torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1696 of 4087

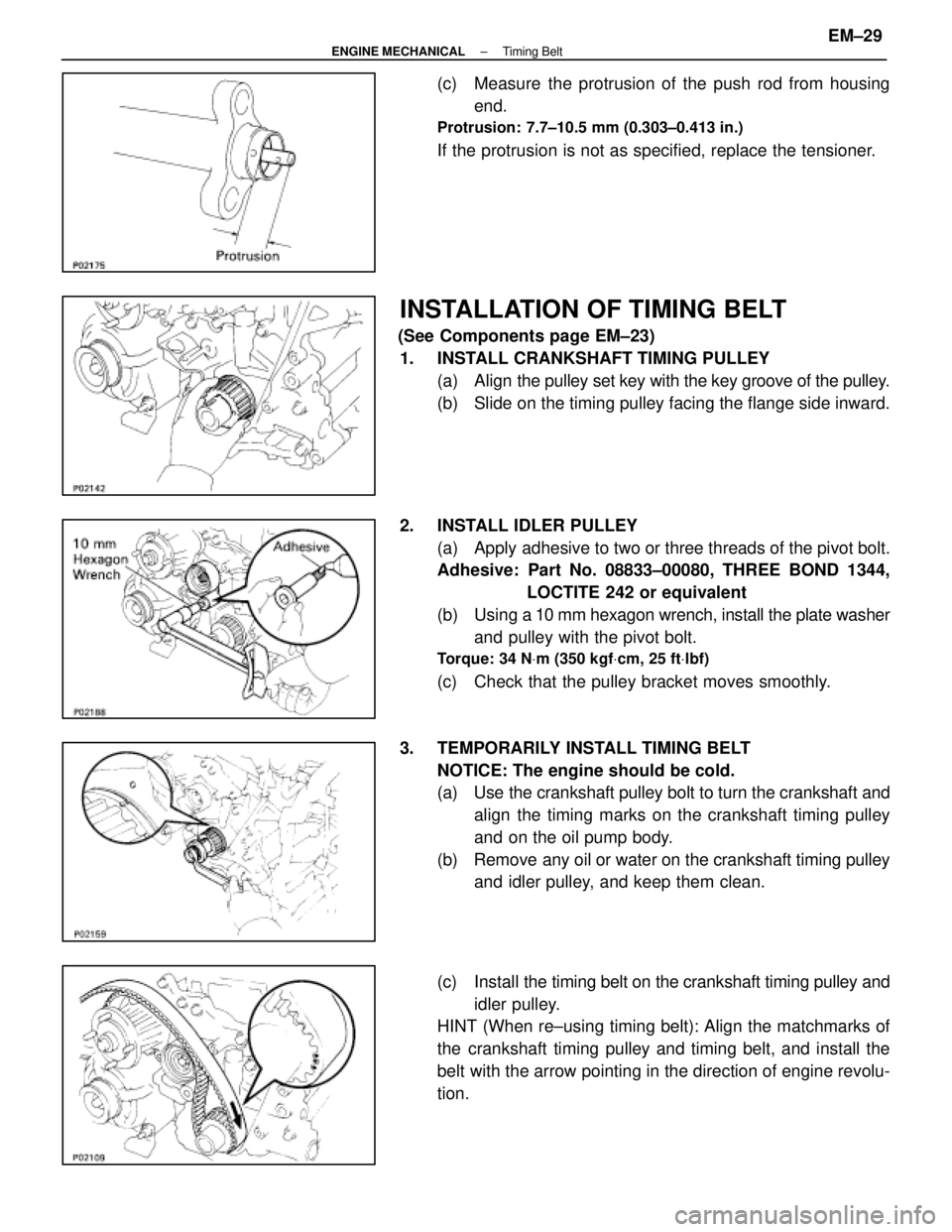

(c) Measure the protrusion of the push rod from housingend.

Protrusion: 7.7±10.5 mm (0.303±0.413 in.)

If the protrusion is not as specified, replace the tensioner.

INSTALLATION OF TIMING BELT

(See Components page EM±23)1. INSTALL CRANKSHAFT TIMING PULLEY (a) Align the pulley set key with the key groove of the pulley.

(b) Slide on the timing pulley facing the flange side inward.

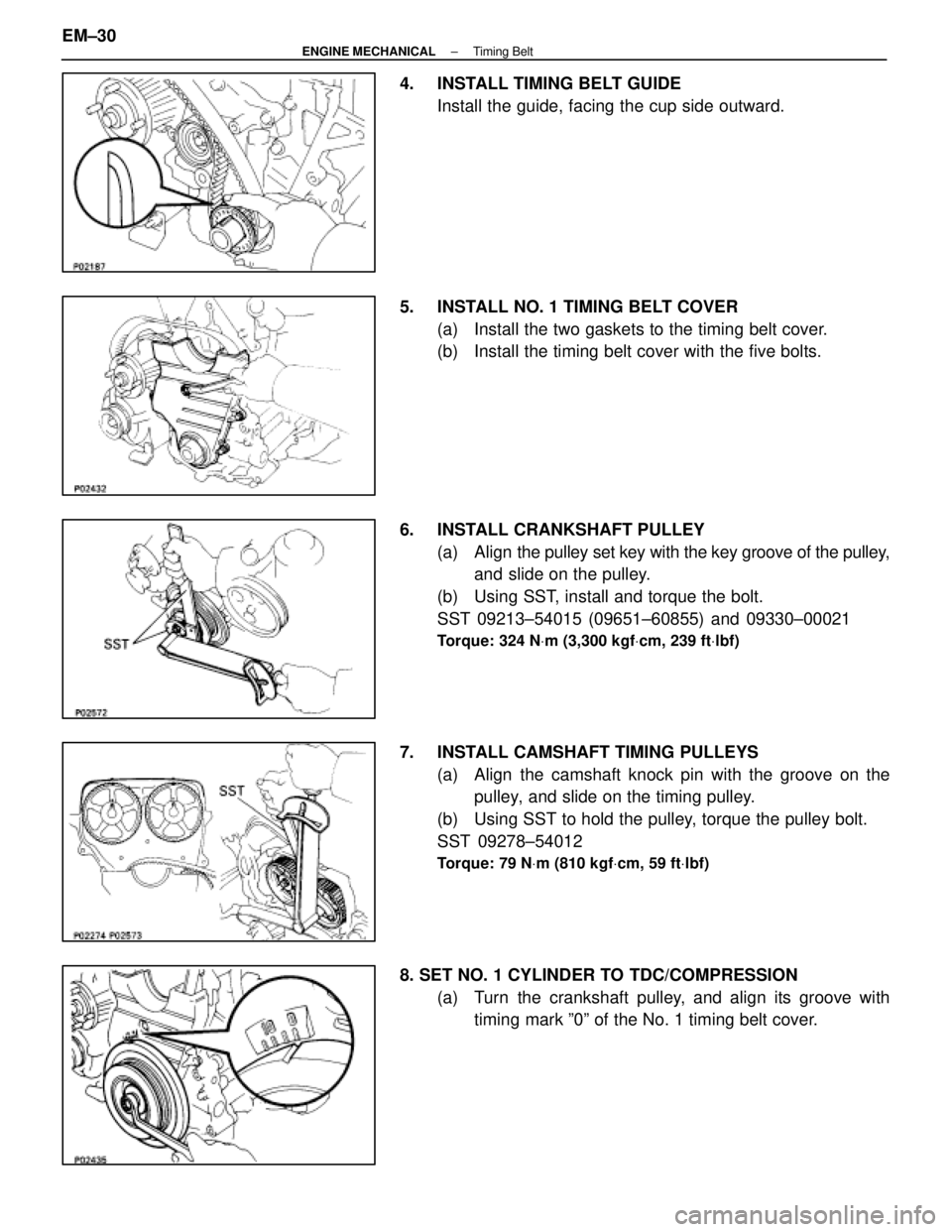

2. INSTALL IDLER PULLEY (a) Apply adhesive to two or three threads of the pivot bolt.

Adhesive: Part No. 08833±00080, THREE BOND 1344, LOCTITE 242 or equivalent

(b) Using a 10 mm hexagon wrench, install the plate washer

and pulley with the pivot bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(c) Check that the pulley bracket moves smoothly.

3. TEMPORARILY INSTALL TIMING BELT NOTICE: The engine should be cold.

(a) Use the crankshaft pulley bolt to turn the crankshaft andalign the timing marks on the crankshaft timing pulley

and on the oil pump body.

(b) Remove any oil or water on the crankshaft timing pulley and idler pulley, and keep them clean.

(c) Install the timing belt on the crankshaft timing pulley and

idler pulley.

HINT (When re±using timing belt): Align the matchmarks of

the crankshaft timing pulley and timing belt, and install the

belt with the arrow pointing in the direction of engine revolu-

tion.

±

ENGINE MECHANICAL Timing BeltEM±29

WhereEverybodyKnowsYourName

Page 1697 of 4087

4. INSTALL TIMING BELT GUIDEInstall the guide, facing the cup side outward.

5. INSTALL NO. 1 TIMING BELT COVER (a) Install the two gaskets to the timing belt cover.

(b) Install the timing belt cover with the five bolts.

6. INSTALL CRANKSHAFT PULLEY (a) Align the pulley set key with the key groove of the pulley,

and slide on the pulley.

(b) Using SST, install and torque the bolt.

SST 09213±54015 (09651±60855) and 09330±00021

Torque: 324 N Vm (3,300 kgf Vcm, 239 ft Vlbf)

7. INSTALL CAMSHAFT TIMING PULLEYS

(a) Align the camshaft knock pin with the groove on thepulley, and slide on the timing pulley.

(b) Using SST to hold the pulley, torque the pulley bolt.

SST 09278±54012

Torque: 79 N Vm (810 kgf Vcm, 59 ft Vlbf)

8. SET NO. 1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley, and align its groove withtiming mark º0º of the No. 1 timing belt cover.

EM±30

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1699 of 4087

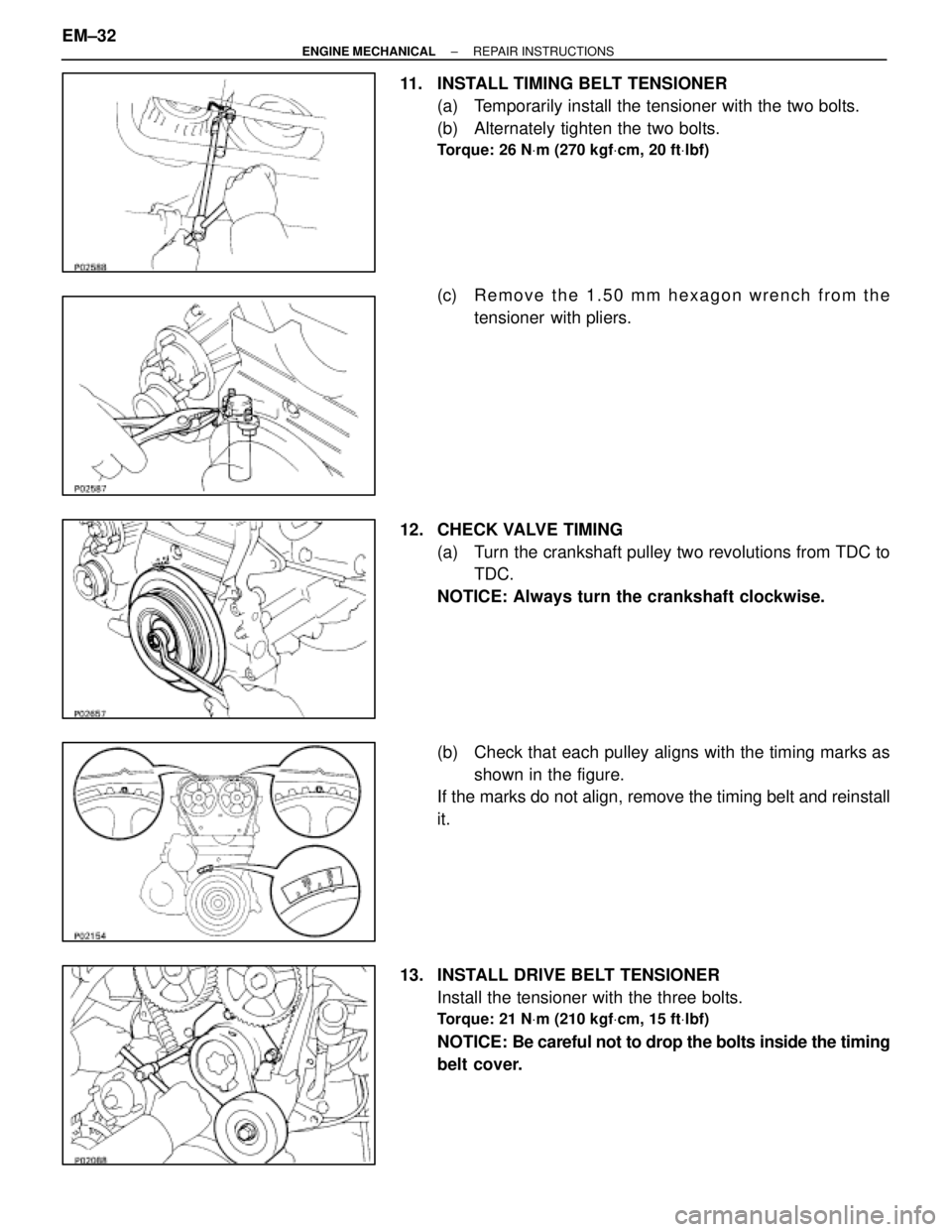

11. INSTALL TIMING BELT TENSIONER(a) Temporarily install the tensioner with the two bolts.

(b) Alternately tighten the two bolts.

Torque: 26 N Vm (270 kgf Vcm, 20 ft Vlbf)

(c) R e m o v e t h e 1 . 5 0 m m h e x agon wrench from the

tensioner with pliers.

12. CHECK VALVE TIMING (a) Turn the crankshaft pulley two revolutions from TDC toTDC.

NOTICE: Always turn the crankshaft clockwise.

(b) Check that each pulley aligns with the timing marks as shown in the figure.

If the marks do not align, remove the timing belt and reinstall

it.

13. INSTALL DRIVE BELT TENSIONER Install the tensioner with the three bolts.

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

NOTICE: Be careful not to drop the bolts inside the timing

belt cover.

EM±32

±

ENGINE MECHANICAL REPAIR INSTRUCTIONS

WhereEverybodyKnowsYourName

Page 1704 of 4087

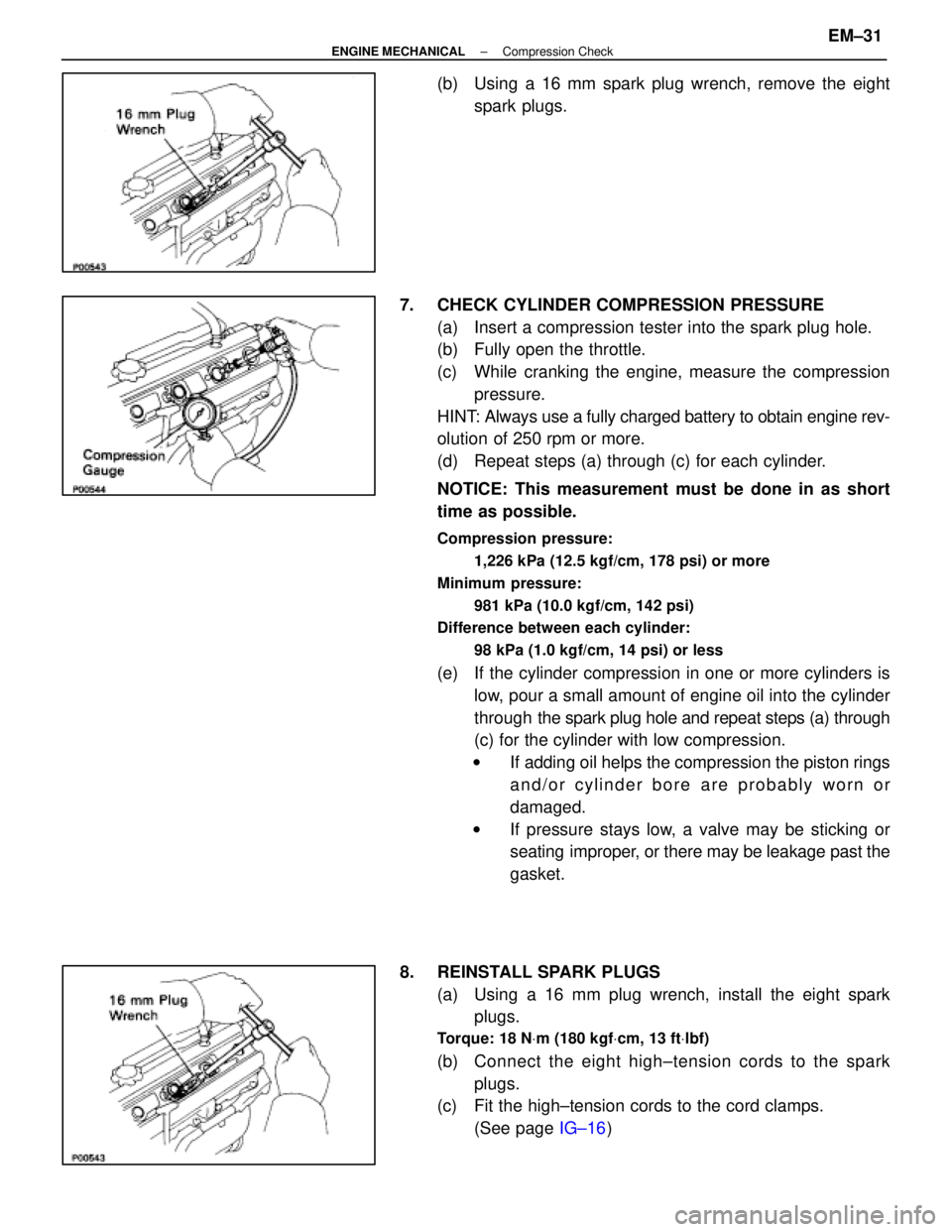

(b) Using a 16 mm spark plug wrench, remove the eightspark plugs.

7. CHECK CYLINDER COMPRESSION PRESSURE (a) Insert a compression tester into the spark plug hole.

(b) Fully open the throttle.

(c) While cranking the engine, measure the compressionpressure.

HINT: Always use a fully charged battery to obtain engine rev-

olution of 250 rpm or more.

(d) Repeat steps (a) through (c) for each cylinder.

NOTICE: This measurement must be done in as short

time as possible.

Compression pressure:

1,226 kPa (12.5 kgf/cm, 178 psi) or more

Minimum pressure: 981 kPa (10.0 kgf/cm, 142 psi)

Difference between each cylinder:

98 kPa (1.0 kgf/cm, 14 psi) or less

(e) If the cylinder compression in one or more cylinders islow, pour a small amount of engine oil into the cylinder

through the spark plug hole and repeat steps (a) through

(c) for the cylinder with low compression.

w If adding oil helps the compression the piston rings

and/or cylinder bore are probably worn or

damaged.

w If pressure stays low, a valve may be sticking or

seating improper, or there may be leakage past the

gasket.

8. REINSTALL SPARK PLUGS (a) Using a 16 mm plug wrench, install the eight sparkplugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

(b) C onnect the eight high±tension cords to the spark

plugs.

(c) Fit the high±tension cords to the cord clamps.

(See page IG±16)

±

ENGINE MECHANICAL Compression CheckEM±31

WhereEverybodyKnowsYourName

Page 1719 of 4087

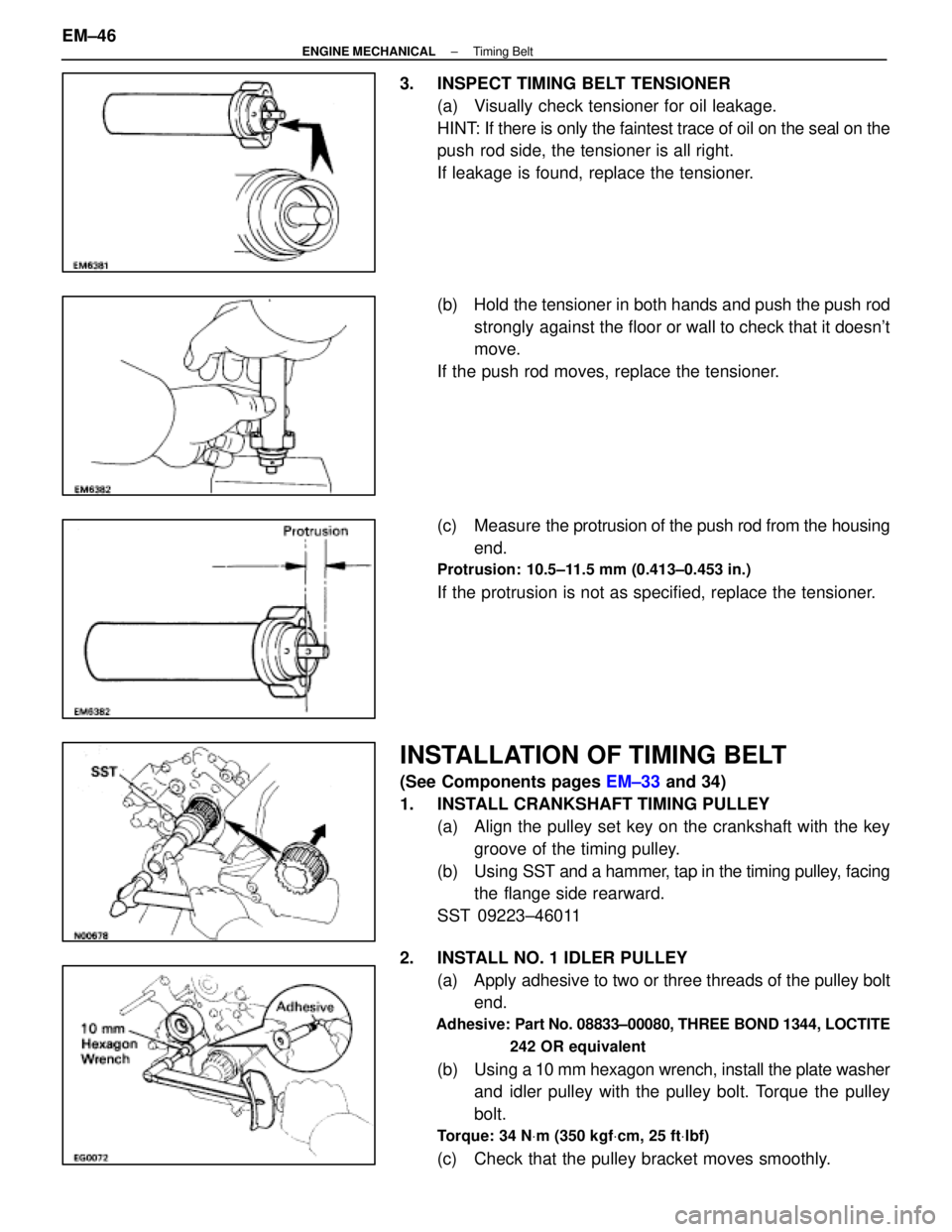

3. INSPECT TIMING BELT TENSIONER(a) Visually check tensioner for oil leakage.

HINT: If there is only the faintest trace of oil on the seal on the

push rod side, the tensioner is all right.

If leakage is found, replace the tensioner.

(b) Hold the tensioner in both hands and push the push rodstrongly against the floor or wall to check that it doesn't

move.

If the push rod moves, replace the tensioner.

(c) Measure the protrusion of the push rod from the housing

end.

Protrusion: 10.5±11.5 mm (0.413±0.453 in.)

If the protrusion is not as specified, replace the tensioner.

INSTALLATION OF TIMING BELT

(See Components pages EM±33 and 34)

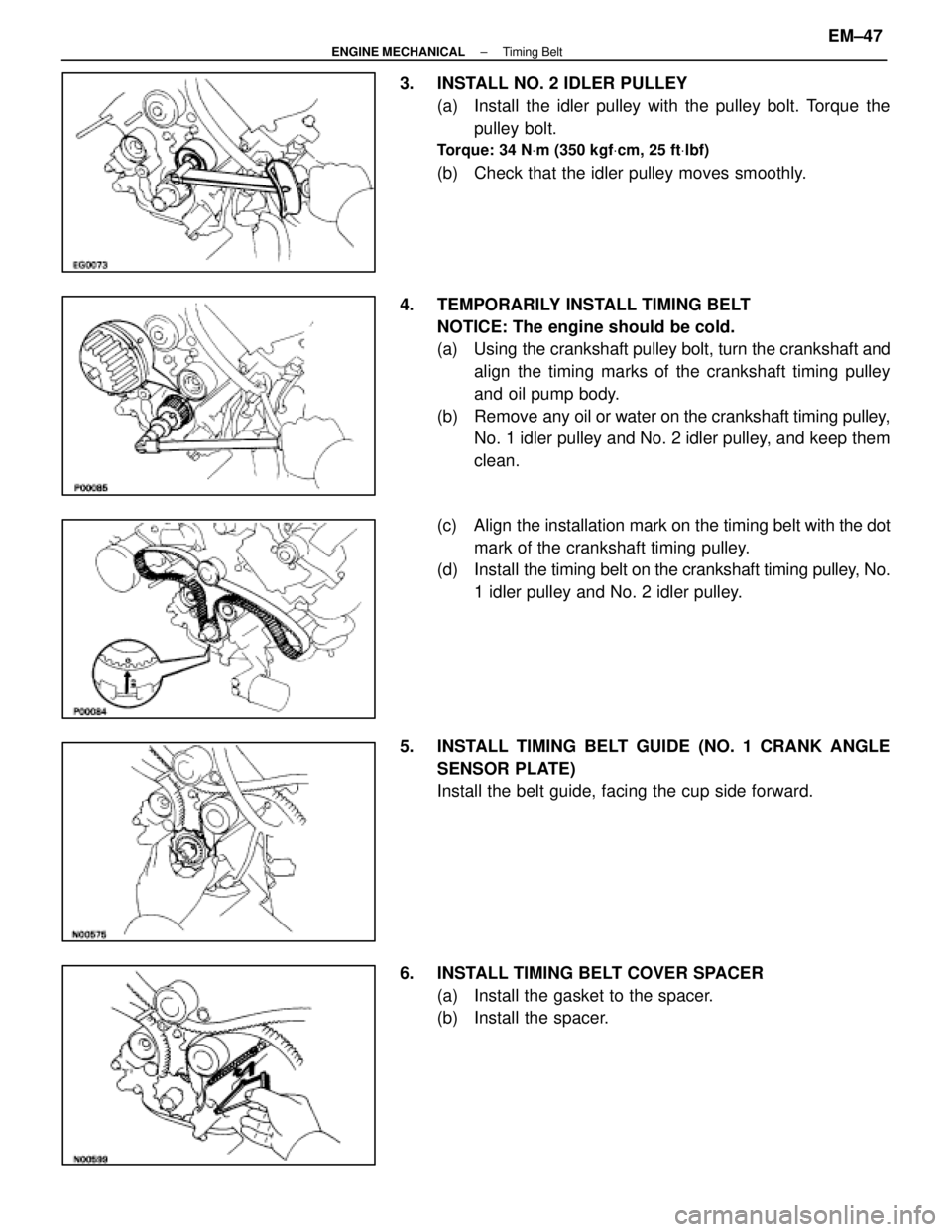

1. INSTALL CRANKSHAFT TIMING PULLEY (a) Align the pulley set key on the crankshaft with the keygroove of the timing pulley.

(b) Using SST and a hammer, tap in the timing pulley, facing

the flange side rearward.

SST 09223±46011

2. INSTALL NO. 1 IDLER PULLEY (a) Apply adhesive to two or three threads of the pulley boltend.

Adhesive: Part No. 08833±00080, THREE BOND 1344, LOCTITE

242 OR equivalent

(b) Using a 10 mm hexagon wrench, install the plate washer

and idler pulley with the pulley bolt. Torque the pulley

bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(c) Check that the pulley bracket moves smoothly.

EM±46

±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1720 of 4087

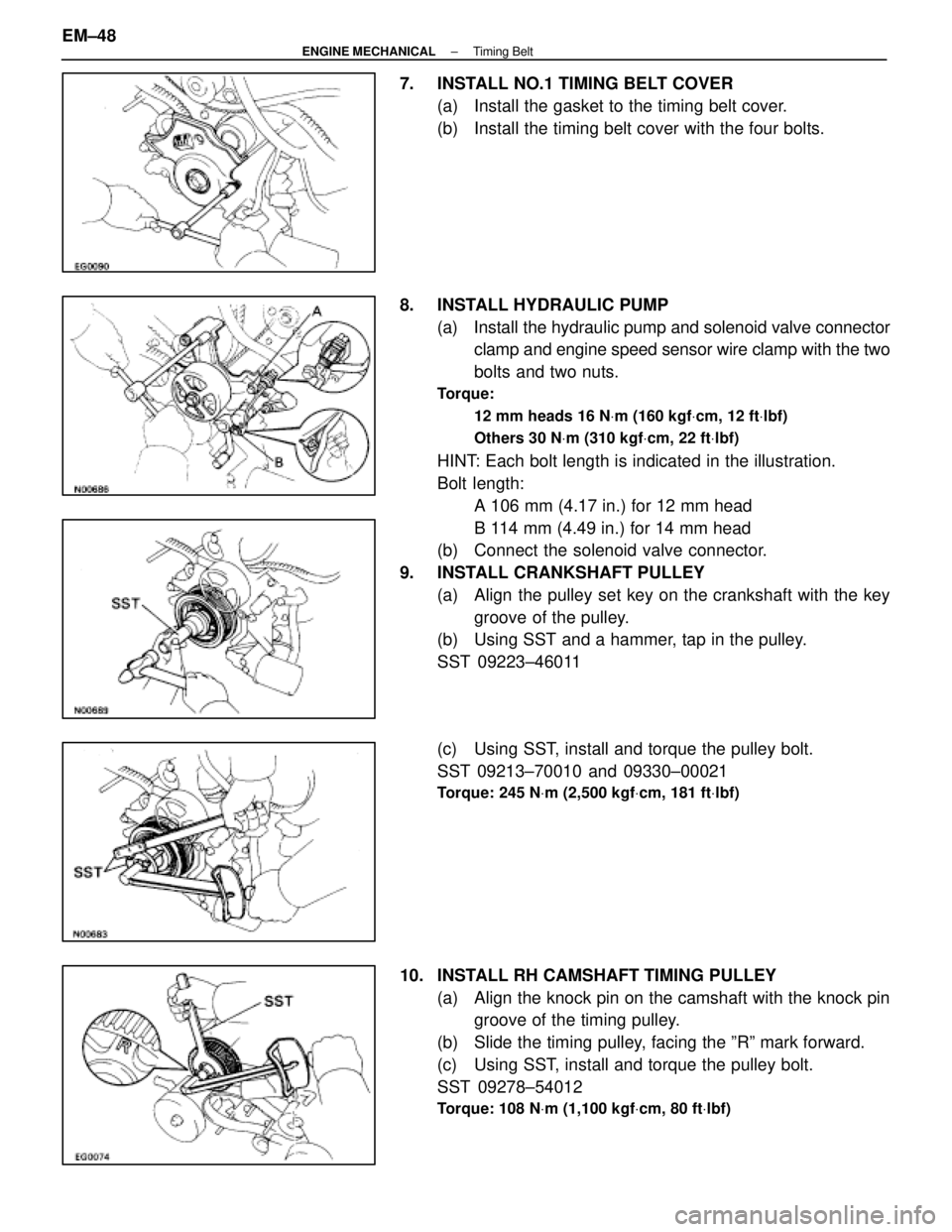

3. INSTALL NO. 2 IDLER PULLEY(a) Install the idler pulley with the pulley bolt. Torque thepulley bolt.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

(b) Check that the idler pulley moves smoothly.

4. TEMPORARILY INSTALL TIMING BELT NOTICE: The engine should be cold.

(a) Using the crankshaft pulley bolt, turn the crankshaft andalign the timing marks of the crankshaft timing pulley

and oil pump body.

(b) Remove any oil or water on the crankshaft timing pulley,

No. 1 idler pulley and No. 2 idler pulley, and keep them

clean.

(c) Align the installation mark on the timing belt with the dot

mark of the crankshaft timing pulley.

(d) Install the timing belt on the crankshaft timing pulley, No.

1 idler pulley and No. 2 idler pulley.

5. INSTALL TIMING BELT GUIDE (NO. 1 CRANK ANGLE SENSOR PLATE)

Install the belt guide, facing the cup side forward.

6. INSTALL TIMING BELT COVER SPACER (a) Install the gasket to the spacer.

(b) Install the spacer.

±

ENGINE MECHANICAL Timing BeltEM±47

WhereEverybodyKnowsYourName

Page 1721 of 4087

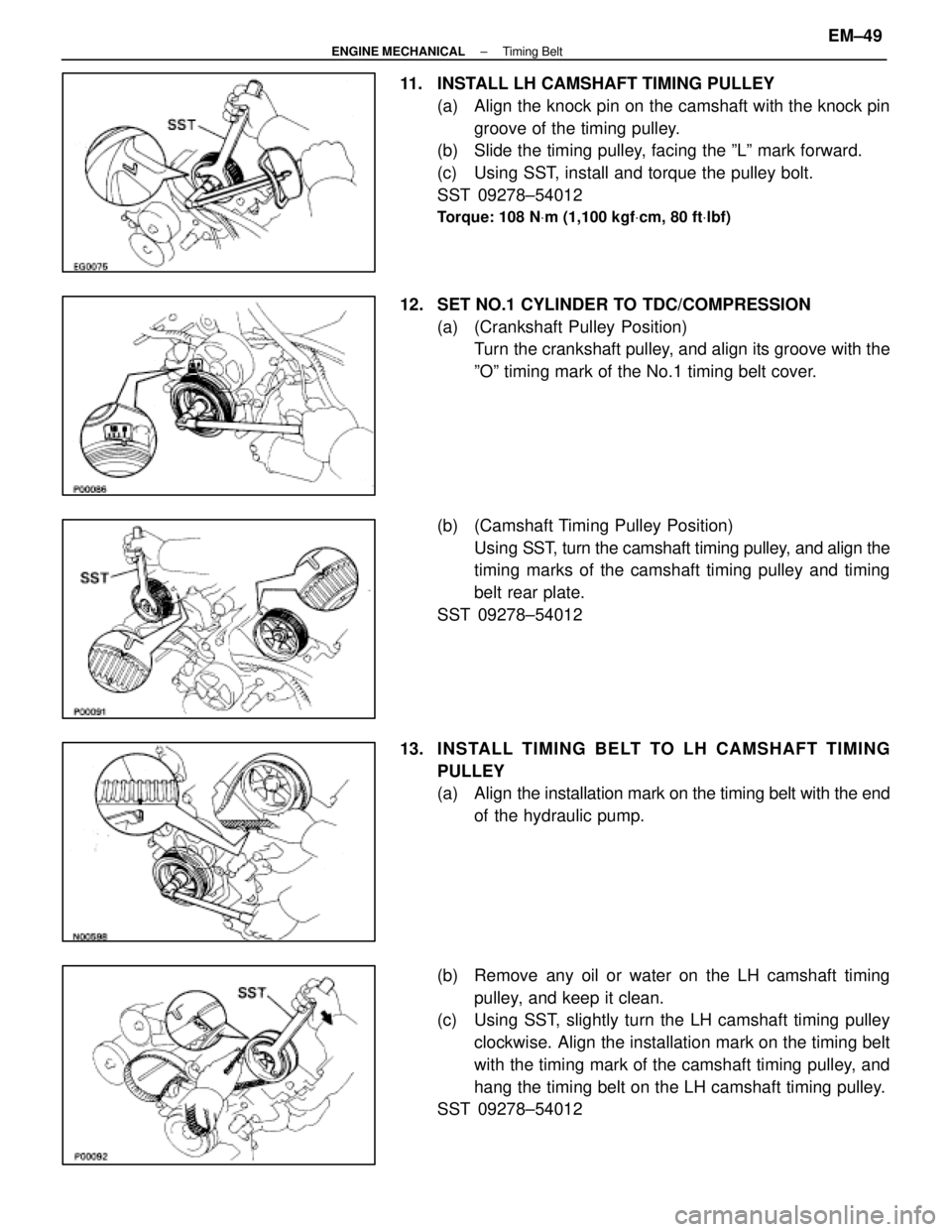

7. INSTALL NO.1 TIMING BELT COVER(a) Install the gasket to the timing belt cover.

(b) Install the timing belt cover with the four bolts.

8. INSTALL HYDRAULIC PUMP (a) Install the hydraulic pump and solenoid valve connectorclamp and engine speed sensor wire clamp with the two

bolts and two nuts.

Torque:

12 mm heads 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

Others 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 106 mm (4.17 in.) for 12 mm head

B 114 mm (4.49 in.) for 14 mm head

(b) Connect the solenoid valve connector.

9. INSTALL CRANKSHAFT PULLEY (a) Align the pulley set key on the crankshaft with the keygroove of the pulley.

(b) Using SST and a hammer, tap in the pulley.

SST 09223±46011

(c) Using SST, install and torque the pulley bolt.

SST 09213±70010 and 09330±00021

Torque: 245 N Vm (2,500 kgf Vcm, 181 ft Vlbf)

10. INSTALL RH CAMSHAFT TIMING PULLEY

(a) Align the knock pin on the camshaft with the knock pingroove of the timing pulley.

(b) Slide the timing pulley, facing the ºRº mark forward.

(c) Using SST, install and torque the pulley bolt.

SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

EM±48±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName

Page 1722 of 4087

11. INSTALL LH CAMSHAFT TIMING PULLEY(a) Align the knock pin on the camshaft with the knock pingroove of the timing pulley.

(b) Slide the timing pulley, facing the ºLº mark forward.

(c) Using SST, install and torque the pulley bolt.

SST 09278±54012

Torque: 108 N Vm (1,100 kgf Vcm, 80 ft Vlbf)

12. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) (Crankshaft Pulley Position)Turn the crankshaft pulley, and align its groove with the

ºOº timing mark of the No.1 timing belt cover.

(b) (Camshaft Timing Pulley Position) Using SST, t urn the camshaft timing pulley, and align the

timing marks of the camshaft timing pulley and timing

belt rear plate.

SST 09278±54012

13. INS TALL TIMING BE LT TO LH CAMS HAFT TIMING PULLEY

(a) Align the installation mark on the timing belt with the end

of the hydraulic pump.

(b) Remove any oil or water on the LH camshaft timing pulley, and keep it clean.

(c) Using SST, slightly turn the LH camshaft timing pulley

clockwise. Align the installation mark on the timing belt

with the timing mark of the camshaft timing pulley, and

hang the timing belt on the LH camshaft timing pulley.

SST 09278±54012

±

ENGINE MECHANICAL Timing BeltEM±49

WhereEverybodyKnowsYourName

Page 1724 of 4087

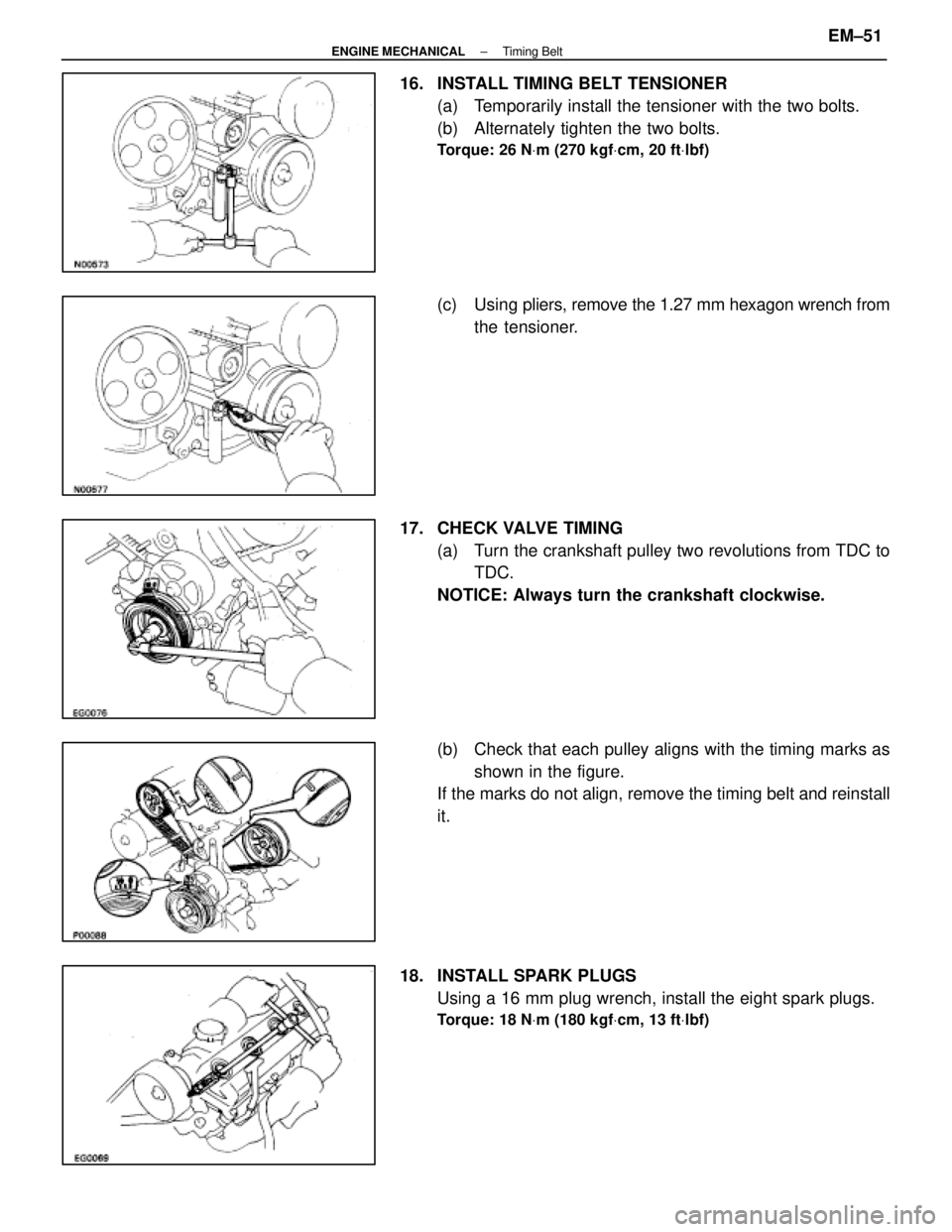

16. INSTALL TIMING BELT TENSIONER(a) Temporarily install the tensioner with the two bolts.

(b) Alternately tighten the two bolts.

Torque: 26 N Vm (270 kgf Vcm, 20 ft Vlbf)

(c) Using pliers, remove the 1.27 mm hexagon wrench from

the tensioner.

17. CHECK VALVE TIMING (a) Turn the crankshaft pulley two revolutions from TDC toTDC.

NOTICE: Always turn the crankshaft clockwise.

(b) Check that each pulley aligns with the timing marks as shown in the figure.

If the marks do not align, remove the timing belt and reinstall

it.

18. INSTALL SPARK PLUGS Using a 16 mm plug wrench, install the eight spark plugs.

Torque: 18 N Vm (180 kgf Vcm, 13 ft Vlbf)

±

ENGINE MECHANICAL Timing BeltEM±51

WhereEverybodyKnowsYourName

Page 1725 of 4087

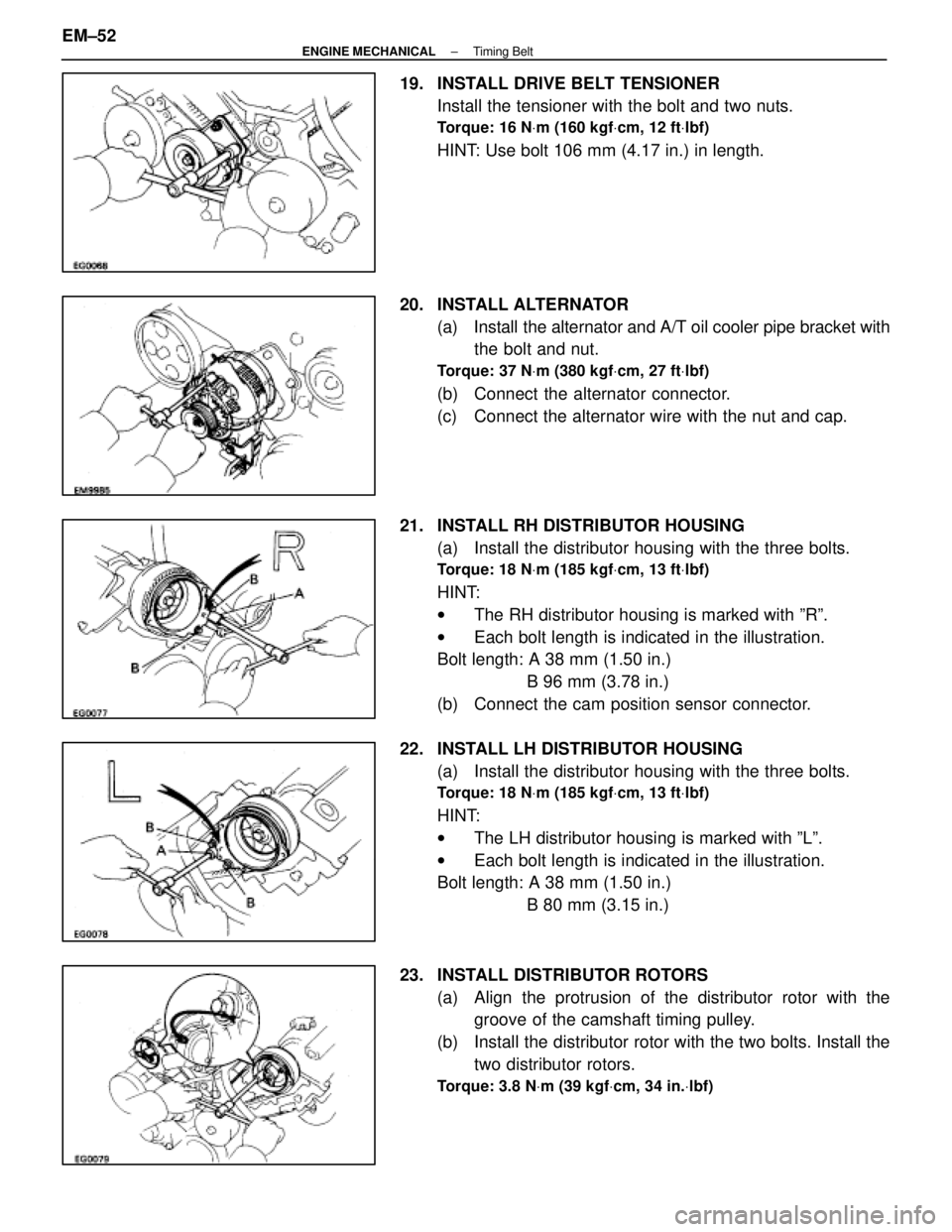

19. INSTALL DRIVE BELT TENSIONERInstall the tensioner with the bolt and two nuts.

Torque: 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

HINT: Use bolt 106 mm (4.17 in.) in length.

20. INSTALL ALTERNATOR (a) Install the alternator and A/T oil cooler pipe bracket withthe bolt and nut.

Torque: 37 N Vm (380 kgf Vcm, 27 ft Vlbf)

(b) Connect the alternator connector.

(c) Connect the alternator wire with the nut and cap.

21. INSTALL RH DISTRIBUTOR HOUSING (a) Install the distributor housing with the three bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT:

w The RH distributor housing is marked with ºRº.

w Each bolt length is indicated in the illustration.

Bolt length: A 38 mm (1.50 in.)

B 96 mm (3.78 in.)

(b) Connect the cam position sensor connector.

22. INSTALL LH DISTRIBUTOR HOUSING (a) Install the distributor housing with the three bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT:

w The LH distributor housing is marked with ºLº.

w Each bolt length is indicated in the illustration.

Bolt length: A 38 mm (1.50 in.)

B 80 mm (3.15 in.)

23. INSTALL DISTRIBUTOR ROTORS (a) Align the protrusion of the distributor rotor with thegroove of the camshaft timing pulley.

(b) Install the distributor rotor with the two bolts. Install the two distributor rotors.

Torque: 3.8 N Vm (39 kgf Vcm, 34 in. Vlbf)

EM±52±

ENGINE MECHANICAL Timing Belt

WhereEverybodyKnowsYourName