LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: start stop button, sunroof, EFI, transmission fluid, Throttle Position sensor, cooling, brake sensor

Page 2921 of 4087

(d) Connect the following hoses:(1) Water by±pass hose to the ISC valve

(2) (USA Spec.) Vacuum hose to throttle body

(3) (Exc. USA Spec.) Three vacuum hoses to throttle body

(4) Heater water hose to heater water valve

(e) Connect the following connectors: (1) Throttle position sensor connector

(2) (w/ TRAC) Sub±throttle position sensor connector

(3) (w/ TRAC) Sub±throttle actuator connector

16. INSTALL LOWER HIGH±TENSION CORD COVER (a) Connect the end portions of the high±tension cord to the

cord clamps

(b) Install the high±tension cord cover with the bolt.

±

STARTING SYSTEM StarterST±31

WhereEverybodyKnowsYourName

Page 2922 of 4087

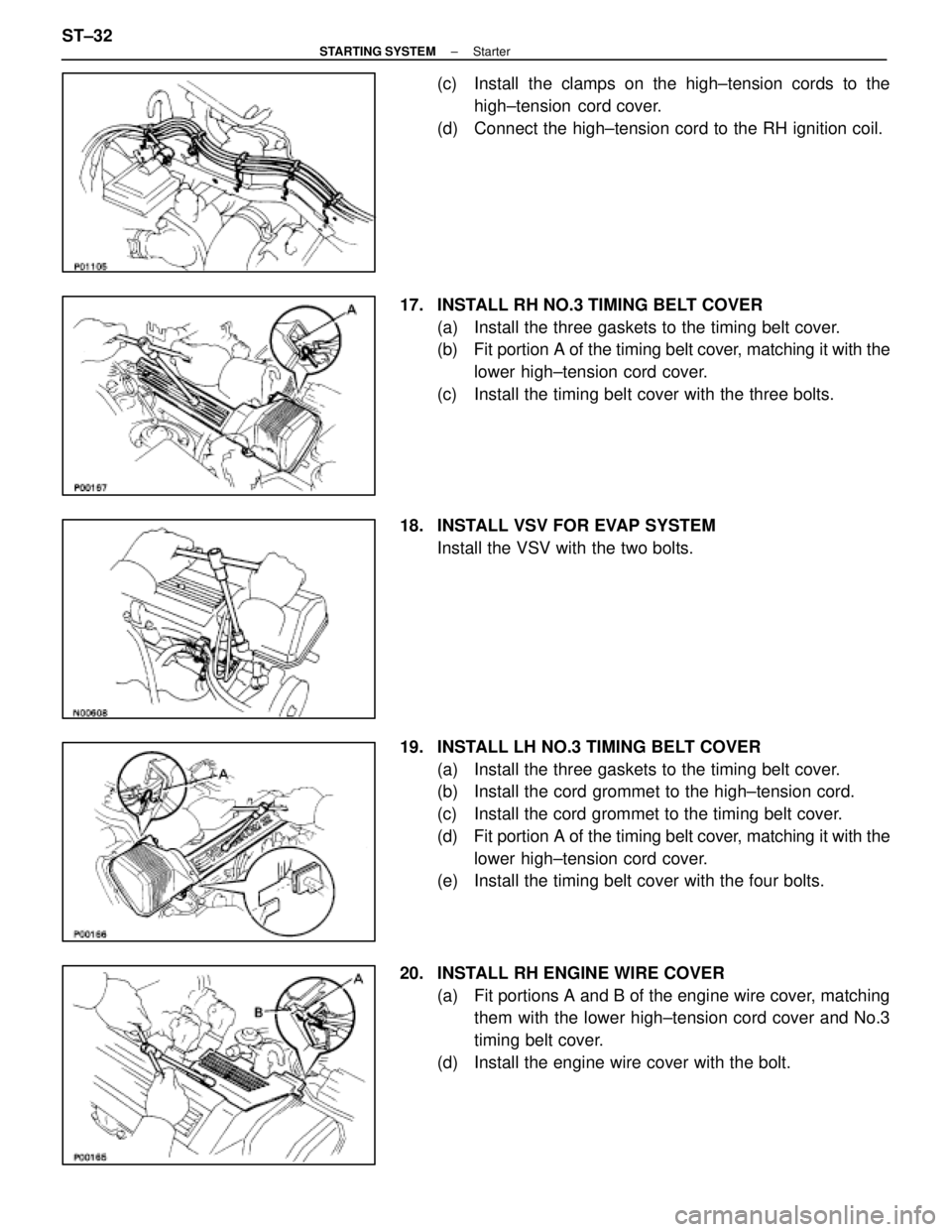

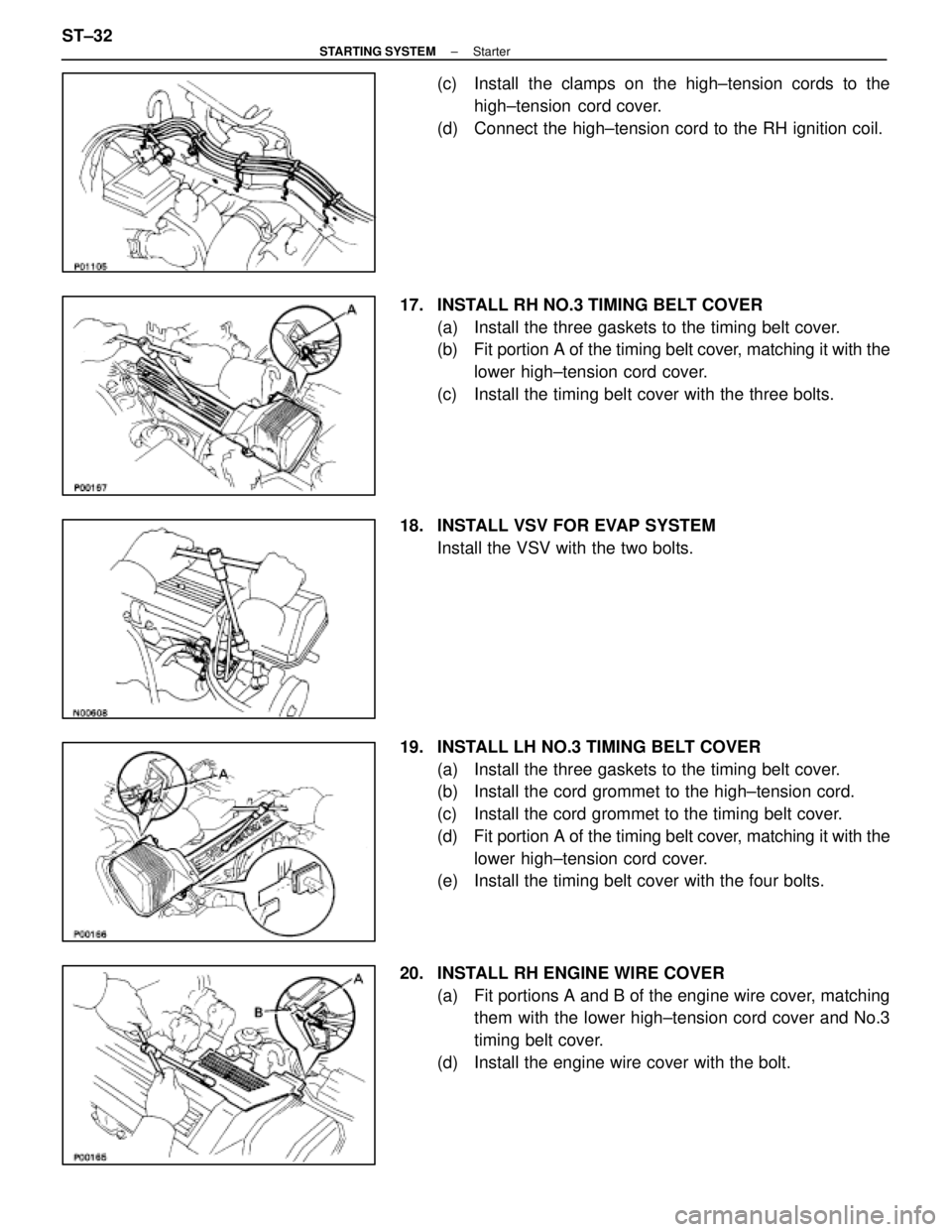

(c) Install the clamps on the high±tension cords to thehigh±tension cord cover.

(d) Connect the high±tension cord to the RH ignition coil.

17. INSTALL RH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(c) Install the timing belt cover with the three bolts.

18. INSTALL VSV FOR EVAP SYSTEM Install the VSV with the two bolts.

19. INSTALL LH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Install the cord grommet to the high±tension cord.

(c) Install the cord grommet to the timing belt cover.

(d) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(e) Install the timing belt cover with the four bolts.

20. INSTALL RH ENGINE WIRE COVER (a) Fit portions A and B of the engine wire cover, matchingthem with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the bolt.

ST±32

±

STARTING SYSTEM Starter

WhereEverybodyKnowsYourName

Page 2923 of 4087

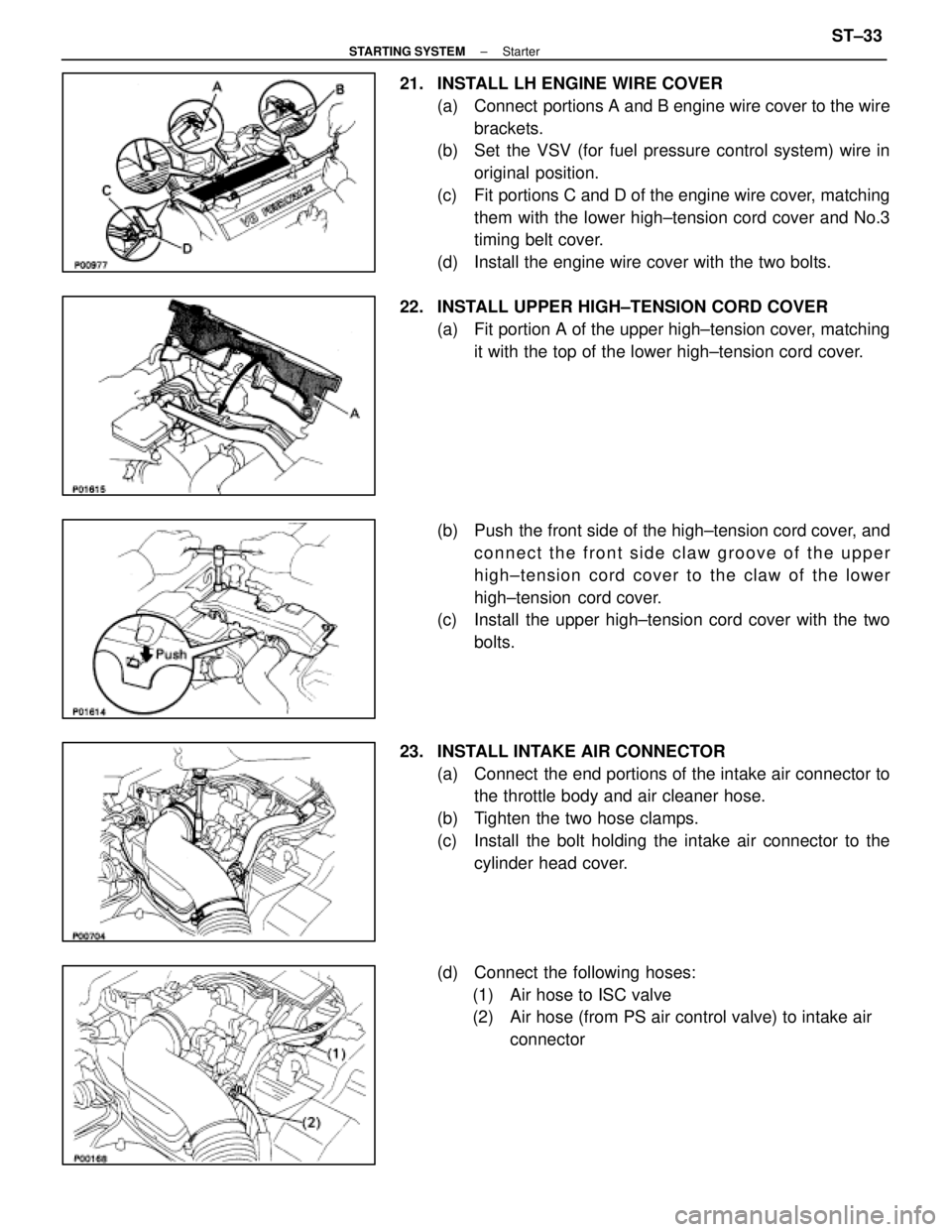

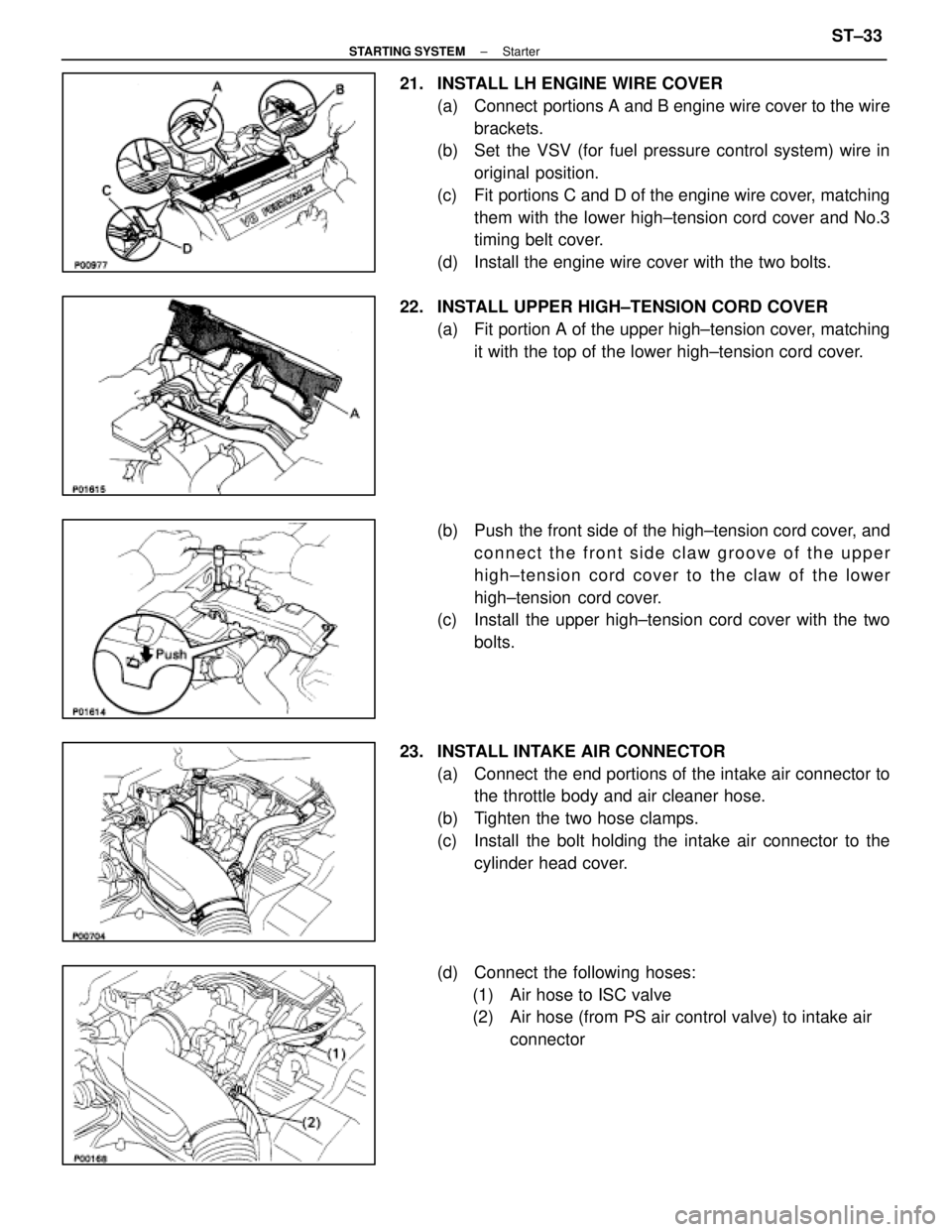

21. INSTALL LH ENGINE WIRE COVER(a) Connect portions A and B engine wire cover to the wirebrackets.

(b) Set the VSV (for fuel pressure control system) wire in

original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the two bolts.

22. INSTALL UPPER HIGH±TENSION CORD COVER (a) Fit portion A of the upper high±tension cover, matchingit with the top of the lower high±tension cord cover.

(b) Push the front side of the high±tension cord cover, and connect the front side claw groove of the upper

high±tension cord cover to the claw of the lower

high±tension cord cover.

(c) Install the upper high±tension cord cover with the two

bolts.

23. INSTALL INTAKE AIR CONNECTOR (a) Connect the end portions of the intake air connector tothe throttle body and air cleaner hose.

(b) Tighten the two hose clamps.

(c) Install the bolt holding the intake air connector to the cylinder head cover.

(d) Connect the following hoses: (1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to intake air connector

±

STARTING SYSTEM StarterST±33

WhereEverybodyKnowsYourName

Page 2924 of 4087

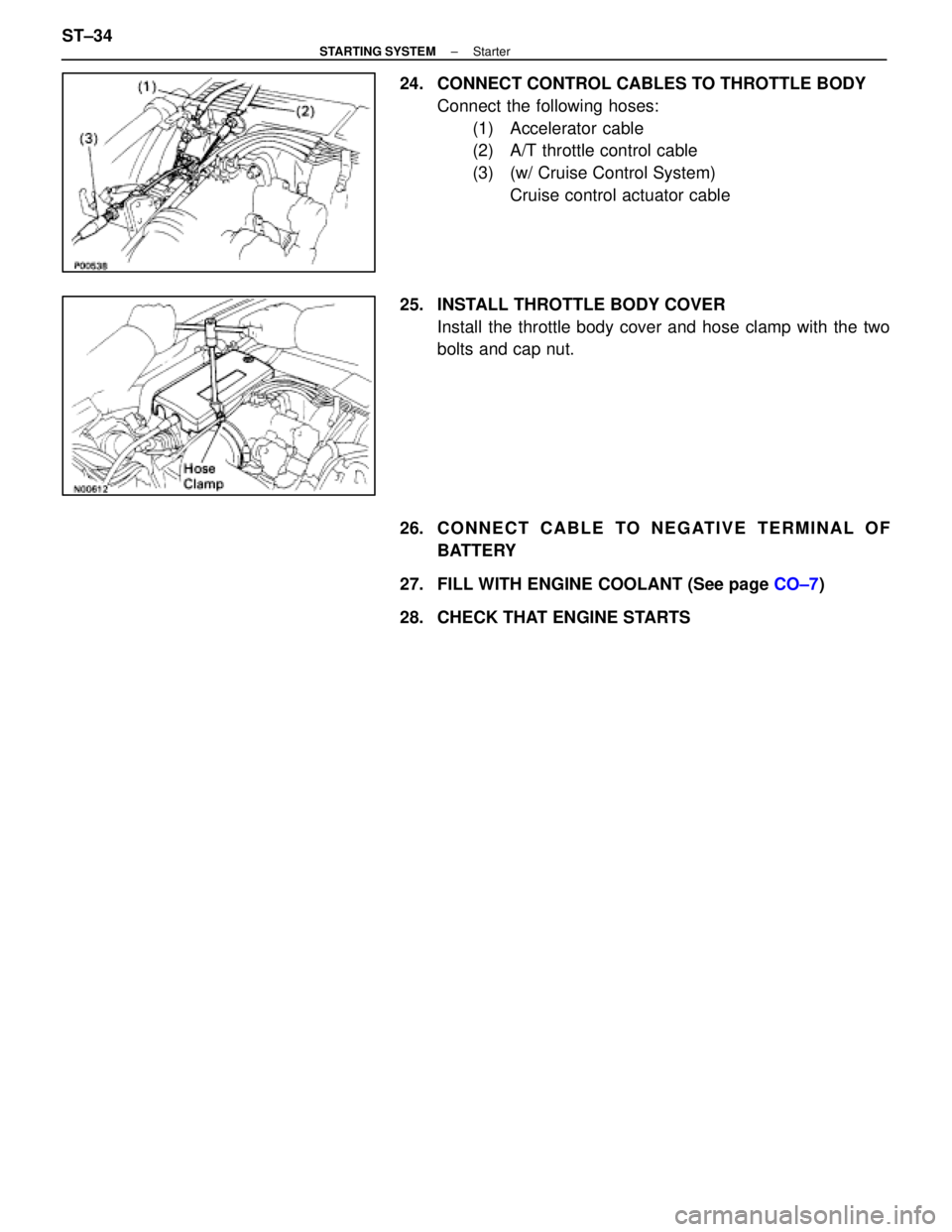

24. CONNECT CONTROL CABLES TO THROTTLE BODYConnect the following hoses:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

25. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

26. C O N N E C T C A B L E TO N E G AT I V E T E R M I N A L O F BATTERY

27. FILL WITH ENGINE COOLANT (See page CO±7)

28. CHECK THAT ENGINE STARTS

ST±34

±

STARTING SYSTEM Starter

WhereEverybodyKnowsYourName

Page 2925 of 4087

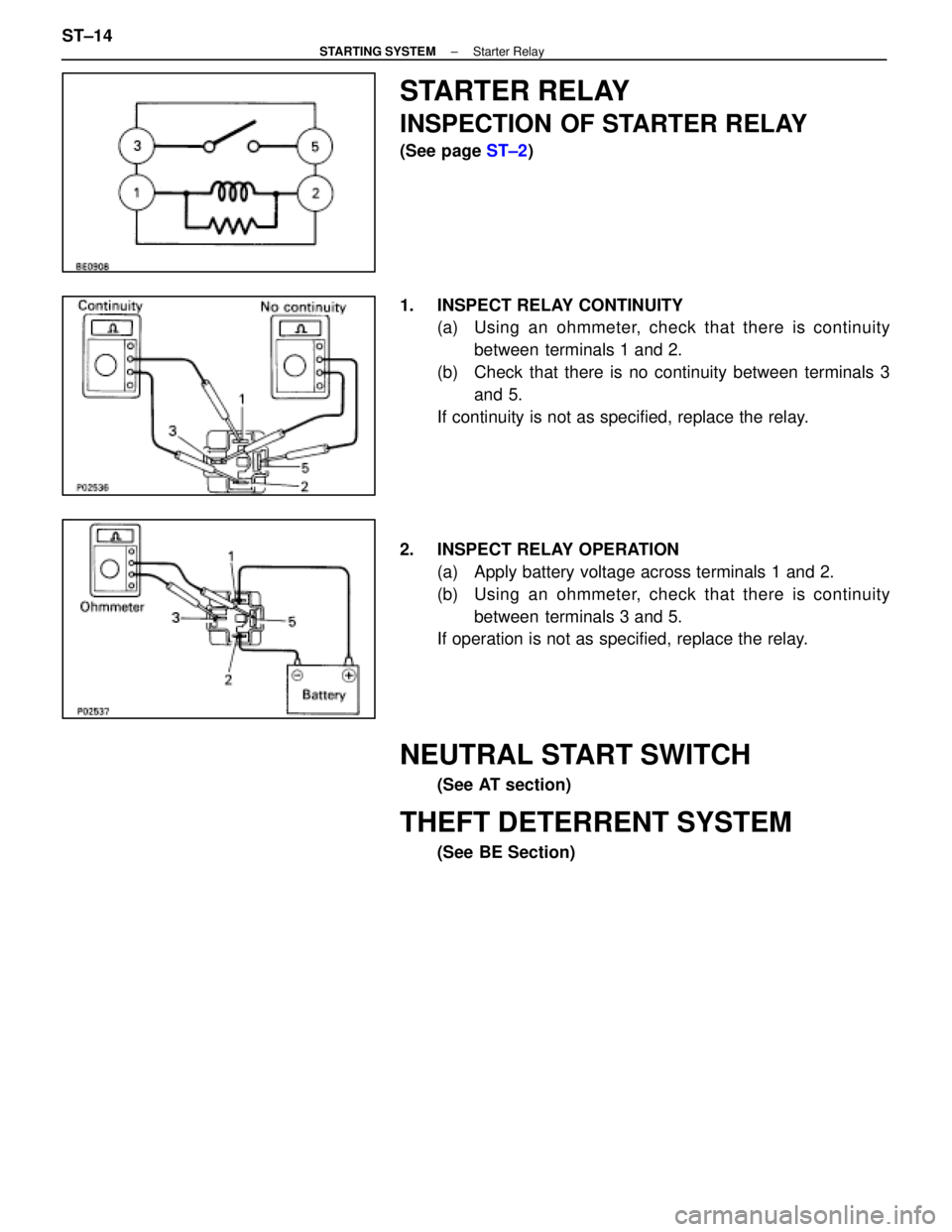

STARTER RELAY

INSPECTION OF STARTER RELAY

(See page ST±2)

1. INSPECT RELAY CONTINUITY (a) Using an ohmmeter, check that there is continuity

between terminals 1 and 2.

(b) Check that there is no continuity between terminals 3 and 5.

If continuity is not as specified, replace the relay.

2. INSPECT RELAY OPERATION (a) Apply battery voltage across terminals 1 and 2.

(b) Using an ohmmeter, check that there is continuitybetween terminals 3 and 5.

If operation is not as specified, replace the relay.

NEUTRAL START SWITCH

(See AT section)

THEFT DETERRENT SYSTEM

(See BE Section)

ST±14

±

STARTING SYSTEM Starter Relay

WhereEverybodyKnowsYourName

Page 2926 of 4087

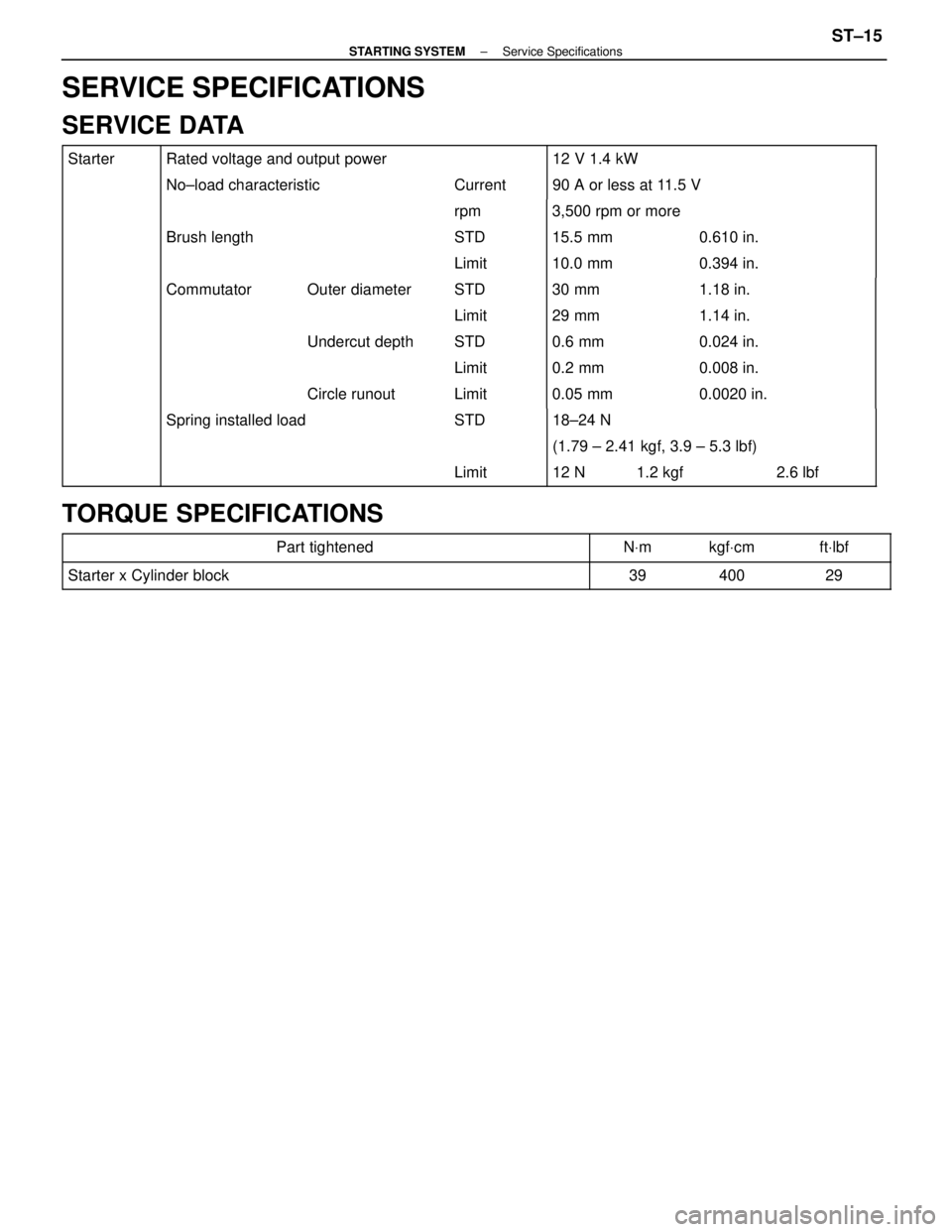

SERVICE SPECIFICATIONS

SERVICE DATA

StarterRated voltage and output power12 V 1.4 kW

No±load characteristicCurrent 90 A or less at 11.5 V

rpm 3,500 rpm or more

Brush lengthSTD 15.5 mm0.610 in.

Limit 10.0 mm0.394 in.

CommutatorOuter diameter STD 30 mm1.18 in.

Limit 29 mm1.14 in.

Undercut depth STD 0.6 mm0.024 in.

Limit 0.2 mm0.008 in.

Circle runout Limit 0.05 mm0.0020 in.

Spring installed loadSTD 18±24 N

(1.79 ± 2.41 kgf, 3.9 ± 5.3 lbf)

Limit12 N1.2 kgf2.6 lbf

TORQUE SPECIFICATIONS

Part tightenedNVmkgf Vcmft Vlbf

Starter x Cylinder block3940029

±

STARTING SYSTEM Service SpecificationsST±15

WhereEverybodyKnowsYourName

Page 2927 of 4087

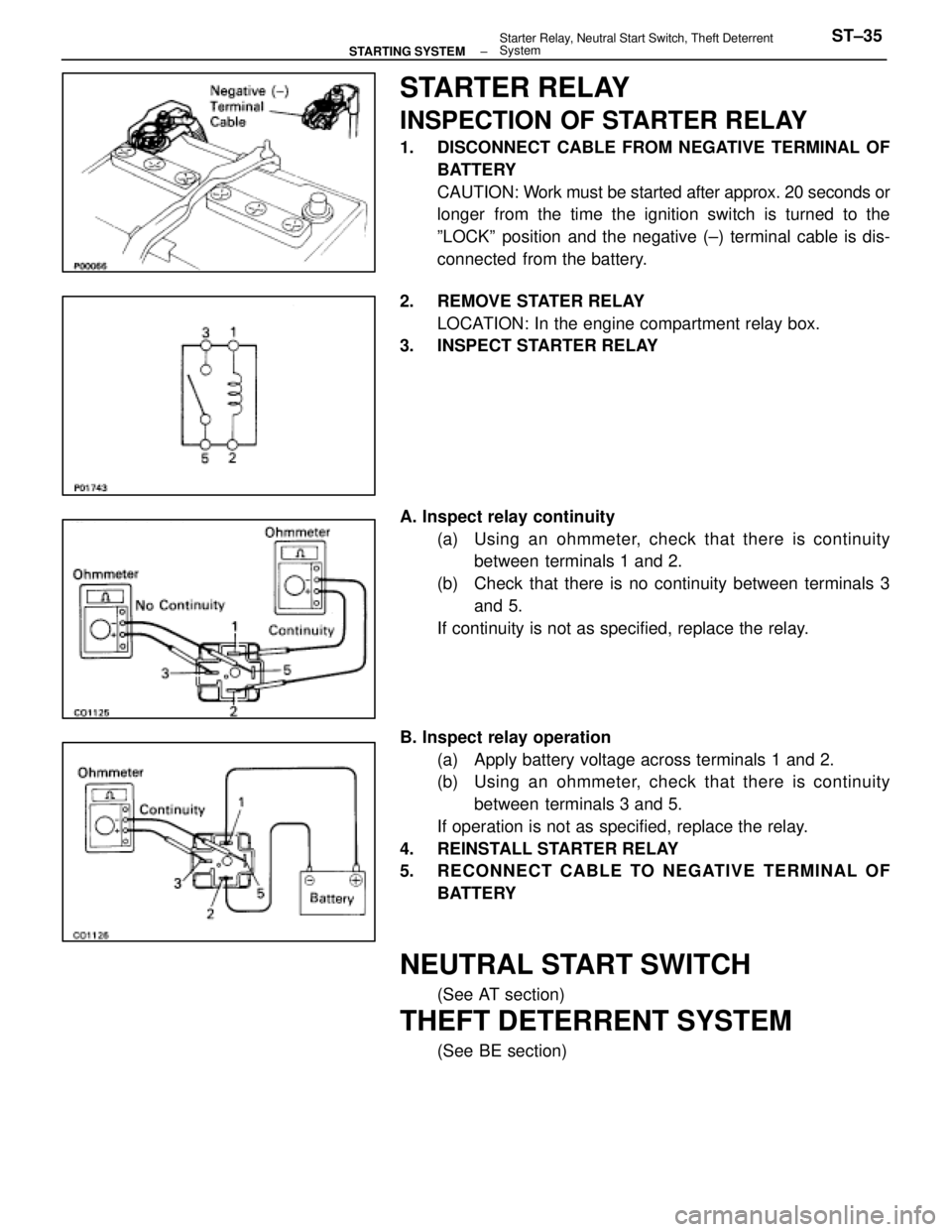

STARTER RELAY

INSPECTION OF STARTER RELAY

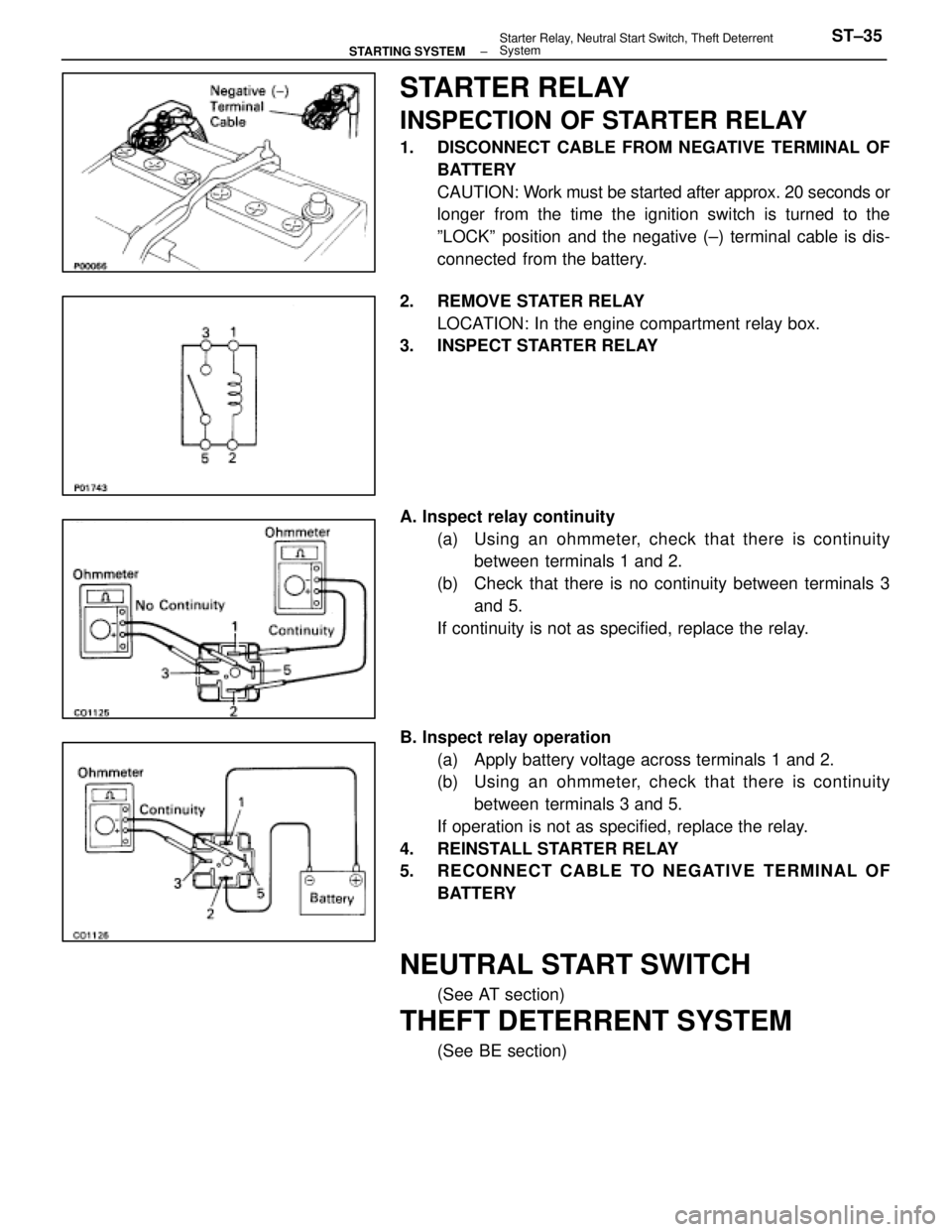

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 seconds or

longer from the time the ignition switch is turned to the

ºLOCKº position and the negative (±) terminal cable is dis-

connected from the battery.

2. REMOVE STATER RELAY LOCATION: In the engine compartment relay box.

3. INSPECT STARTER RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuitybetween terminals 1 and 2.

(b) Check that there is no continuity between terminals 3 and 5.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 1 and 2.

(b) Using an ohmmeter, check that there is continuitybetween terminals 3 and 5.

If operation is not as specified, replace the relay.

4. REINSTALL STARTER RELAY

5. RECONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

NEUTRAL START SWITCH

(See AT section)

THEFT DETERRENT SYSTEM

(See BE section)

±

STARTING SYSTEM Starter Relay, Neutral Start Switch, Theft Deterrent

SystemST±35

WhereEverybodyKnowsYourName

Page 2928 of 4087

SR±52).

IN±33).

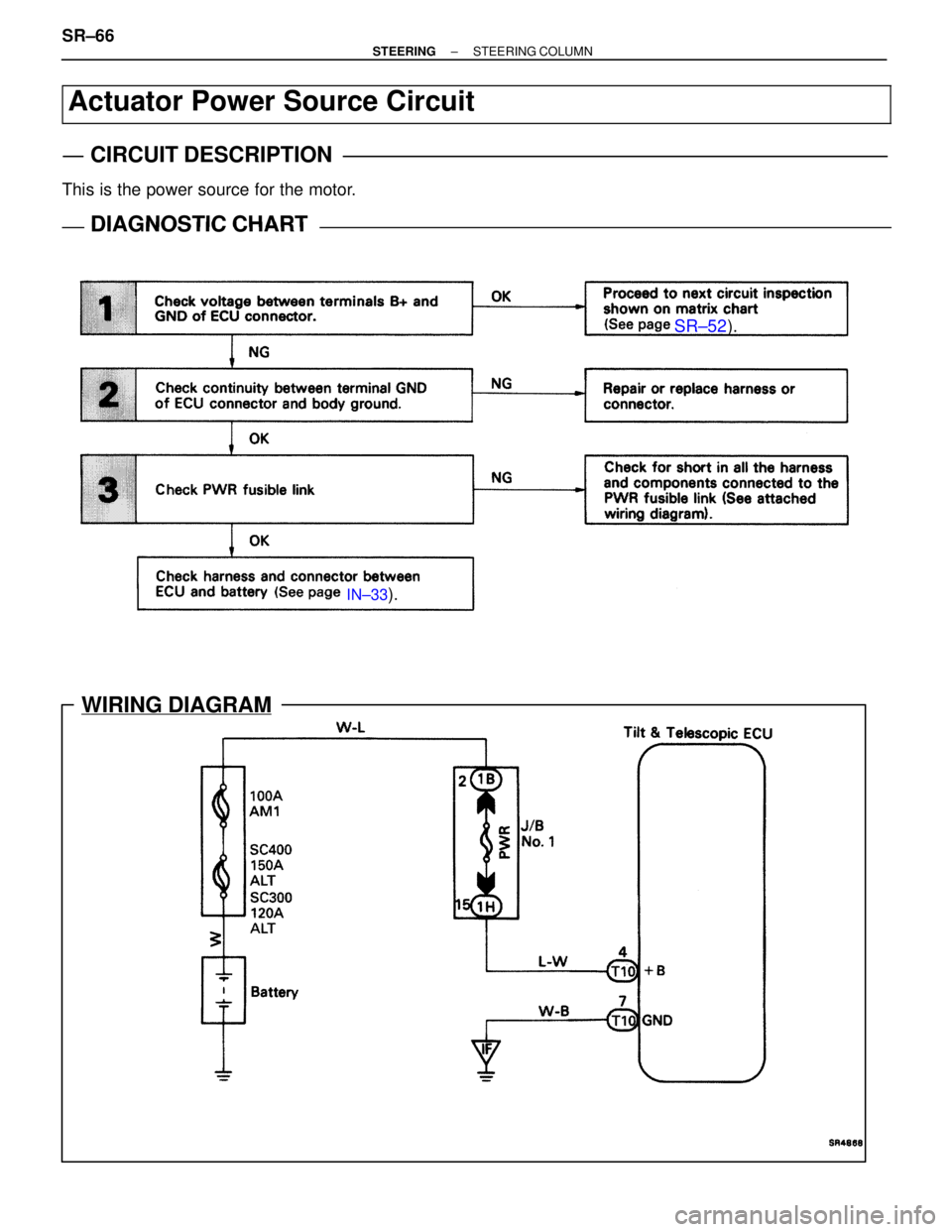

WIRING DIAGRAM

Actuator Power Source Circuit

CIRCUIT DESCRIPTION

This is the power source for the motor.

DIAGNOSTIC CHARTDIAGNOSTIC CHART

SR±66±

STEERING STEERING COLUMN

WhereEverybodyKnowsYourName

Page 2929 of 4087

NGOK

OKNG

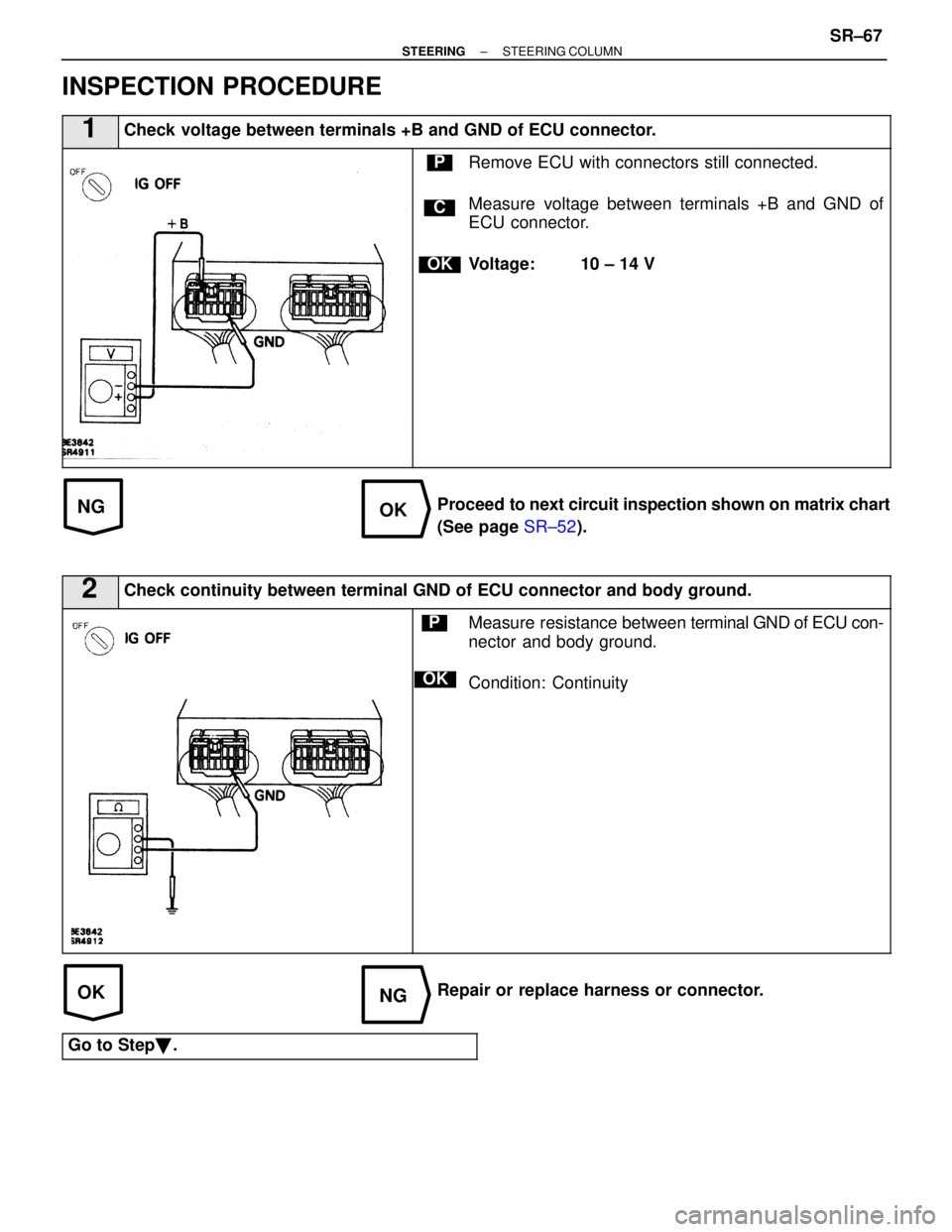

INSPECTION PROCEDURE

1Check voltage between terminals +B and GND of ECU connector.

C

OK

PRemove ECU with connectors still connected.

Measure voltage between terminals +B and GND of

ECU connector.

Voltage: 10 ± 14 V

Proceed to next circuit inspection shown on matrix chart

(See page SR±52).

2Check continuity between terminal GND of ECU connector and body ground.

OK

PMeasure resistance between terminal GND of ECU con-

nector and body ground.

Condition: Continuity

Repair or replace harness or connector.

Go to Step �.

±

STEERING STEERING COLUMNSR±67

WhereEverybodyKnowsYourName

Page 2930 of 4087

OKNG

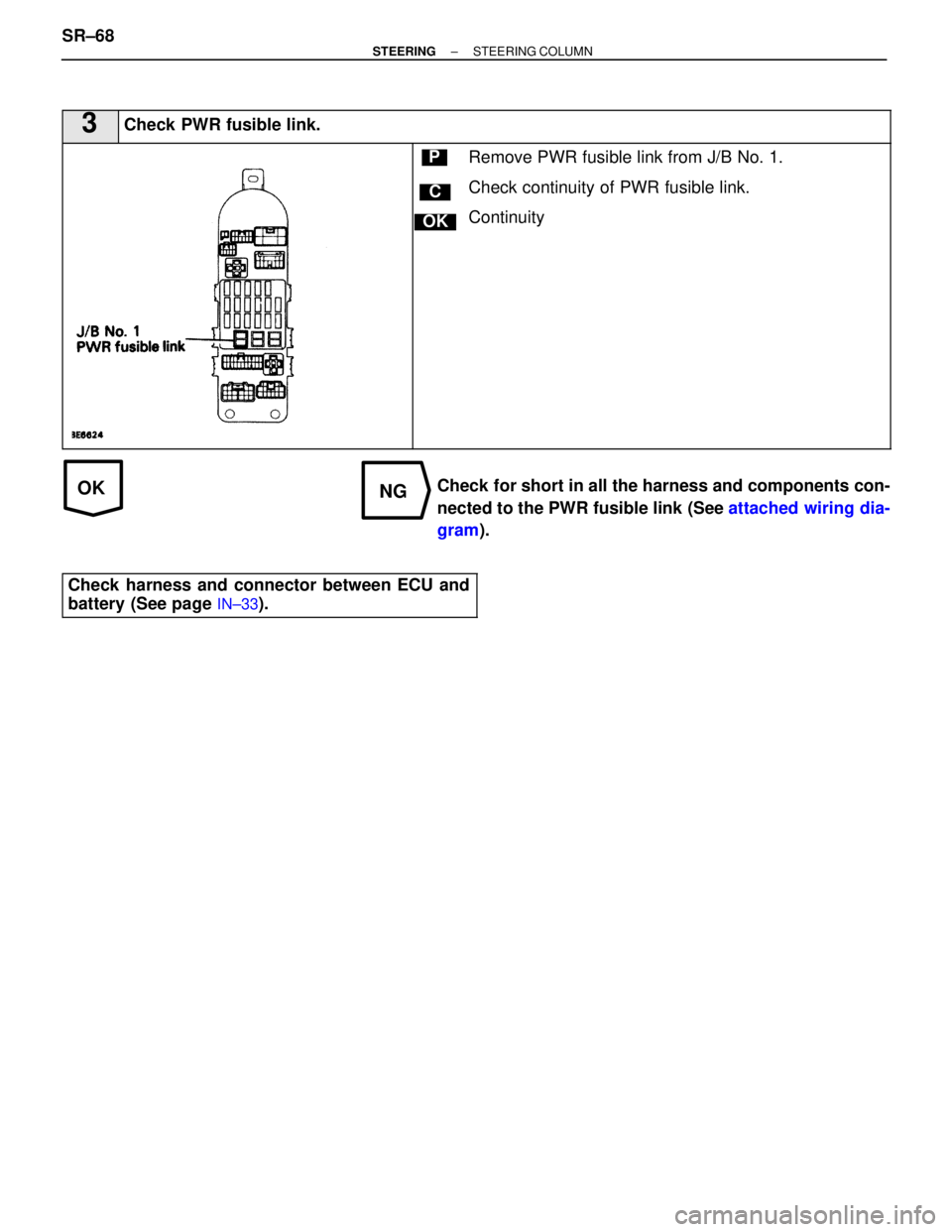

3Check PWR fusible link.

C

OK

PRemove PWR fusible link from J/B No. 1.

Check continuity of PWR fusible link.

Continuity

Check for short in all the harness and components con-

nected to the PWR fusible link (See attached wiring dia-

gram ).

Check harness and connector between ECU and

battery (See page

IN±33).

SR±68±

STEERING STEERING COLUMN

WhereEverybodyKnowsYourName

Trending: manual radio set, headrest, seat adjustment, battery location, transmission, clock, airbag