LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: fuses, fuel, bulb, warning lights, tire type, fuse box location, engine oil capacity

Page 791 of 4087

NGOK

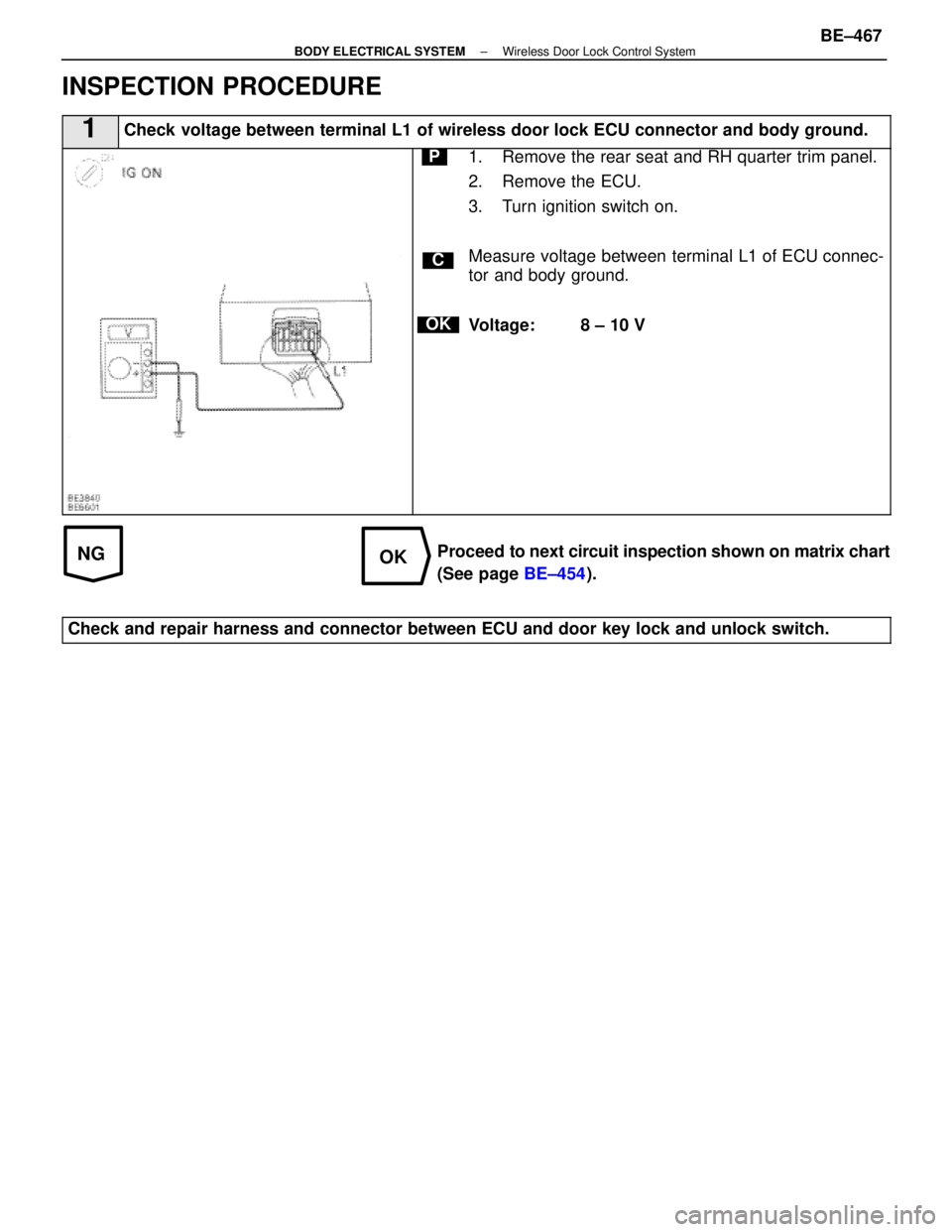

INSPECTION PROCEDURE

1Check voltage between terminal L1 of wireless door lock ECU connector and bod\

y ground.

C

OK

P1. Remove the rear seat and RH quarter trim panel.

2. Remove the ECU.

3. Turn ignition switch on.

Measure voltage between terminal L1 of ECU connec-

tor and body ground.

Voltage: 8 ± 10 V

Proceed to next circuit inspection shown on matrix chart

(See page BE±454).

Check and repair harness and connector between ECU and door key lock and\

unlock switch.

±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control SystemBE±467

WhereEverybodyKnowsYourName

Page 792 of 4087

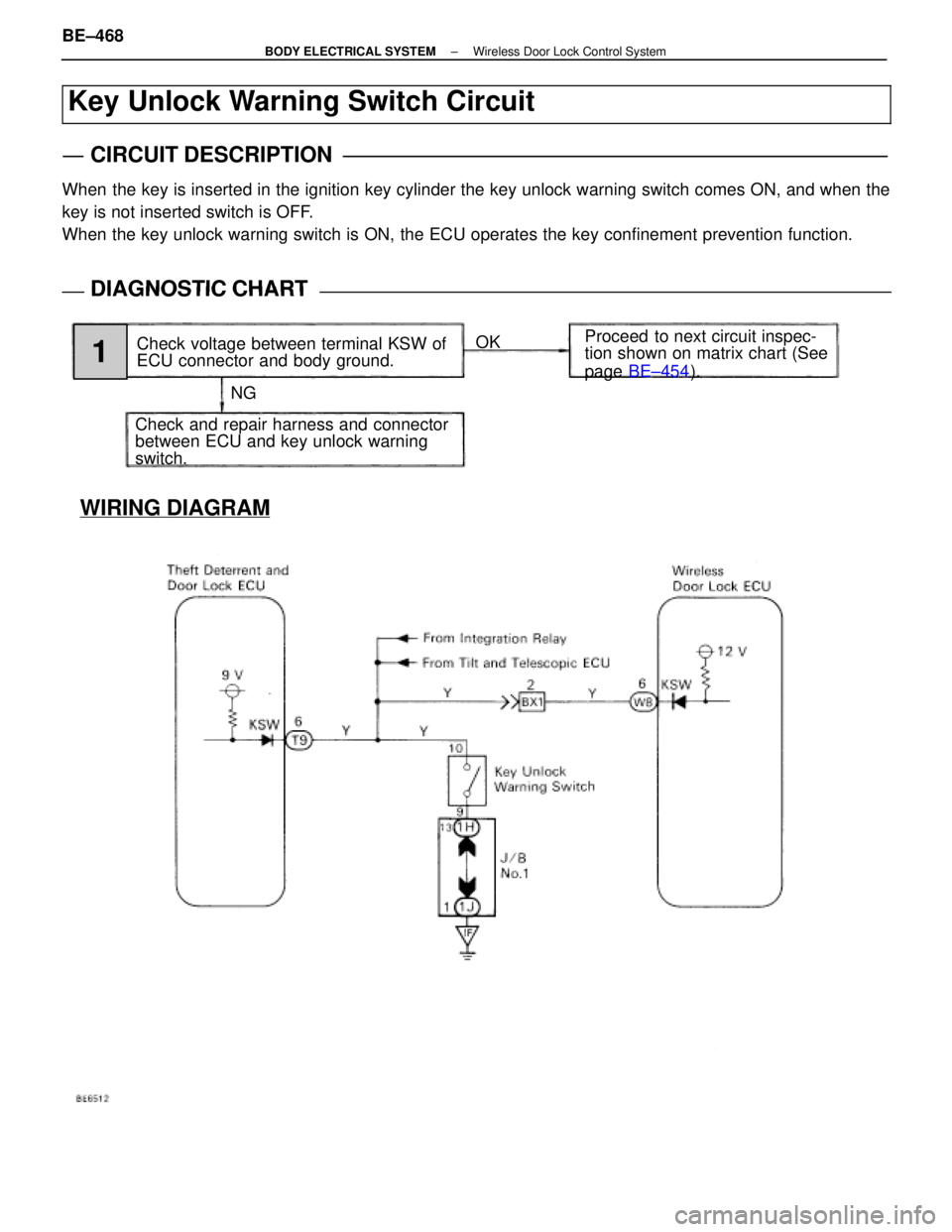

WIRING DIAGRAM

Key Unlock Warning Switch Circuit

CIRCUIT DESCRIPTION

When the key is inserted in the ignition key cylinder the key unlock warning\

switch comes ON, and when the

key is not inserted switch is OFF.

When the key unlock warning switch is ON, the ECU operates the key confi\

nement prevention function.

DIAGNOSTIC CHARTDIAGNOSTIC CHART

NGOK

Proceed to next circuit inspec-

tion shown on matrix chart (See

page

BE±454 ).

Check voltage between terminal KSW of

ECU connector and body ground.

Check and repair harness and connector

between ECU and key unlock warning

switch.

1

BE±468±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control System

WhereEverybodyKnowsYourName

Page 793 of 4087

NGOK

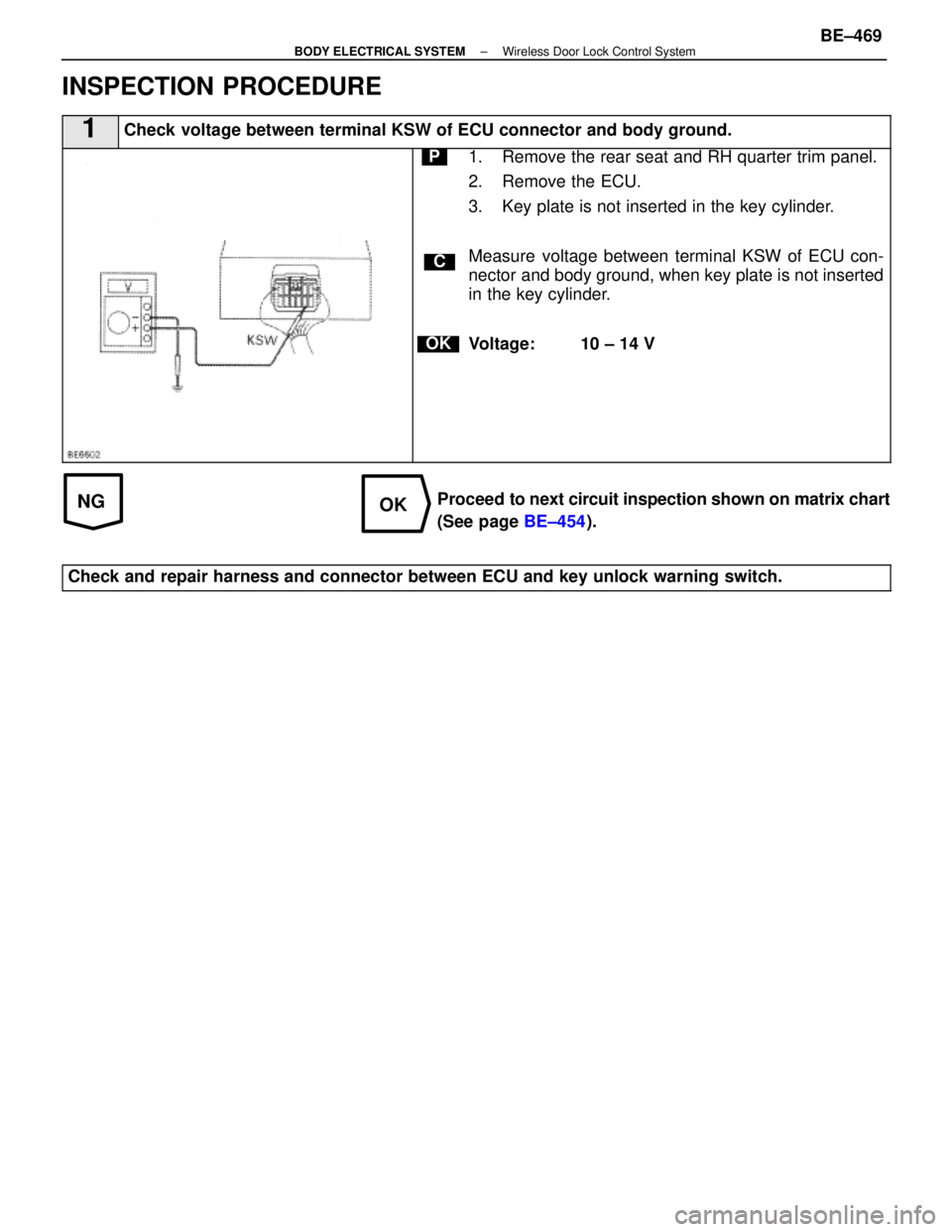

INSPECTION PROCEDURE

1Check voltage between terminal KSW of ECU connector and body ground.

C

OK

P1. Remove the rear seat and RH quarter trim panel.

2. Remove the ECU.

3. Key plate is not inserted in the key cylinder.

Measure voltage between terminal KSW of ECU con-

nector and body ground, when key plate is not inserted

in the key cylinder.

Voltage: 10 ± 14 V

Proceed to next circuit inspection shown on matrix chart

(See page BE±454).

Check and repair harness and connector between ECU and key unlock warnin\

g switch.

±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control SystemBE±469

WhereEverybodyKnowsYourName

Page 794 of 4087

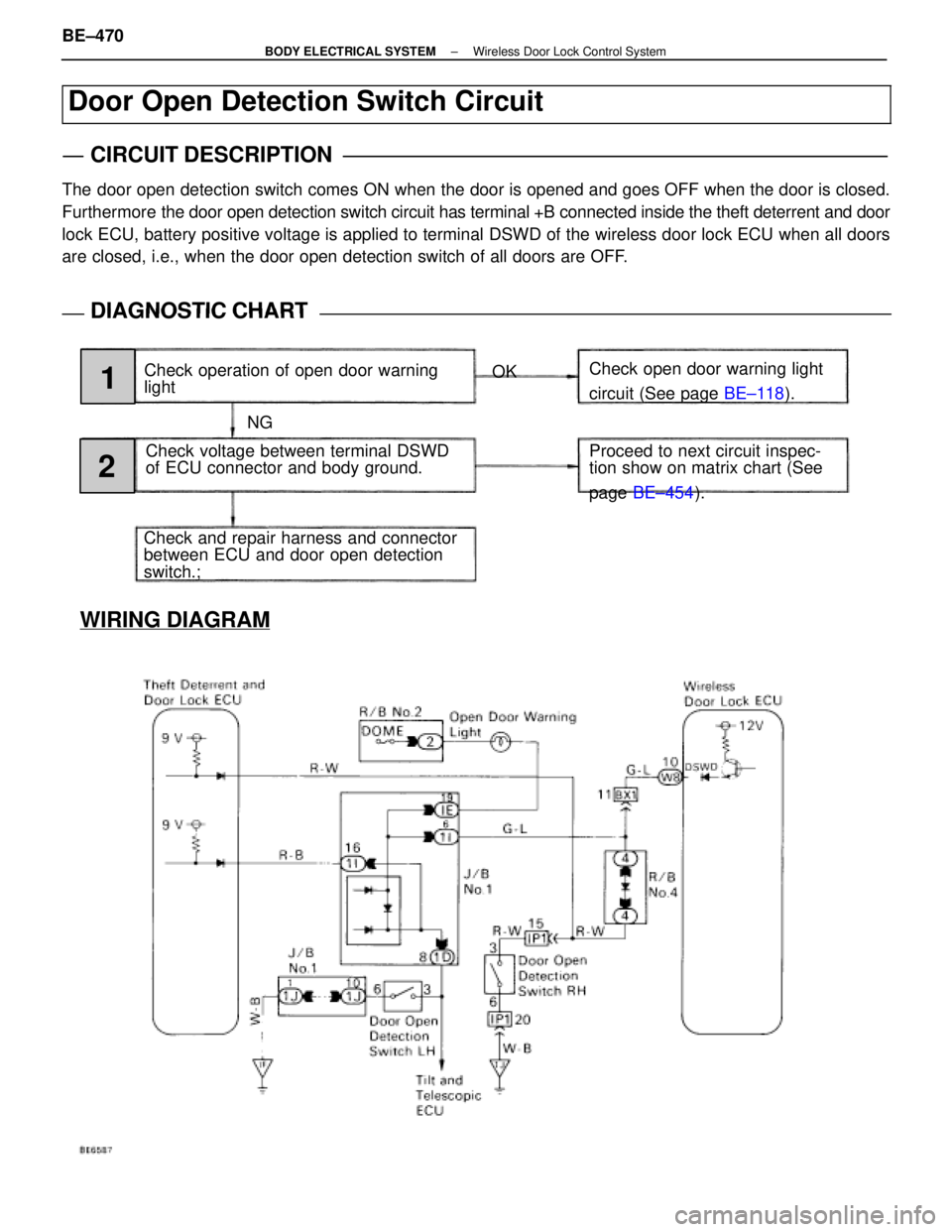

WIRING DIAGRAM

Door Open Detection Switch Circuit

CIRCUIT DESCRIPTION

The door open detection switch comes ON when the door is opened and goes OFF when the door is closed.

Furthermore the door open detection switch circuit has terminal +B connected inside \

the theft deterrent and door

lock ECU, battery positive voltage is applied to terminal DSWD of the wirele\

ss door lock ECU when all doors

are closed, i.e., when the door open detection switch of all doors are O\

FF.

DIAGNOSTIC CHARTDIAGNOSTIC CHART

NG OK

Check open door warning light

circuit (See page

BE±118).

Check operation of open door warning

light

Check voltage between terminal DSWD

of ECU connector and body ground. Proceed to next circuit inspec-

tion show on matrix chart (See

page

BE±454 ).

Check and repair harness and connector

between ECU and door open detection

switch.;

1

2

BE±470±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control System

WhereEverybodyKnowsYourName

Page 795 of 4087

OKNG

NGOK

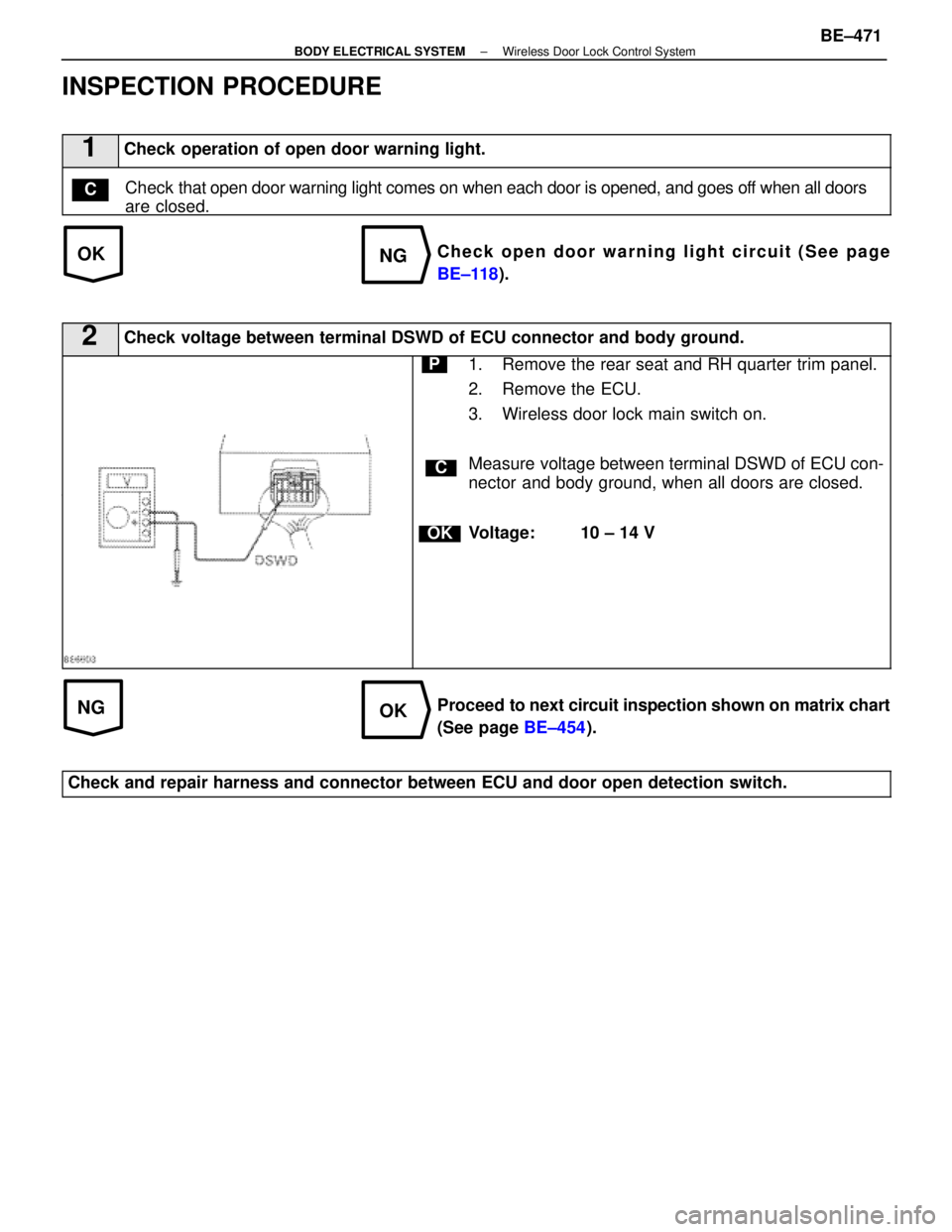

INSPECTION PROCEDURE

1Check operation of open door warning light.

Check that open door warning light comes on when each door is opened, and goes\

off when all doors

are closed.C

Check open door warning light circuit (See page

BE±118 ).

2Check voltage between terminal DSWD of ECU connector and body ground.

C

OK

P1. Remove the rear seat and RH quarter trim panel.

2. Remove the ECU.

3. Wireless door lock main switch on.

Measure voltage between terminal DSWD of ECU con-

nector and body ground, when all doors are closed.

Voltage: 10 ± 14 V

Proceed to next circuit inspection shown on matrix chart

(See page BE±454).

Check and repair harness and connector between ECU and door open detecti\

on switch.

±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control SystemBE±471

WhereEverybodyKnowsYourName

Page 796 of 4087

±MEMO± BE±472

±

BODY ELECTRICAL SYSTEM Wireless Door Lock Control System

WhereEverybodyKnowsYourName

Page 797 of 4087

BODY ELECTRICAL SYSTEM

±

BODY ELECTRICAL SYSTEMBE±1

WhereEverybodyKnowsYourName

Page 798 of 4087

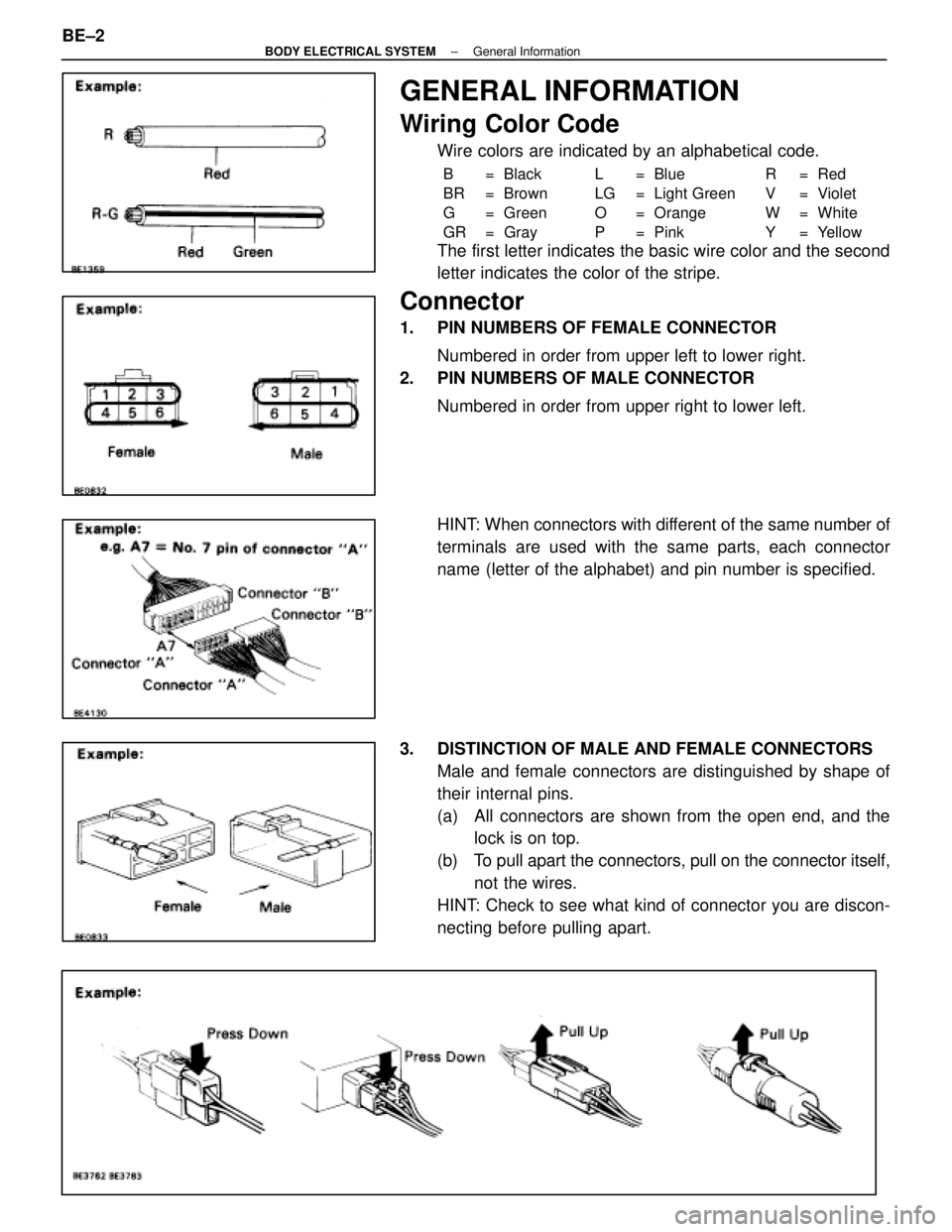

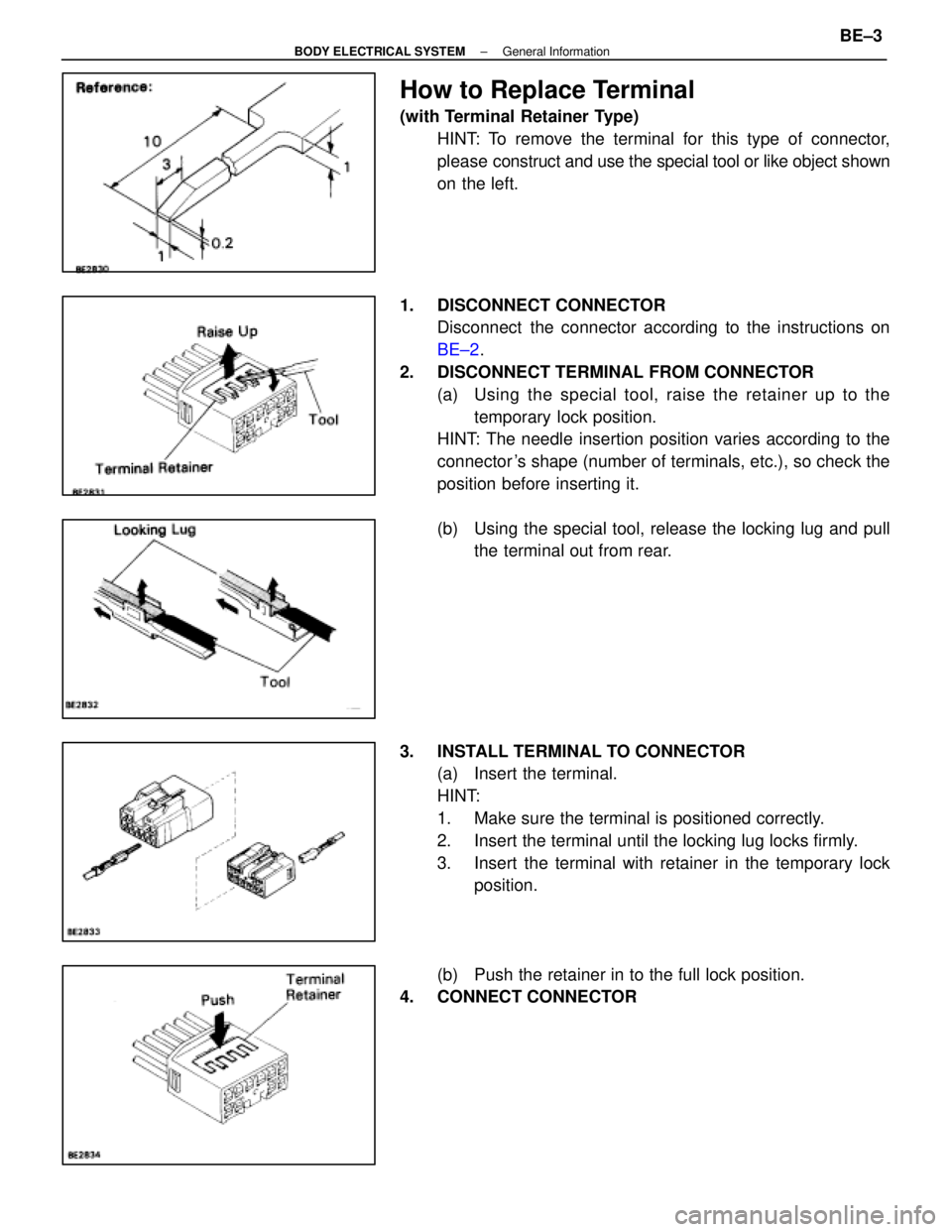

GENERAL INFORMATION

Wiring Color Code

Wire colors are indicated by an alphabetical code.

B = Black L = Blue R = Red

BR = Brown LG = Light Green V = Violet

G = Green O = Orange W = White

GR = Gray P = Pink Y = Yellow

The first letter indicates the basic wire color and the second

letter indicates the color of the stripe.

Connector

1. PIN NUMBERS OF FEMALE CONNECTORNumbered in order from upper left to lower right.

2. PIN NUMBERS OF MALE CONNECTOR

Numbered in order from upper right to lower left.

HINT: When connectors with different of the same number of

terminals are used with the same parts, each connector

name (letter of the alphabet) and pin number is specified.

3. DISTINCTION OF MALE AND FEMALE CONNECTORS Male and female connectors are distinguished by shape of

their internal pins.

(a) All connectors are shown from the open end, and thelock is on top.

(b) To pull apart the connectors, pull on the connector itself, not the wires.

HINT: Check to see what kind of connector you are discon-

necting before pulling apart.

BE±2

±

BODY ELECTRICAL SYSTEM General Information

WhereEverybodyKnowsYourName

Page 799 of 4087

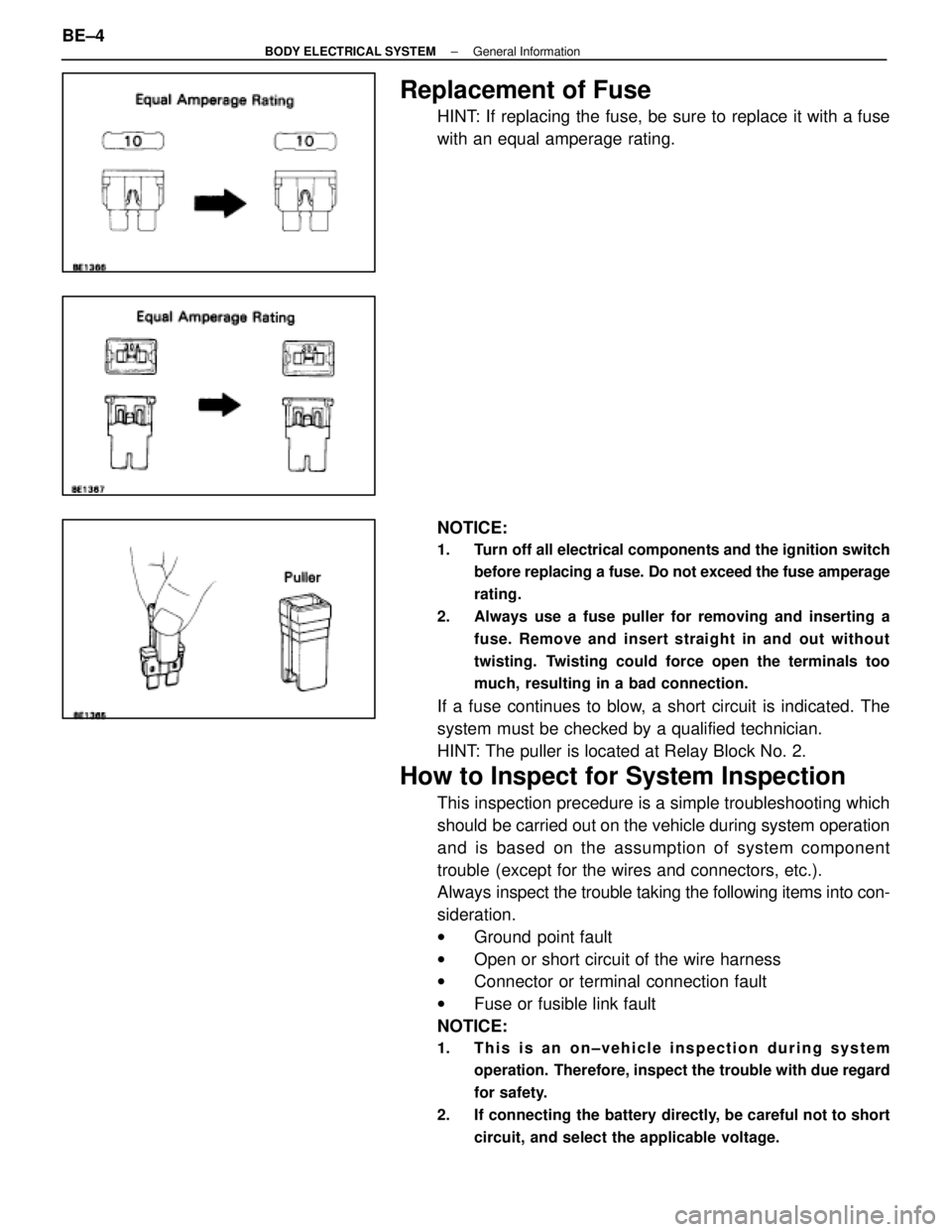

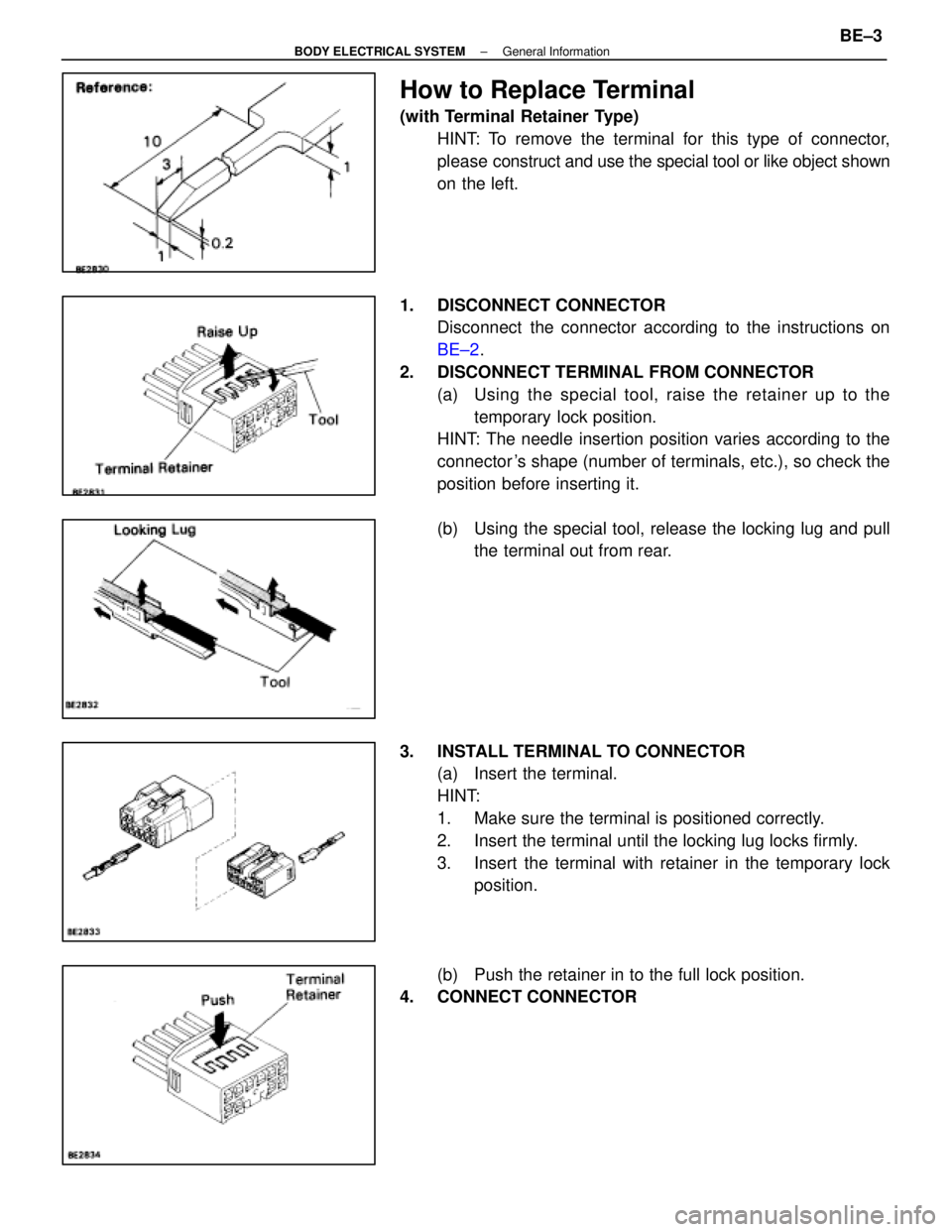

How to Replace Terminal

(with Terminal Retainer Type)HINT: To remove the terminal for this type of connector,

please construct and use the special tool or like object shown

on the left.

1. DISCONNECT CONNECTOR Disconnect the connector according to the instructions on

BE±2 .

2. DISCONNECT TERMINAL FROM CONNECTOR (a) Using the special tool, raise the retainer up to thetemporary lock position.

HINT: The needle insertion position varies according to the

connector 's shape (number of terminals, etc.), so check the

position before inserting it.

(b) Using the special tool, release the locking lug and pull the terminal out from rear.

3. INSTALL TERMINAL TO CONNECTOR (a) Insert the terminal.

HINT:

1. Make sure the terminal is positioned correctly.

2. Insert the terminal until the locking lug locks firmly.

3. Insert the terminal with retainer in the temporary lockposition.

(b) Push the retainer in to the full lock position.

4. CONNECT CONNECTOR

±

BODY ELECTRICAL SYSTEM General InformationBE±3

WhereEverybodyKnowsYourName

Page 800 of 4087

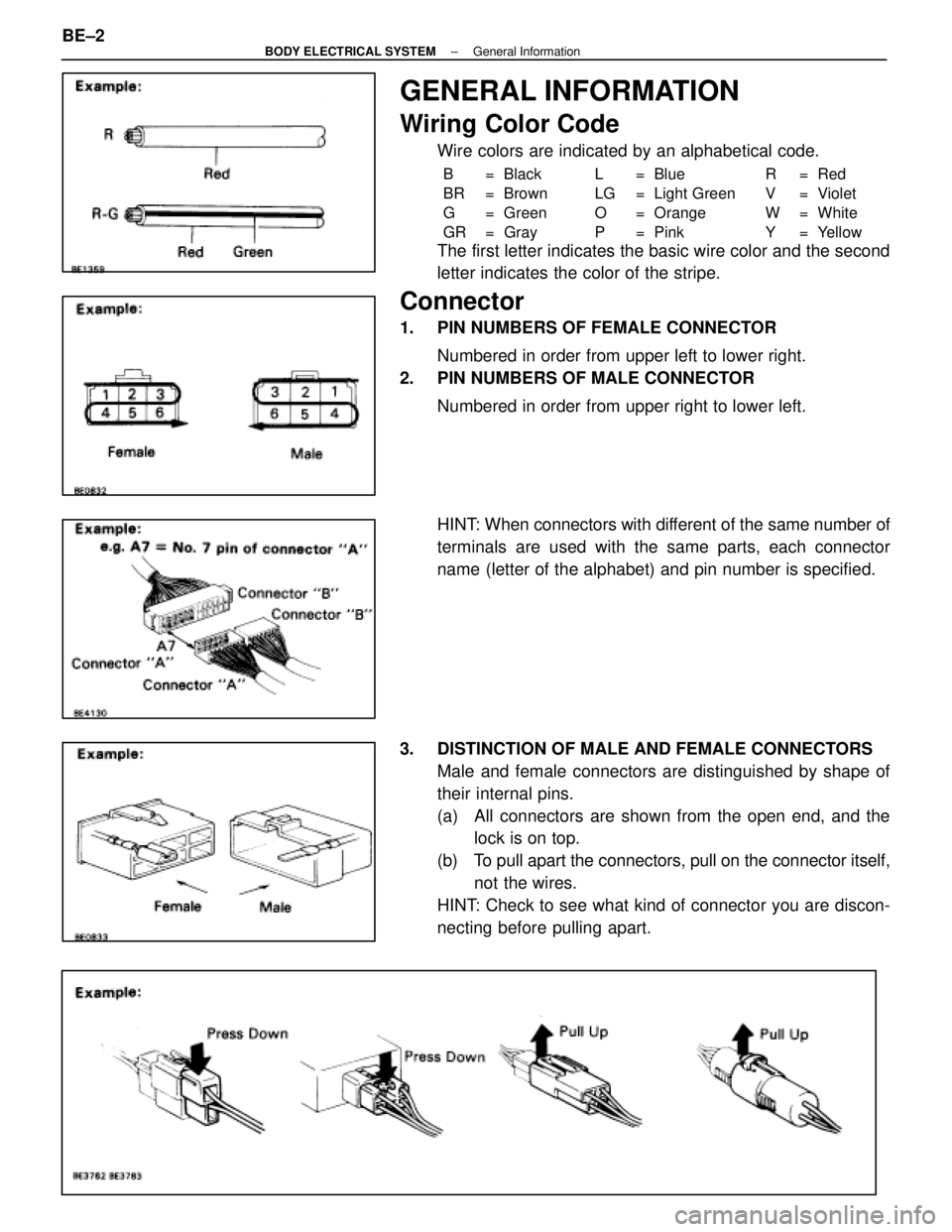

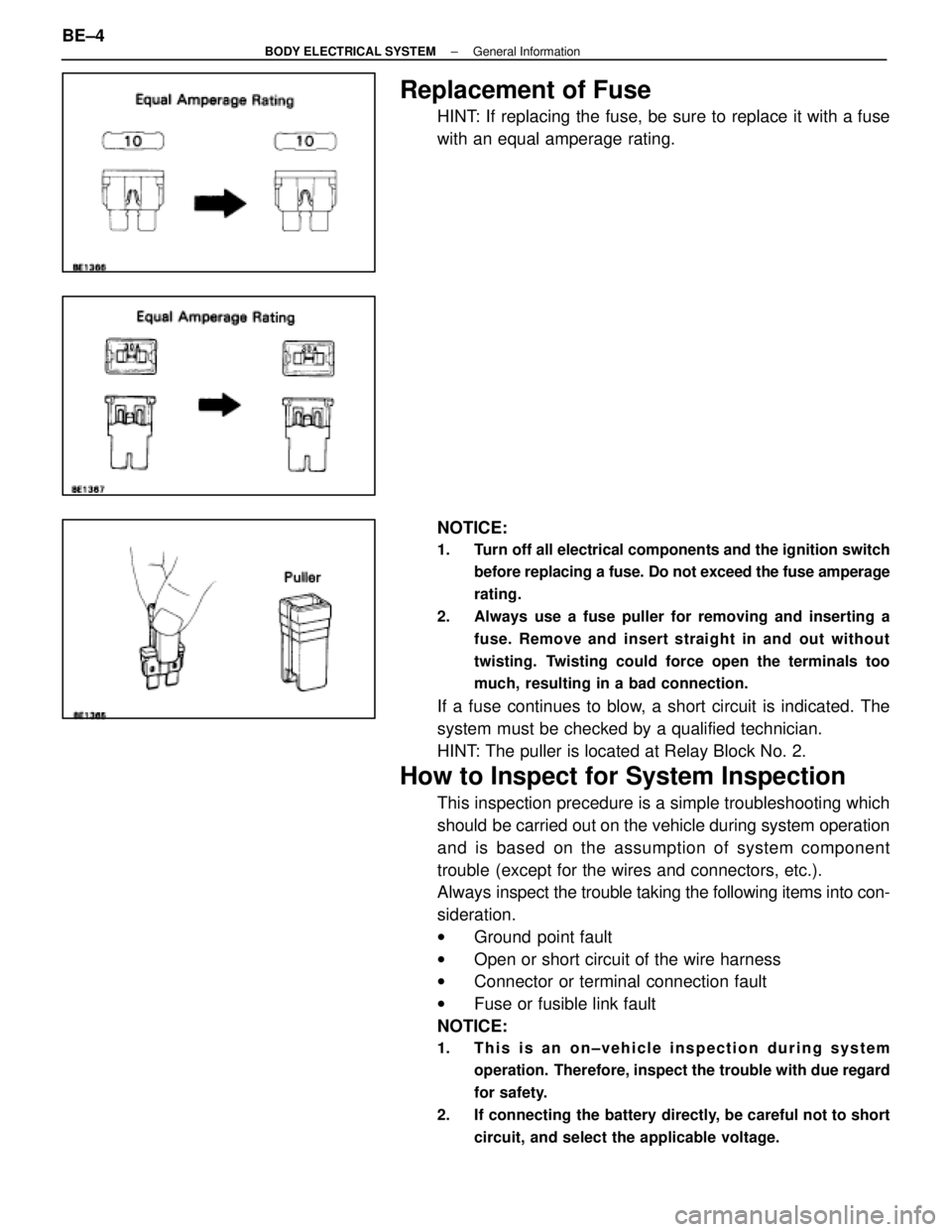

Replacement of Fuse

HINT: If replacing the fuse, be sure to replace it with a fuse

with an equal amperage rating.

NOTICE:

1. Turn off all electrical components and the ignition switchbefore replacing a fuse. Do not exceed the fuse amperage

rating.

2. Always use a fuse puller for removing and inserting a fuse. Remove and insert straight in and out without

twisting. Twisting could force open the terminals too

much, resulting in a bad connection.

If a fuse continues to blow, a short circuit is indicated. The

system must be checked by a qualified technician.

HINT: The puller is located at Relay Block No. 2.

How to Inspect for System Inspection

This inspection precedure is a simple troubleshooting which

should be carried out on the vehicle during system operation

and is based on the assumption of system component

trouble (except for the wires and connectors, etc.).

Always inspect the trouble taking the following items into con-

sideration.

wGround point fault

w Open or short circuit of the wire harness

w Connector or terminal connection fault

w Fuse or fusible link fault

NOTICE:

1. This is an on±vehicle inspection during system

operation. Therefore, inspect the trouble with due regard

for safety.

2. If connecting the battery directly, be careful not to short circuit, and select the applicable voltage.

BE±4±

BODY ELECTRICAL SYSTEM General Information

WhereEverybodyKnowsYourName

Trending: fuel, diagram, seats, service indicator, interior lights, air bleeding, transmission oil