LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 4071 of 4087

11 3

M

64 5 31 2

1K

4

2

2

2 2

I11

B7 B7 I11

EB1

3 IE1

15

IP1

20

IP1

8IP1 19

IP 1

15 IP1 6IP1 18 IP1 5IP114 IE 1

14 BT1 9

IP1

7

A

15 UL1

A

12 DSWP

A

7 LSW P

A

3 ACT±

A

4 ACT+

B

12 DS WH

A

5 TOA

1

SRLY25 13

2

31

2

31

IJ EA

2 1

PRND 2 L

146578 9

GR

R±B

L

G±W G

W

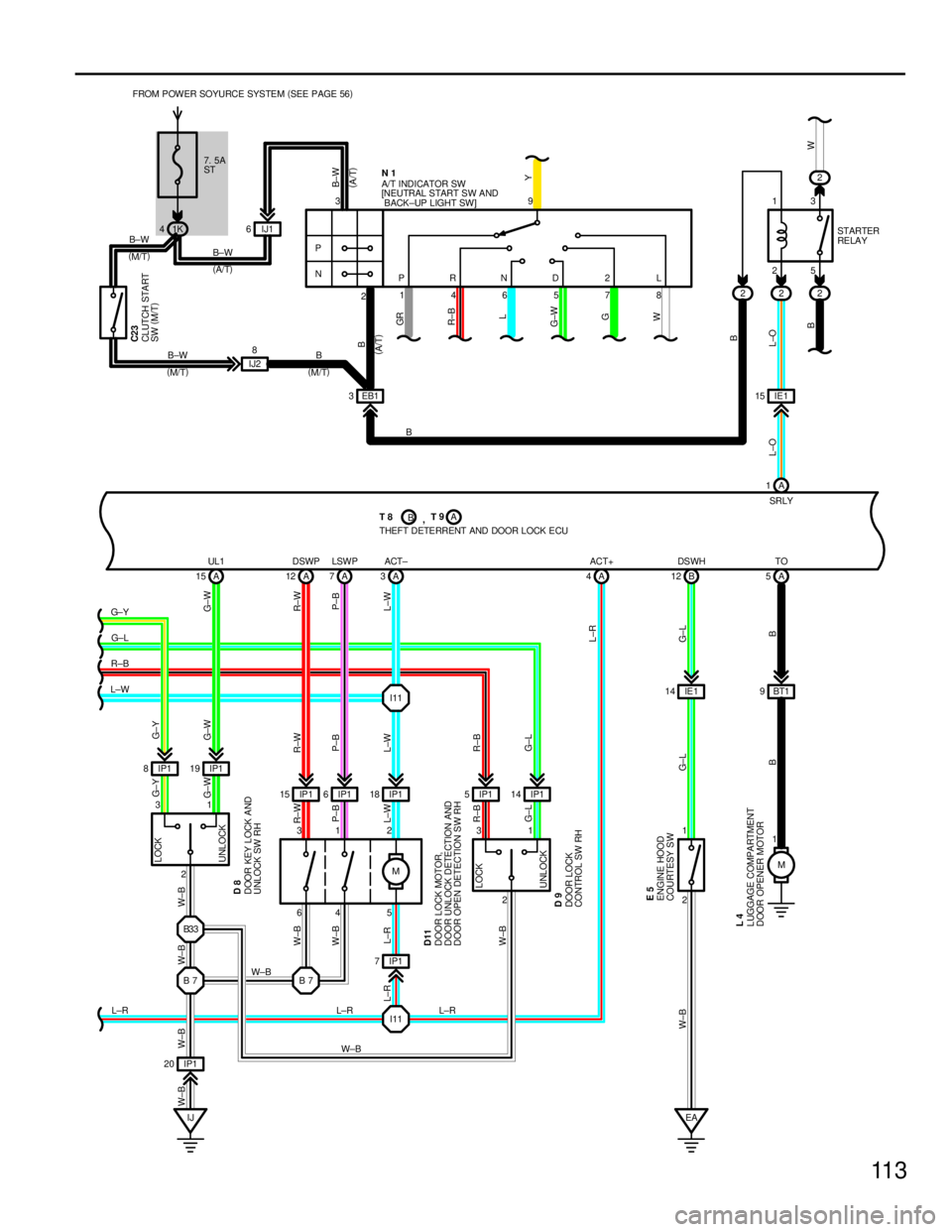

A/T INDICATOR SW

[NEUTRAL START SW AND BACK±UP LIGHT SW]

N1

2

3

FROM POWER SOYURCE SYSTEM

(

SEE PAGE 56 )

7. 5A

ST

P

N STARTER

RE LA Y

THEFT DETERRENT AND DOOR LOCK ECU

LOCK

UNLOCK

LOCK

UNLOCK

DOOR KEY LOCK AND

UNLOCK SW RH

DOOR LOCK MOTOR,

DOOR UNLOCK DETE CTION AND

DOOR OPEN DETECTION SW RH DOOR LOCK

CONTROL SW RHENGINE HOOD

COURTESY SW

LUGGAGE COMPARTMENT

DOOR OPENER MOTOR

G± Y G±L

R±B

L±W

L±R W±B

L±R L±R B

Y

W

B

L±O B

B

L±O

B

G±L L±R

G±L B

W±B W±B

L±R

W±B W±B W±B

W±B W±B

L±R R±BG±L

L±W

P±B

R±W G±W

G±Y G±Y

G±W

R±W P±B

L±W

R±BG±L L±W

P±B

R±W

G±W

L4 E5

D9

D11 D8

T8

,T

9

B A

M

1

IJ1

6

B±W

( A/T )

IJ28

B±W B

( M/T )(

M/T)

B±W

( A/T )

B±W

( M/T )

CLUTCH STA RT

SW (

M/T )

C23

( A/T )

B3 3

W±BW±B

WhereEverybodyKnowsYourName

Page 4072 of 4087

11 4

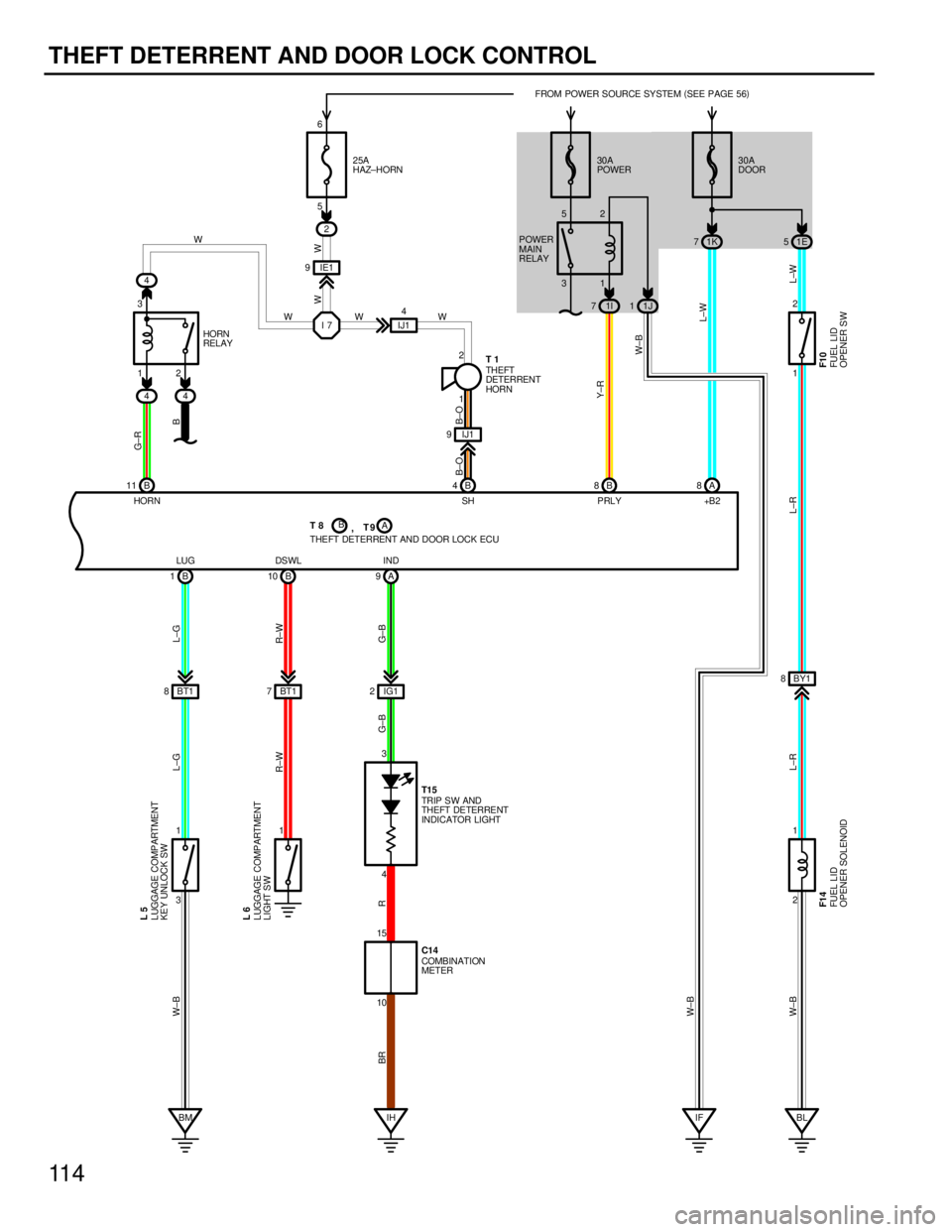

THEFT DETERRENT AND DOOR LOCK CONTROL

2

5

1K

71E 5

44 1I

71J 1

3 11 IE1

9

2

1

BM IF BL

BT1

8BT1 7IG1 2IJ1

4

IJ1

9

B

11

HORN B

4

SH B

8

PRLY A

8

+B 2

B

1 LUG

B

10 DS WL

A

9 IND

4

I72

12

1

4

3

3

15

10 1 2

BY1

8

IH FROM POWER SOURCE SYSTEM

(

SEE PAGE 56 )

25A

HAZ±HORN 30A

POWER30A

DOOR

POWER

MAIN

RELAY

W

WW W

G±R

WW

B±O

B±O

Y±RW±B

L±W

L±W

L±R

L±R

W±B W±B G±B

R±W L±G

L±G

R±W G±B

R

BR W±B

TRIP S W AND

THEFT DETERRENT

INDICATOR LIGHT

COMB INATION

METER

FUEL L I D

OPENER SOLENOID

FUEL LI D

OPENER SW

THEFT

DETERRENT

HORN

HORN

RELAY

LUGGAGE COMPARTMENT

LIGHT SW LUGGAGE COMPARTMENT

KEYUNLOCKSW

THEFT DETERRENT AND DOOR LOCK ECU T8

,T9 T1

F1 0

F1 4

T1 5

C14

L6 L5

B

A

B

6

52

31

WhereEverybodyKnowsYourName

Page 4073 of 4087

11 5

CURRENT ALWAYS FLOWS TO TERMINAL (A)8 OF THE DOOR LOCK ECU THROUGH THE DOOR FUSE, AND TO TERMINAL (A)20

THROUGH THE DOME FUSE.

WHEN THE IGNITION SW IS TURNED ON, THE CURRENT FLOWING THROUGH THE ECU±IG FUSE " TERMINAL (A)2 OF THE ECU "

TERMINAL (B)8 FLOWS THROUGH THE COIL SIDE OF THE POWER MAIN RELAY TO GROUND, CAUSING THE RELAY TO OPERATE.

THE CURRENT FLOWING THROUGH THE POWER FUSE FLOWS TO THE DOOR LOCK CONTROL SW LH, CAUSING THE INDICATOR

LIGHT TO LIGHT UP.

1. MANUAL LOCK OPERATION

WHEN THE DOOR CONTROL SW OR KEY SW ARE PUSHED TO LOCK POSITION, A LOCK SIGNAL IS INPUT TO TERMINAL (A)17, (A)14

(FOR KEY SW) OF THE DOOR LOCK ECU AND CAUSES THE ECU TO FUNCTION. CURRENT FLOWS FROM TERMINAL (A)8 OF THE

ECU " TERMINAL (A)4 " TERMINAL 5 OF THE DOOR LOCK MOTORS " TERMINAL 2 " TERMINAL (A)3 OF THE ECU " TERMINAL

(A)16 " TO GROUND AND THE DOOR LOCK MOTOR CAUSES THE DOOR TO LOCK.

2. MANUAL UNLOCK OPERATION

WHEN THE DOOR LOCK CONTROL SW OR KEY ARE PUSHED TO UNLOCK POSITION, AN UNLOCK SIGNAL IS INPUT TO TERMINAL

(A)18, (A)10 (FOR KEY SW LH) OR (A)15 (FOR KEY SW RH) OF THE DOOR LOCK ECU AND CAUSES THE ECU TO FUNCTION.

CURRENT FLOWS FROM TERMINAL (A)8 OF THE ECU " TERMINAL (A)3 " TERMINAL 2 OF THE DOOR LOCK MOTORS " TERMINAL

5 " TERMINAL (A)4 OF THE ECU "TERMINAL (A)16 " TO GROUND AND THE DOOR LOCK MOTOR CAUSES THE DOOR TO

UNLOCK.

WHEN UNLOCK OPERATION OCCURS USING THE LH DOOR KEY SW, PERFORMING THE UNLOCK OPERATION ONCE UNLOCKS

ONLY THE DRIVER'S DOOR. TO UNLOCK ALL THE OTHER DOORS TOGETHER, UNLOCK OPERATION MUST BE PERFORMED AGAIN

WITHIN 3 SECONDS OF THE FIRST OPERATION.

3. IGNITION KEY REMINDER OPERATION

* OPERATION OF DOOR LOCK BUTTON (OPERATION OF DOOR LOCK MOTORS)

WHEN THE IGNITION KEY IS IN THE CYLINDER (UNLOCK WARNING SW ON) AND THE DOOR IS OPENED AND LOCKED USING

DOOR LOCK BUTTON (DOOR LOCK MOTOR), THE DOOR IS LOCKED ONCE BUT EACH DOOR IS UNLOCKED SOON BY THE

OPERATION OF THE ECU. AS A RESULT OF ECU ACTIVATION, THE CURRENT FLOWS FROM TERMINAL (A)8 OF THE ECU "

TERMINAL (A)3 " TERMINAL 2 OF THE DOOR LOCK MOTORS " TERMINAL 5 " TERMINAL (A)4 OF THE ECU " TERMINAL (A)16

" TO GROUND AND CAUSES ALL THE DOORS TO UNLOCK.

THE SAME APPLIES TO OPERATION OF THE DOOR LOCK CONTROL SW AND DOOR LOCK KEY SW.

* KEY LESS LOCK OPERATION

WHEN THE IGNITION KEY IS STILL INSERTED IN THE CYLINDER (UNLOCK WARNING SW ON), THE DOOR IS OPEN AND UNLOCK

OPERATION IS PREVENTED BY KEEPING THE DOOR LOCK BUTTON PRESSED TO THE LOCK SIDE, THE DOOR IS KEPT IN THE

LOCK CONDITION. IF THE DOOR IS THEN CLOSED, A SIGNAL IS INPUT TO THE ECU FROM THE DOOR COURTESY SW. THIS

ACTIVATES THE ECU AND EACH DOOR IS UNLOCKED.

SYSTEM OUTLINE

WhereEverybodyKnowsYourName

Page 4074 of 4087

11 6

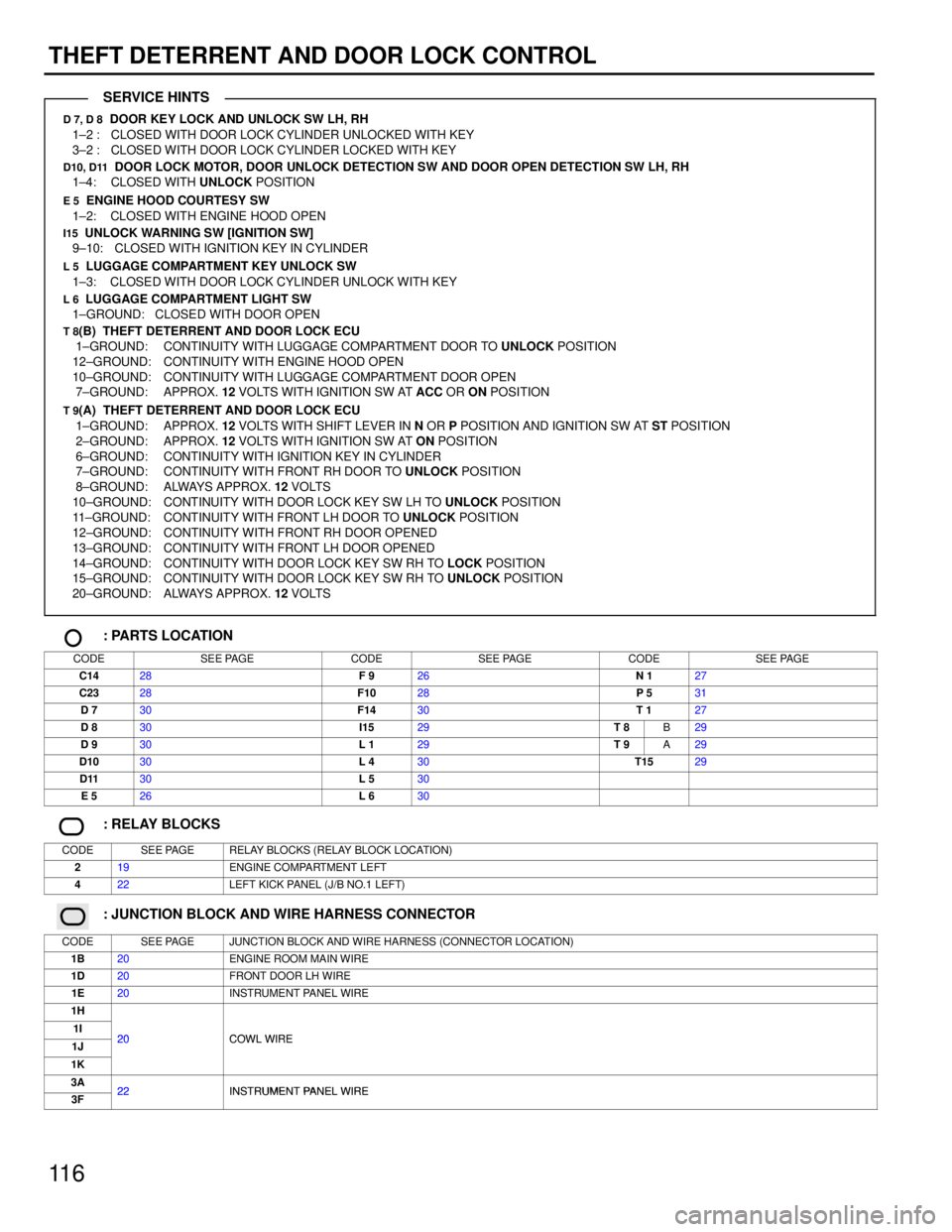

THEFT DETERRENT AND DOOR LOCK CONTROL

D 7, D 8 DOOR KEY LOCK AND UNLOCK SW LH, RH

1±2 : CLOSED WITH DOOR LOCK CYLINDER UNLOCKED WITH KEY

3±2 : CLOSED WITH DOOR LOCK CYLINDER LOCKED WITH KEY

D10, D11 DOOR LOCK MOTOR, DOOR UNLOCK DETECTION SW AND DOOR OPEN DETECTION SW LH, RH

1±4: CLOSED WITH UNLOCK POSITION

E 5 ENGINE HOOD COURTESY SW

1±2: CLOSED WITH ENGINE HOOD OPEN

I15 UNLOCK WARNING SW [IGNITION SW]

9±10: CLOSED WITH IGNITION KEY IN CYLINDER

L 5 LUGGAGE COMPARTMENT KEY UNLOCK SW

1±3: CLOSED WITH DOOR LOCK CYLINDER UNLOCK WITH KEY

L 6 LUGGAGE COMPARTMENT LIGHT SW

1±GROUND: CLOSED WITH DOOR OPEN

T 8(B) THEFT DETERRENT AND DOOR LOCK ECU

1±GROUND: CONTINUITY WITH LUGGAGE COMPARTMENT DOOR TO UNLOCK POSITION

12±GROUND: CONTINUITY WITH ENGINE HOOD OPEN

10±GROUND: CONTINUITY WITH LUGGAGE COMPARTMENT DOOR OPEN

7±GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ACC OR ON POSITION

T 9(A) THEFT DETERRENT AND DOOR LOCK ECU

1±GROUND: APPROX. 12 VOLTS WITH SHIFT LEVER IN N OR P POSITION AND IGNITION SW AT ST POSITION

2±GROUND: APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

6±GROUND: CONTINUITY WITH IGNITION KEY IN CYLINDER

7±GROUND: CONTINUITY WITH FRONT RH DOOR TO UNLOCK POSITION

8±GROUND: ALWAYS APPROX. 12 VOLTS

10±GROUND: CONTINUITY WITH DOOR LOCK KEY SW LH TO UNLOCK POSITION

11±GROUND: CONTINUITY WITH FRONT LH DOOR TO UNLOCK POSITION

12±GROUND: CONTINUITY WITH FRONT RH DOOR OPENED

13±GROUND: CONTINUITY WITH FRONT LH DOOR OPENED

14±GROUND: CONTINUITY WITH DOOR LOCK KEY SW RH TO LOCK POSITION

15±GROUND: CONTINUITY WITH DOOR LOCK KEY SW RH TO UNLOCK POSITION

20±GROUND: ALWAYS APPROX. 12 VOLTS

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1428F 926N 127

C2328F1028P 531

D 730F1430T 127

D 830I1529T 8B29

D 930L 129T 9A29

D1030L 430T1529

D1130L 530

E 526L 630

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

219ENGINE COMPARTMENT LEFT

422LEFT KICK PANEL (J/B NO.1 LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1B20ENGINE ROOM MAIN WIRE

1D20FRONT DOOR LH WIRE

1E20INSTRUMENT PANEL WIRE

1H

1I20COWL WIRE1J20COWL WIRE

1K

3A22INSTRUMENT PANEL WIRE3F22INSTRUMENT PANEL WIRE

SERVICE HINTS

WhereEverybodyKnowsYourName

Page 4075 of 4087

11 7

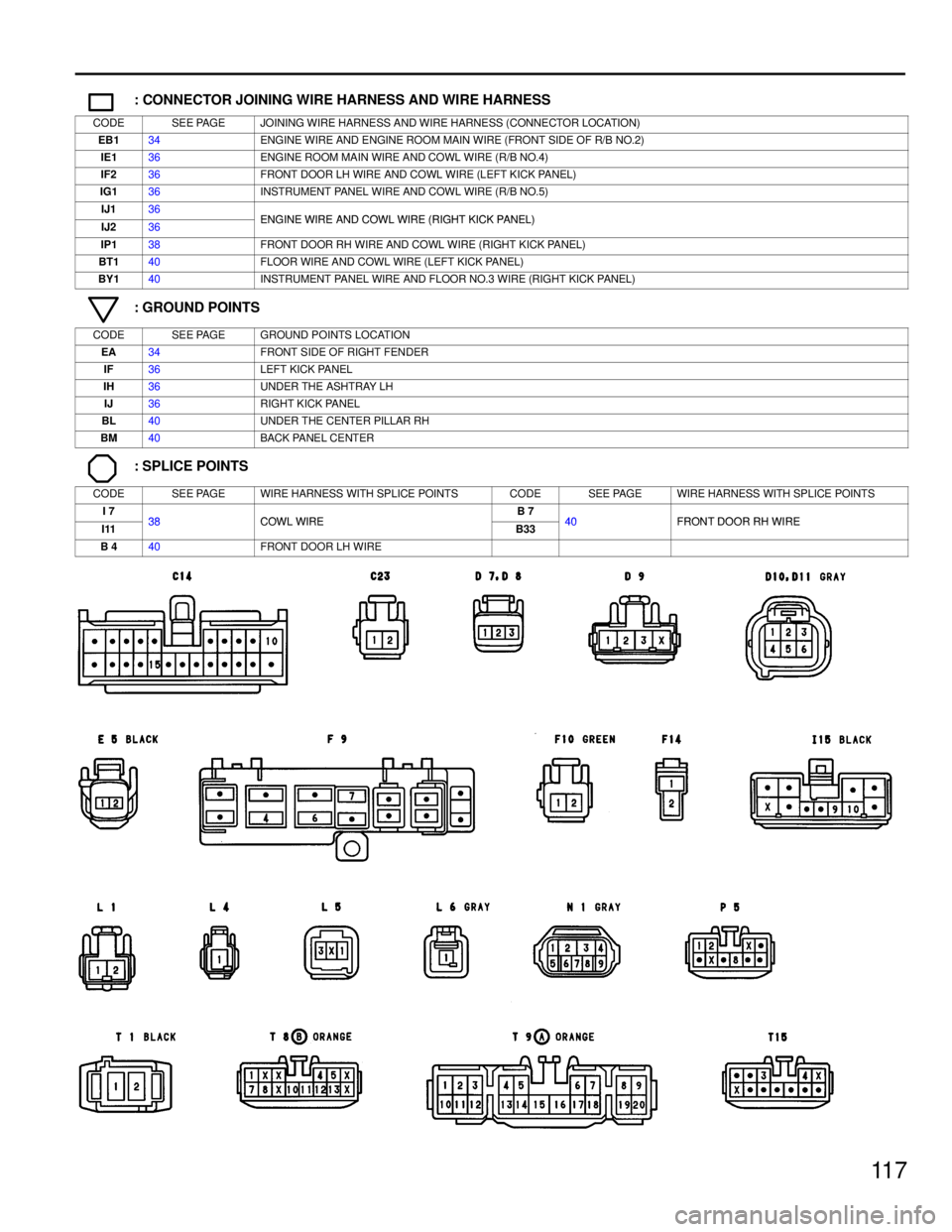

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EB134ENGINE WIRE AND ENGINE ROOM MAIN WIRE (FRONT SIDE OF R/B NO.2)

IE136ENGINE ROOM MAIN WIRE AND COWL WIRE (R/B NO.4)

IF236FRONT DOOR LH WIRE AND COWL WIRE (LEFT KICK PANEL)

IG136INSTRUMENT PANEL WIRE AND COWL WIRE (R/B NO.5)

IJ136ENGINE WIRE AND COWL WIRE (RIGHT KICK PANEL)IJ236ENGINE WIRE AND COWL WIRE (RIGHT KICK PANEL)

IP138FRONT DOOR RH WIRE AND COWL WIRE (RIGHT KICK PANEL)

BT140FLOOR WIRE AND COWL WIRE (LEFT KICK PANEL)

BY140INSTRUMENT PANEL WIRE AND FLOOR NO.3 WIRE (RIGHT KICK PANEL)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA34FRONT SIDE OF RIGHT FENDER

IF36LEFT KICK PANEL

IH36UNDER THE ASHTRAY LH

IJ36RIGHT KICK PANEL

BL40UNDER THE CENTER PILLAR RH

BM40BACK PANEL CENTER

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I 738COWL WIREB 740FRONT DOOR RH WIREI1138COWL WIREB3340FRONT DOOR RH WIRE

B 440FRONT DOOR LH WIRE

WhereEverybodyKnowsYourName

Page 4076 of 4087

10

TROUBLESHOOTING

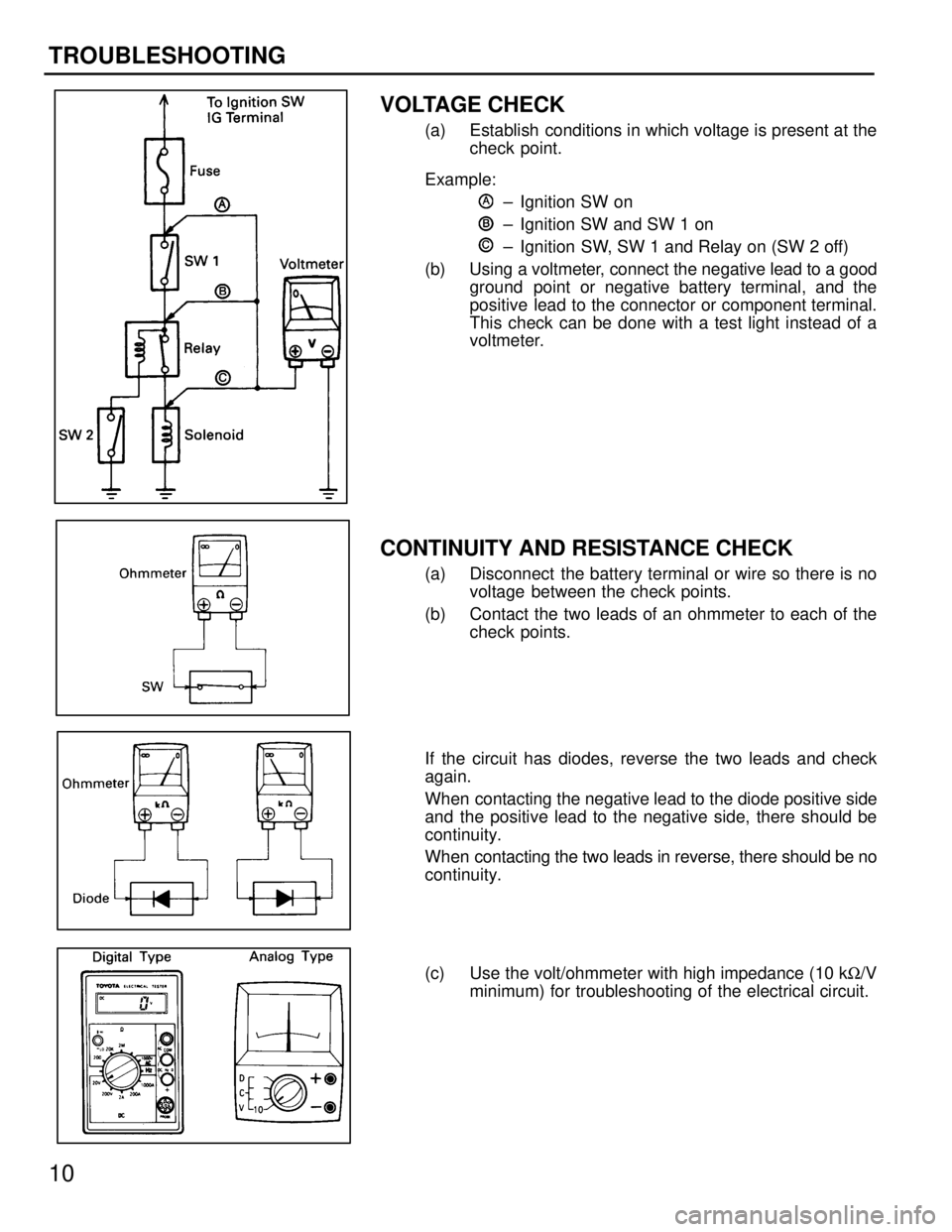

VOLTAGE CHECK

(a) Establish conditions in which voltage is present at thecheck point.

Example: ± Ignition SW on

± Ignition SW and SW 1 on

± Ignition SW, SW 1 and Relay on (SW 2 off)

(b) Using a voltmeter, connect the negative lead to a good ground point or negative battery terminal, and the

positive lead to the connector or component terminal.

This check can be done with a test light instead of a

voltmeter.

CONTINUITY AND RESISTANCE CHECK

(a) Disconnect the battery terminal or wire so there is novoltage between the check points.

(b) Contact the two leads of an ohmmeter to each of the check points.

If the circuit has diodes, reverse the two leads and check

again.

When contacting the negative lead to the diode positive side

and the positive lead to the negative side, there should be

continuity.

When contacting the two leads in reverse, there should be no

continuity.

(c) Use the volt/ohmmeter with high impedance (10 k W/V

minimum) for troubleshooting of the electrical circuit.

WhereEverybodyKnowsYourName

Page 4077 of 4087

11

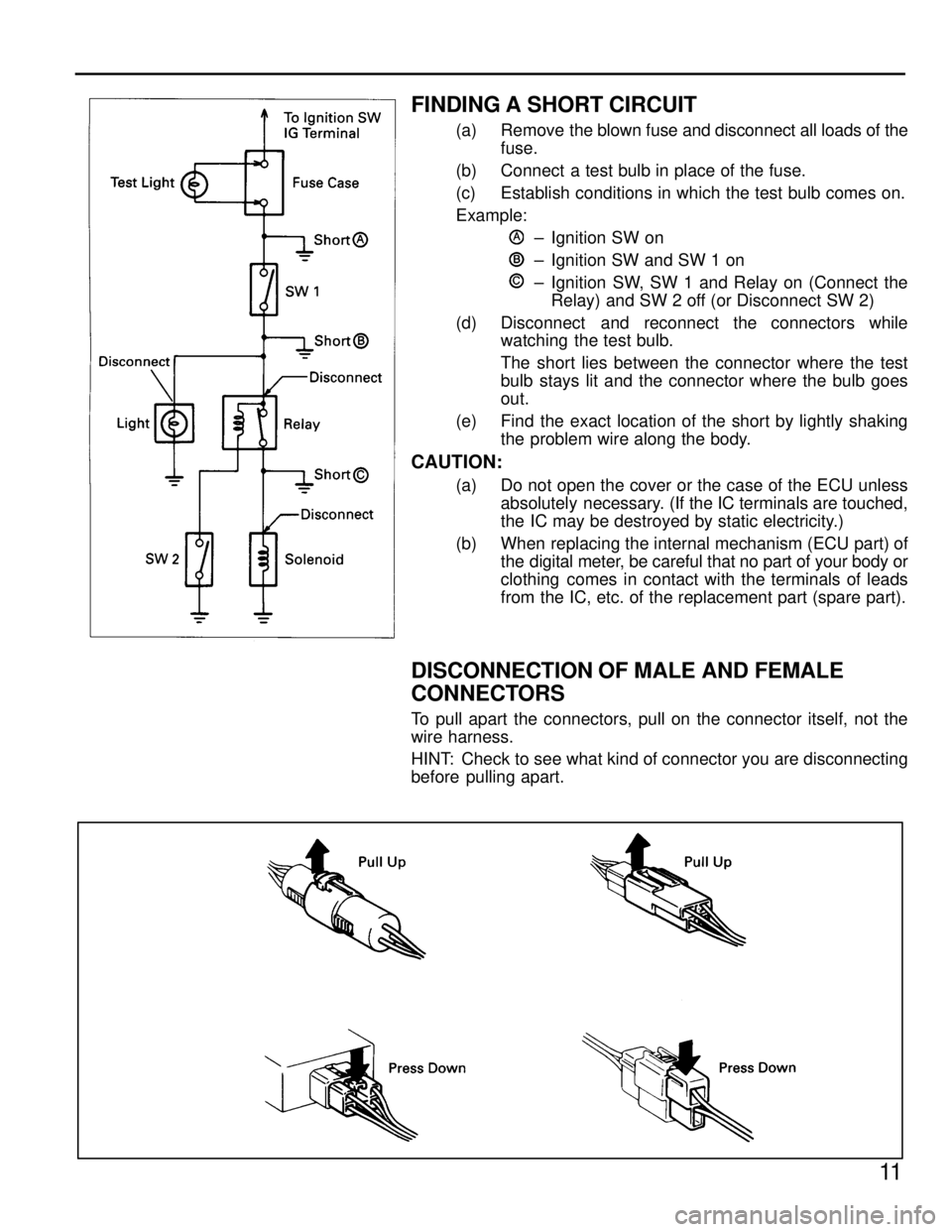

FINDING A SHORT CIRCUIT

(a) Remove the blown fuse and disconnect all loads of thefuse.

(b) Connect a test bulb in place of the fuse.

(c) Establish conditions in which the test bulb comes on.

Example: ± Ignition SW on

± Ignition SW and SW 1 on

± Ignition SW, SW 1 and Relay on (Connect theRelay) and SW 2 off (or Disconnect SW 2)

(d) Disconnect and reconnect the connectors while watching the test bulb.

The short lies between the connector where the test

bulb stays lit and the connector where the bulb goes

out.

(e) Find the exact location of the short by lightly shaking the problem wire along the body.

CAUTION:

(a) Do not open the cover or the case of the ECU unlessabsolutely necessary. (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) When replacing the internal mechanism (ECU part) of the digital meter, be careful that no part of your body or

clothing comes in contact with the terminals of leads

from the IC, etc. of the replacement part (spare part).

DISCONNECTION OF MALE AND FEMALE

CONNECTORS

To pull apart the connectors, pull on the connector itself, not the

wire harness.

HINT: Check to see what kind of connector you are disconnecting

before pulling apart.

WhereEverybodyKnowsYourName

Page 4078 of 4087

12

TROUBLESHOOTING

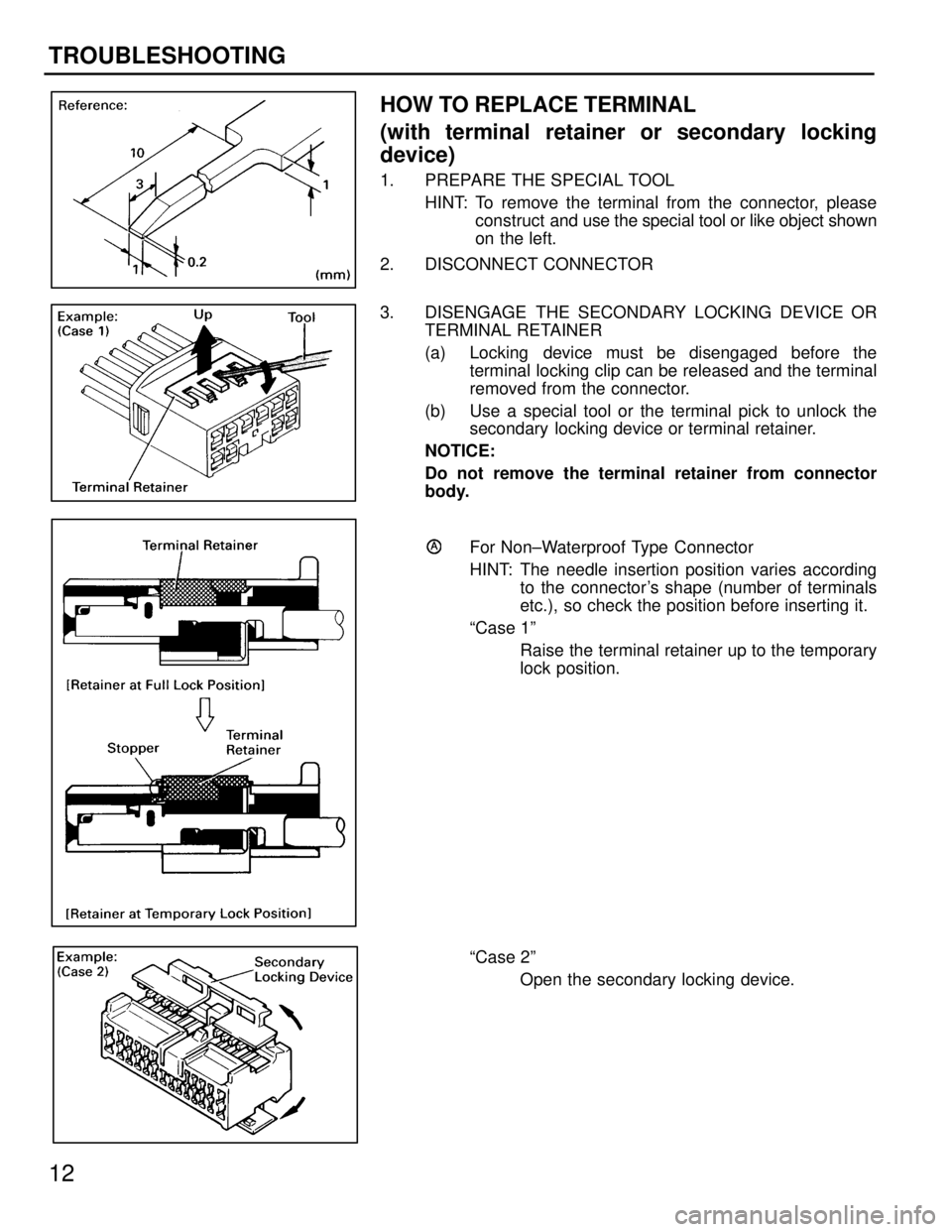

HOW TO REPLACE TERMINAL

(with terminal retainer or secondary locking

device)

1. PREPARE THE SPECIAL TOOLHINT: To remove the terminal from the connector, please construct and use the special tool or like object shown

on the left.

2. DISCONNECT CONNECTOR

3. DISENGAGE THE SECONDARY LOCKING DEVICE OR TERMINAL RETAINER

(a) Locking device must be disengaged before theterminal locking clip can be released and the terminal

removed from the connector.

(b) Use a special tool or the terminal pick to unlock the secondary locking device or terminal retainer.

NOTICE:

Do not remove the terminal retainer from connector

body.

For Non±Waterproof Type Connector

HINT: The needle insertion position varies according to the connector's shape (number of terminals

etc.), so check the position before inserting it.

ªCase 1º Raise the terminal retainer up to the temporary

lock position.

ªCase 2º Open the secondary locking device.

WhereEverybodyKnowsYourName

Page 4079 of 4087

13

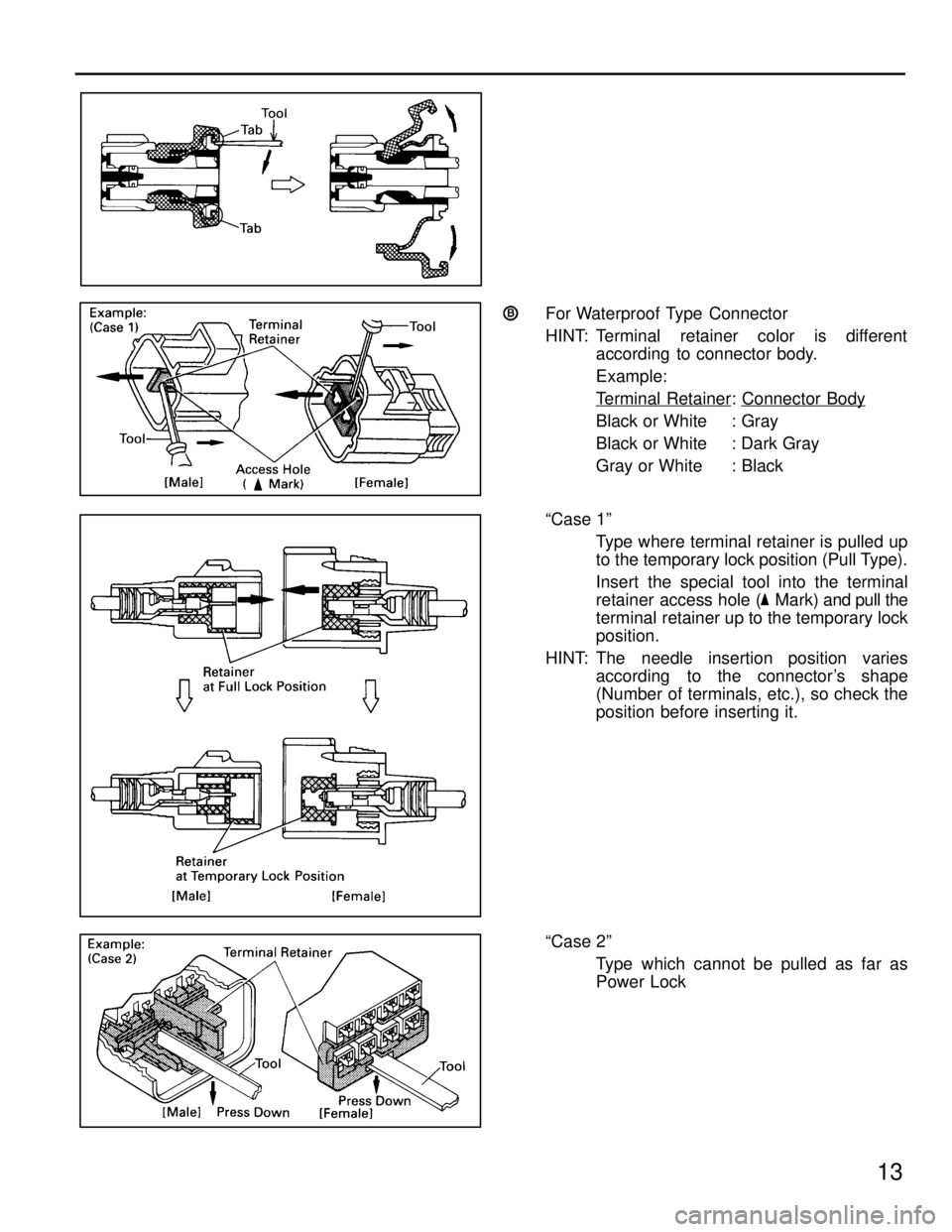

For Waterproof Type Connector

HINT: Terminal retainer color is differentaccording to connector body.

Example:

Terminal Retainer

: Connector Body

Black or White : Gray

Black or White : Dark Gray

Gray or White : Black

ªCase 1º Type where terminal retainer is pulled up

to the temporary lock position (Pull Type).

Insert the special tool into the terminal

retainer access hole ( Mark) and pull the

terminal retainer up to the temporary lock

position.

HINT: The needle insertion position varies according to the connector's shape

(Number of terminals, etc.), so check the

position before inserting it.

ªCase 2º Type which cannot be pulled as far as

Power Lock

WhereEverybodyKnowsYourName

Page 4080 of 4087

14

TROUBLESHOOTING

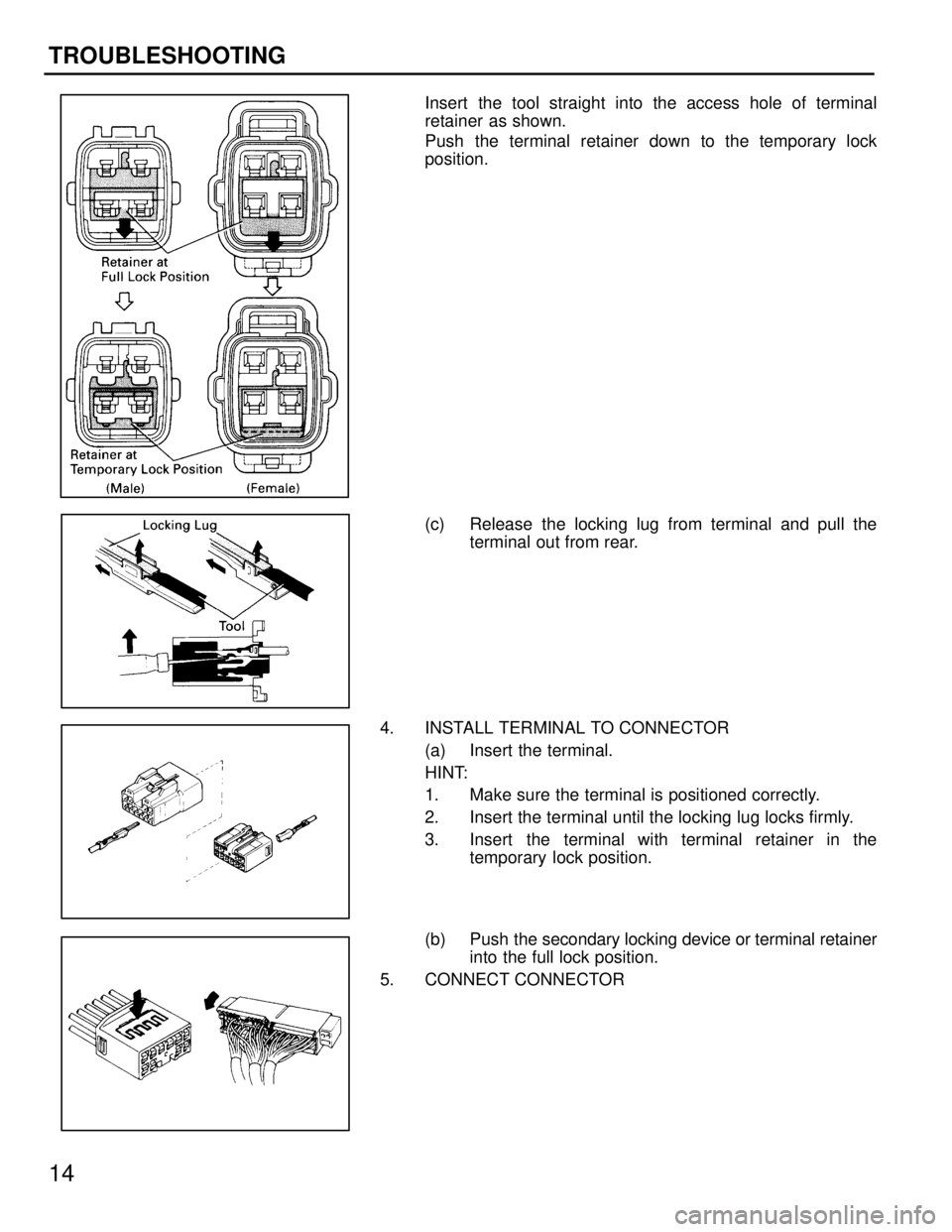

Insert the tool straight into the access hole of terminal

retainer as shown.

Push the terminal retainer down to the temporary lock

position.

(c) Release the locking lug from terminal and pull theterminal out from rear.

4. INSTALL TERMINAL TO CONNECTOR (a) Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with terminal retainer in thetemporary lock position.

(b) Push the secondary locking device or terminal retainer into the full lock position.

5. CONNECT CONNECTOR

WhereEverybodyKnowsYourName