lock LINCOLN AVIATOR 2004 Manual Online

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2004, Model line: AVIATOR, Model: LINCOLN AVIATOR 2004Pages: 336, PDF Size: 3.69 MB

Page 236 of 336

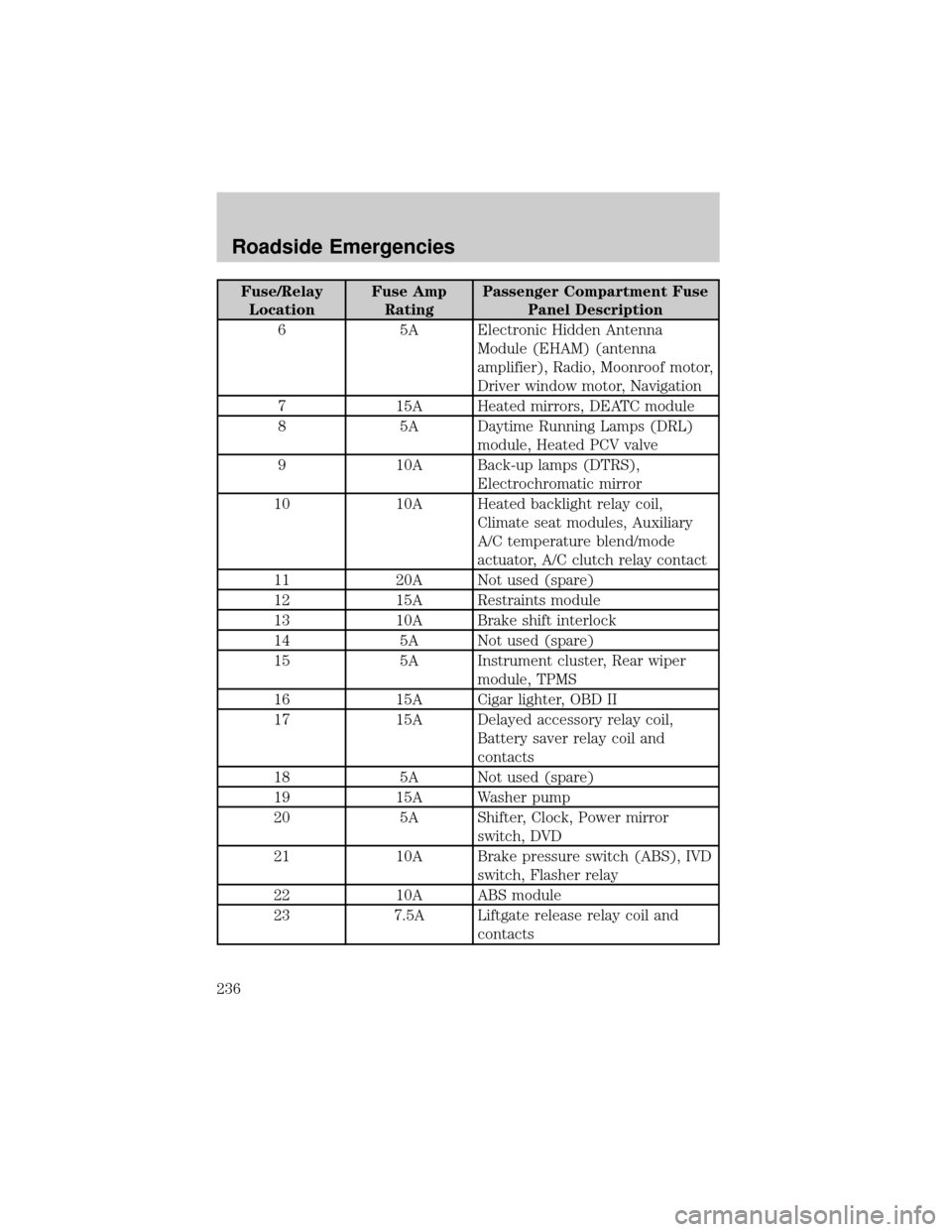

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

6 5A Electronic Hidden Antenna

Module (EHAM) (antenna

amplifier), Radio, Moonroof motor,

Driver window motor, Navigation

7 15A Heated mirrors, DEATC module

8 5A Daytime Running Lamps (DRL)

module, Heated PCV valve

9 10A Back-up lamps (DTRS),

Electrochromatic mirror

10 10A Heated backlight relay coil,

Climate seat modules, Auxiliary

A/C temperature blend/mode

actuator, A/C clutch relay contact

11 20A Not used (spare)

12 15A Restraints module

13 10A Brake shift interlock

14 5A Not used (spare)

15 5A Instrument cluster, Rear wiper

module, TPMS

16 15A Cigar lighter, OBD II

17 15A Delayed accessory relay coil,

Battery saver relay coil and

contacts

18 5A Not used (spare)

19 15A Washer pump

20 5A Shifter, Clock, Power mirror

switch, DVD

21 10A Brake pressure switch (ABS), IVD

switch, Flasher relay

22 10A ABS module

23 7.5A Liftgate release relay coil and

contacts

Roadside Emergencies

236

Page 237 of 336

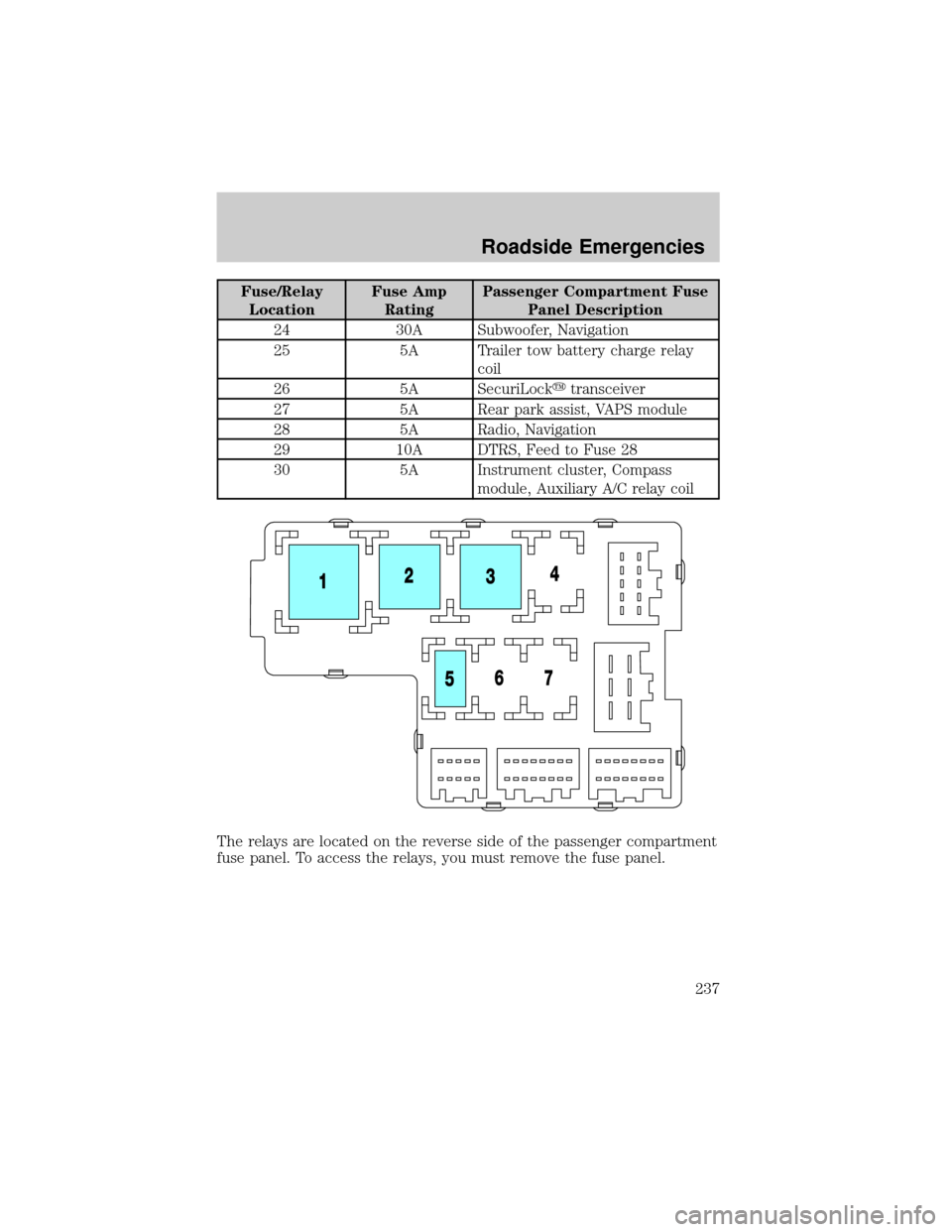

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse

Panel Description

24 30A Subwoofer, Navigation

25 5A Trailer tow battery charge relay

coil

26 5A SecuriLockytransceiver

27 5A Rear park assist, VAPS module

28 5A Radio, Navigation

29 10A DTRS, Feed to Fuse 28

30 5A Instrument cluster, Compass

module, Auxiliary A/C relay coil

The relays are located on the reverse side of the passenger compartment

fuse panel. To access the relays, you must remove the fuse panel.

Roadside Emergencies

237

Page 239 of 336

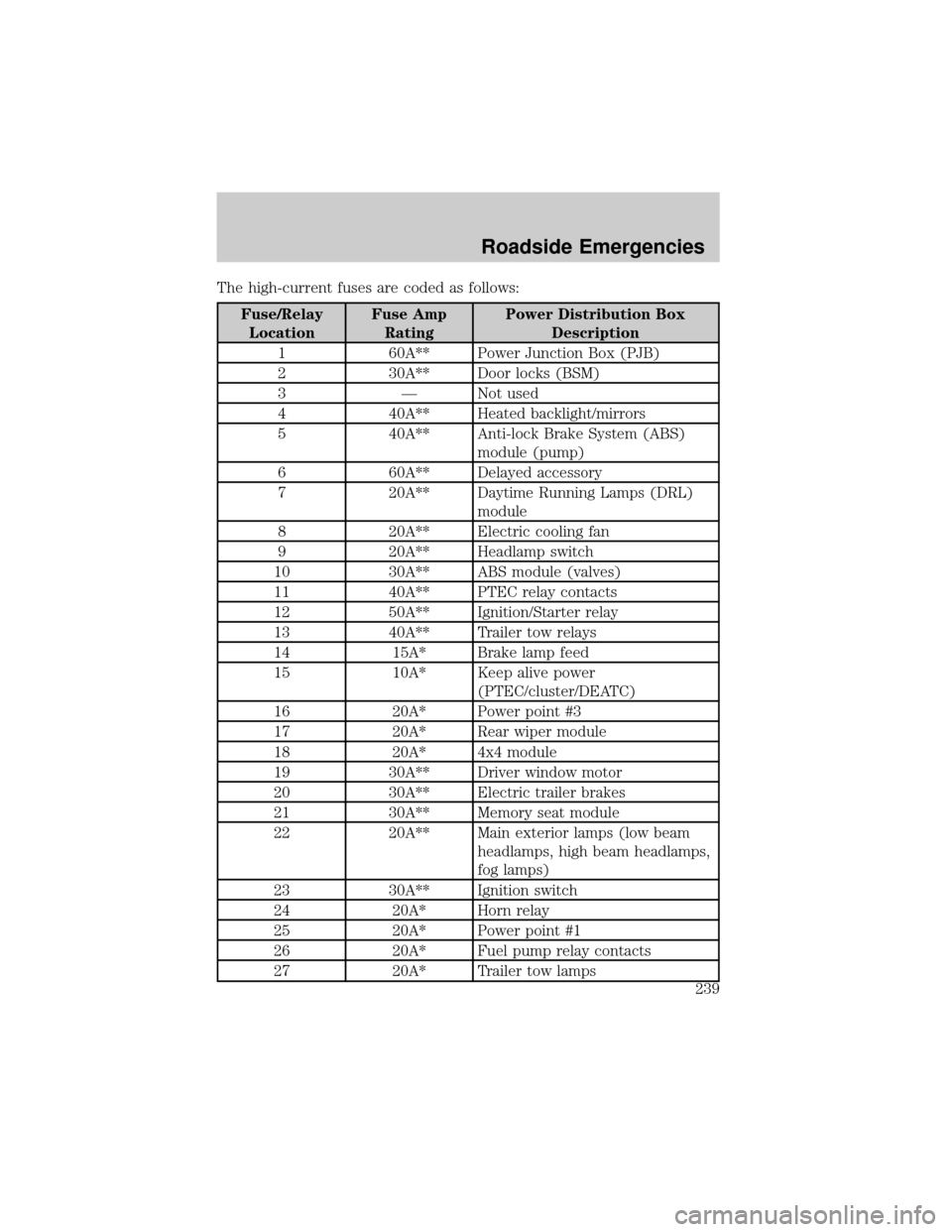

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

1 60A** Power Junction Box (PJB)

2 30A** Door locks (BSM)

3 Ð Not used

4 40A** Heated backlight/mirrors

5 40A** Anti-lock Brake System (ABS)

module (pump)

6 60A** Delayed accessory

7 20A** Daytime Running Lamps (DRL)

module

8 20A** Electric cooling fan

9 20A** Headlamp switch

10 30A** ABS module (valves)

11 40A** PTEC relay contacts

12 50A** Ignition/Starter relay

13 40A** Trailer tow relays

14 15A* Brake lamp feed

15 10A* Keep alive power

(PTEC/cluster/DEATC)

16 20A* Power point #3

17 20A* Rear wiper module

18 20A* 4x4 module

19 30A** Driver window motor

20 30A** Electric trailer brakes

21 30A** Memory seat module

22 20A** Main exterior lamps (low beam

headlamps, high beam headlamps,

fog lamps)

23 30A** Ignition switch

24 20A* Horn relay

25 20A* Power point #1

26 20A* Fuel pump relay contacts

27 20A* Trailer tow lamps

Roadside Emergencies

239

Page 244 of 336

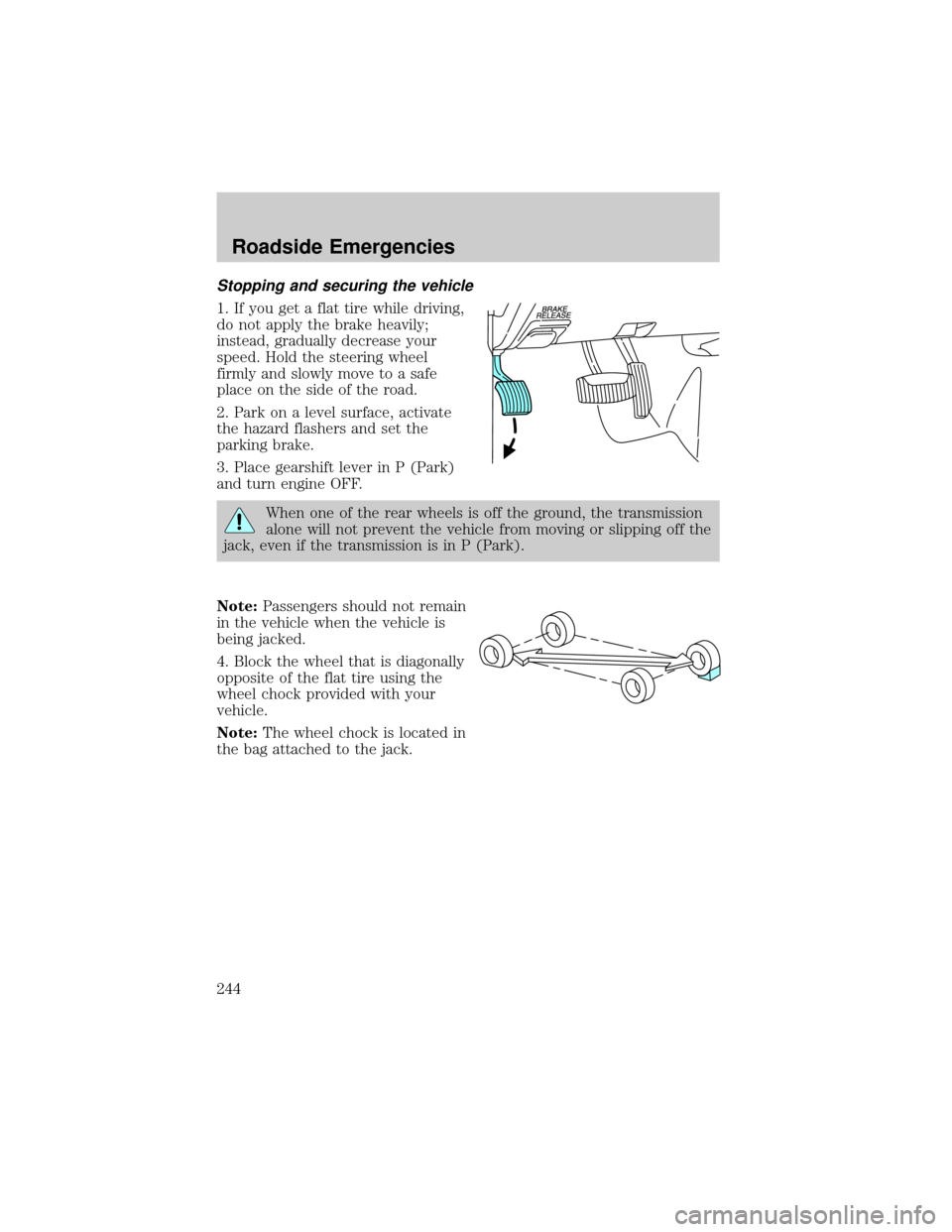

Stopping and securing the vehicle

1. If you get a flat tire while driving,

do not apply the brake heavily;

instead, gradually decrease your

speed. Hold the steering wheel

firmly and slowly move to a safe

place on the side of the road.

2. Park on a level surface, activate

the hazard flashers and set the

parking brake.

3. Place gearshift lever in P (Park)

and turn engine OFF.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park).

Note:Passengers should not remain

in the vehicle when the vehicle is

being jacked.

4. Block the wheel that is diagonally

opposite of the flat tire using the

wheel chock provided with your

vehicle.

Note:The wheel chock is located in

the bag attached to the jack.

Roadside Emergencies

244

Page 245 of 336

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire Under the vehicle, just in front of

the rear bumper. The spare tire

winch drive nut is located at the

rear center of the cargo area

under a lid.

Jack, lug nut wrench, jack handle,

wheel chockBehind the rear seat under the

carpeted floor lid in the cargo

floor. The tools are located in a

bag attached to the jack.

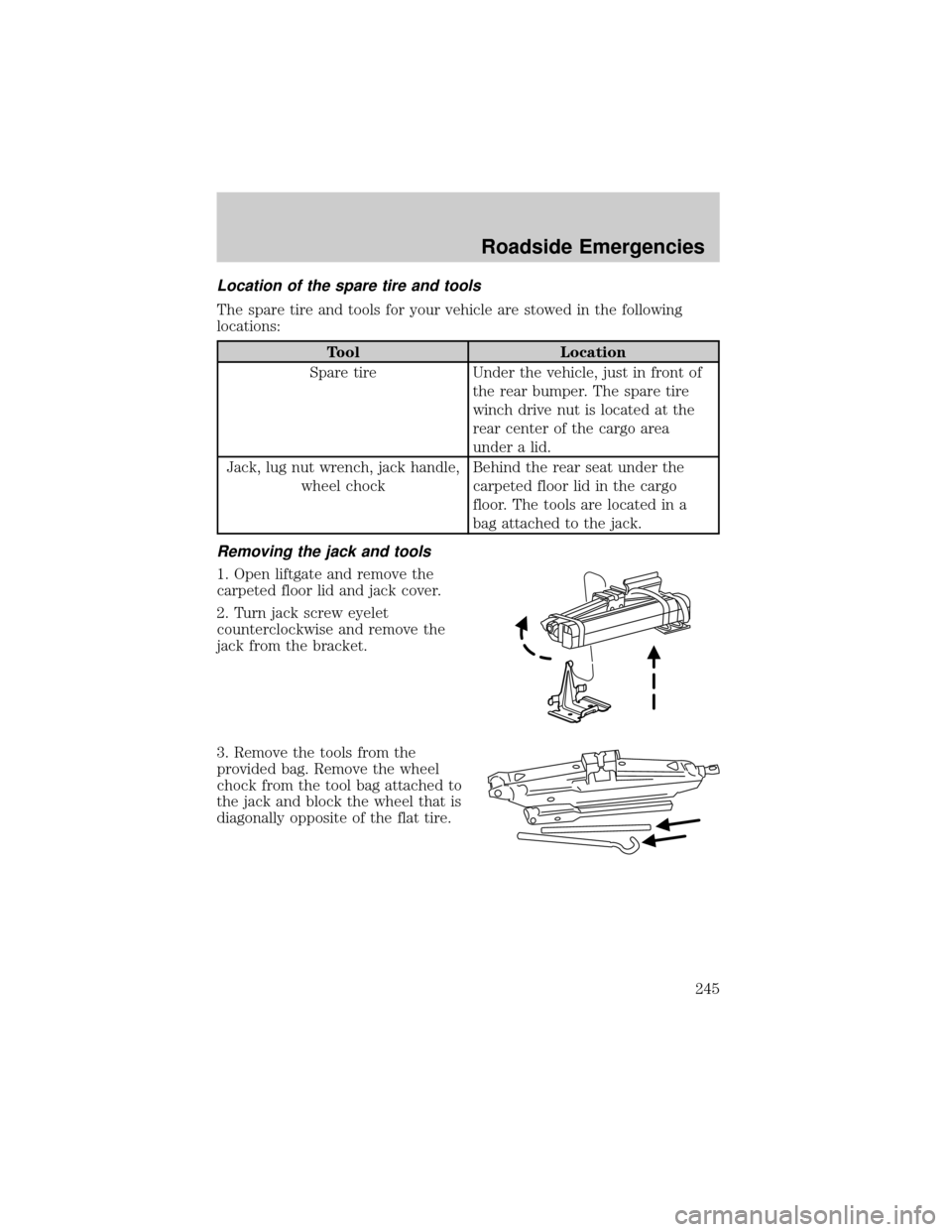

Removing the jack and tools

1. Open liftgate and remove the

carpeted floor lid and jack cover.

2. Turn jack screw eyelet

counterclockwise and remove the

jack from the bracket.

3. Remove the tools from the

provided bag. Remove the wheel

chock from the tool bag attached to

the jack and block the wheel that is

diagonally opposite of the flat tire.

Roadside Emergencies

245

Page 247 of 336

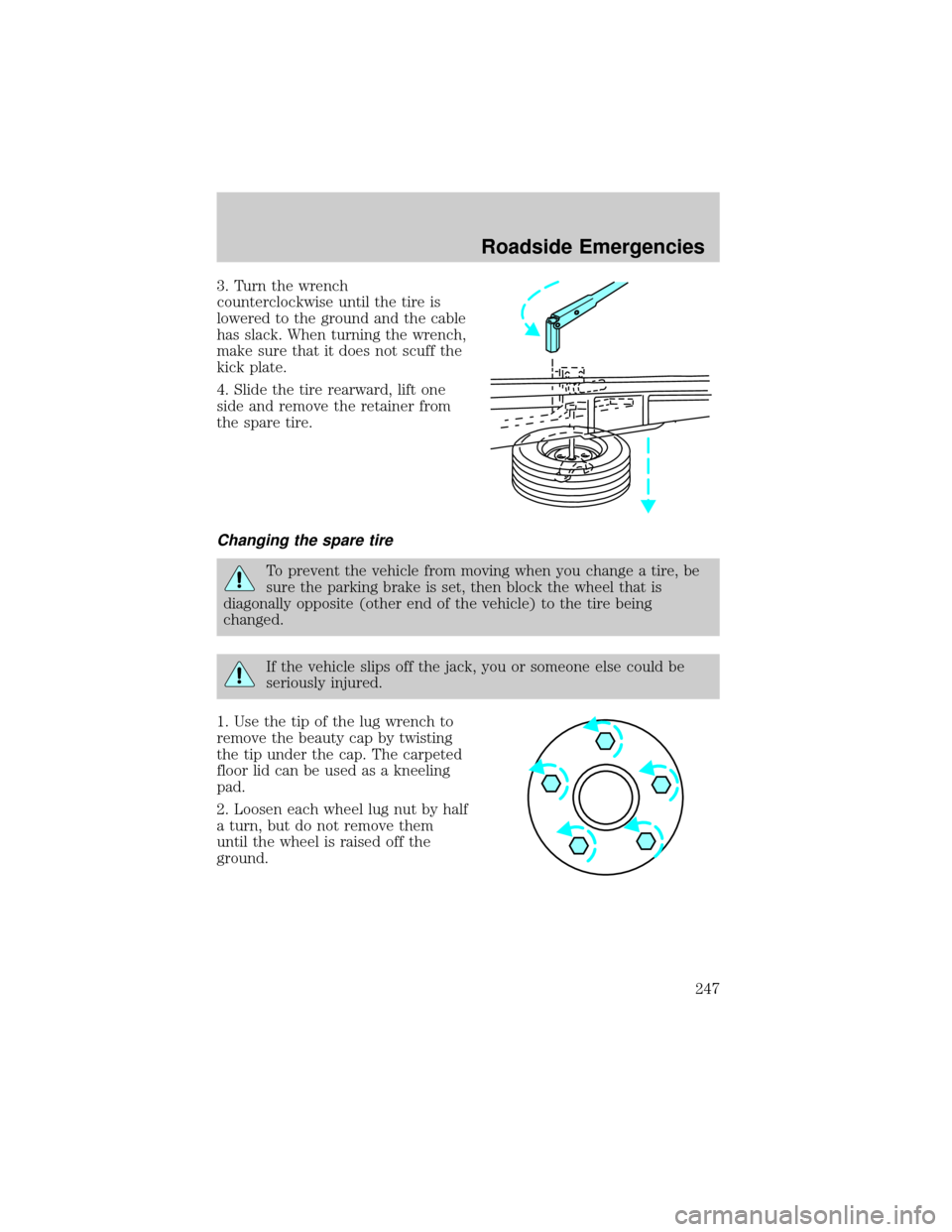

3. Turn the wrench

counterclockwise until the tire is

lowered to the ground and the cable

has slack. When turning the wrench,

make sure that it does not scuff the

kick plate.

4. Slide the tire rearward, lift one

side and remove the retainer from

the spare tire.

Changing the spare tire

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block the wheel that is

diagonally opposite (other end of the vehicle) to the tire being

changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

1. Use the tip of the lug wrench to

remove the beauty cap by twisting

the tip under the cap. The carpeted

floor lid can be used as a kneeling

pad.

2. Loosen each wheel lug nut by half

a turn, but do not remove them

until the wheel is raised off the

ground.

Roadside Emergencies

247

Page 248 of 336

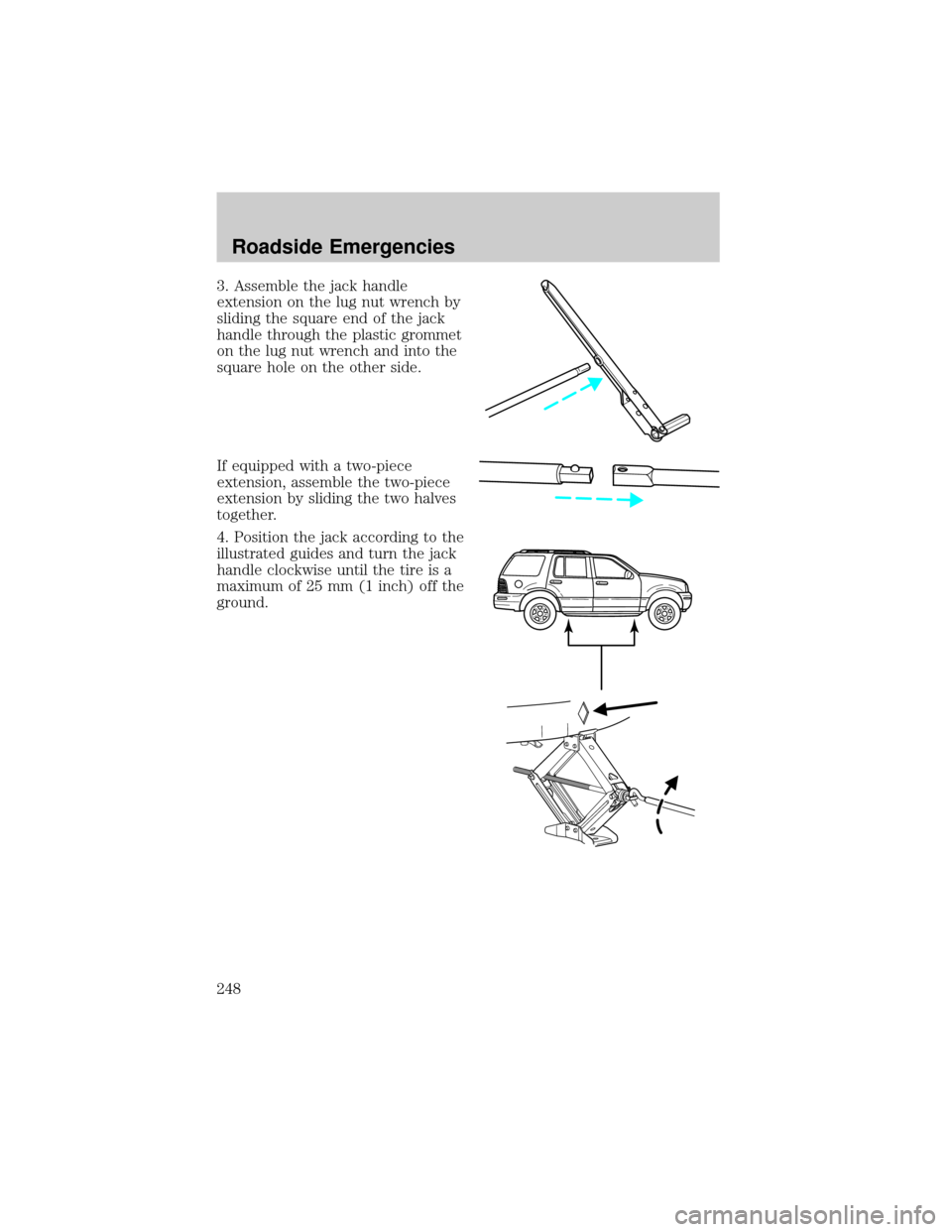

3. Assemble the jack handle

extension on the lug nut wrench by

sliding the square end of the jack

handle through the plastic grommet

on the lug nut wrench and into the

square hole on the other side.

If equipped with a two-piece

extension, assemble the two-piece

extension by sliding the two halves

together.

4. Position the jack according to the

illustrated guides and turn the jack

handle clockwise until the tire is a

maximum of 25 mm (1 inch) off the

ground.

Roadside Emergencies

248

Page 249 of 336

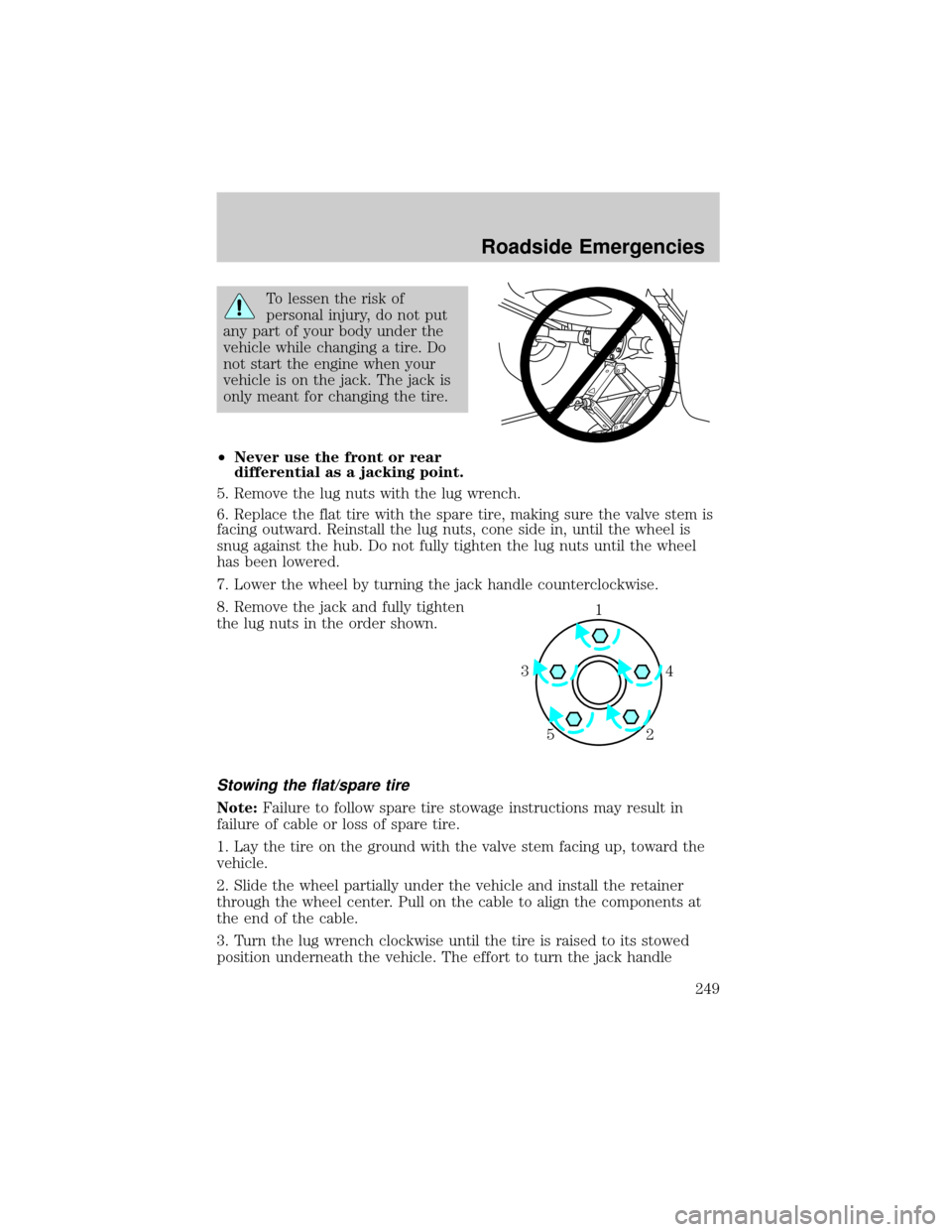

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

²Never use the front or rear

differential as a jacking point.

5. Remove the lug nuts with the lug wrench.

6. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts, cone side in, until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

7. Lower the wheel by turning the jack handle counterclockwise.

8. Remove the jack and fully tighten

the lug nuts in the order shown.

Stowing the flat/spare tire

Note:Failure to follow spare tire stowage instructions may result in

failure of cable or loss of spare tire.

1. Lay the tire on the ground with the valve stem facing up, toward the

vehicle.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the lug wrench clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

1

4 3

2 5

Roadside Emergencies

249

Page 250 of 336

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. If your vehicle is equipped with a spare tire lock and key, be sure to

install the spare tire lock into the bumper drive tube with the spare tire

lock key and jack handle.

6. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

Re-stowing the jack and tools

1. Unblock the wheels.

2. Replace beauty cap, stow the jack and tools in their respective

locations, making sure they are fully secured so they do not rattle when

you drive.

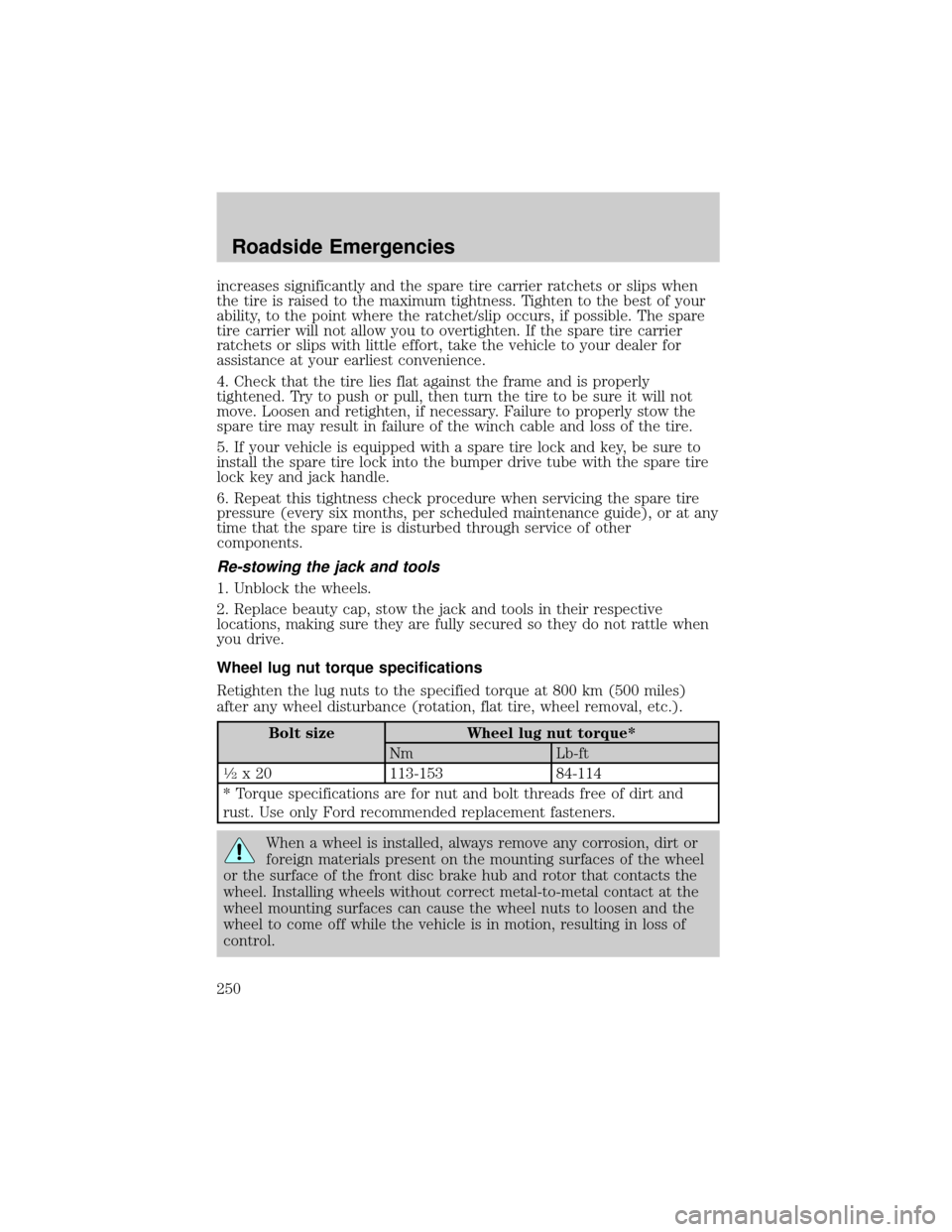

Wheel lug nut torque specifications

Retighten the lug nuts to the specified torque at 800 km (500 miles)

after any wheel disturbance (rotation, flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

1¤2x 20 113-153 84-114

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the front disc brake hub and rotor that contacts the

wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the

wheel to come off while the vehicle is in motion, resulting in loss of

control.

Roadside Emergencies

250

Page 267 of 336

PAINT CHIPS

Your dealer has touch-up paint and sprays to match your vehicle's color.

Take your color code (printed on a sticker in the driver's door jam) to

your dealer to ensure you get the correct color.

²Remove particles such as bird droppings, tree sap, insect deposits, tar

spots, road salt and industrial fallout before repairing paint chips.

²Always read the instructions before using the products.

ALUMINUM WHEELS AND WHEEL COVERS

Aluminum wheels and wheel covers are coated with a clearcoat paint

finish. In order to maintain their shine:

²Clean weekly with Motorcraft Wheel and Tire Cleaner (ZC-37±A),

which is available from your dealer. Heavy dirt and brake dust

accumulation may require agitation with a sponge. Rinse thoroughly

with a strong stream of water.

²Never apply any cleaning chemical to hot or warm wheel rims or

covers.

²Some automatic car washes may cause damage to the finish on your

wheel rims or covers. Chemical-strength cleaners, or cleaning

chemicals, in combination with brush agitation to remove brake dust

and dirt, could wear away the clearcoat finish over time.

²Do not use hydrofluoric acid-based or high caustic-based wheel

cleaners, steel wool, fuels or strong household detergent.

²To remove tar and grease, use Motorcraft Bug and Tar Remover

(ZC-42), available from your dealer.

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

²Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

²Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

²Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

Cleaning

267