torque MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 6 of 677

HOW TO USE TtiIS MANUAL GI

HOW TO USE THIS MANUAL

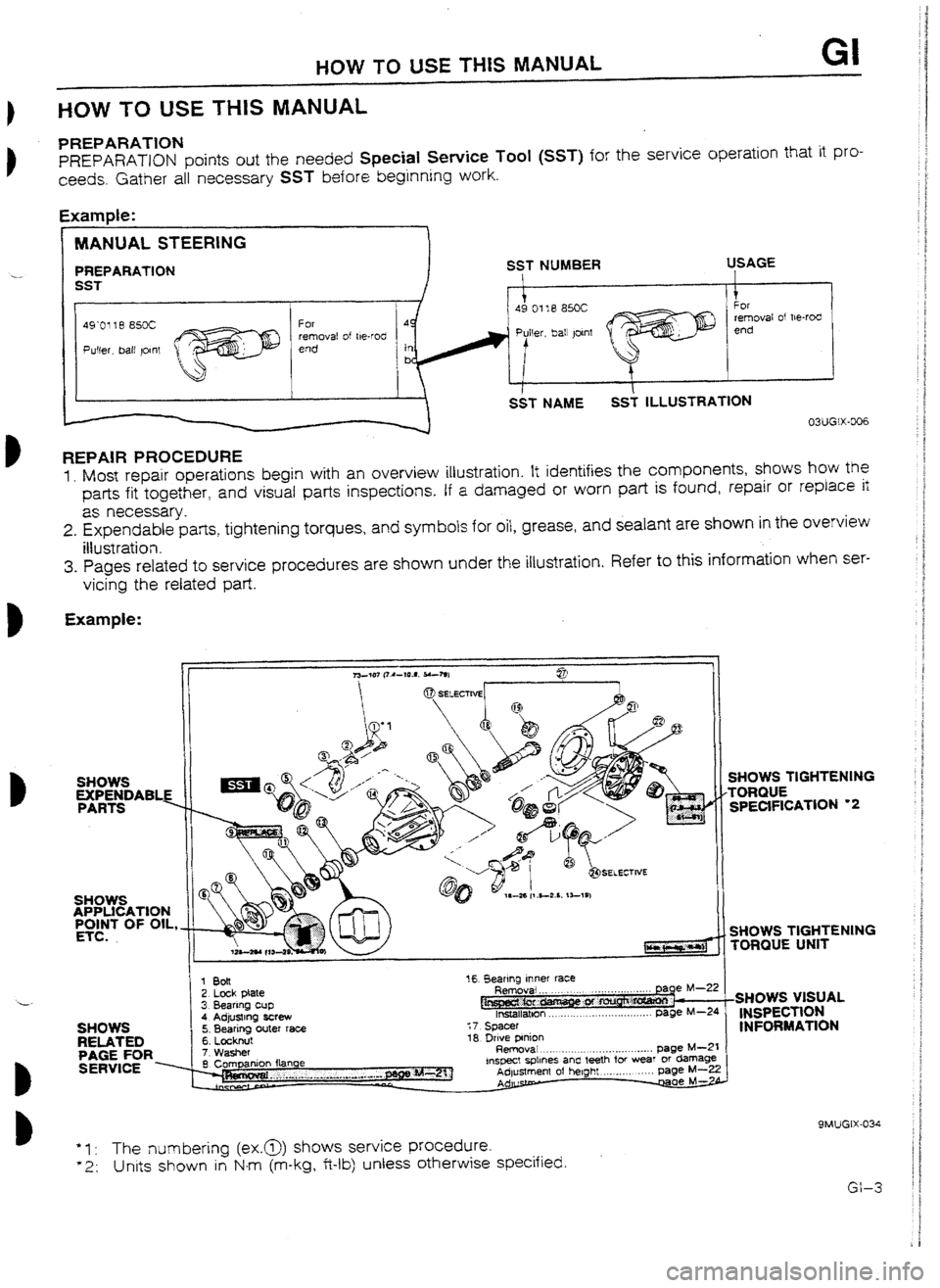

PREPARATION

PREPARATON points out the needed SpeciaI Service Tool (SST) for the service operation that it pro-

ceeds. Gather all necessary SST before beginning work.

Example:

MANUAL STEERING

PREPARATION

remova! of W-rod

REPAIR PROCEDURE I.

Most repair operations begin with an overview illustration. It identifies the components, shows how the

parts fit together, and visual parts inspections. If a

damaged or worn part is found, repair or replace it

as necessary.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

iItustration.

3. Pages related to service procedures are shown under the illustration. Refer to this information when ser-

vicing the related part.

Example: --__ __-

EXPENDABLE iI

-

SHOWS TlGHTENlNG

TORQUE UNIT

-

SHOWS Zh REiAT&

PAGE FOR 1 8oit

16 Bearing lnne

2. Lock plate Removal . .

,.

3. Bearrng cup

I!.~ f%

fnstallatbon ._ . . . ._. . . . . .

I

A Adirtstma drew - _ ‘.v,--..s ----. 5. Bearing outer race :7 Spacer

G I h-tnllt 1R hriu* mninn

I V. LVYR*IY. .” I.~.1 7Washer Rerr&l'~ .._. . . . . ..__ . . . . . . . ..__......... page M---21

- -0mpanlon f&we inspect spllnes and teeth for wear or damage Adlustment of heloht ._._..... . . . . . DaPe k&Z?

I

r..r...~r.--~.~r....e.-..c~~...~.,~.-*

Q SERVICE x

9MUGlx-034 ‘I : The numbering (ex.@))

shows service procedure. ‘2: Units shown

in N-m (m-kg, Wb) unless otherwise specified.

Page 9 of 677

GI FUNDAMENTAL PROCEDURES

9MUGtX-040

SMLIGIX-041

SMUGIX-004

1. Inspection of parts

When removed, each part should be carefully inspected for

malfunctioning, deformation, damage, and other problems.

2. Arrangement of parts

All disassembled parts should be carefully arranged for re-

assembly.

Be sure to separate or otherwise identify the parts to be

replaced from those that will be reused.

3. Cleaning parts for reuse

All parts to be reused should be carefully and thoroughly

cleaned in the appropriate method.

REASSEMBLY

Standard values, such as torques and certain adjustments

must be strictly observed in the reassembly of all parts.

Refer to STANDARD BOLT AND NUT TIGHTENING TORQUE

in Section TD for tightening torques not mentioned in the main

text.

If removed, these parts should be replaced with new ones:

1. Oil seals 2. Gaskets

3. O-rings

4. Lock washers

5. Cotter pins 6. Nylon nuts

Depending on location:

1. Sealant should be applied to gaskets.

2. Oil should be applied to the moving components of parts.

3. Specified oil or grease should

be applied at the prescribed

locations (such as oil seals) before reassembly.

‘31-6

Page 13 of 677

GI IDENTIFICATION NUMBER LOCATIONSIUNITSIABBREVlATlONS

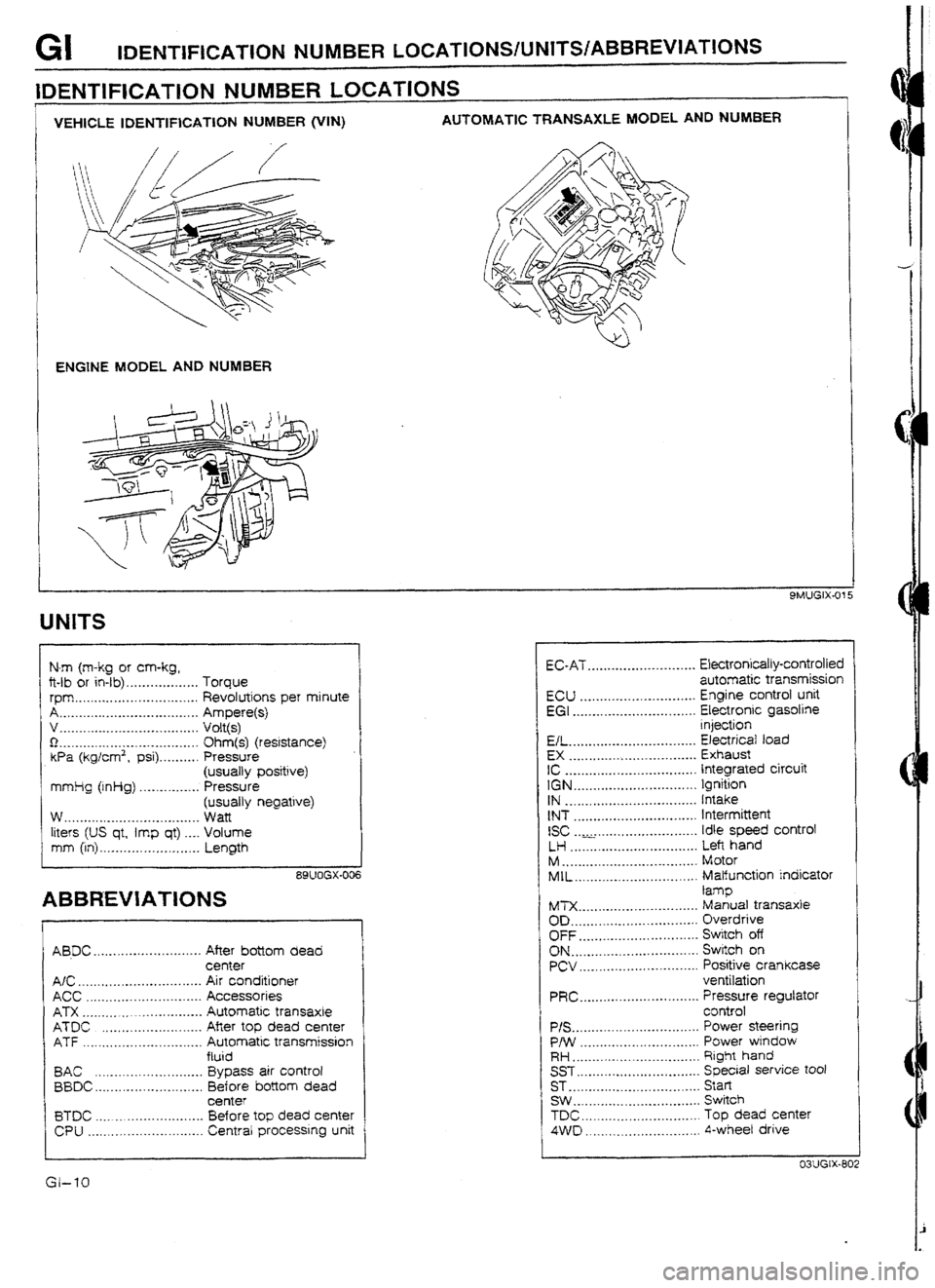

IDENTIFICATCON NUMBER LOCATIONS

I

VEHKZLE IDENTIFICATION NUMBER @‘IN) AUTOMATIC TRANSAXLE MODEL AND NUM8ER

ENGINE MODEL AND NUMBER

UNlTS

N-m (m-kg or cm-kg,

ft-lb or in-lb) . . . . . .._.......... Torque

rpm ._._..._.. . . . . . . .._.._.._. . .._. Revolutions per minute

A . . .._._._...__.._.._.._. .__...._. . . Ampere(s)

v .._.... .* .*... ..__.._...*. ..*. .*. ,. Volt(s)

0 I.._._............**..-.-*..-....... Ohm(s) (resistance)

Wa (kg/cm2, psi) . . . . . . . . . . Pressure

(usually positive)

mmlig (inHg) . . . . . . .._.._... Pressure

(usually negative)

w . . . ..*.....e*.-..-..-.....*.e..... Watt

liters (US qt, imp qt) .._. Volume

mm (in) ,_._.._._..._.,_. .~. . ..__ Length

89UOGX-006

ABBREVIATIONS

AB.DC ........................... After bottom dead

center

A/C _ .............................. Air conditioner

ACC ............................. Accessories

ATX ............................. Automatic transaxte

ATDC ......................... Afier top dead center

ATF .............................. Automatic transmission

ftuid

BAC ........................... Bypass air control

BBDC.. ......................... Before bottom dead

center

BTDC ........................... Before top dead center

CPU ............................. Central processing unit t EC-AT ........................... Ekctronically-controlled

automatic transmission

ECU ............................. Engine control unit

EGI ............................... Electronic gasotine

injection

EL ................................ Electricaf toad

EX ................................ Exhaust

IC ................................. Integrated circuit

IGN ............................... Ignition

IN ................................. Intake

tNT ............................... Intermittent

ISC ............................. Idle speed control

LH ................................ Left hand

M .................................. Motor

MIL ............................... Malfunction indicator

lamp

tb4TX. ............................. Manual transaxle

OD. ............................... Overdrive

OFF .............................. Switch off

ON ................................ Switch on PCV .............................. Positive crankcase

ventilation

PRC.. ............................ Pressure regulator

control

P/S ................................ Power steering

P/W .............................. Power wtndow

RH.. .............................. Right hand

SST ............................... Special service tool

ST .................................

Start

SW . . .............................. Switch

TDC. ............................. Top dead center

4VVD ............................. 4-wheel drive

Page 31 of 677

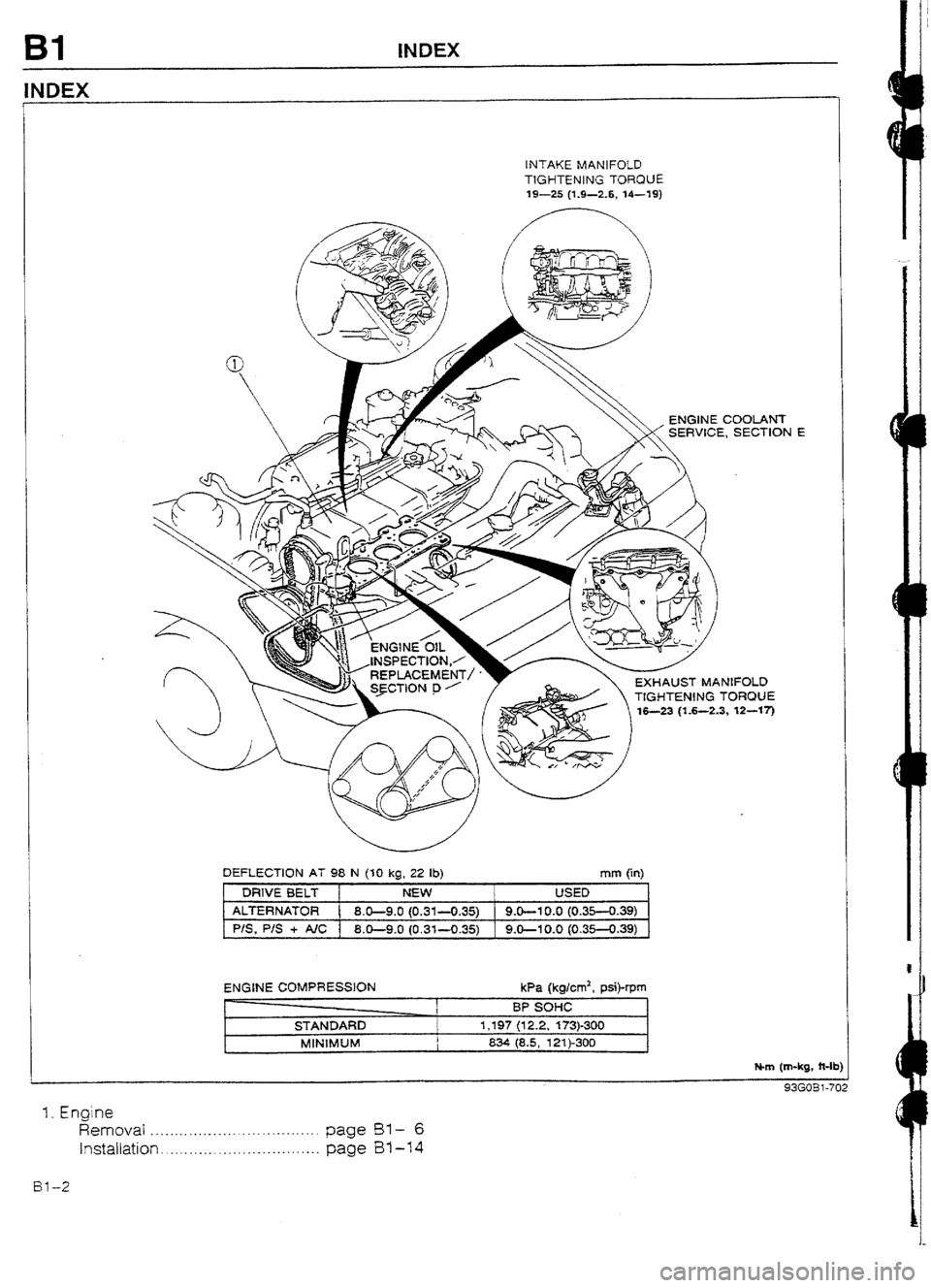

Bl INDEX

INDEX

INTAKE MANIFOLD

TIGHTENING TORQUE

19-25 (1.9-2.6, U-19)

EXHAUST MANIFOLD

TtGHTIEN!NG TORQUE

,3, 12-w-j

DEFLECTION AT 98 N (30 kg, 22 lb)

mm (in)

DRIVE BELT NEW USED

AlTERNATOR

8.0-9.0 (0.31-0.35) 9.0-l 0.0 (0.35-0.39)

PIS, P/S + AIC 1 8.0-9-O (0.31-O-35) 9.0-I 0.0 (0.35-0.39)

ENGINE COMPRESSION

STANDARD

MlNlMUM kPa (kglcm2, psi)-rpm

BP sol-lc

1,197 (12.2, 173)-300

834 (8.5, 121)-300

N-m (m-kg, ?t-It

cIz!f-mRl-71

1. Engine

Removal . . . . . . ..*..*-..............-....... page BY-- 6

Installation . . . . . . ..__. . . . . . . . .._...... . . . .

page B1-14

Bl-2

Page 42 of 677

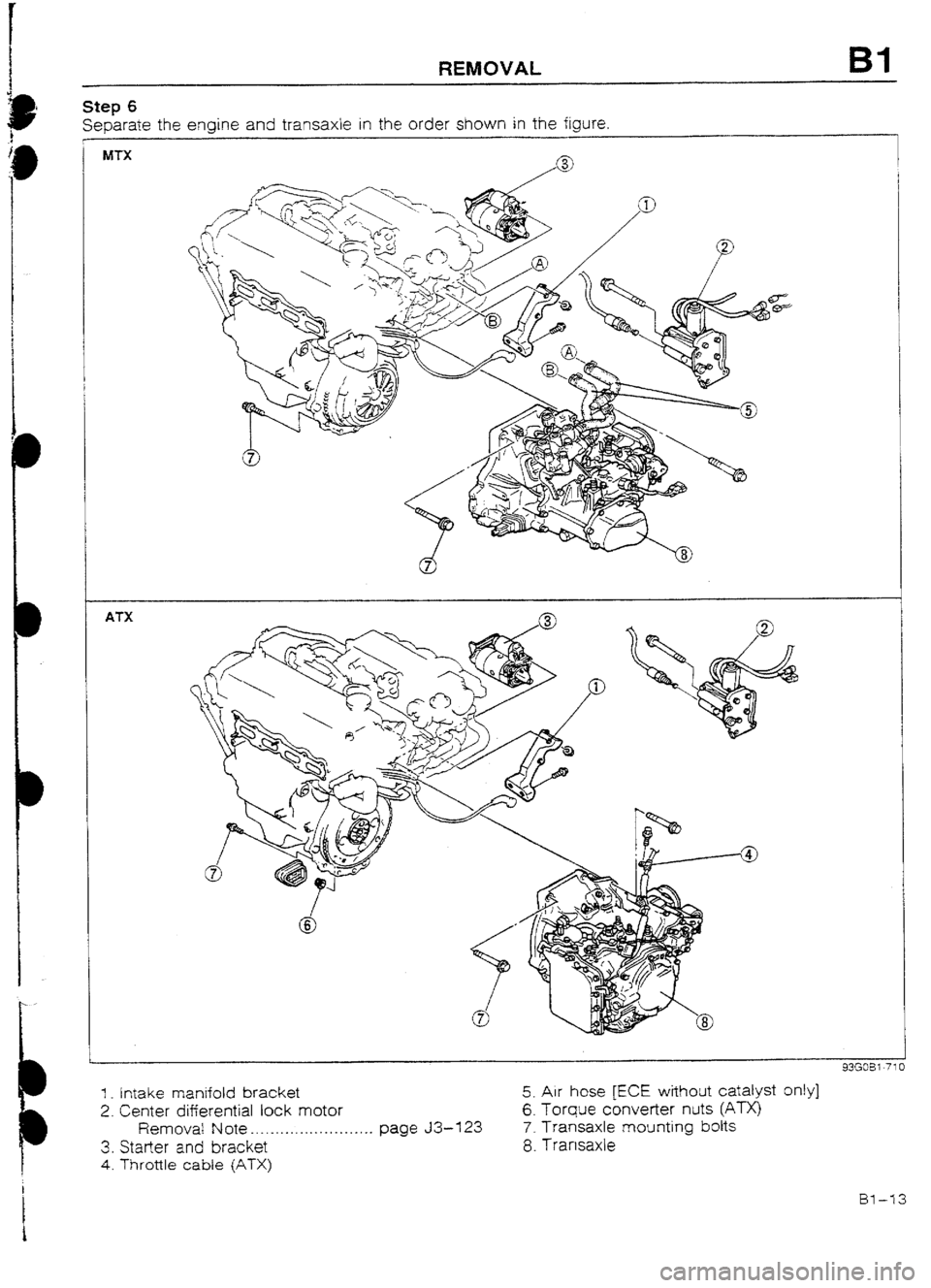

REMOVAL Bl

Step 6

Separate the engine and transaxle in the order shown in the figure,

MTX

ATX

43GX3i-71

1 _ Intake manifold bracket 5. Air hose [ECE without catalyst only)

2. Center differential lock motor 6. Torque converter nuts @TX)

Removal Note . . _. _. . . ._. . . . . . . . . . . . . _. page 33-l 23 7. Transaxle mounting bolts

3. Starter and bracket 8. Tramaxle

4. Throttle cable (ATX)

Bl-73

Page 43 of 677

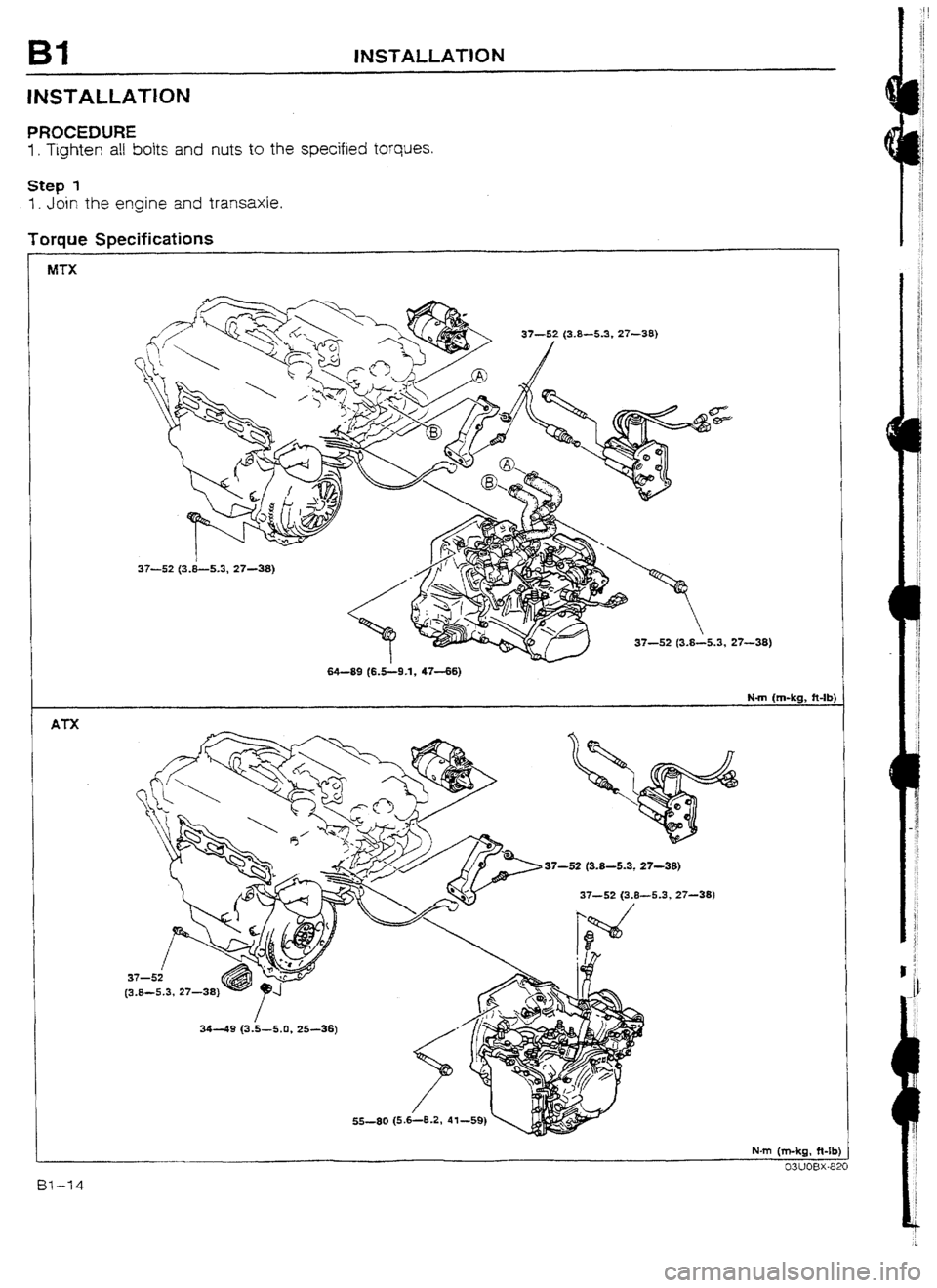

Bl INSTALLATiON

INSTALLATION

PROCEDURE

I. Tighten all bolts and nuts to the specified torques.

Step I

1. Join the engine and transaxle.

Toraue Snecifications

1- - -r--

MTX

37-52 (3.8-5.3, 27-38)

37-52 (3.8-5.3, 27-38)

ATX

64-89 (6 S-9 -1, 4746)

Nm (m-kg, ft-lb)

37-52 (3.8-5.3, 27-38)

55-80 (5.6-8.2, 41-59)

N-m (m-kg, ft-lb

51-14

Page 44 of 677

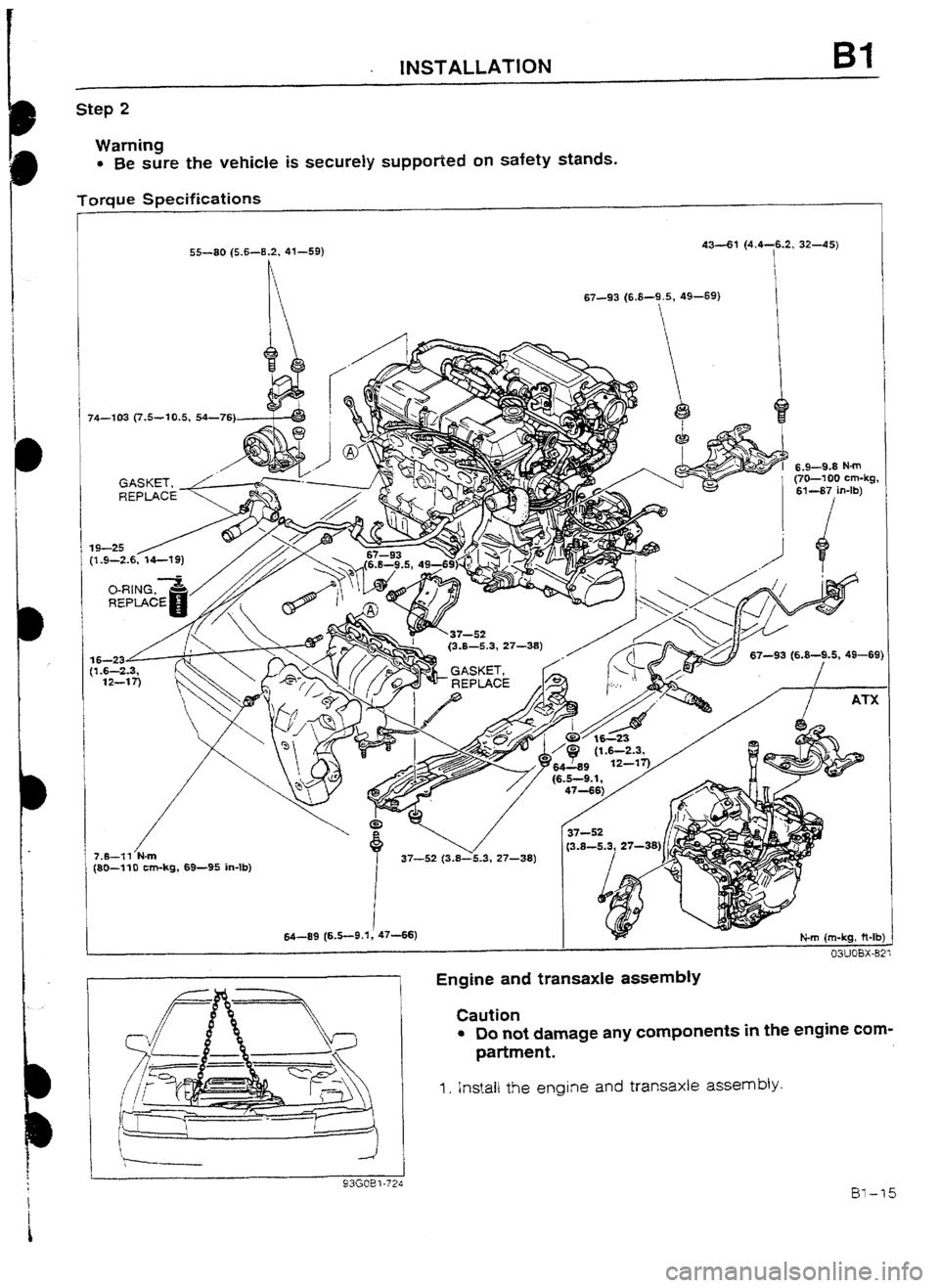

INSTALLATlON ES1

Step 2

Warning

l Be sure the vehicle is securely suppofied on safety stands.

Torque Specifications

I

I i 74-103 (7.5--10.5, 54-76)

/ 7.8-?I N-m

(80--flO cm-kg, 69-95 in-lb) 55-80 (5.fG-8.2, 41-59) 43-61 (4.4-6.2, 32-45)

I

1

I 64-89 (6.5-9.1, 4746) 67-93 (6.8-9.5, 49-69)

7 37-5x 27-38)

Engine and transaxle assembly

Caution

l Do not damage any components in the engine com-

partment.

1. Install the engine and transaxle assembly.

Page 45 of 677

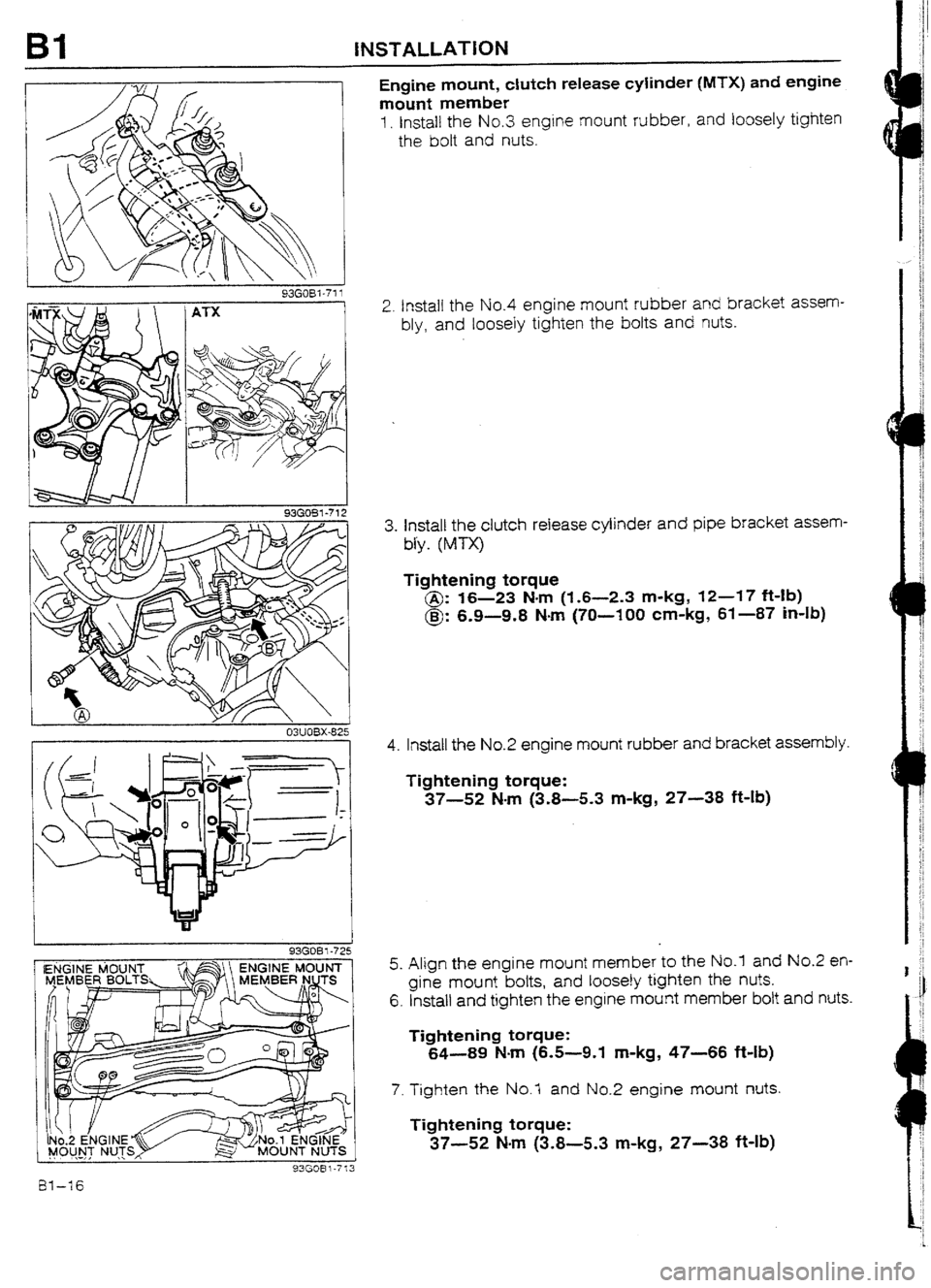

Bl INSTALLATION

Engine mount, clutch release cyiinder (MTX) and engine

mount member

1. Install the No.3 engine mount rubber, and loosely tighten

the bolt and nuts.

2. Install the No.4 engine

mount rubber and bracket assem-

bly, and loosely tighten the

k~olts and nuts.

3. Install the clutch release cylinder and pipe bracket assem-

U-y.

(MTX)

Tightening torque

@: 16-23 Nm (1.6-2.3 m-kg, 12-47 ft-lb)

@: 6.9-9.8

N-m (70-100 cm-kg, 61-87 Mb)

I

93GOBl-72 J .-, , . . ,.

I

93GOBi-713

4. Install the No.2 engine mount rubber and bracket assembly.

Tightening torque:

37-52 Nm (3.8-5.3 m-kg, 27-38 ft-lb)

5. Align the engine mount member to the No.1 and No.2 en-

gine mount bolts, and loosely tighten the nuts.

6. Install and tighten the engine mount member bolt

and nuts.

Tightening torque:

64-89 N-m (6.5-9.1 m-kg, 47-66

ft-Lb)

7. Tighten the No.7 and No.2 engine mount nuts.

Tightening torque:

37-52 Mm (3.8-5.3 m-kg, 27-38 ft.lb)

Page 46 of 677

INSTALLATlON

MTX 1 A-I-X

WUOBX-828

43GOBl-72t

Step 3

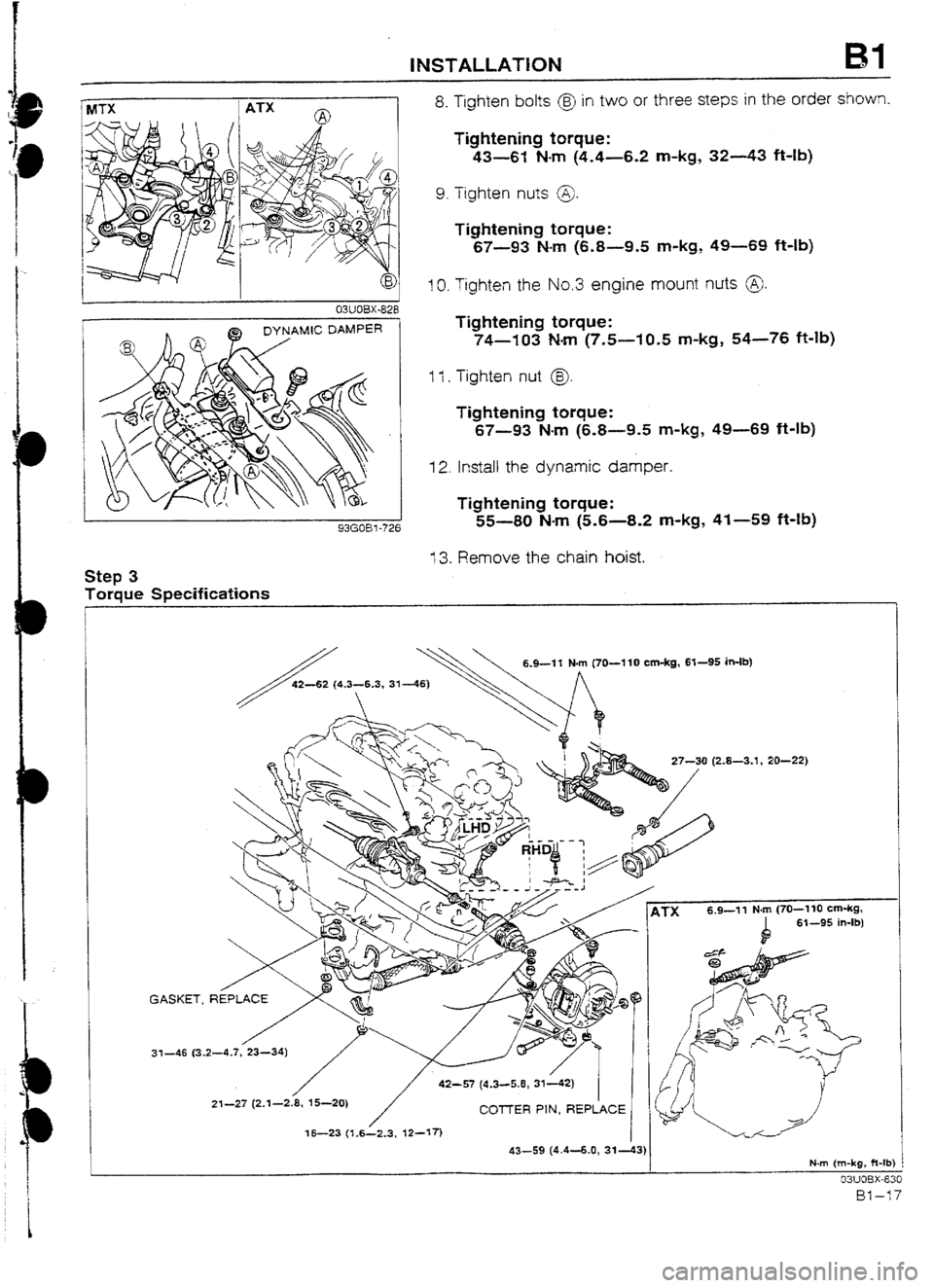

Torque Specifications 8. Tighten bolts @ in two or three steps in the order shown.

Tightening torque:

43-61 N-m (4.4-6.2 m-kg, 32-43 ft-lb)

9. Tighten nuts @J.

Tightening torque:

67-93 N-m (6.8-9.5 m-kg, 49-69 ft-lb)

IO. Tighten the No.3 engine mount nuts 0.

Tightening torque:

74-103 Nom (7,5--f0,5 m-kg, 54-76 ft-lb)

Ii. Tighten nut @.

Tightening torque:

67-93 N-m (6.8-9.5 m-kg, 49-69 ft-lb)

12. Install the dynamic damper.

Tightening torque:

55-W N-m (5.6-8.2 m-kg, 41-59 ft-Ib)

13. Remove the chain hoist.

6.9-11 N-m (70-l 10 cm-kg, 63-95 in-lb)

-8-3.1, 20-22)

&TX 6.9-11 N-m (70-130 cm-kg,

b 6% -95 in-lb) /

42-57 (4.3~5.8,31142)

21-27 (2.1-2.8, 15-20)

COTTER PIN, REPLACE

16-23 (1.6L2.3, Q-17)

N-m {m-kg, ft-tb

03UOBX-8:

Page 47 of 677

81 INSTALLATION

93GOBl-714

I 93E082-061

i 03UOBX-848

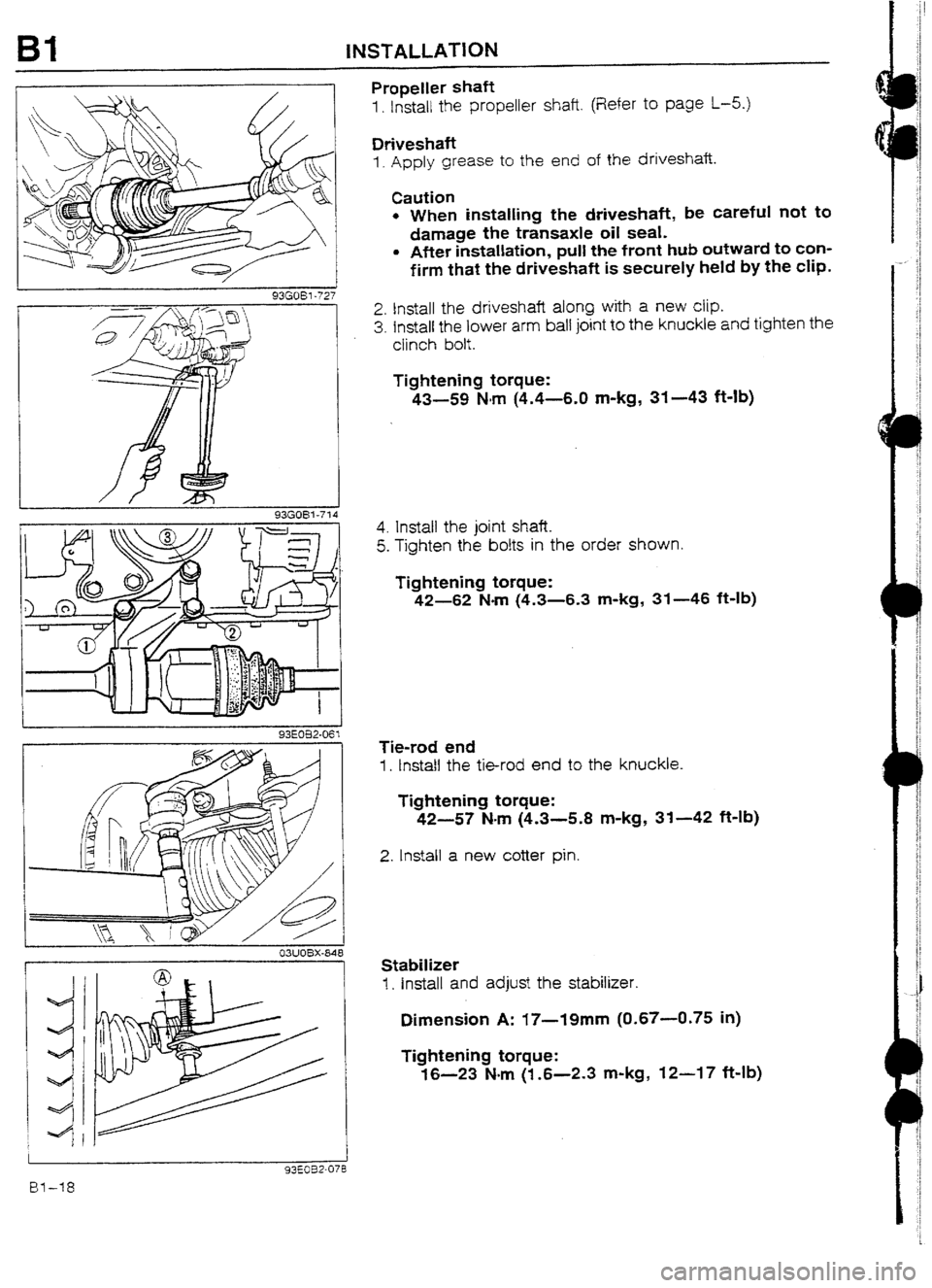

Propeller shaft

1. Install the propeller shaft. (Refer to page l-5.)

Driveshaft

I. Apply grease to the end of the driveshafi.

Caution

l When installing the driveshaft, be careful not to

damage the transaxle oil seal.

l After installation, pult the front hub outward to con-

firm that the driveshaft is securely held by the cIip.

2. Install the driveshaft along with a new clip.

3. fnstall the lower arm ball joint to the knuckle and tighten the

ciinch bolt.

Tightening torque:

43-59 Nm (4.4-6.0 m-kg, 31-43 ft-lb)

4. Install the joint shaft.

5. Tighten the bolts in the order shown.

Tightening torque:

42-62 Nom (4.3-6.3 m-kg, 31-46 f&lb)

Tie-rod end

1. InstaIl the tie-rod end to the knuckle.

Tightening torque:

42-57 N-m (4.3-5.8 m-kg, 31-42 ft-lb)

2. Install a new cotter pin.

Stabilizer

I. install and adjust the stabilizer.

Dimension A: i7-19mm (0.67-0.75 in)

Tightening torque:

16-23 Nm (l-6-2.3 m-kg, 12-17 Mb)

I

I