LINCOLN NAVIGATOR 2010 Owners Manual

Manufacturer: LINCOLN, Model Year: 2010, Model line: NAVIGATOR, Model: LINCOLN NAVIGATOR 2010Pages: 385, PDF Size: 2.96 MB

Page 311 of 385

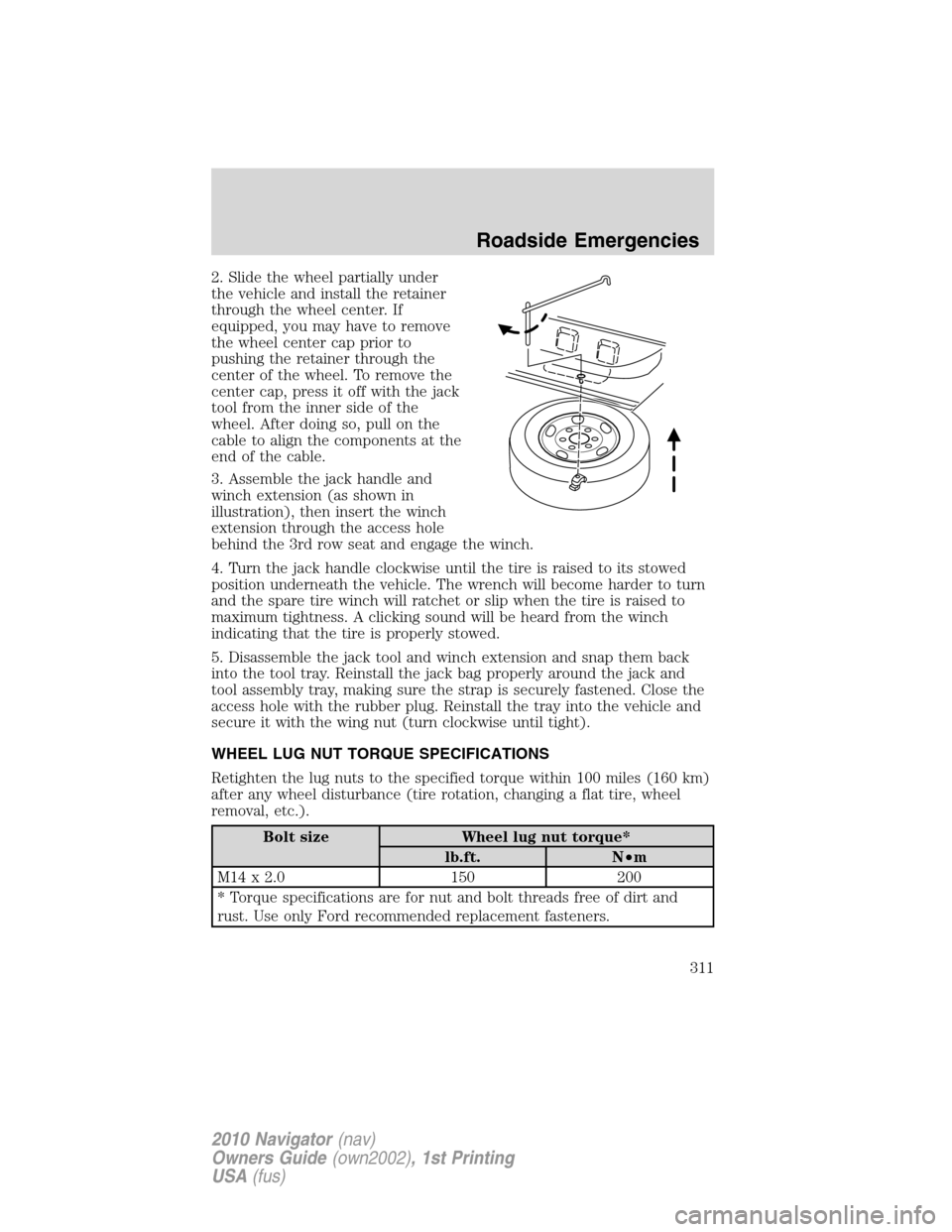

2. Slide the wheel partially under

the vehicle and install the retainer

through the wheel center. If

equipped, you may have to remove

the wheel center cap prior to

pushing the retainer through the

center of the wheel. To remove the

center cap, press it off with the jack

tool from the inner side of the

wheel. After doing so, pull on the

cable to align the components at the

end of the cable.

3. Assemble the jack handle and

winch extension (as shown in

illustration), then insert the winch

extension through the access hole

behind the 3rd row seat and engage the winch.

4. Turn the jack handle clockwise until the tire is raised to its stowed

position underneath the vehicle. The wrench will become harder to turn

and the spare tire winch will ratchet or slip when the tire is raised to

maximum tightness. A clicking sound will be heard from the winch

indicating that the tire is properly stowed.

5. Disassemble the jack tool and winch extension and snap them back

into the tool tray. Reinstall the jack bag properly around the jack and

tool assembly tray, making sure the strap is securely fastened. Close the

access hole with the rubber plug. Reinstall the tray into the vehicle and

secure it with the wing nut (turn clockwise until tight).

WHEEL LUG NUT TORQUE SPECIFICATIONS

Retighten the lug nuts to the specified torque within 100 miles (160 km)

after any wheel disturbance (tire rotation, changing a flat tire, wheel

removal, etc.).

Bolt size Wheel lug nut torque*

lb.ft. N•m

M14 x 2.0 150 200

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

Roadside Emergencies

311

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 312 of 385

WARNING:When a wheel is installed, always remove any

corrosion, dirt or foreign materials present on the mounting

surfaces of the wheel or the surface of the wheel hub, brake drum or

brake disc that contacts the wheel. Ensure that any fasteners that

attach the rotor to the hub are secured so they do not interfere with

the mounting surfaces of the wheel. Installing wheels without correct

metal-to-metal contact at the wheel mounting surfaces can cause the

wheel nuts to loosen and the wheel to come off while the vehicle is in

motion, resulting in loss of control.

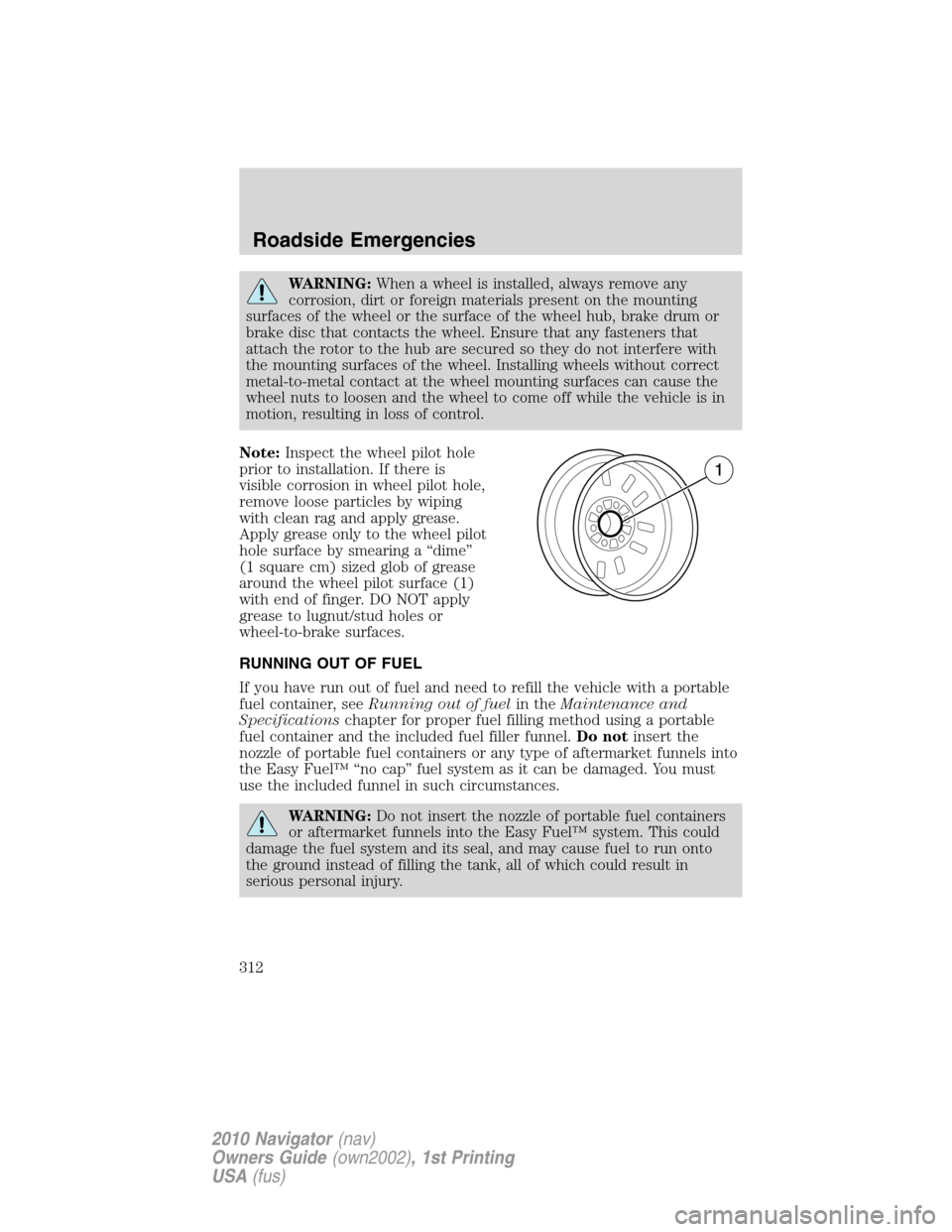

Note:Inspect the wheel pilot hole

prior to installation. If there is

visible corrosion in wheel pilot hole,

remove loose particles by wiping

with clean rag and apply grease.

Apply grease only to the wheel pilot

hole surface by smearing a “dime”

(1 square cm) sized glob of grease

around the wheel pilot surface (1)

with end of finger. DO NOT apply

grease to lugnut/stud holes or

wheel-to-brake surfaces.

RUNNING OUT OF FUEL

If you have run out of fuel and need to refill the vehicle with a portable

fuel container, seeRunning out of fuelin theMaintenance and

Specificationschapter for proper fuel filling method using a portable

fuel container and the included fuel filler funnel.Do notinsert the

nozzle of portable fuel containers or any type of aftermarket funnels into

the Easy Fuel™ “no cap” fuel system as it can be damaged. You must

use the included funnel in such circumstances.

WARNING:Do not insert the nozzle of portable fuel containers

or aftermarket funnels into the Easy Fuel™ system. This could

damage the fuel system and its seal, and may cause fuel to run onto

the ground instead of filling the tank, all of which could result in

serious personal injury.

Roadside Emergencies

312

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 313 of 385

JUMP STARTING

WARNING:The gases around the battery can explode if

exposed to flames, sparks, or lit cigarettes. An explosion could

result in injury or vehicle damage.

WARNING:Batteries contain sulfuric acid which can burn skin,

eyes and clothing, if contacted.

Do not attempt to push-start your automatic transmission

vehicle. Automatic transmissions do not have push-start

capability. Attempting to push-start a vehicle with an automatic

transmission may cause transmission damage.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

automatic transmission must relearn its shift strategy. As a result, the

transmission may have firm and/or soft shifts. This operation is

considered normal and will not affect function or durability of the

transmission. Over time, the adaptive learning process will fully update

transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect from any electrical

surges. Turn all other accessories off.

Roadside Emergencies

313

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 314 of 385

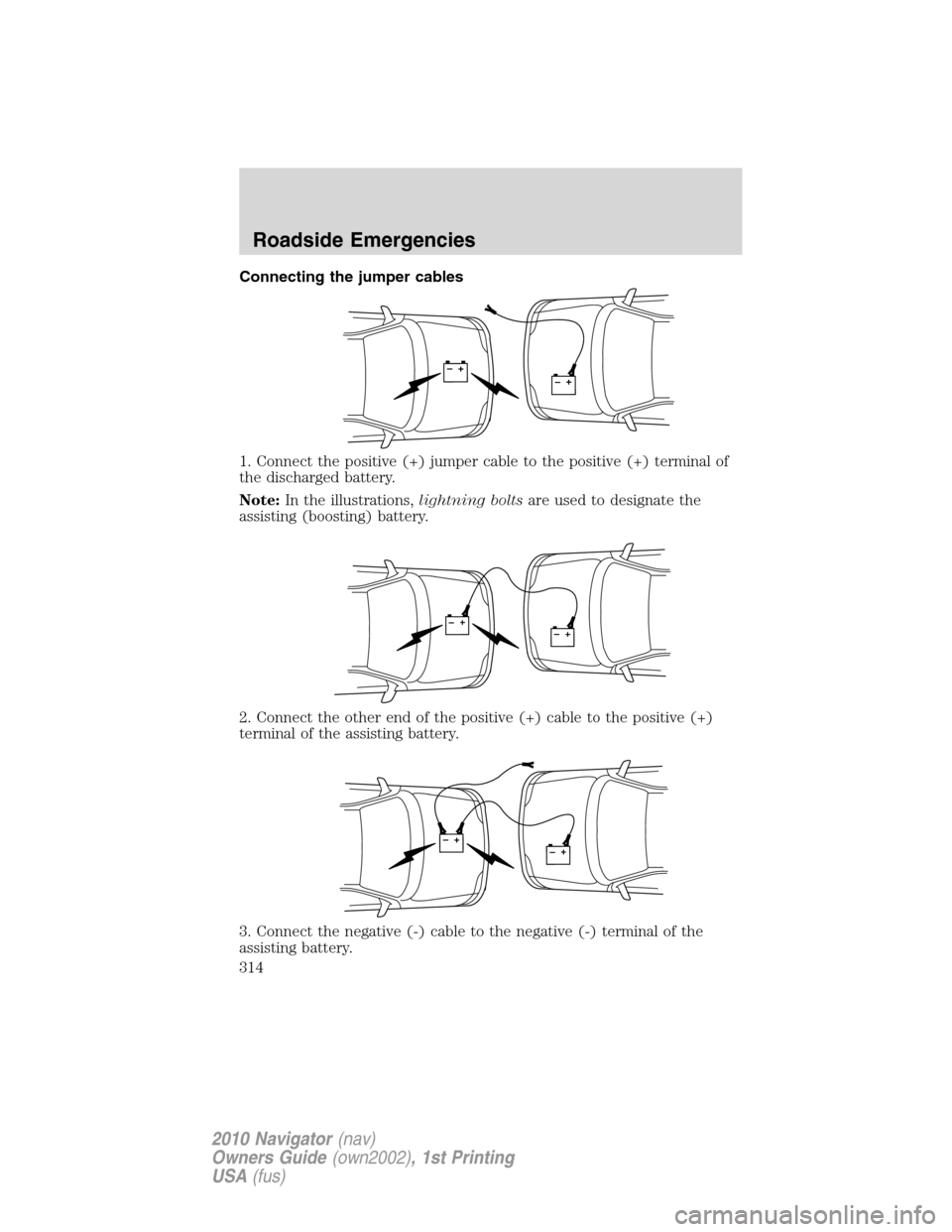

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

+–+–

+–+–

+–+–

Roadside Emergencies

314

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 315 of 385

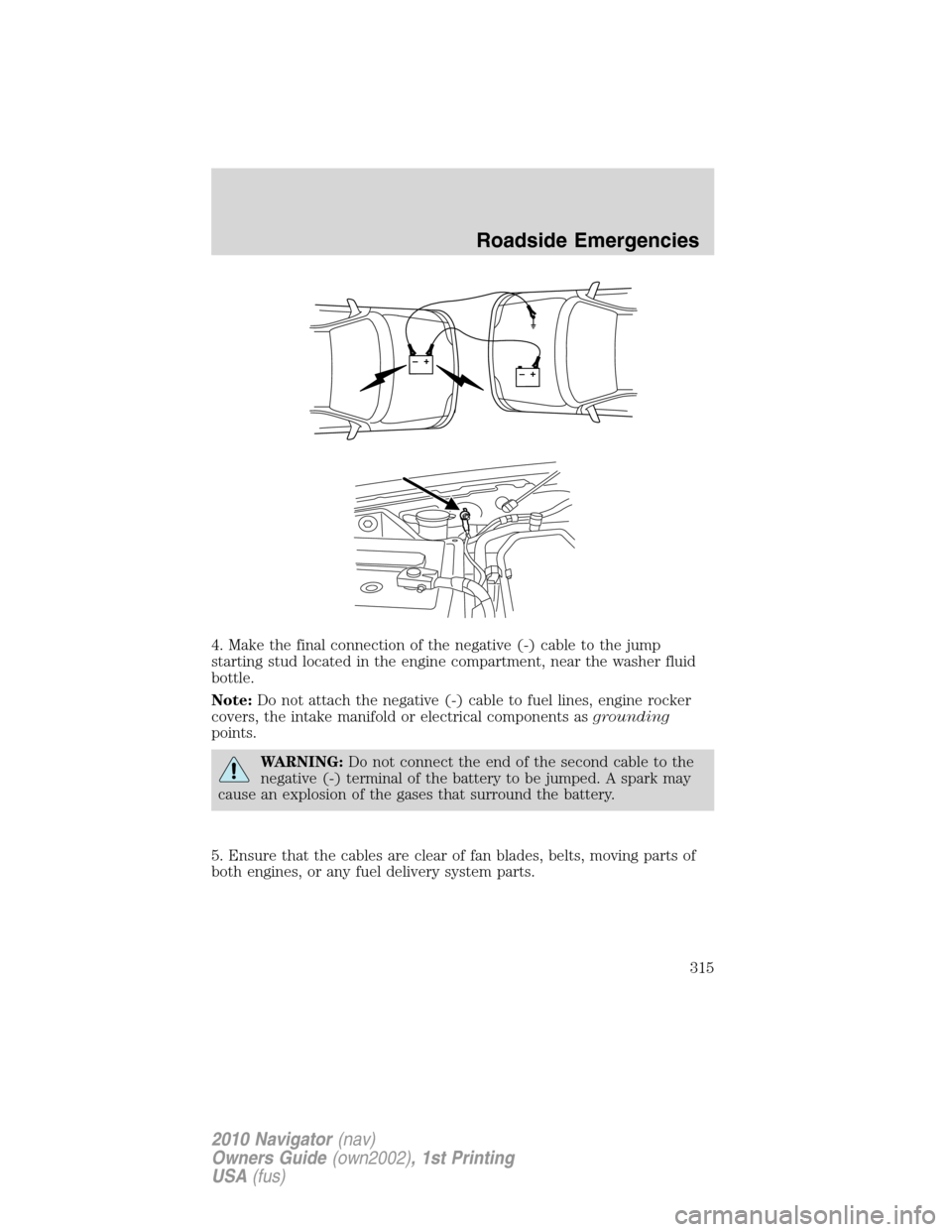

4. Make the final connection of the negative (-) cable to the jump

starting stud located in the engine compartment, near the washer fluid

bottle.

Note:Do not attach the negative (-) cable to fuel lines, engine rocker

covers, the intake manifold or electrical components asgrounding

points.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

+–+–

Roadside Emergencies

315

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 316 of 385

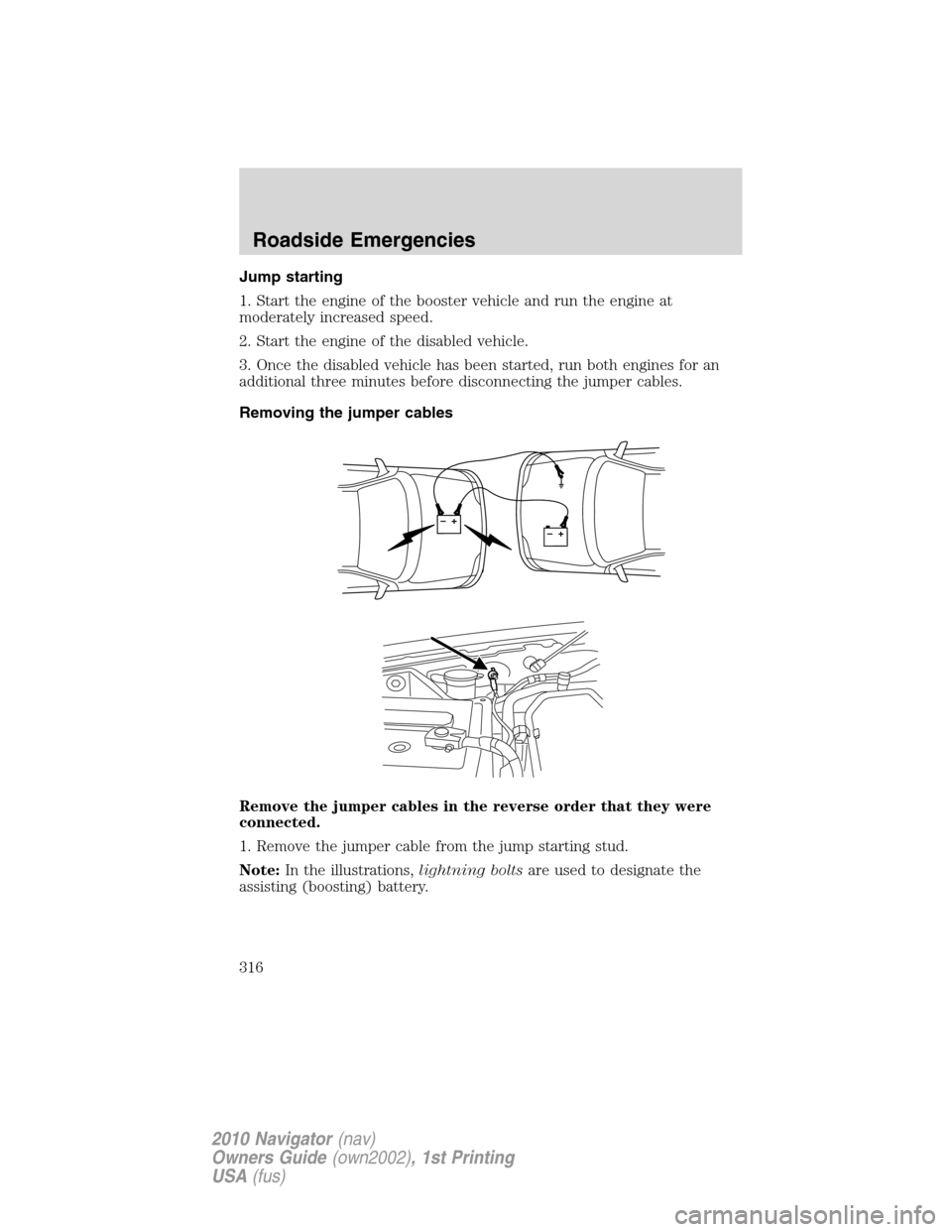

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from the jump starting stud.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

Roadside Emergencies

316

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 317 of 385

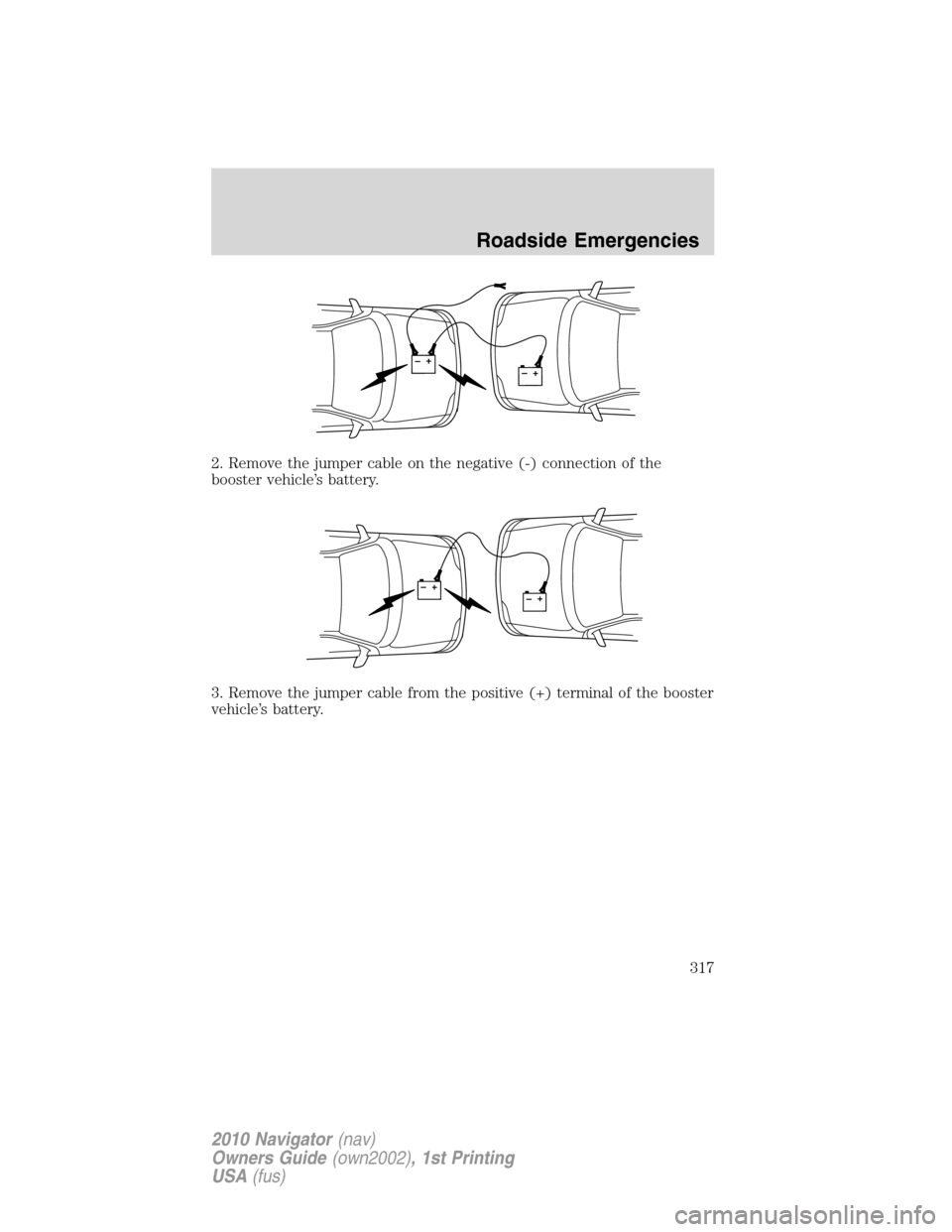

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

+–+–

+–+–

Roadside Emergencies

317

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 318 of 385

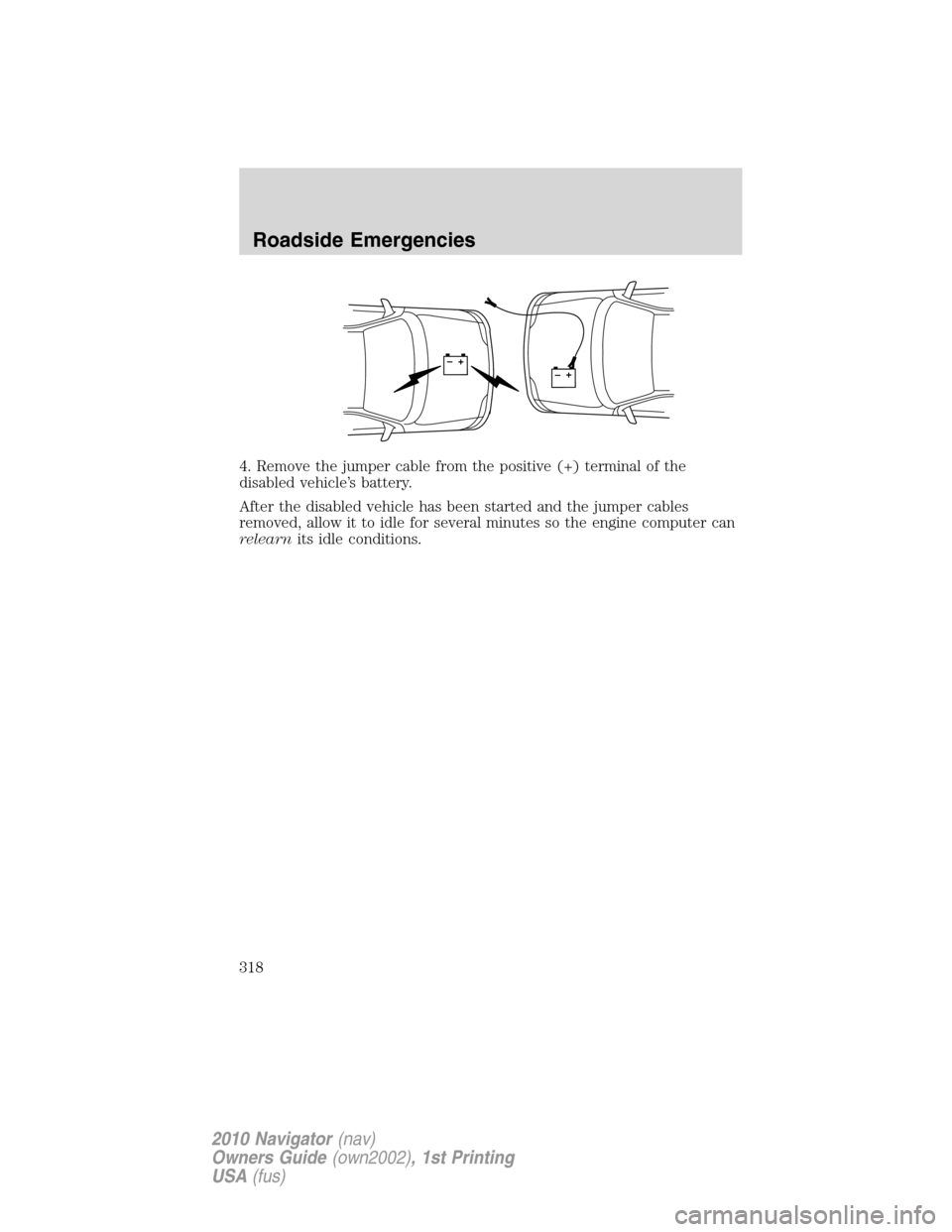

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

Roadside Emergencies

318

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 319 of 385

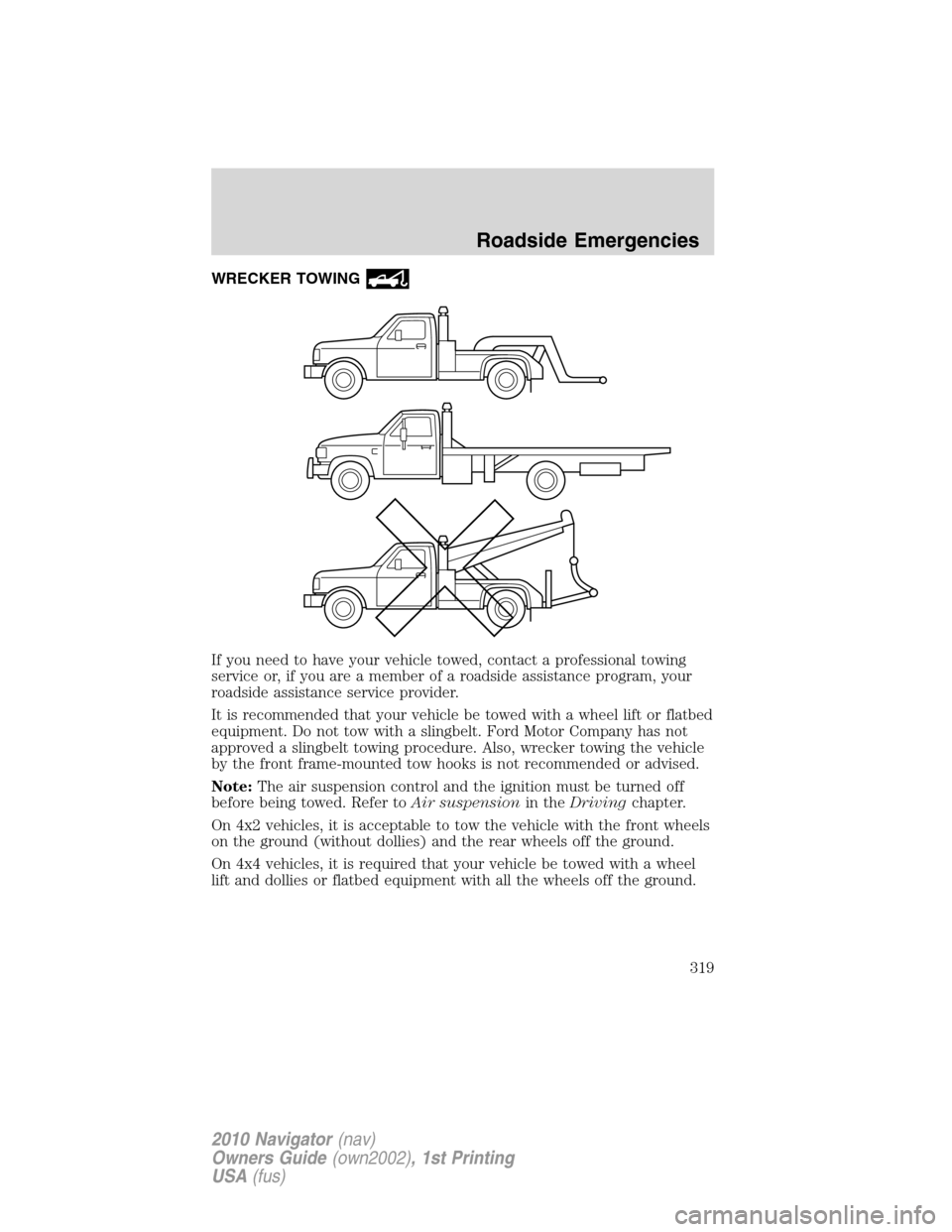

WRECKER TOWING

If you need to have your vehicle towed, contact a professional towing

service or, if you are a member of a roadside assistance program, your

roadside assistance service provider.

It is recommended that your vehicle be towed with a wheel lift or flatbed

equipment. Do not tow with a slingbelt. Ford Motor Company has not

approved a slingbelt towing procedure. Also, wrecker towing the vehicle

by the front frame-mounted tow hooks is not recommended or advised.

Note:The air suspension control and the ignition must be turned off

before being towed. Refer toAir suspensionin theDrivingchapter.

On 4x2 vehicles, it is acceptable to tow the vehicle with the front wheels

on the ground (without dollies) and the rear wheels off the ground.

On 4x4 vehicles, it is required that your vehicle be towed with a wheel

lift and dollies or flatbed equipment with all the wheels off the ground.

Roadside Emergencies

319

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)

Page 320 of 385

If the vehicle is towed by other means or incorrectly, vehicle

damage may occur.

Ford Motor Company produces a towing manual for all authorized tow

truck operators. Have your tow truck operator refer to this manual for

proper hook-up and towing procedures for your vehicle.

Emergency towing

In case of a roadside emergency with a disabled vehicle (without access

to wheel dollies, car hauling trailer, or flatbed transport vehicle) your

vehicle (regardless of transmission powertrain configuration) can be flat

towed (all wheels on the ground) under the following conditions:

•Vehicle is facing forward so that it is being towed in a forward

direction.

•Place the transmission in N (Neutral). Refer toBrake shift interlock

in theDrivingchapter for specific instructions if you cannot move the

gear shift lever into N (Neutral).

•Maximum speed is not to exceed 35 mph (56 km/h).

•Maximum distance is 50 miles (80 km).

Roadside Emergencies

320

2010 Navigator(nav)

Owners Guide(own2002), 1st Printing

USA(fus)