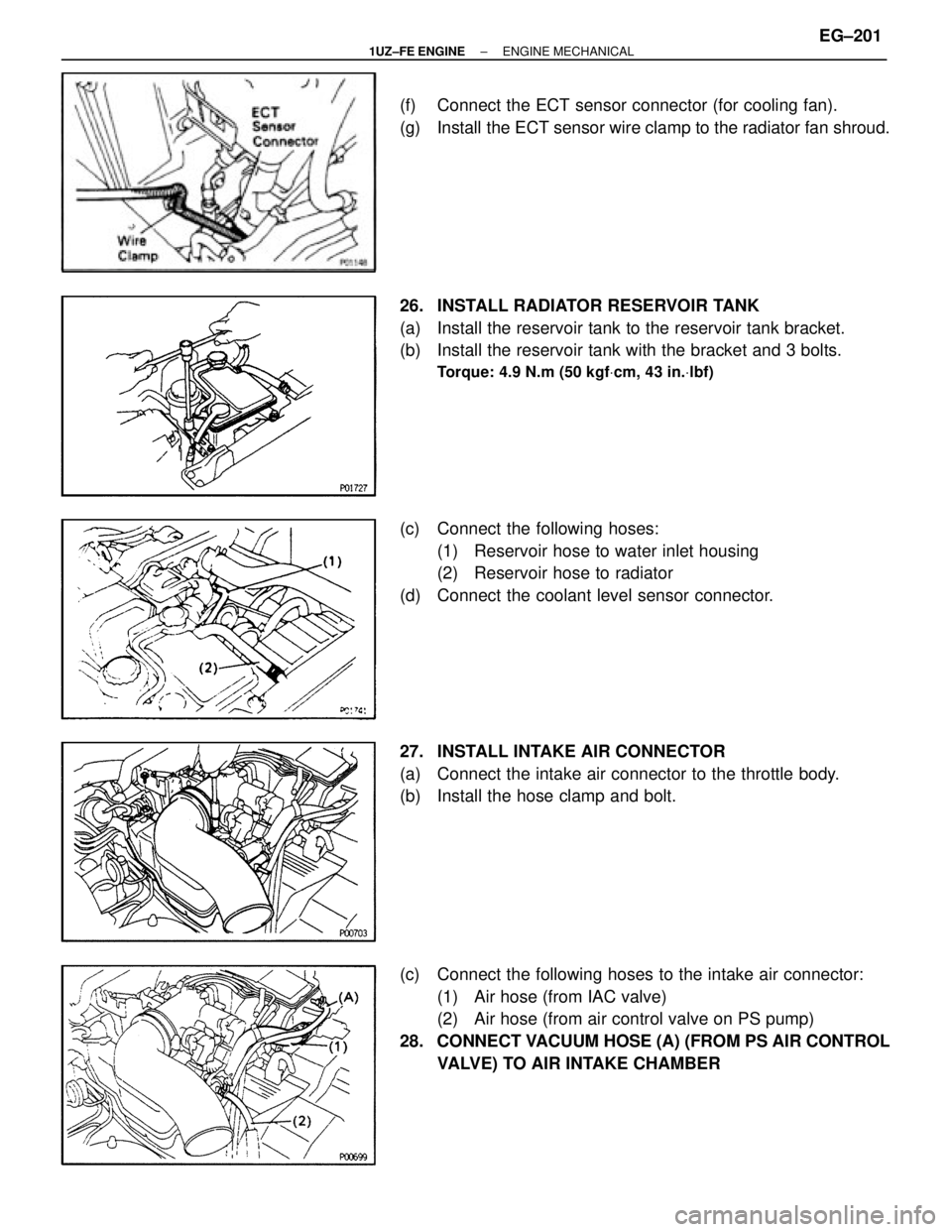

(f) Connect the ECT sensor connector (for cooling fan).

(g) Install the ECT sensor wire clamp to the radiator fan shroud.

26. INSTALL RADIATOR RESERVOIR TANK

(a) Install the reservoir tank to the reservoir tank bracket.

(b) Install the reservoir tank with the bracket and 3 bolts.

Torque: 4.9 N.m (50 kgfVcm, 43 in. Vlbf)

(c) Connect the following hoses:

(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

27. INSTALL INTAKE AIR CONNECTOR

(a) Connect the intake air connector to the throttle body.

(b) Install the hose clamp and bolt.

(c) Connect the following hoses to the intake air connector: (1) Air hose (from IAC valve)

(2) Air hose (from air control valve on PS pump)

28. CONNECT VACUUM HOSE (A) (FROM PS AIR CONTROL VALVE) TO AIR INTAKE CHAMBER

±

1UZ±FE ENGINE ENGINE MECHANICALEG±201

WhereEverybodyKnowsYourName

Page 1601 of 4087

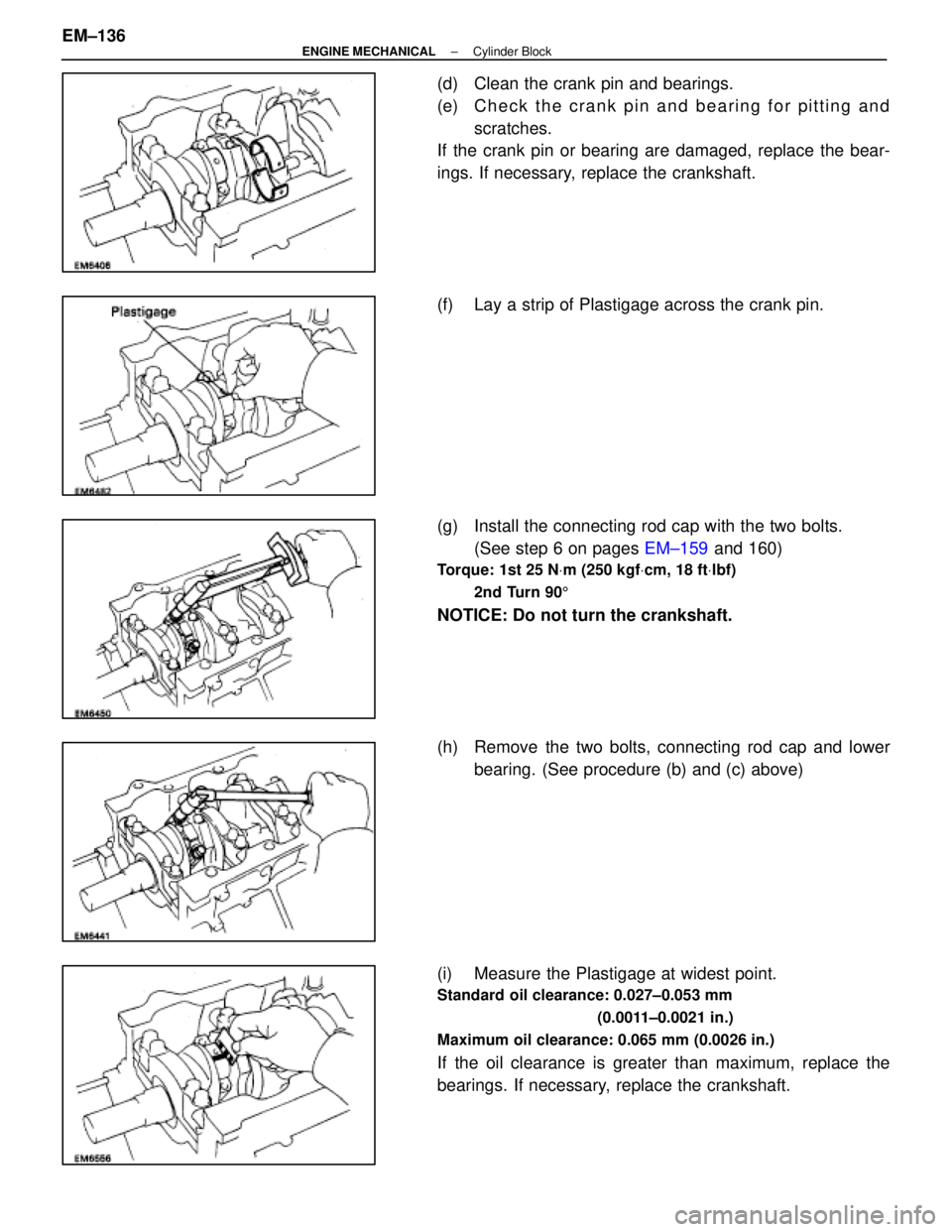

(d) Clean the crank pin and bearings.

(e) C h e c k t h e c r a n k p i n a n d b e a r i n g f o r p i t t i n g a n dscratches.

If the crank pin or bearing are damaged, replace the bear-

ings. If necessary, replace the crankshaft.

(f) Lay a strip of Plastigage across the crank pin.

(g) Install the connecting rod cap with the two bolts.

(See step 6 on pages EM±159 and 160)

Torque: 1st 25 N Vm (250 kgf Vcm, 18 ft Vlbf)

2nd Turn 90 5

NOTICE: Do not turn the crankshaft.

(h) Remove the two bolts, connecting rod cap and lower

bearing. (See procedure (b) and (c) above)

(i) Measure the Plastigage at widest point.

Standard oil clearance: 0.027±0.053 mm (0.0011±0.0021 in.)

Maximum oil clearance: 0.065 mm (0.0026 in.)

If the oil clearance is greater than maximum, replace the

bearings. If necessary, replace the crankshaft.

EM±136

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1604 of 4087

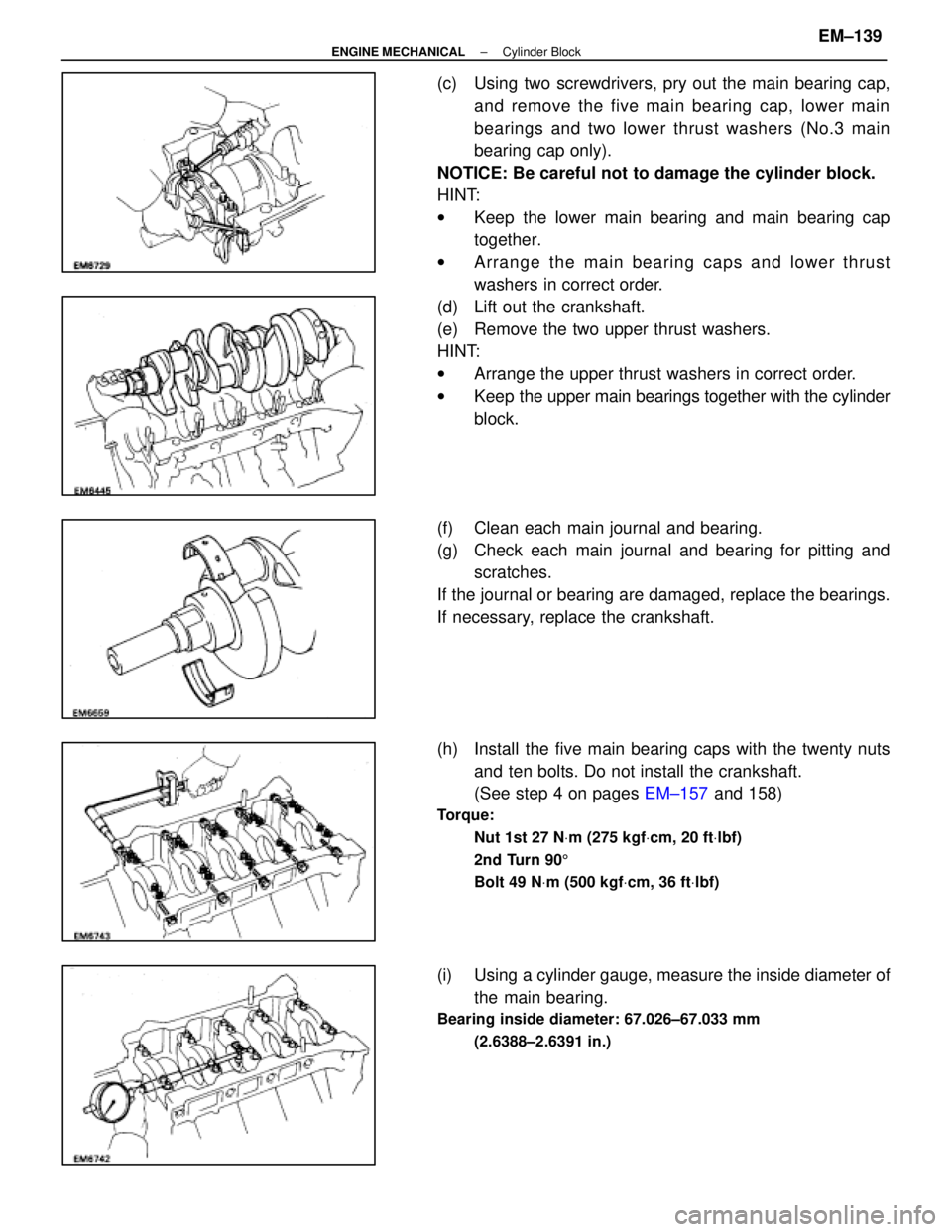

(c) Using two screwdrivers, pry out the main bearing cap,and remove the five main bearing cap, lower main

bearings and two lower thrust washers (No.3 main

bearing cap only).

NOTICE: Be careful not to damage the cylinder block.

HINT:

w Keep the lower main bearing and main bearing cap

together.

w Arrange the main bearing caps and lower thrust

washers in correct order.

(d) Lift out the crankshaft.

(e) Remove the two upper thrust washers.

HINT:

w Arrange the upper thrust washers in correct order.

w Keep the upper main bearings together with the cylinder

block.

(f) Clean each main journal and bearing.

(g) Check each main journal and bearing for pitting and scratches.

If the journal or bearing are damaged, replace the bearings.

If necessary, replace the crankshaft.

(h) Install the five main bearing caps with the twenty nuts and ten bolts. Do not install the crankshaft.

(See step 4 on pages EM±157 and 158)

Torque:

Nut 1st 27 N Vm (275 kgf Vcm, 20 ft Vlbf)

2nd Turn 90 5

Bolt 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

(i) Using a cylinder gauge, measure the inside diameter of

the main bearing.

Bearing inside diameter: 67.026±67.033 mm

(2.6388±2.6391 in.)

±

ENGINE MECHANICAL Cylinder BlockEM±139

WhereEverybodyKnowsYourName

Page 1609 of 4087

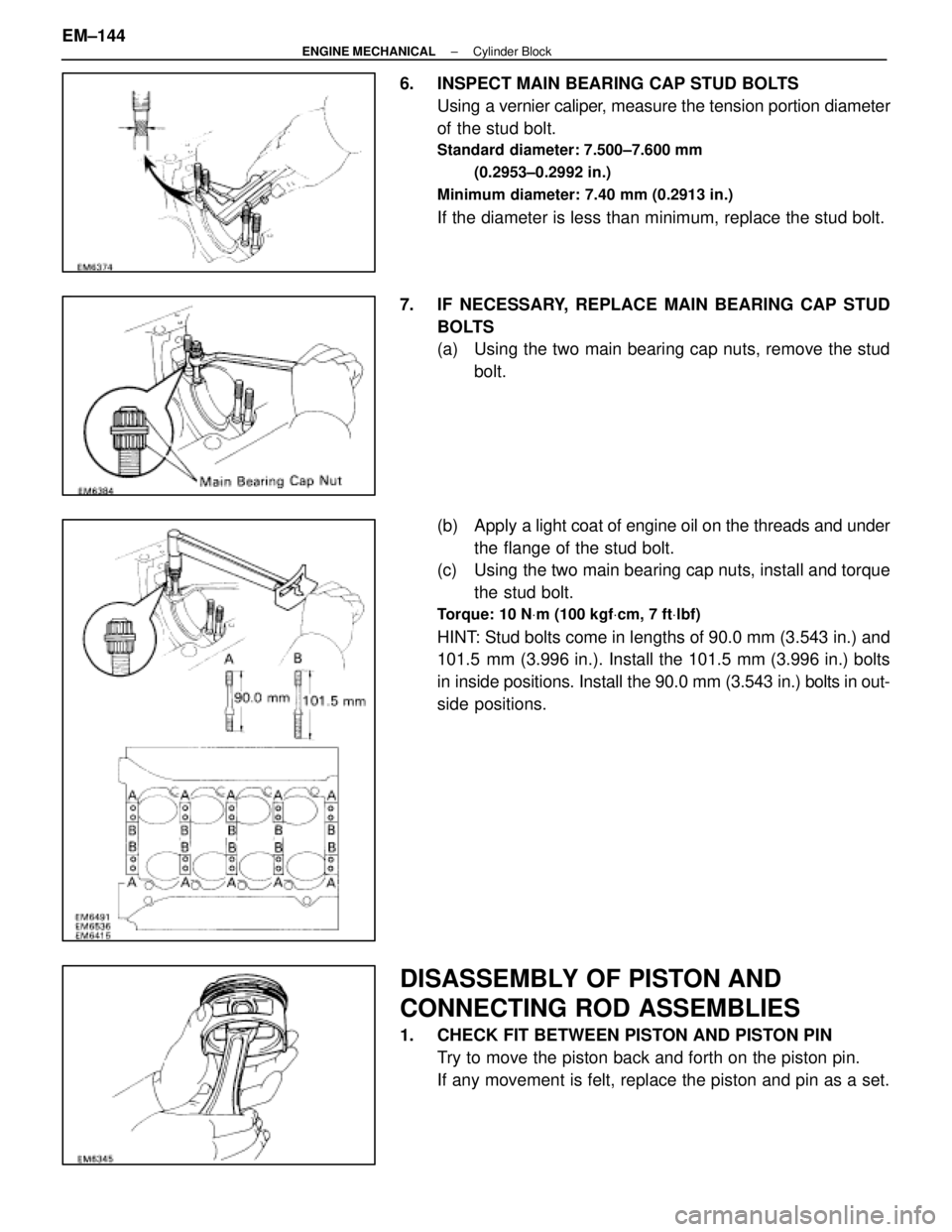

6. INSPECT MAIN BEARING CAP STUD BOLTSUsing a vernier caliper, measure the tension portion diameter

of the stud bolt.

Standard diameter: 7.500±7.600 mm

(0.2953±0.2992 in.)

Minimum diameter: 7.40 mm (0.2913 in.)

If the diameter is less than minimum, replace the stud bolt.

7. IF NECESSARY, REPLACE MAIN BEARING CAP STUD BOLTS

(a) Using the two main bearing cap nuts, remove the studbolt.

(b) Apply a light coat of engine oil on the threads and under

the flange of the stud bolt.

(c) Using the two main bearing cap nuts, install and torque

the stud bolt.

Torque: 10 N Vm (100 kgf Vcm, 7 ft Vlbf)

HINT: Stud bolts come in lengths of 90.0 mm (3.543 in.) and

101.5 mm (3.996 in.). Install the 101.5 mm (3.996 in.) bolts

in inside positions. Install the 90.0 mm (3.543 in.) bolts in out-

side positions.

DISASSEMBLY OF PISTON AND

CONNECTING ROD ASSEMBLIES

1. CHECK FIT BETWEEN PISTON AND PISTON PIN

Try to move the piston back and forth on the piston pin.

If any movement is felt, replace the piston and pin as a set.

EM±144

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1622 of 4087

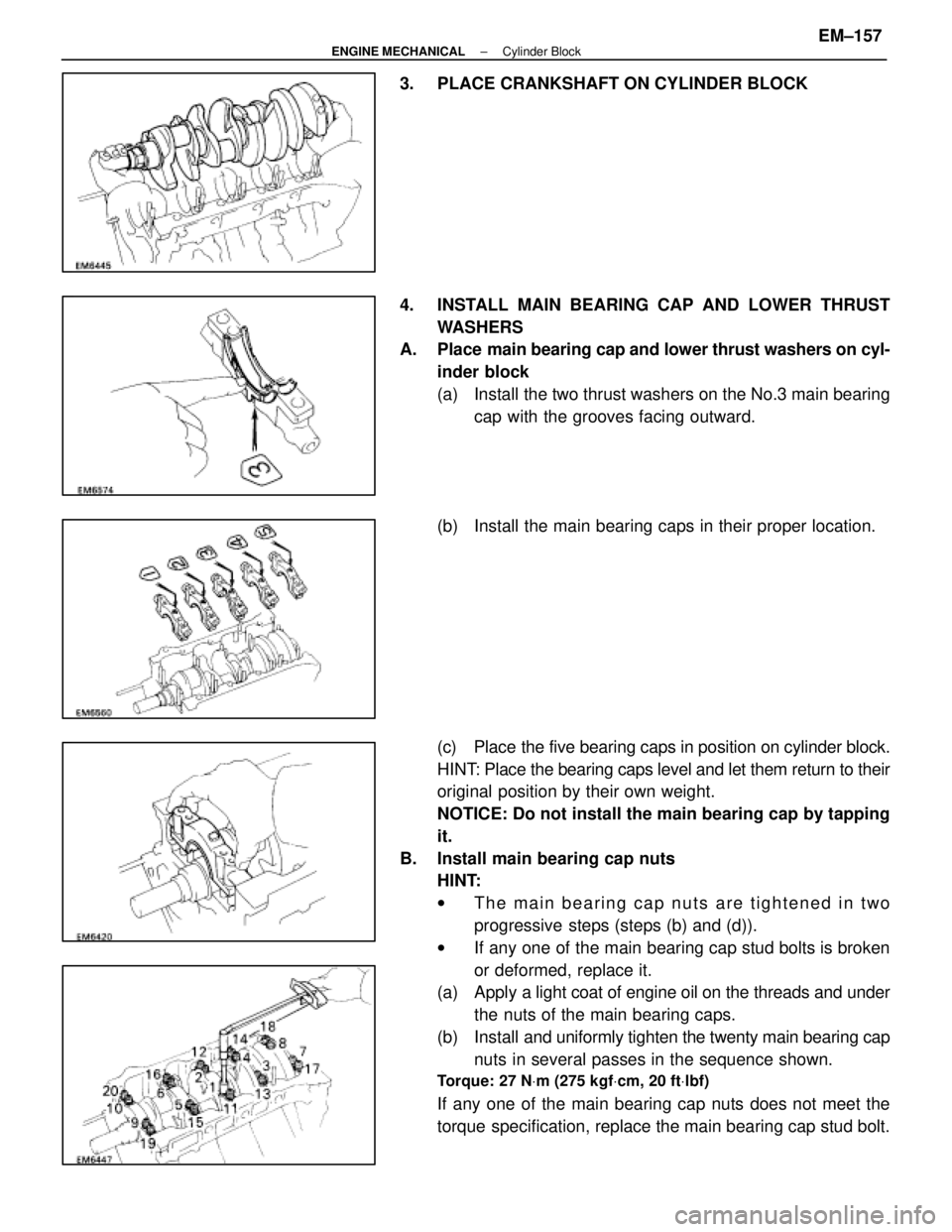

3. PLACE CRANKSHAFT ON CYLINDER BLOCK

4. INSTALL MAIN BEARING CAP AND LOWER THRUSTWASHERS

A. Place main bearing cap and lower thrust washers on cyl-

inder block

(a) Install the two thrust washers on the No.3 main bearing cap with the grooves facing outward.

(b) Install the main bearing caps in their proper location.

(c) Place the five bearing caps in position on cylinder block.

HINT: Place the bearing caps level and let them return to their

original position by their own weight.

NOTICE: Do not install the main bearing cap by tapping

it.

B. Install main bearing cap nuts HINT:

wThe main bearing cap nuts are tightened in two

progressive steps (steps (b) and (d)).

w If any one of the main bearing cap stud bolts is broken

or deformed, replace it.

(a) Apply a light coat of engine oil on the threads and under

the nuts of the main bearing caps.

(b) Install and uniformly tighten the twenty main bearing cap

nuts in several passes in the sequence shown.

Torque: 27 N Vm (275 kgf Vcm, 20 ft Vlbf)

If any one of the main bearing cap nuts does not meet the

torque specification, replace the main bearing cap stud bolt.

±

ENGINE MECHANICAL Cylinder BlockEM±157

WhereEverybodyKnowsYourName

Page 1623 of 4087

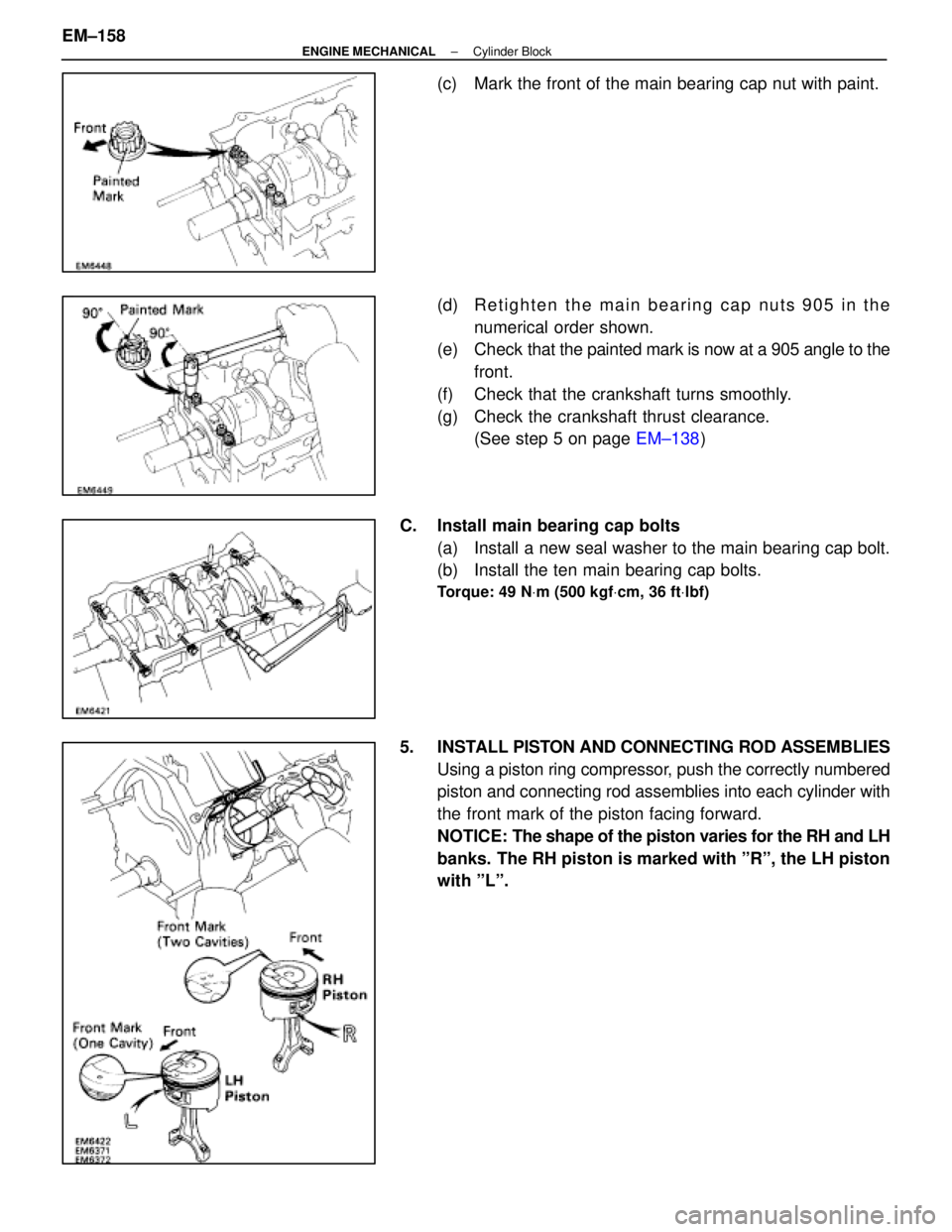

(c) Mark the front of the main bearing cap nut with paint.

(d) R e t i g h t e n t h e m a i n b e a r i n g c a p n u t s 9 0 5 i n t h enumerical order shown.

(e) Check that the painted mark is now at a 905 angle to the

front.

(f) Check that the crankshaft turns smoothly.

(g) Check the crankshaft thrust clearance. (See step 5 on page EM±138)

C. Install main bearing cap bolts (a) Install a new seal washer to the main bearing cap bolt.

(b) Install the ten main bearing cap bolts.

Torque: 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

5. INSTALL PISTON AND CONNECTING ROD ASSEMBLIES

Using a piston ring compressor, push the correctly numbered

piston and connecting rod assemblies into each cylinder with

the front mark of the piston facing forward.

NOTICE: The shape of the piston varies for the RH and LH

banks. The RH piston is marked with ºRº, the LH piston

with ºLº.

EM±158

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1624 of 4087

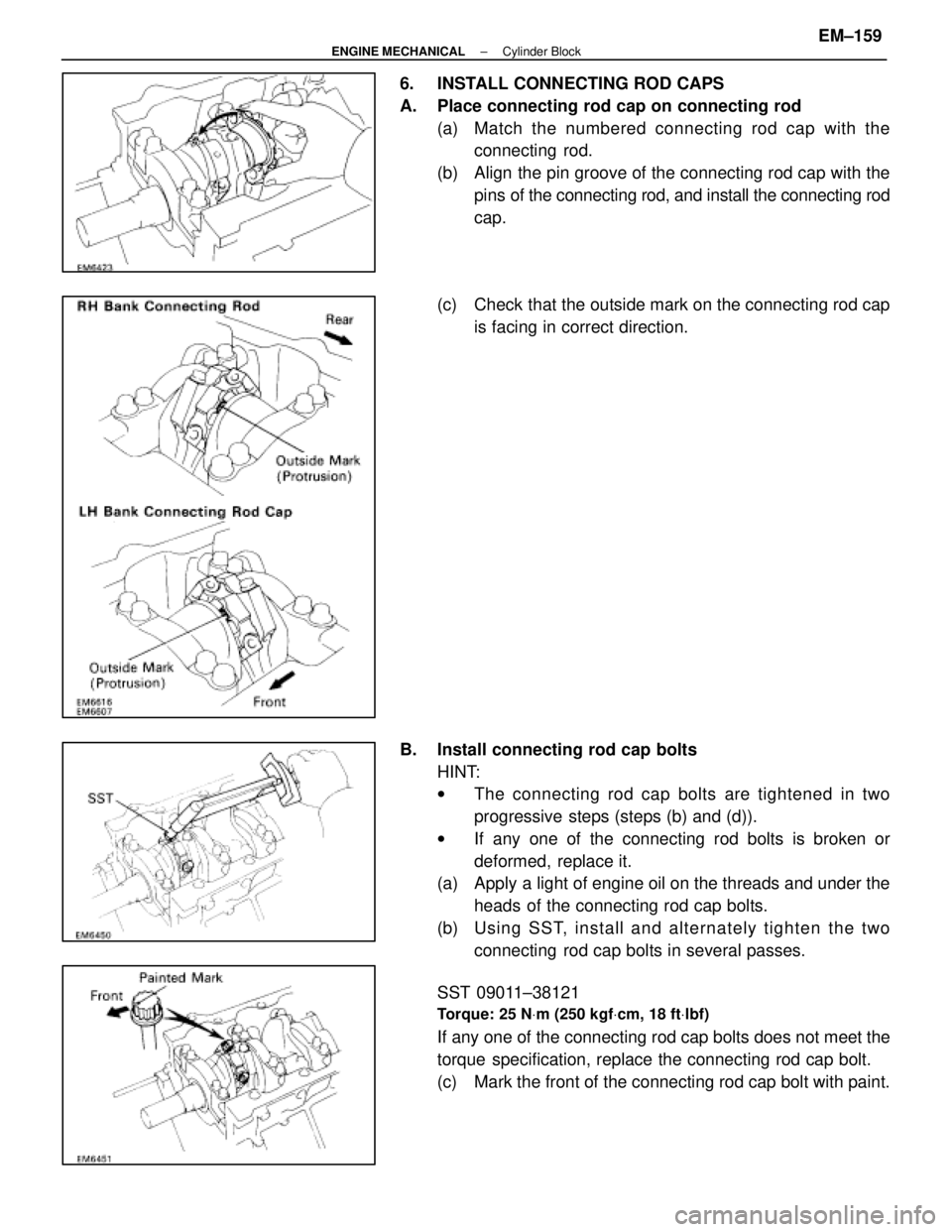

6. INSTALL CONNECTING ROD CAPS

A. Place connecting rod cap on connecting rod(a) Match the numbered c onnecting rod cap with the

connecting rod.

(b) Align the pin groove of the connecting rod cap with the pins of the connecting rod, and install the connecting rod

cap.

(c) Check that the outside mark on the connecting rod cap is facing in correct direction.

B. Install connecting rod cap bolts HINT:

wThe connecting rod cap bolts are tightened in two

progressive steps (steps (b) and (d)).

w If any one of the connecting rod bolts is broken or

deformed, replace it.

(a) Apply a light of engine oil on the threads and under the

heads of the connecting rod cap bolts.

(b) Usin g SS T, in sta ll an d alte rn a te ly tig h te n th e two connecting rod cap bolts in several passes.

SST 09011±38121

Torque: 25 N Vm (250 kgf Vcm, 18 ft Vlbf)

If any one of the connecting rod cap bolts does not meet the

torque specification, replace the connecting rod cap bolt.

(c) Mark the front of the connecting rod cap bolt with paint.

±

ENGINE MECHANICAL Cylinder BlockEM±159

WhereEverybodyKnowsYourName

Page 1625 of 4087

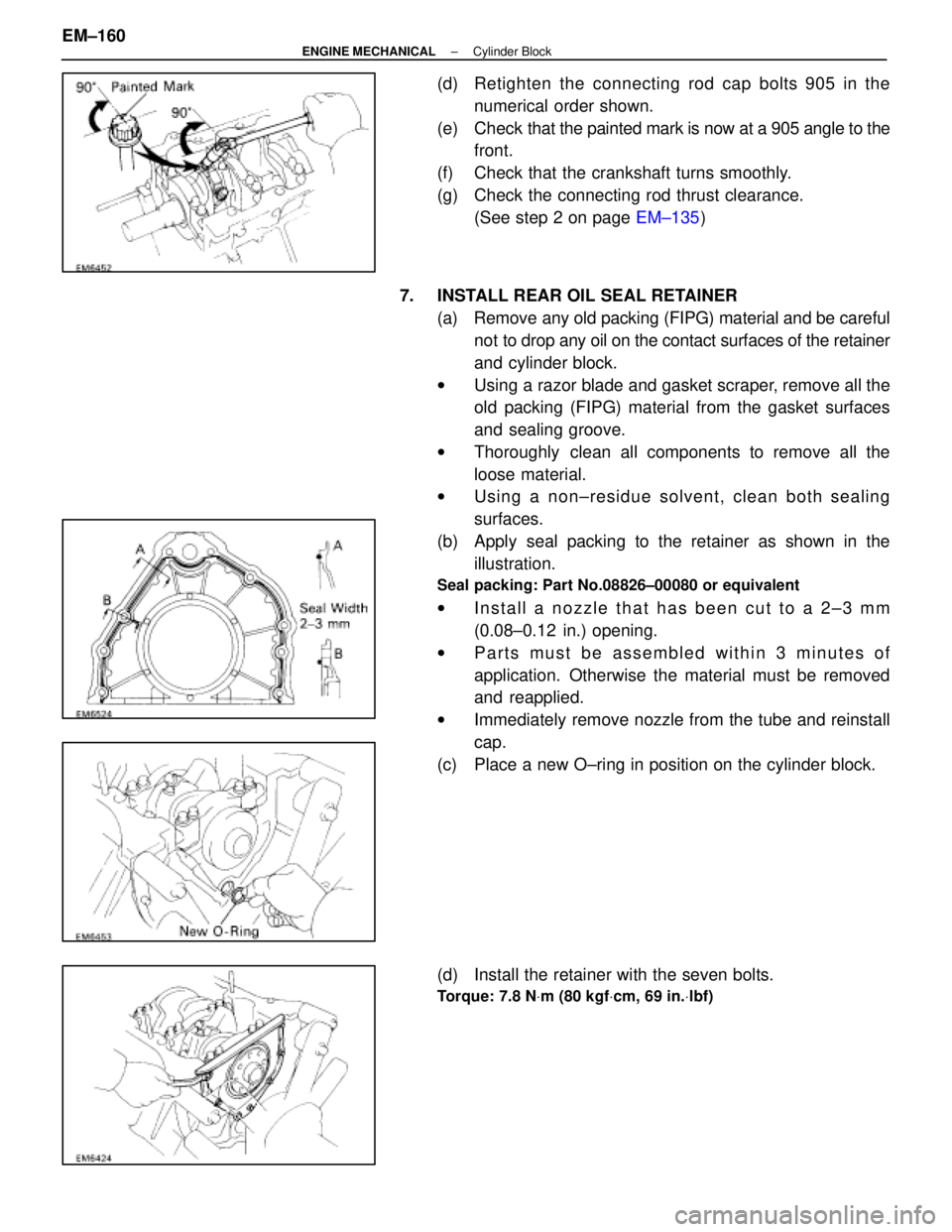

(d) Retighten the connecting rod cap bolts 905 in thenumerical order shown.

(e) Check that the painted mark is now at a 905 angle to the

front.

(f) Check that the crankshaft turns smoothly.

(g) Check the connecting rod thrust clearance. (See step 2 on page EM±135)

7. INSTALL REAR OIL SEAL RETAINER (a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the retainer

and cylinder block.

w Using a razor blade and gasket scraper, remove all the

old packing (FIPG) material from the gasket surfaces

and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the retainer as shown in the illustration.

Seal packing: Part No.08826±00080 or equivalent

wInstall a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

w Parts must be assembled within 3 minutes of

application. Otherwise the material must be removed

and reapplied.

w Immediately remove nozzle from the tube and reinstall

cap.

(c) Place a new O±ring in position on the cylinder block.

(d) Install the retainer with the seven bolts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

EM±160±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName