rear LOTUS ELISE 2005 Owner's Guide

[x] Cancel search | Manufacturer: LOTUS, Model Year: 2005, Model line: ELISE, Model: LOTUS ELISE 2005Pages: 205, PDF Size: 4.51 MB

Page 86 of 205

ohs149

RELEASING ROOF SIDE RAIL

Soft Top - Removal

WARNING:Do not attempt to remove the soft top roof whilst the

car is in motion. This could cause a crash in which you or

others could be killed or seriously injured.

1. With the car stationary, open both doors or lower both door windows.

2. On the inside face of the right hand roof side rail, locate the

two latch release levers: Pull the two lever handles towards each other to release the side rail latches (press down on the

side rail if necessary to relieve the load on the latch pins), and rotate the rail upwards to release the canopy tension.

3. Repeat step (2) for the

left hand side rail.

NOTICE: Releasing the right hand roof side rail first, will minimise

the possibility of the canopy tensioning cable adjusters causing damage to the roof seals.

4. Free the front and rear tensioning cables from the gutters be

-

fore carefully rolling up each side of the roof canopy towards the centre. Lift the roof assembly off the car, and pack in the

roof bag.

External Operations

84

oh_croft_InD.indd 8420/05/2004 07:59:01ProCarManuals.com

Page 87 of 205

5. Unhook the two roof stays and pack in the roof bag. Stow the

bag in the rear luggage compartment.

NOTICE: If the roof is not fully dry, it should be stowed for no longer than 1 or 2 days before unrolling or refitting and allowing

to air dry completely. Prolonged stowage of a wet or damp roof

will promote rotting of the fabric.

HARD TOP ROOF

NOTICE:

• The hard top roof has been designed to provide a seasonal,

rather than single trip option. Some owners may prefer to

entrust the fitting and removal of the hard top roof to their

dealer.

• When stowing the roof off the car, care should be taken to

avoid damage to the roof corners; e.g. use a suitable soft

floor covering on which to stand the roof. Note that there is

no provision for on-board hard top roof stowage.

• Fitment or removal of the hardtop is made considerably easier

with the assistance of a second person.

• Use only the ‘Torx’ tool supplied in the car tool kit (in the

battery cover rear pocket), to tighten or release the roof

fixing screws.

• The hardtop roof fixings are tethered to the roof panel to guard

against their loss.

WARNING:

Take care to avoid trapping hands or fingers when fitting

or removing the hard top.

External Operations

85

oh_croft_InD.indd 8520/05/2004 07:59:01ProCarManuals.com

Page 88 of 205

b330

FRONT SPIGOT BRACKET

Hard Top - Fitting

1. Open both doors, and preferably with the aid of an assistant, lower the roof onto the car holding aside the loose tethered

fixings to avoid their entrapment or their causing paint damage. Position the rear edge of the roof first before locating the front

edge against the windscreen header rail.

2. Locate a front spigot bracket into its latch plate lower slot (lifting the roof slightly to allow this) and retain to the roof with the Torx bolt. Use only the special Torx tool supplied in the car tool kit (stowed in the battery cover pocket), and do not

fully tighten at this stage.

3. Repeat step (2) for the opposite front spigot bracket.

External Operations

86

oh_croft_InD.indd 8620/05/2004 07:59:02ProCarManuals.com

Page 89 of 205

4. Engage a rear hook bracket with the lower tongue on its rear latch plate, and retain to the roof with the Torx bolt. Use only

the special tool supplied, and do not fully tighten at this stage.

Ensure that the hook is fully located onto the tongue.

5. Repeat step (4) for the opposite rear hook bracket. 6. Push the roof fully forwards before tightening the front spigot brackets using only the special Torx tool supplied. Hold each

rear hook bracket in alignment whilst tightening the single

fixing screw for each bracket. Do not overtighten.

h2

FITTING REAR HOOK BRACKET

External Operations

87

oh_croft_InD.indd 8720/05/2004 07:59:02ProCarManuals.com

Page 90 of 205

REAR CORNER COVER PANEL

7. Fit the trimmed cover panels to each rear corner of the roof, noting that the panels are handed for left and right sides. Press

the panels firmly into position fully to engage the ‘Velcro’ fixing

patches.

WARNING: Do not drive the car with the cover panels removed.

Injury could result from contact with the roof brackets in

a car collision.

External Operations

88

oh_croft_InD.indd 8820/05/2004 07:59:02ProCarManuals.com

Page 94 of 205

ohs149

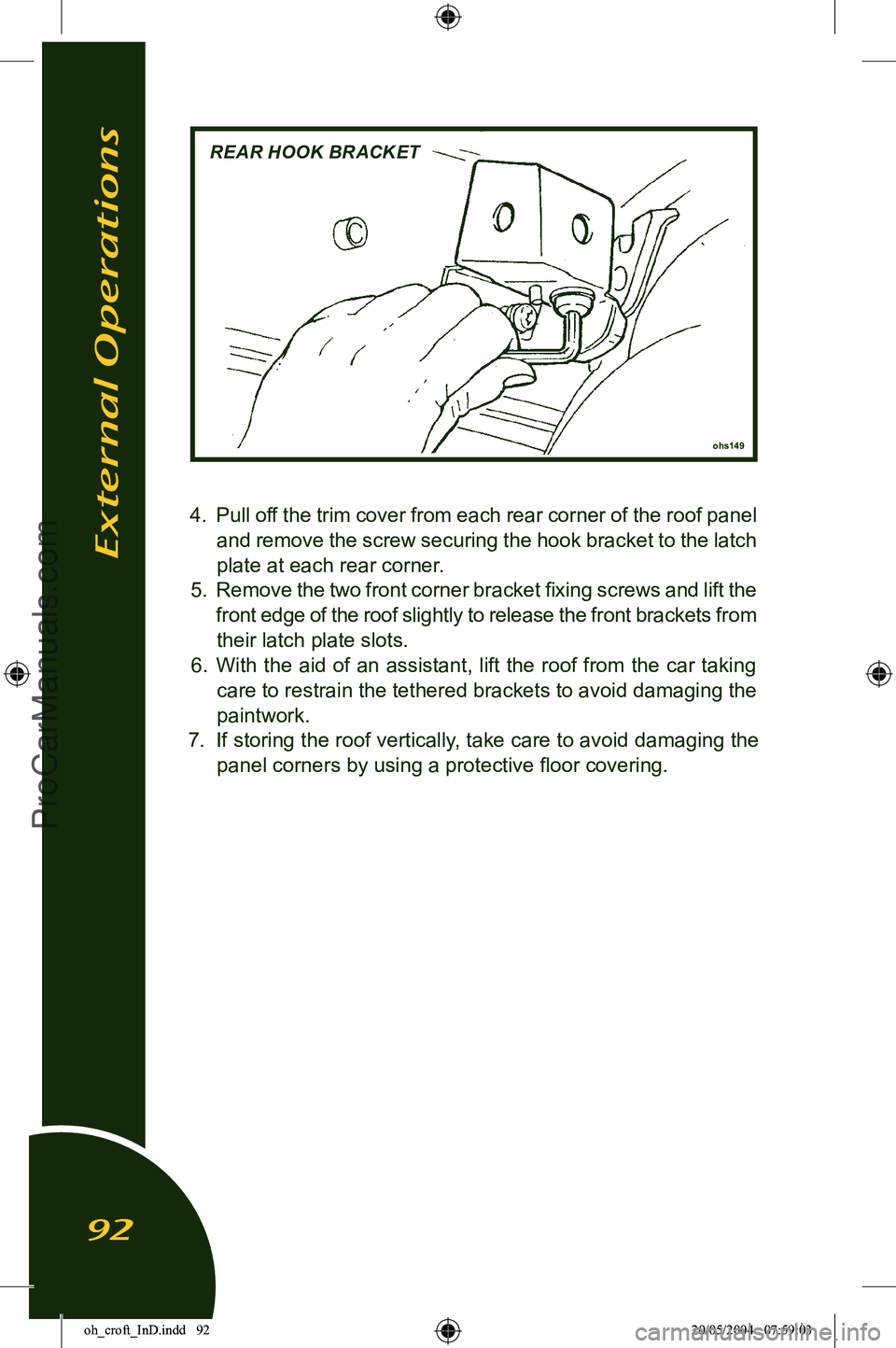

REAR HOOK BRACKET

4. Pull off the trim cover from each rear corner of the roof panel and remove the screw securing the hook bracket to the latch plate at each rear corner.

5. Remove the two front corner bracket fixing screws and lift the

front edge of the roof slightly to release the front brackets

from

their latch plate slots.

6. With the aid of an assistant, lift the roof from the car taking care to restrain the tethered brackets to avoid damaging the

paintwork.

7. If storing the roof vertically, take care to avoid damaging the panel corners by using a protective floor covering.

External Operations

92

oh_croft_InD.indd 9220/05/2004 07:59:03ProCarManuals.com

Page 95 of 205

SERVICING AND MAINTENANCEBODYCARE

Body Features Lotus are among the world leaders in the field of automotive

composite moulding design and manufacturing techniques.

Composite materials have major advantages for specialist car bodies, and these brief notes introduce some features of the

construction and service properties of automotive composite bodies. The manufacturing process enables the thickness of com

-

posite mouldings to be varied in order to provide ef ficient structures of high strength and low weight. Composites will not

corrode, so the strength of composite components is retained regardless of age, unless physical damage is sustained. On

the Elise, the body construction utilises several mouldings to

form a single unit for the whole of the nose and front wings, and

a second unit for the whole of the rear body aft of the doors.

These two moulded assemblies are fixed using threaded fasten

-

ers to permit easy removal for access to chassis or powertrain

components, or to allow simple and economic accident repair.

Other composite mouldings include the door shells, sills, front access panels, windscreen frame and rear bulkhead, some panels being bonded to the aluminium alloy chassis with an

elastomeric adhesive.

Several different processes are used to manufacture the

various panels depending on the functional requirements, with the main outer panels using an injection compression mould

-

ing technique which eliminates the ‘gelcoat’ used on the outer

surface of conventionally manufactured composite panels. This

process provides considerably increased resistance to surface

damage from minor knocks, where a conventional composite panel would suffer cracking of the gel coat, or a steel panel be

-

come dented. If severe damage is caused to a composite panel

where the underlying structure is broken, repairs may take the

form of panel replacement, or of panel repair using techniques

where new composite material is integrated with the old to result in undiminished panel strength.

Servicing & Maintenance

93

oh_croft_InD.indd 9320/05/2004 07:59:03ProCarManuals.com

Page 102 of 205

pressing firmly to ensure that the handle is fully seated. With-

draw the dipstick again to inspect the oil level, which should lie between the two dimples on the end of the stick. The oil level

should be maintained at the upper of these two marks in order

to provide optimum engine protection.

Topping Up

: If topping up is necessary, unscrew the oil filler cap

from the left hand end of the cam cover. Add a suitable quantity of the recommended engine oil (see ‘Recommended Lubricants’)

taking care not to spill any oil onto engine or electrical compo

-

nents; use a funnel if necessary. The difference between high and low dipstick marks is equiv

-

alent to 1.6 U.S. quarts (1.5 litre). Allow several minutes for the oil to drain through to the sump before re-checking the oil level.

Do NOT over fill, or lubrication will be degraded and consump

-

tion increased as the oil becomes aerated. Refit the filler cap,

turning clockwise until secure.

Engine Oil Change The use of high quality oil, renewed at the specified intervals,

is the key to engine longevity and sustained performance. Ad

-

here strictly to the engine oil and filter change intervals specified

in the Maintenance Schedule.

For access to the engine sump and filter, the engine bay

undertray must first be removed. This is most easily achieved

with the car raised on a garage hydraulic lift, or alternatively, parked over an inspection pit.

The drain plug is located at the rear of the sump, and should

be removed to drain the sump immediately after a run when

the oil is warm and the impurities are still held in suspension.

On cars fitted with front mounted oil coolers, it is not necessary routinely to attempt to drain the cooler circuit. Servicing & Maintenance

100

oh_croft_InD.indd 10020/05/2004 07:59:05ProCarManuals.com

Page 111 of 205

Washer ReservoirThe windscreen washer reservoir is situated at the left hand

rear of the engine bay, and should be kept topped up with clean

water and a suitable proprietary solvent.

NOTICE:

Do NOT use radiator antifreeze in the reservoir as

this could seriously damage the paintwork and/or some plastic components.

The washer jets are mounted each side of the wiper spindle,

and may, if necessary, be cleared or adjusted using a suitable pin.

Wiper Blade To replace the single wiper blade, lift the arm away from the

‘screen, swing the blade through 90°, depress the retaining tab and slide the blade down the arm to unhook and release.

When refitting, ensure that the retaining clip is re-engaged

in the wiper arm slot.

ohs36a

ohs130

WASHER RESERVOIR CAPWIPER BLADE FITMENT

Servicing & Maintenance

109

Retaining tab

Wiper arm

oh_croft_InD.indd 10920/05/2004 07:59:08ProCarManuals.com

Page 112 of 205

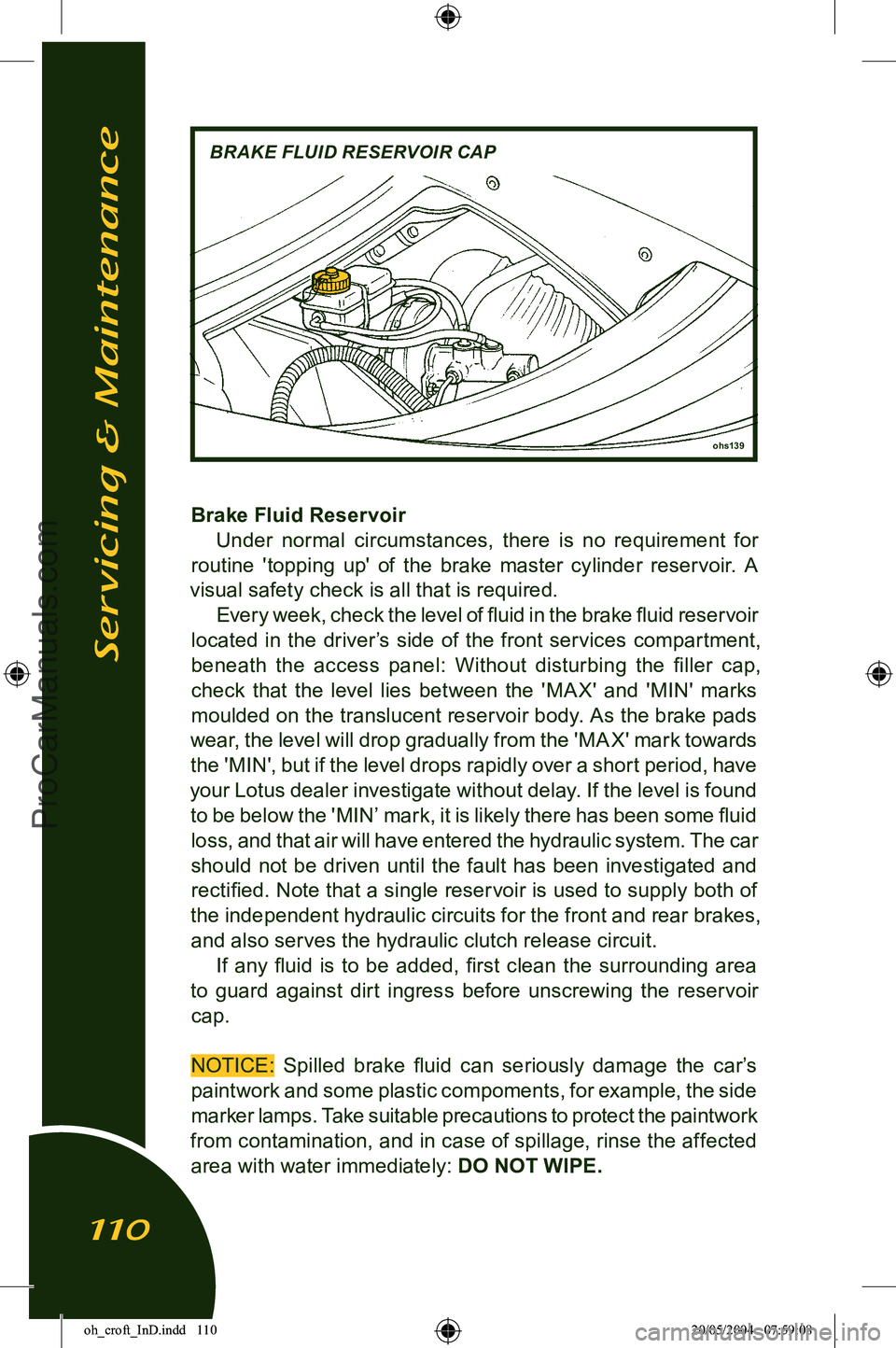

Brake Fluid ReservoirUnder normal circumstances, there is no requirement for

routine 'topping up' of the brake master cylinder reservoir. A

visual safety check is all that is required. Every week, check the level of fluid in the brake fluid reservoir

located in the driver’s side of the front services compartment, beneath the access panel: Without disturbing the filler cap,

check that the level lies between the 'MA X' and 'MIN' marks moulded on the translucent reservoir body. As the brake pads

wear, the level will drop gradually from the 'MA X' mark towards the 'MIN', but if the level drops rapidly over a short period, have

your Lotus dealer investigate without delay. If the level is found

to be below the 'MIN’ mark, it is likely there has been some fluid loss, and that air will have entered the hydraulic system. The car

should not be driven until the fault has been investigated and rectified. Note that a single reservoir is used to supply both of

the independent hydraulic circuits for the front and rear brakes, and also serves the hydraulic clutch release circuit. If any fluid is to be added, first clean the surrounding area

to guard against dirt ingress before unscrewing the reservoir cap.

NOTICE: Spilled brake fluid can seriously damage the car’s paintwork and some plastic compoments, for example, the side

marker lamps. Take suitable precautions to protect the paintwork

from contamination, and in case of spillage, rinse the affected area with water immediately: DO NOT WIPE.

ohs139

BRAKE FLUID RESERVOIR CAP

Servicing & Maintenance

110

oh_croft_InD.indd 11020/05/2004 07:59:08ProCarManuals.com