Maintenance LINCOLN MKZ 2013 Owner's Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2013, Model line: MKZ, Model: LINCOLN MKZ 2013Pages: 474, PDF Size: 3.79 MB

Page 278 of 474

Checking the fluid level

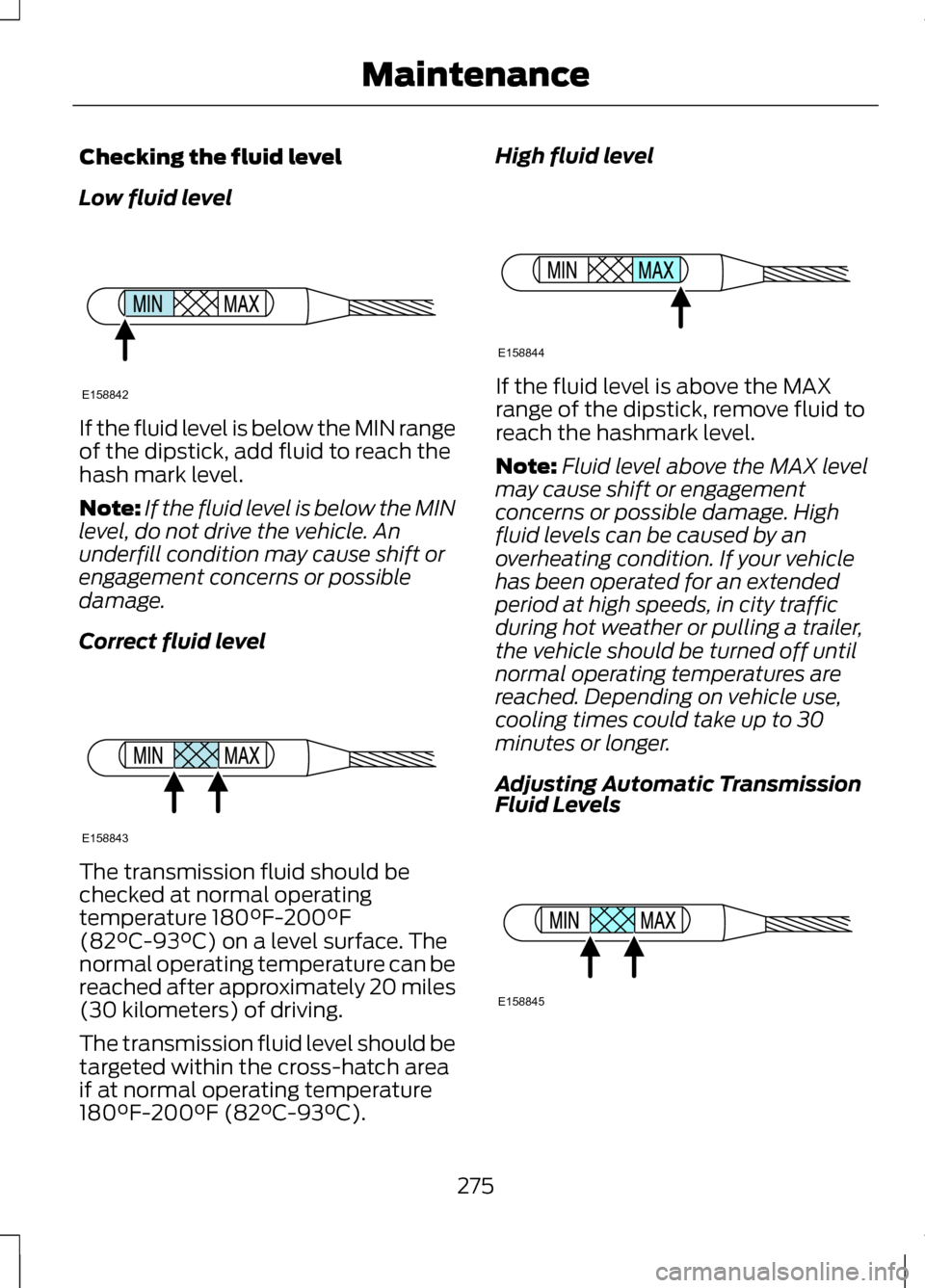

Low fluid level

If the fluid level is below the MIN range

of the dipstick, add fluid to reach the

hash mark level.

Note:

If the fluid level is below the MIN

level, do not drive the vehicle. An

underfill condition may cause shift or

engagement concerns or possible

damage.

Correct fluid level The transmission fluid should be

checked at normal operating

temperature 180°F-200°F

(82°C-93°C) on a level surface. The

normal operating temperature can be

reached after approximately 20 miles

(30 kilometers) of driving.

The transmission fluid level should be

targeted within the cross-hatch area

if at normal operating temperature

180°F-200°F (82°C-93°C). High fluid level

If the fluid level is above the MAX

range of the dipstick, remove fluid to

reach the hashmark level.

Note:

Fluid level above the MAX level

may cause shift or engagement

concerns or possible damage. High

fluid levels can be caused by an

overheating condition. If your vehicle

has been operated for an extended

period at high speeds, in city traffic

during hot weather or pulling a trailer,

the vehicle should be turned off until

normal operating temperatures are

reached. Depending on vehicle use,

cooling times could take up to 30

minutes or longer.

Adjusting Automatic Transmission

Fluid Levels 275

MaintenanceE158842 E158843 E158844 E158845

Page 279 of 474

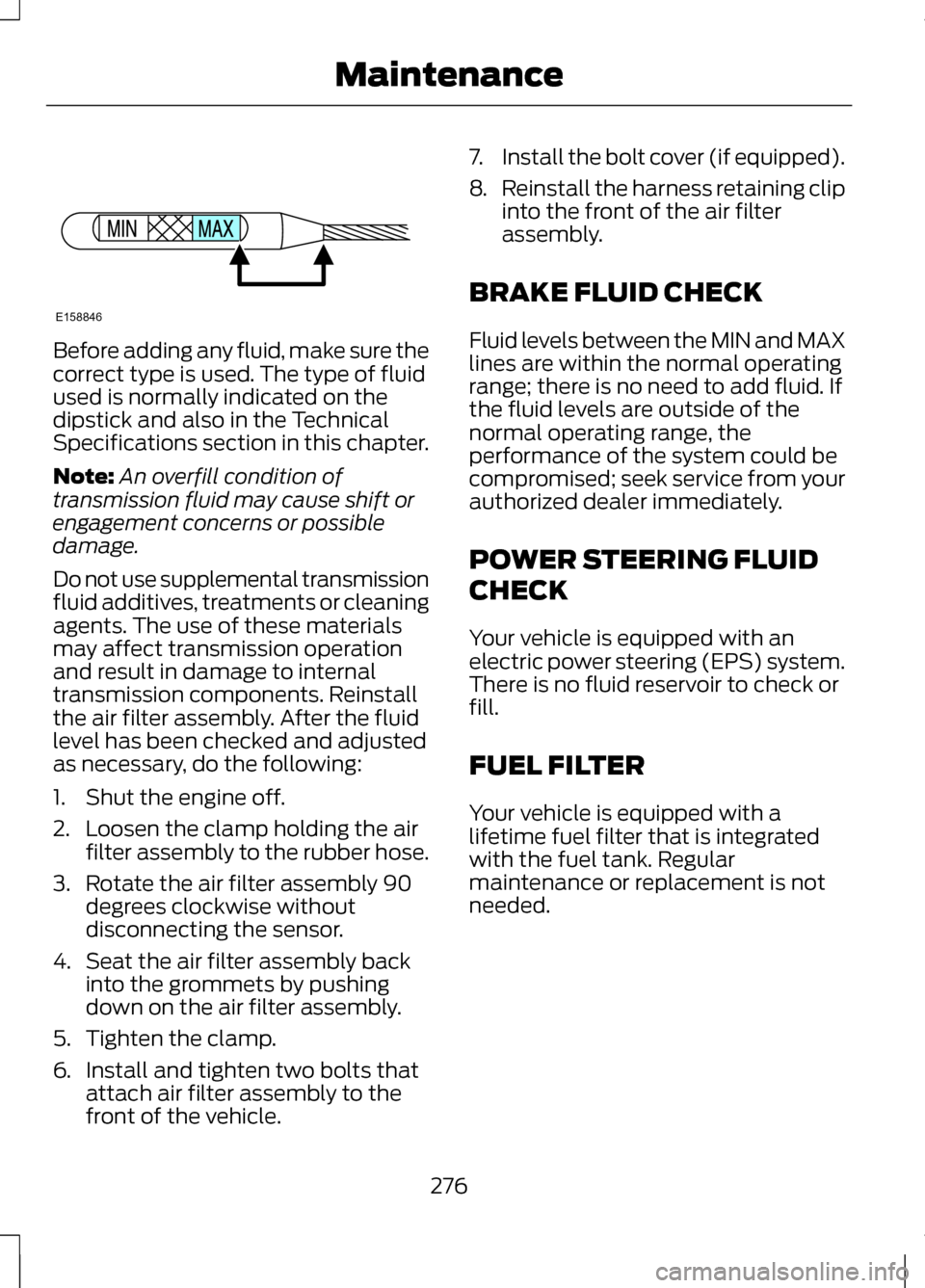

Before adding any fluid, make sure the

correct type is used. The type of fluid

used is normally indicated on the

dipstick and also in the Technical

Specifications section in this chapter.

Note:

An overfill condition of

transmission fluid may cause shift or

engagement concerns or possible

damage.

Do not use supplemental transmission

fluid additives, treatments or cleaning

agents. The use of these materials

may affect transmission operation

and result in damage to internal

transmission components. Reinstall

the air filter assembly. After the fluid

level has been checked and adjusted

as necessary, do the following:

1. Shut the engine off.

2. Loosen the clamp holding the air filter assembly to the rubber hose.

3. Rotate the air filter assembly 90 degrees clockwise without

disconnecting the sensor.

4. Seat the air filter assembly back into the grommets by pushing

down on the air filter assembly.

5. Tighten the clamp.

6. Install and tighten two bolts that

attach air filter assembly to the

front of the vehicle. 7.

Install the bolt cover (if equipped).

8. Reinstall the harness retaining clip

into the front of the air filter

assembly.

BRAKE FLUID CHECK

Fluid levels between the MIN and MAX

lines are within the normal operating

range; there is no need to add fluid. If

the fluid levels are outside of the

normal operating range, the

performance of the system could be

compromised; seek service from your

authorized dealer immediately.

POWER STEERING FLUID

CHECK

Your vehicle is equipped with an

electric power steering (EPS) system.

There is no fluid reservoir to check or

fill.

FUEL FILTER

Your vehicle is equipped with a

lifetime fuel filter that is integrated

with the fuel tank. Regular

maintenance or replacement is not

needed.

276

MaintenanceE158846

Page 280 of 474

WASHER FLUID CHECK

WARNING

If you operate your vehicle in

temperatures below 40°F (5°C),

use washer fluid with antifreeze

protection. Failure to use washer fluid

with antifreeze protection in cold

weather could result in impaired

windshield vision and increase the risk

of injury or accident. Note:

The front and rear washer

systems are supplied from the same

reservoir.

Add fluid to fill the reservoir if the level

is low. Only use a washer fluid that

meets Ford specifications. See

Capacities and Specifications

(page 325).

State or local regulations on volatile

organic compounds may restrict the

use of methanol, a common

windshield washer antifreeze additive.

Washer fluids containing

non-methanol antifreeze agents

should be used only if they provide

cold weather protection without

damaging the vehicle ’s paint finish,

wiper blades or washer system. CHANGING THE 12V

BATTERY WARNINGS

Batteries normally produce

explosive gases which can cause

personal injury. Therefore, do not

allow flames, sparks or lighted

substances to come near the battery.

When working near the battery,

always shield your face and protect

your eyes. Always provide proper

ventilation. When lifting a plastic-cased

battery, excessive pressure on

the end walls could cause acid to flow

through the vent caps, resulting in

personal injury and/or damage to the

vehicle or battery. Lift the battery with

a battery carrier or with your hands on

opposite corners. Keep batteries out of reach of

children. Batteries contain

sulfuric acid. Avoid contact with skin,

eyes or clothing. Shield your eyes

when working near the battery to

protect against possible splashing of

acid solution. In case of acid contact

with skin or eyes, flush immediately

with water for a minimum of 15

minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Battery posts, terminals and

related accessories contain lead

and lead compounds. Wash hands

after handling. 277

Maintenance

Page 281 of 474

Your vehicle is equipped with a

Motorcraft® maintenance-free

battery which normally does not

require additional water during its life

of service.

Note:

If your battery has a

cover/shield, make sure it is reinstalled

after the battery has been cleaned or

replaced.

For longer, trouble-free operation,

keep the top of the battery clean and

dry. Also, make certain the battery

cables are always tightly fastened to

the battery terminals.

If you see any corrosion on the battery

or terminals, remove the cables from

the terminals and clean with a wire

brush. You can neutralize the acid with

a solution of baking soda and water.

It is recommended that the negative

battery cable terminal be

disconnected from the battery if you

plan to store your vehicle for an

extended period of time.

To ensure proper operation of the

battery management system (BMS),

any electrical devices that are added

to the vehicle should not have their

ground connection made directly at

the negative battery post. A

connection at the negative battery

post can cause inaccurate

measurements of the battery

condition and potential incorrect

system operation. Note:

Electrical or electronic

accessories or components added to

the vehicle by the dealer or the owner

may adversely affect battery

performance and durability and may

also affect the performance of other

electrical systems in the vehicle.

When a battery replacement is

required, the battery should only be

replaced with a Ford recommended

replacement battery that matches

the electrical requirements of the

vehicle.

When the battery is disconnected or

a new battery installed, the automatic

transmission must relearn its adaptive

strategy. As a result of this, the

transmission may shift firmly when

first driven. This operation is

considered normal and will fully

update transmission operation to its

optimum shift feel.

If the battery has been disconnected

or a new battery has been installed,

the clock and the preset radio stations

must be reset once the battery is

reconnected.

Note: Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized standards

for disposal. Call your local authorized

recycling center to find out more about

recycling automotive batteries.

278

Maintenance

Page 282 of 474

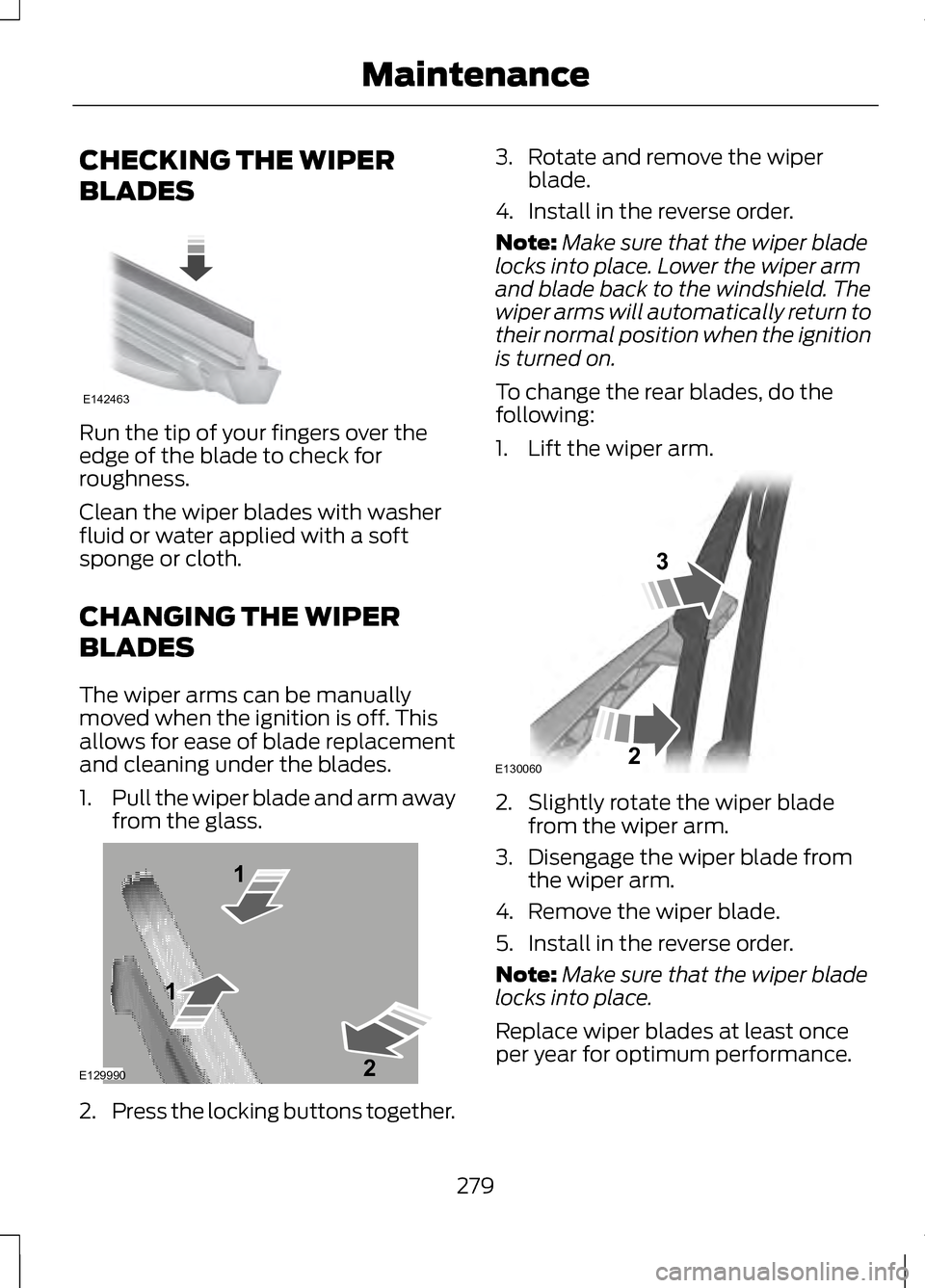

CHECKING THE WIPER

BLADES

Run the tip of your fingers over the

edge of the blade to check for

roughness.

Clean the wiper blades with washer

fluid or water applied with a soft

sponge or cloth.

CHANGING THE WIPER

BLADES

The wiper arms can be manually

moved when the ignition is off. This

allows for ease of blade replacement

and cleaning under the blades.

1.

Pull the wiper blade and arm away

from the glass. 2.

Press the locking buttons together. 3. Rotate and remove the wiper

blade.

4. Install in the reverse order.

Note: Make sure that the wiper blade

locks into place. Lower the wiper arm

and blade back to the windshield. The

wiper arms will automatically return to

their normal position when the ignition

is turned on.

To change the rear blades, do the

following:

1. Lift the wiper arm. 2. Slightly rotate the wiper blade

from the wiper arm.

3. Disengage the wiper blade from the wiper arm.

4. Remove the wiper blade.

5. Install in the reverse order.

Note: Make sure that the wiper blade

locks into place.

Replace wiper blades at least once

per year for optimum performance.

279

MaintenanceE142463 E129990

1

1 2 E130060

3

2

Page 283 of 474

Poor wiper quality can be improved

by cleaning the wiper blades and the

windshield.

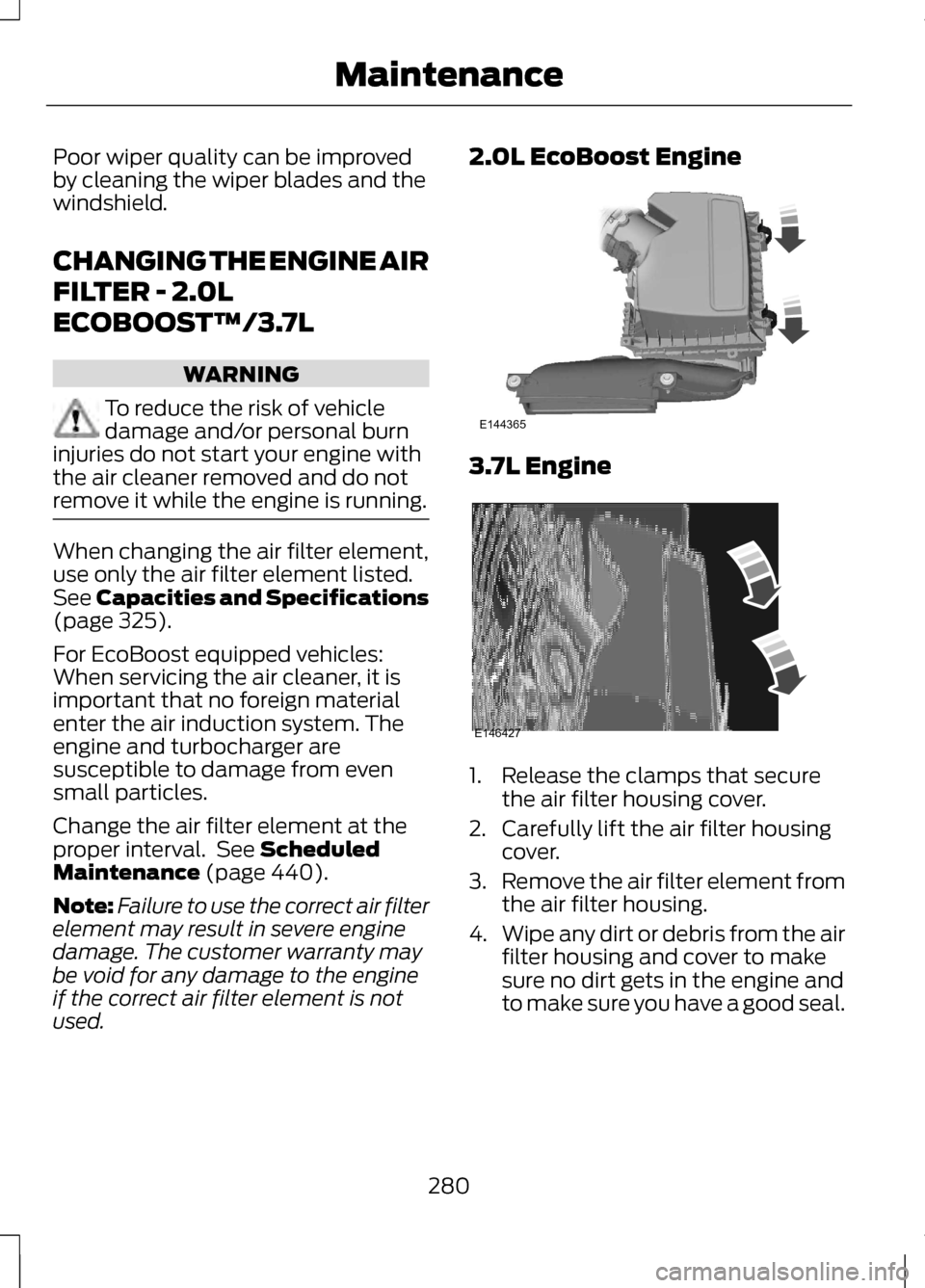

CHANGING THE ENGINE AIR

FILTER - 2.0L

ECOBOOST™/3.7L

WARNING

To reduce the risk of vehicle

damage and/or personal burn

injuries do not start your engine with

the air cleaner removed and do not

remove it while the engine is running. When changing the air filter element,

use only the air filter element listed.

See Capacities and Specifications

(page 325).

For EcoBoost equipped vehicles:

When servicing the air cleaner, it is

important that no foreign material

enter the air induction system. The

engine and turbocharger are

susceptible to damage from even

small particles.

Change the air filter element at the

proper interval. See

Scheduled

Maintenance (page 440).

Note: Failure to use the correct air filter

element may result in severe engine

damage. The customer warranty may

be void for any damage to the engine

if the correct air filter element is not

used. 2.0L EcoBoost Engine

3.7L Engine

1. Release the clamps that secure

the air filter housing cover.

2. Carefully lift the air filter housing cover.

3. Remove the air filter element from

the air filter housing.

4. Wipe any dirt or debris from the air

filter housing and cover to make

sure no dirt gets in the engine and

to make sure you have a good seal.

280

MaintenanceE144365 E146427

Page 284 of 474

5. Install a new air filter element. Be

careful not to crimp the filter

element edges between the air

filter housing and cover. This could

cause filter damage and allow

unfiltered air to enter the engine if

not properly seated.

6. Install the air filter housing cover.

7. Engage the clamps to secure the air filter housing cover to the air

filter housing.

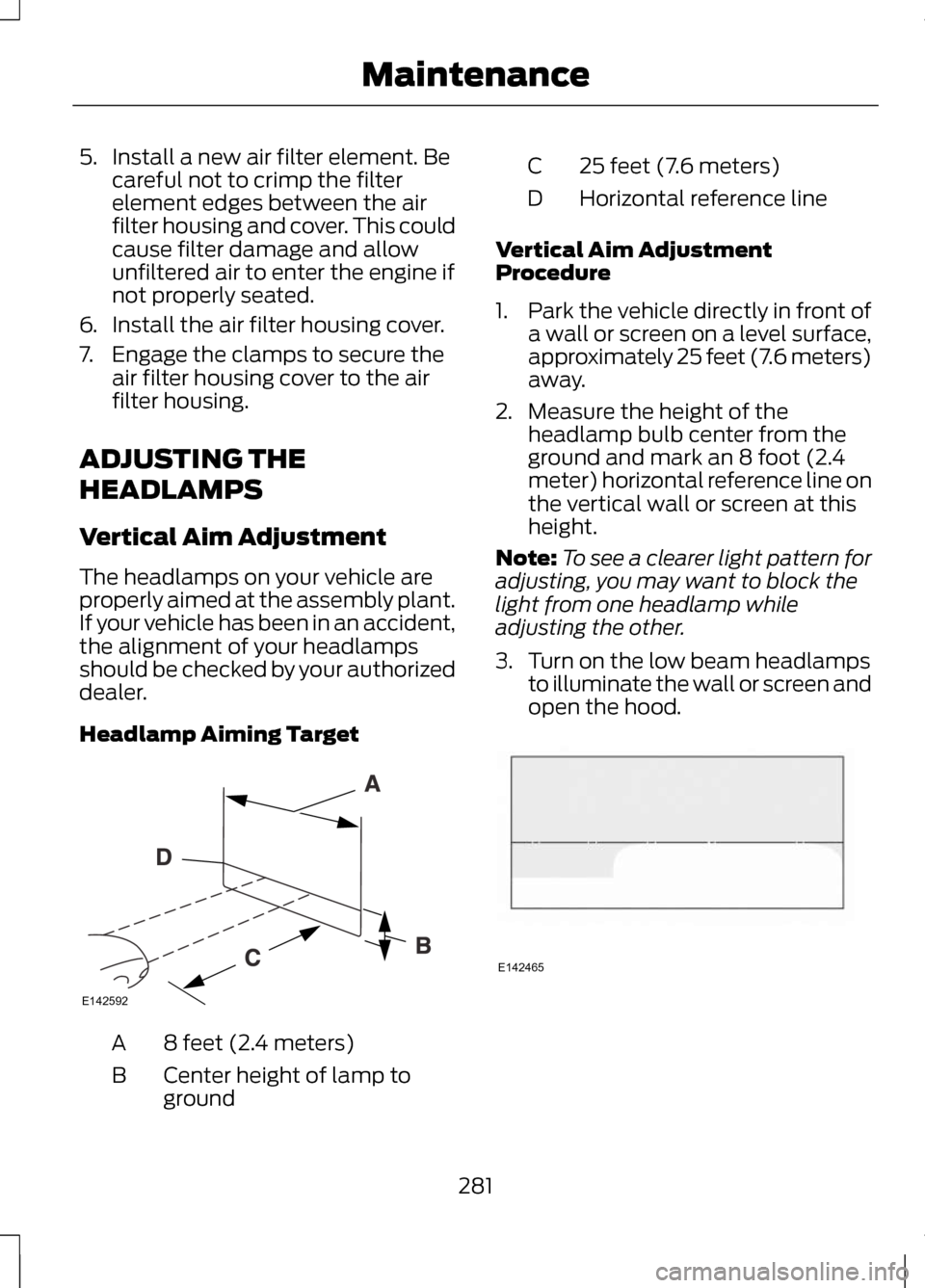

ADJUSTING THE

HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are

properly aimed at the assembly plant.

If your vehicle has been in an accident,

the alignment of your headlamps

should be checked by your authorized

dealer.

Headlamp Aiming Target 8 feet (2.4 meters)

A

Center height of lamp to

ground

B 25 feet (7.6 meters)

C

Horizontal reference line

D

Vertical Aim Adjustment

Procedure

1. Park the vehicle directly in front of

a wall or screen on a level surface,

approximately 25 feet (7.6 meters)

away.

2. Measure the height of the headlamp bulb center from the

ground and mark an 8 foot (2.4

meter) horizontal reference line on

the vertical wall or screen at this

height.

Note: To see a clearer light pattern for

adjusting, you may want to block the

light from one headlamp while

adjusting the other.

3. Turn on the low beam headlamps to illuminate the wall or screen and

open the hood. 281

MaintenanceE142592 E142465

Page 285 of 474

4. On the wall or screen you will

observe a flat zone of high

intensity light located at the top of

the right hand portion of the beam

pattern. If the top edge of the high

intensity light zone is not at the

horizontal reference line, the

headlamp will need to be adjusted. 5. Locate the vertical adjuster on

each headlamp. Using a Phillips

#2 screwdriver, turn the adjuster

either clockwise or

counterclockwise in order to adjust

the vertical aim of the headlamp.

The horizontal edge of the brighter

light should touch the horizontal

reference line.

6. Close the hood and turn off the

lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for this

vehicle and is not adjustable.

REMOVING A HEADLAMP

See an authorized dealer. CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented to

accommodate normal changes in

pressure. Condensation can be a

natural by-product of this design.

When moist air enters the lamp

assembly through the vents, there is

a possibility that condensation can

occur when the temperature is cold.

When normal condensation occurs, a

thin film of mist can form on the

interior of the lens. The thin mist

eventually clears and exits through

the vents during normal operation.

Clearing time may take as long as 48

hours under dry weather conditions.

Examples of acceptable condensation

are:

•

Presence of thin mist (no streaks,

drip marks or droplets).

• Fine mist covers less than 50% of

the lens.

Examples of unacceptable moisture

(usually caused by a lamp water leak)

are:

• Water puddle inside the lamp.

• Large water droplets, drip marks

or streaks present on the interior

of the lens.

Take your vehicle to a dealer for

service if any of the above conditions

of unacceptable moisture are present.

Replacing Bulbs

For replacing bulbs, see your

authorized dealer.

282

MaintenanceE150095

Page 286 of 474

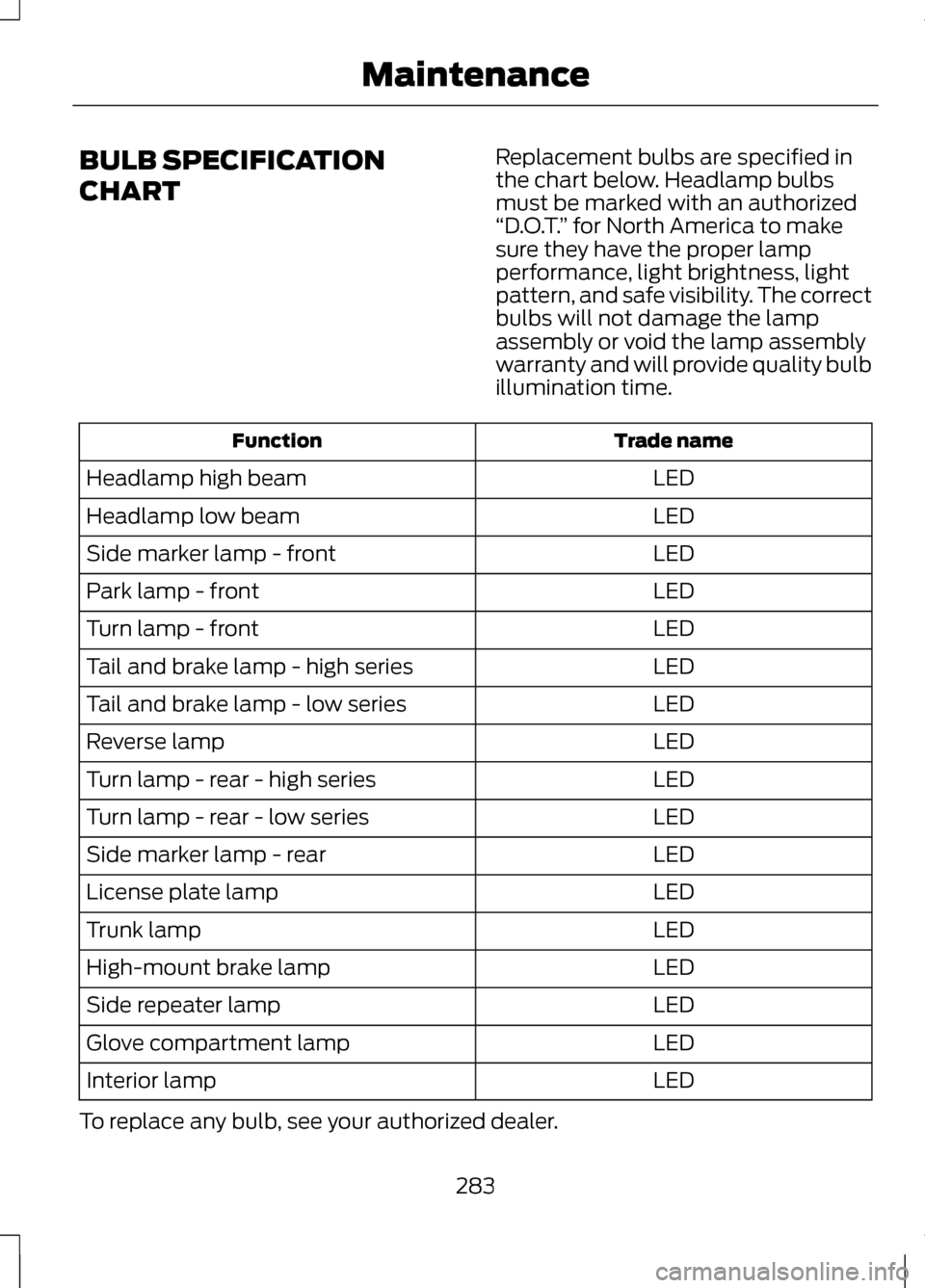

BULB SPECIFICATION

CHART

Replacement bulbs are specified in

the chart below. Headlamp bulbs

must be marked with an authorized

“D.O.T.

” for North America to make

sure they have the proper lamp

performance, light brightness, light

pattern, and safe visibility. The correct

bulbs will not damage the lamp

assembly or void the lamp assembly

warranty and will provide quality bulb

illumination time. Trade name

Function

LED

Headlamp high beam

LED

Headlamp low beam

LED

Side marker lamp - front

LED

Park lamp - front

LED

Turn lamp - front

LED

Tail and brake lamp - high series

LED

Tail and brake lamp - low series

LED

Reverse lamp

LED

Turn lamp - rear - high series

LED

Turn lamp - rear - low series

LED

Side marker lamp - rear

LED

License plate lamp

LED

Trunk lamp

LED

High-mount brake lamp

LED

Side repeater lamp

LED

Glove compartment lamp

LED

Interior lamp

To replace any bulb, see your authorized dealer.

283

Maintenance

Page 292 of 474

Note:

To check for compatibility, first

test any cleaner or stain remover on an

inconspicuous part of the leather.

You should:

• remove dust and loose dirt with a

vacuum cleaner.

• clean spills and stains as quickly

as possible.

• To check for compatibility, first

test any cleaner or stain remover

on an inconspicuous part of the

leather.

Do not use the following products as

these may damage the leather:

• oil/petroleum-based leather

conditioners.

• household cleaners.

• alcohol solutions.

• solvents or cleaners intended for

rubber, vinyl and plastics.

CLEANING THE ALLOY

WHEELS

Note: Do not apply a cleaning

chemical to warm or hot wheel rims

and covers.

Note: Some automatic car washes

may cause damage to the finish on

your wheel rims and covers.

Note: Industrial-strength (heavy-duty)

cleaners or cleaning chemicals, in

combination with brush agitation to

remove brake dust and dirt, could wear

away the clear coat finish over a period

time. Note:

Do not use hydrofluoric

acid-based or high caustic-based

wheel cleaners, steel wool, fuels or

strong household detergents.

Note: If you intend parking your vehicle

for an extended period after cleaning

the wheels with a wheel cleaner, drive

your vehicle for a few minutes before

doing so. This will reduce the risk of

increased corrosion of the brake discs.

Alloy wheels and wheel covers are

coated with a clear coat paint finish.

To maintain their condition we

recommend that you:

• Clean the wheels weekly, with the

recommended Ford service wheel

and tire cleaner. Apply using

manufacturer's instructions. Use

Motorcraft® Wheel and Tire

Cleaner. See cleaning products

(page ?).

• Use a sponge to remove heavy

deposits of dirt and brake dust

accumulation.

• Rinse thoroughly with a strong

stream of water when you have

completed the cleaning process.

• To remove tar and grease, use

Motorcraft® Bug and Tar Remover.

See cleaning products (page ?).

VEHICLE STORAGE

If you plan on storing your vehicle for

an extended period of time (30 days

or more), read the following

maintenance recommendations to

make sure your vehicle stays in good

operating condition.

289

Vehicle Care