ECU MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 108 of 677

-- -

“-

I t-

SQLENOlD VALVE AEAR WINOOW

(PRESSURE IQNITION HEADLIG t IT

DEFFIOSTER

REGULATOR SWITCH SWITCH

SWITCH

CONTROL)

lNJECTOR ELECTRICAL

MAIN RELAY , FAN

AX SWITCH

r DliiGNOSlS BLOWER Ivc

CONNECTOR SWITCH RELAY

ECU

AIRFLOW METER

Tt

WATE!

THERMOSENSOR

CLUTCH [/ t

-I

’ NEUTRAL

SWITCH SWITCH 4X4 CONTROL UNIT

1

FbEL

PUMP

TRANSFER PUMP TRANSFER

PUMP SWlTCtJ

Page 112 of 677

SUPPLEMENTAL SERVICE INFORMATION, FUEL SYSTEM Fl

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison with Mazda 323 Workshop Manuals

(I 203-I U-89F, 1204-I O-89F, I2061 O-89F).

fuel tank

l Removal I Inspection I Installation

4x4 control unit (Fuel pump control unit)

l Inspection procedure added

l Replacement procedure added

Transfer pump switch

l Inspection procedure added

l Replacement procedure added

Transfer pump

l Inspection procedure added

l Replacement procedure added

Exhaust system components

l Removai I Inspection I installation 93GOF? -706

FUELSYSTEM

PRECAUTION

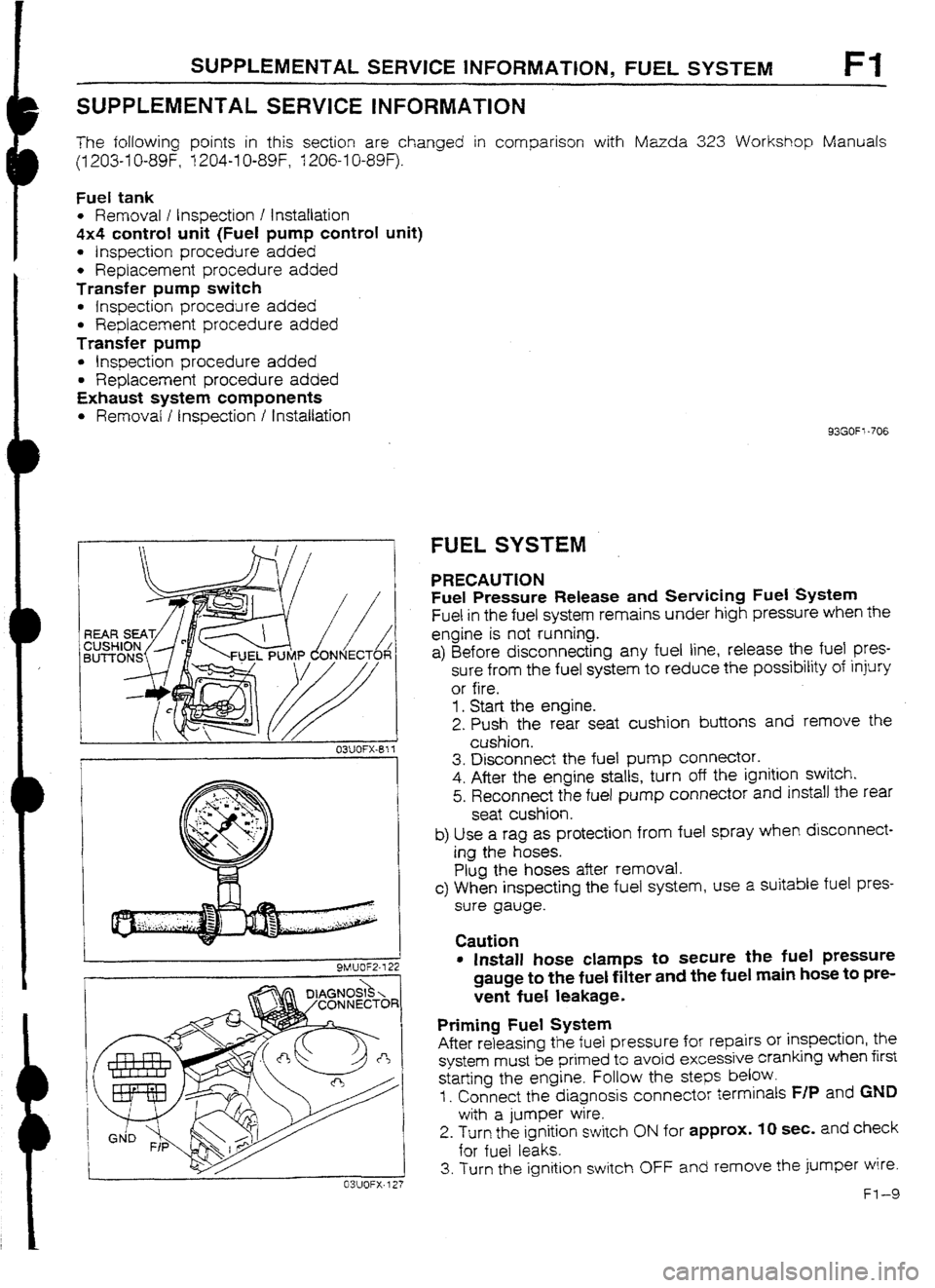

Fuel Pressure Release and Sewicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel

pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c> When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure tile fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the

steps below.

I. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch ON for approx. IO sec. and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

Fl-9

Page 120 of 677

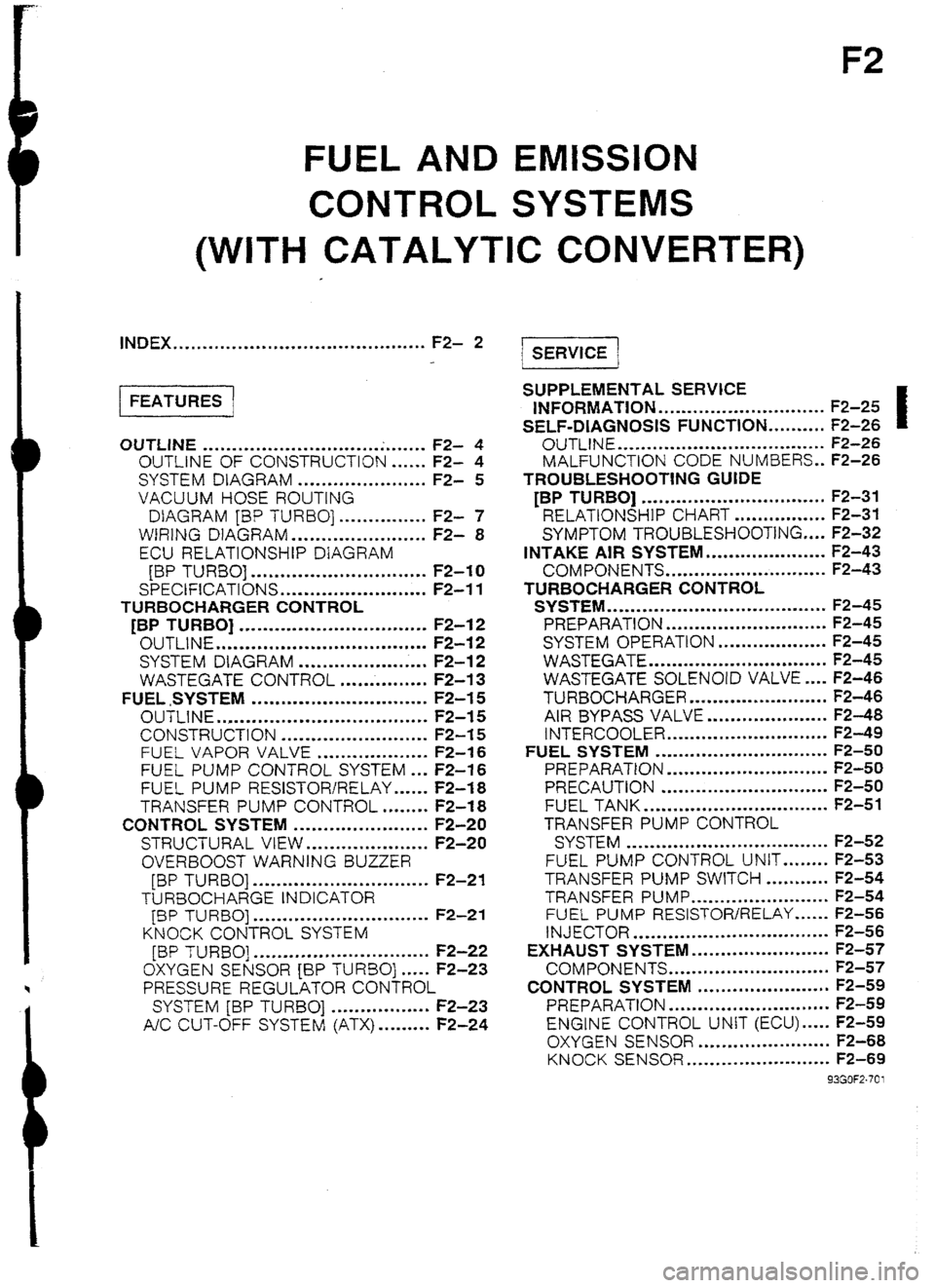

F2

FUEL AND EMISSION

CONTROL SYSTEMS

(WITH CATALYTIC CONVERTER)

.

INDEX ..*.........**.*.........*..........*...... F2- 2

OUTLINE ...................................... F2- 4

OUTLINE OF CONSTRUCTION.. .... F2- 4

SYSTEM DIAGRAM ...................... F2- 5

VACUUM HOSE ROUTING

DIAGRAM [BP TURBO] ............... F2- 7

WIRING DlAGRAM.. ..................... FZ- 8

ECU REtATlONSHIP DIAGRAM

[BP TURBO] .............................. F2-10

SPEClFtCATlONS. ........................ F2-11

TURBOCHARGER CONTROL

[BP TURBO] ................................ F2-I 2

OUTLINE .................................... F2-I 2

SYSTEM DIAGRAM ................. .; ... F2-12

WASTEGATE CONTROL ...............

F2-13

FUEL,SYSTEM

.............................. F2-15

OUTLINE

.................................... F2-15

CONSTRUCTlON ......................... F2-15

FUEL VAPOR VALVE ................... F2-16

FUEL PUMP CONTROL SYSTEM.. . F2-16

FUEL PUMP RESISTOR/RELAY ...... F2-18

TRANSFER PUMP CONTROL. ....... F2-I 8

CONTROL SYSTEM ....................... F2-20

STRUCTURAL VIEW.. ................... F2-20

OVERBOOST WARN!NG BUZZER

[BP TURBO] .............................. F2-21

TURBOCI-IARGE INDICATOR

[BP TURBO] .............................. F2-21

KNOCK CONTROL SYSTEM

[BP TURBO] .............................. F2-22

OXYGEN SENSOR [BP TURBO]. .... F2-23

PRESSURE REGULATOR CONTROL

SYSTEM [BP TURBO] ................. F2-23

A/C CUT-OFF SYSTEM (ATX) .........

F2-24 SUPPLEMENTAL SERVICE

INFORMATION ............................. F2-25

SELF-DIAGNOSIS FUNCTION .......... F2-26

OUTLINE

.................................... F2-26

MALFUNCTION CODE NUMBERS . . F2-26

TROUBLESHOOTtNG GUIDE

[BP TURBO1

................................ F2-31

RELATlONSHlP CHART ................ F2-31

SYMPTOM TRUUBLESH0OTlNG .... F2-32

tNTAKE AIR SYSTEM ..................... F2-43

COMPONENTS ............................ F2-43

TURBOCHARGERCONTROL

SYSTEM ...................................... F2-45

PREPARATION ............................ F2-45

SYSTEM OPERATION ................... F2-45

WASTEGATE ............................... F2-45

WASTEGATE SOLENOID VALVE.. .. F2-46

TURBOCHARGER ........................ F2-46

AIR BYPASS VALVE ..................... F2-48

INTERCOOLER ............................ F2-49

FUEL SYSTEM .............................. F2-50

PREPARATION ............................ F2-50

PRECAUTION ............................. F2-50

FUEL TANK

................................ F2-51

TRANSFER PUMP CONTROL

SYSTEM ................................... F2-52

FUEL PUMP CONTROL UNIT ........ F2-53

TRANSFER PUMP SWITCH ........... F2-54

TRANSFER PUMP.. ...................... F2-54

FUEL PUMP RESISTOR/RELAY ...... F2-56

INJECTOR

.................................. F2-56

EXHAUST SYSTEM

COMPONENTS .................................................... ;ff;

CONTROL SYSTEM ....................... F2-59

PREPARATION

............................ F2-59

ENGINE CONTROL UNIT (ECU) ..... F2-59

OXYGEN SENSOR ....................... F2-68

KNOCK SENSOR ......................... F2-69

93GOF2.701

Page 127 of 677

![MAZDA 232 1990 Suplement User Guide F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER MAZDA 232 1990 Suplement User Guide F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER](/img/28/57056/w960_57056-126.png)

F2 OUTLINE

ECU RELATIONSHIP DlAGRAM [BP TURBO]

INPUT DEVICE KNOCK SENSOR

KNOCK

i( CONTROL

DlSTRlBUTOR ,-, UNIT

NC SWITCH

--k/L SWITCHS

{REAR WINDOW DEFROSTER SWITCH.

HEADLIGHT SWITCH, BLOWER SWITCH,

ELECTRICAL FAN SWITCH)

BATTERY A

THRO77LE

SENSOR

NEUTRAL/ IDENTIFICATION

CLUTCH SWITCH

DIAGNOSIS

CONNECTOR

(TEN TERMINAL) INTAKE AIR

THERMOSENSOR

OUTPUT DEVICE

CIRCUIT

OPENING

SOLENOID VALVE

(PRESSURE REGULATOR

WASTEGATE

SOLENOID VALVE

RESISTOR/RELAY

SOLENOID VALVE

(PURGE CONTROL)

93GOFZ-71

F2-10

Page 130 of 677

![MAZDA 232 1990 Suplement User Guide TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torq MAZDA 232 1990 Suplement User Guide TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torq](/img/28/57056/w960_57056-129.png)

TURBOCHARGER CONTROL [BP TURBO] F2

WASTEGATE CONTROL

The engine control unit controls the wastegate solenoid valve to give higher boost to the engine in the higher

rpm range, increasing engine torque

and power.

System

Diagram

I

t

1 ECU

i i

AIRFLOW METER ACTUATOR

WASTEGATE

WASTEGATE

SOLENOID VALVE

r ACTUATOR

WASTEGATE SOLENOID VALVE

: OFF (VALVE CLOSED)

ACTUATOR

BOOST

PRESSURE

WASTEGATE SULENOlD VALVE

: ON (VALVE OPEN) Operation

Engine speed below 5,300 rpm

The

wastegate solenoid valve is OFF. Boost pressure is ap-

plied directly to the actuator and the wastegate opens when

the boost pressure exceeds 49 kPa (0.5 kg/cm , 7.1

psi).

Engine speed above 5,300 rpm

The wastegate

solenoid valve is UN. Some boost pressure is

bypassed to the intake manifold, limiting the opening of the

wastegate to increase boost pressure and

improve engine per-

formance.

F2-13

Page 133 of 677

F2 FUEL SYSTEM

FUEL VAPOR VALVE

FUEL VAPOR VALVE

93GOF2-722

The fuel vapor valve is installed in the fuel tank to allow fuel vapors within the tank to escape to the charcoal

canister.

The fuel vapor valve contains a shut-off valve to prevent raw fuel from escaping during hard cornering

01

at other times when there is significant fuel slosh.

FUEL PUMP CONTROL SYSTEM [BP TURBO]

Outline

l The fuel pump control system supplies electric power to the fuel pump at ail times while the engine is

running. The fuel pump can thus operate even though the fuel pump switch in the airflow meter OFF.

rhe fuel pump switch may open (switch OFF) on deceleration due to back-flow of air from the turbocharger.]

l To improve fuel pump longevity, the fuel pump is controlled by the engine control unit (ECU). (Refer to

next page.)

MAIN RELAY (FUEL 1NJ RELAY)

I I FUEL PUMP

RESISTOR/RELAY ECU

I

ON

P CIRCUIT OPENING

I--

DIAGNOSIS

CONNECTOR

TERMINAL F/P CPU

F2-16

Page 134 of 677

FUEL SYSTEM F2

Two-stage WeI pump operation

Engine running (Except heavy load or cranking)

The ECU 1 I circuit is ON, opening the contact plate in the fuel pump resistor/relay. Current from the circuit

opening relay to the fuel pump flows through the resistor in the fuel pump resistor/relay, and the voltage

to the fuel pump is reduced to approx. WV, causing the fuel pump to operate at a reduced speed to im-

move fuel pump longevity.

MAIN RELAY

Engine under heavy load or cranking

The ECU 1 I circuit is OFF and the contact plate in the fuel pump resistor/relay is closed. Unreduced battery

current flows to the fuel pump through the contact plate, causing the fuel pump speed and output to be

increased to meet the demands of the engine.

I

L

:: _:

:.i

I,. I,

:: :

_:. :

. . :

:: :_

.:: 1.

pi ‘.

. . ::

:: :_ c

-. .>:

i :: . . . . . . . . .

:; .::..:.y ::.

. . . . . . . ..__. I

93GW2-725

FZ-17

Page 135 of 677

![MAZDA 232 1990 Suplement User Guide F2 FUEL SYSTEM

93GOF2-726

FUEL PUMP RESISTOR/RELAY [BP TURBO]

The fuel pump resistorlretay supplies battery voltage to the

fuel pump when the ECU 11 circuit is OFF, and approx. 1 OV

when the ECU MAZDA 232 1990 Suplement User Guide F2 FUEL SYSTEM

93GOF2-726

FUEL PUMP RESISTOR/RELAY [BP TURBO]

The fuel pump resistorlretay supplies battery voltage to the

fuel pump when the ECU 11 circuit is OFF, and approx. 1 OV

when the ECU](/img/28/57056/w960_57056-134.png)

F2 FUEL SYSTEM

93GOF2-726

FUEL PUMP RESISTOR/RELAY [BP TURBO]

The fuel pump resistorlretay supplies battery voltage to the

fuel pump when the ECU 11 circuit is OFF, and approx. 1 OV

when the ECU 11 circuit is ON. It is mounted on the firewall.

TRANSFER PUMP CONTROL

Outline

The fuel tank is buitt with separate right and left sections to accommodate the. installation of the propeller

shaft. As fuel is puited from the right side of the tank, the transfer pump pumps the fuel from the left to the

right (fuel pumb) side to balance the fuel level.

FUEL IN LEFT TANK

I

FUEL PUMP CONTROL. UNIT

/ TRANSFER PUMP

TRANSFER PUMP SWITCH: OFF

NO FUEL IN LEFT

TANK

FUEL PUMP CONTROL UNIT / TRiNSFER PUMP

TRANSFER PUMP SWITCH: UN

93GOF2-727

Operation 1. Whenever the ignition switch is ON and fuel is in the left (transfer pump)

side of the fuel tank the fuel pump switch is open, the transfer pump circuit in the fuel pump control unit is

closed, and the transfer pump

operates.

2. When the fuel in the left side of the tank drips betow a specified point, the fuel pump switch is grounded

and the transfer pump stops operation.

3. To prevent the transfer pump from

being turned ON and OFF repeatedly, possibly shorting the life of the

pump, when the vehicle is driven on a rough

road and the fuel level is low, there is a ten-second delay

circuit in the control unit to delay the turning ON and OFF the pump.

f2--I 8

Page 138 of 677

![MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en MAZDA 232 1990 Suplement User Guide CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by en](/img/28/57056/w960_57056-137.png)

CONTROL SYSTEM

WE~DOST WARNlNG BUZZER [BP TURBO]

To improve engine reliability, the overboost warning buzzer installed in the instrument cluster sounds during

overboost conditions as detected by engine

speed and intake air amount caiculations within the ECU. The

driver is thus warned to reduce engine

speed.

DETECTtON

OVERBOOST

BUZZER

TURBOCHARGE INDICATOR [BP TURBO]

When the turbocharger boost pressure calcul’ated by intake air amount and engine speed reaches the predeter-

mined level and the transaxle is in gear, the turbocharge indicator illuminates to inform the driver of turbocharge

operation.

1

AIRFLOW METER

DISTRI BUTUR

rd” i

4 NEUTRAUCLUTCH

SWITCH ECU

* CALCULATION

-, OF

BOOST

PRESSURE

TURBOCHARGE

INDICATOR

Page 139 of 677

![MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL MAZDA 232 1990 Suplement User Guide F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTAL](/img/28/57056/w960_57056-138.png)

F2 CONTROL SYSTEM

KNOCK CONTROL SYSTEM [BP TURBO]

This svstem retards the ignition timina when enaine knocking occurs because of usage of low octane fuel, etc.

1NTAKE

MANIFO

KNOCK SENSOR

(INSTALLED BETWEEN No.2 AND

No.3 CYLINDER)

IGNITER

KNOCK iX?NTROL

UNIT

Operation

When the engine vibrates, the knock sensor generates a slight voltage signal that is the sent to the knock

control unit. The knock control unit determines whether the signal is a knocking signal. If it is a knocking

signal, the ignition spark is retarded according to the intensity of the knock to a maximum of 4O.

Inhibition of spark retardation

In order to improve drivability and fuel economy, the ECU inhibits the above spark retardation when the

‘engine load Ls light, the coolant temperature is below O°C (32OF), the engine is cranking during engine test

conditions.

Note

l The knock ~ensur and knock control unit cannot be inspected individually.

When a matfunction code number 05 is indicated, replace the knock controt unit or sensor

only after inspecting the related wiring and connectors.

F2-22