ECU MAZDA 232 1990 Suplement Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 157 of 677

![MAZDA 232 1990 Suplement Owners Guide F2 TROUBLESHOUTING GUIDE

I 22 KNOCKtNG [8P TURBO] I

IESCW-

l Abnormal combustron accompanied by audible “pinging” noise rim

TROUBLESHOOTING HtNTS]

3 incorrect ignition timing (Too advanced) @ MAZDA 232 1990 Suplement Owners Guide F2 TROUBLESHOUTING GUIDE

I 22 KNOCKtNG [8P TURBO] I

IESCW-

l Abnormal combustron accompanied by audible “pinging” noise rim

TROUBLESHOOTING HtNTS]

3 incorrect ignition timing (Too advanced) @](/img/28/57056/w960_57056-156.png)

F2 TROUBLESHOUTING GUIDE

I 22 KNOCKtNG [8P TURBO] I

IESCW-

l Abnormal combustron accompanied by audible “pinging” noise rim

TROUBLESHOOTING HtNTS]

3 incorrect ignition timing (Too advanced) @ Low octan fuel used

2

Knock control system malfunction @ Air/Fuel mixture lean

3 Carbon deposits in cylinder l Fuel injection amount not correct

3 Overheating l Fuel line pressure decreases while accelerating

TEP INSPECTION ACTlON

1

Connect System Selector to diagnosis connector Yes Go to next step

and set Test Switch to “SELF TEST” and check

for correct ignition timing at idle after warm-up’

ignition timing: BTDC 10 f lo

No Adjust

2 Check if “00” is displayed on Self-Diagnosis Yes Go to next step

Checker with igmtlon switch UN*

No Matf unction Code No. displayed

Check for cause (Refer to specified

check sequence) *

“88” flashes

Check ECU terminal 1 F voltage

Vottage: Approx. 12V

(Ignition switch ON) 0 page FZ-60

4 If OK, replace ECU

W: SELF TEST

4 If not OK, check wiring between

ECU and Self-Diagnosis Checker

3 Check for correct fuel line pressure at idle* Yes Check if fuel Iine pressure decreases

when accelerating quickly

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm2, 38-46 psi)

(vacuum hose to pressure regulator dis-

connected) 4 If decreases, check for clogging

between fuel pump and pressure

regulator

e If no decrease, go to next step

No tow pressure Check

fuel line pressure while pinching

fuel return hose

3 If fuel line pressure quickly in-

creases, check pressure

regulator*

4 If fuel line pressure gradually in-

creases, check for clogging be-

tween fuel pump and

pressure

regutator

If not clogged, check fuel pump

maximum pressure*

- -

.-

Refer to 323 Workshop Manual [1203-IO-89f (Europe} or t204-IO-89f (Australia)]. F2-40

Page 158 of 677

I

F2

fNSPECTlON ACTION

I Check if cootrng system IS OK’

YES Go to next step

No Repair or reptace

l Thermostat l

l Electric cooling fan * l Radiator*

5 Try known good ECU and check if condltlon Yes Replace ECU * rnproves

NO Change fuel to another brand or use

higher octane fuel

l Refer to 323 Workshop Manual [1203-l O-89F (Europe) or It 204-I O-89F (Australia)]. %%‘3OF2-748 -

F2-4 I

Page 167 of 677

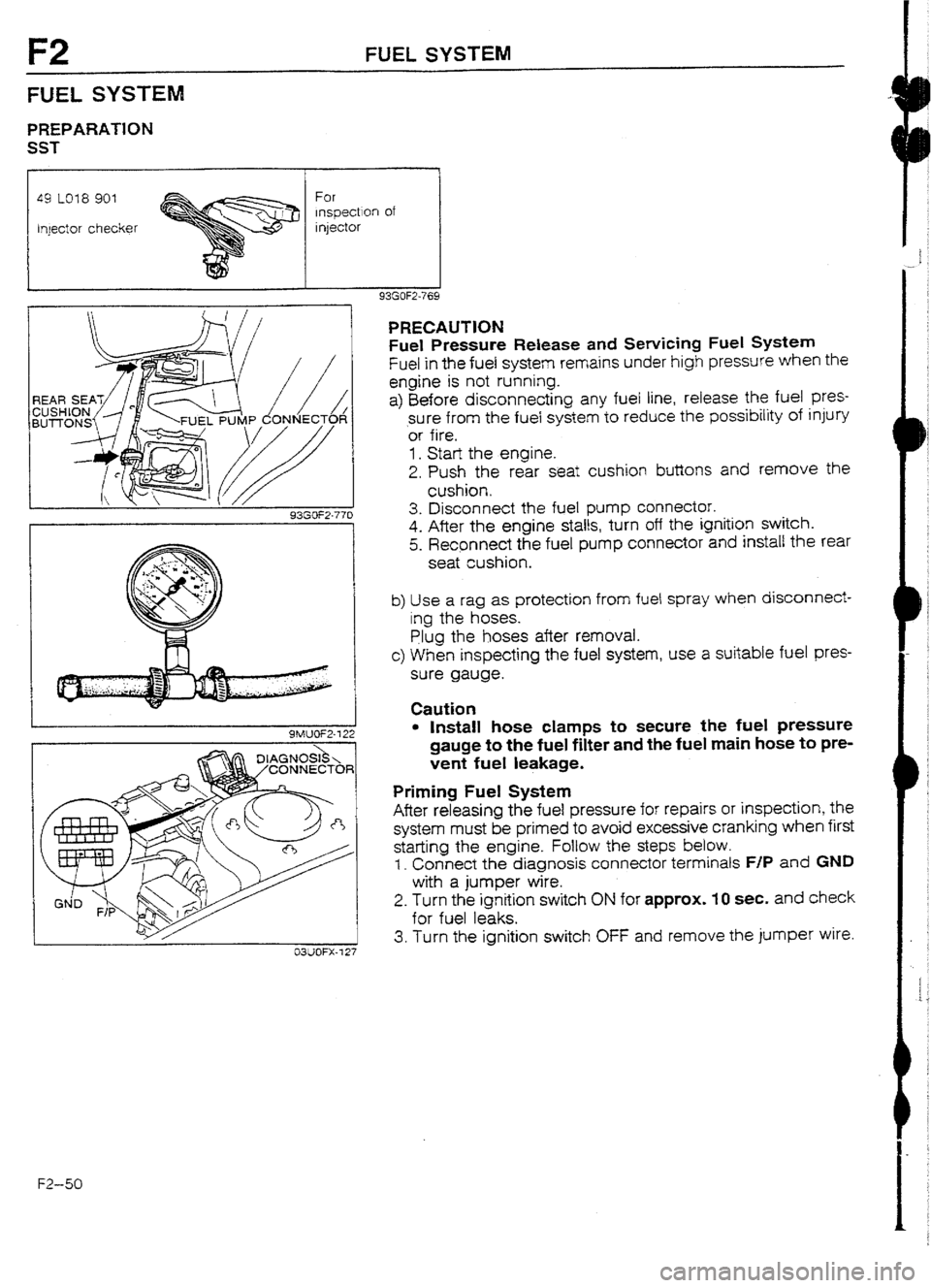

F2 FUEL SYSTEM

FUEL

SYSTEM

PREPARATlON

SST

49 LO18 901

Injector checker For

lnsgectlon of

injector

93GOF2.770

9MUOF2-722

03UOFX-7 27

F2-50

PRECAUTION

Fuel Pressure

Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

‘or fife,

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion,

3. Disconnect the fuel pump connector.

4. After the engine stalts, turn off the ignition switch.

5. Recpnnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after

removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuet leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps

below.

1. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 set, and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

Page 173 of 677

F2 FUEL SYSTEM

93GOF2-775

1 93GOF2-78(

93GOF2-78:

1

93GOF2-78;

-

93GOF2-783

FUEL PUMP RESISTOR/RELAY

System Operation

I. Remove the rear seat cushion.

2,

Measure the voltage at the fuel pump connector terminal

A {G/O).

Voltage

r Crankinq Approx. 12V

I

I- Others t ACKXOX. I OV i

3. If not within specification, perform the following inspection,

and repair or replace if necessary.

l Fuel pump resistor/relay resistance. (Refer to below.)

l ECU II terminal voltage. (Refer to page F2-60.)

l Wiring harness and connector.

inspection

1.. Disconnect the connector.

2. Ground the fuel pump resister relay terminal D.

3. Apply 12V to terminal C and check for continuity between

terminals A and B.

Terminal C

12 applied

ov Continutty between A and B

NO

Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.62-0.66Q [at 20% (68OF)l

INJECTOR

Volume Test

1. Remove the injectors with the delivery pipe.

2. Affix the injectors to the delivery pipe with wire.

Caution

l Affix the injectors firmly to the delivery pipe so that

no movement of the-injectors is possible.

Warning

l Be extremely careful when working with fuel.

Always work away from sparks or open flames.

3. Connect the SST to the battery and injector.

4. Check the injection volume with a graduated container.

Injection volume:

BP SUHC....44-47 cc (2.68-2.87 cu in)/15 sec.

BP Turbo

. ...87-105 cc (5.31 -6.41 cu in)/15 sec.

Caution

l When using the SST, make sure of the SST num-

ber and use correct one.

5. If nut correct, replace the injector(s).

Page 176 of 677

CONTROL SYSTEM F2

CONTROLSYSTEM

PREPARATION

SST

49 HOt8 9A3

Self-dragnosls

checker

Engrne signal

IT-iOFlllO~ 49 GO18 904

Sheet System selector

I 93GUF2-786

For inspection of ECU

93GOF2-787

93GOF2-801

TERMNALS 1

--I”- -

03UOFX

ENGINE CONTROL UNIT (ECU)

Inspection

1. Disconnect the ECU connectors.

2. Connect the SSTs (Engine Signal Monitor and Adapt-

er) to the ECU as shown.

3. Place

the SST (Sheet) 011 the Engine Signal Monitor.

4. Measure the voltage at each terminal.

(Refer to pages FZ-60 to F2-67.)

5. If any ECU terminal voltage is incorrect, check the related

input or output devices and wiring. If no problem is found,

reptace the ECU. (Refer to above.)

Caution l

Never apply voltage to SST terminals A and B.

F2-59

Page 178 of 677

CONTROL SYSTEM F2

Incorrect voltage Possible cause

Always OV

l ROOM 10A fuse burned l Open circuit in wiring from ROOM 10A fuse to ECU termrnal IA

Always OV

I l Main relay maifunctlon l Open or short crrcu~t in wirrng from main relay to ECU termrnal 1 B

Always OV (Srarrer turns)

l Open or short circuit in wiring from ignition switch to ECU terminal 1C

Always UV

l Main relay (FUEL INJ relay} malfunctron l Open circuit in wiring from main relay to diagnosis connector terminal + B l Open or short circuit in wiring from dragnosls connector terminal MEN to

ECU terminal 1D

Always approx. 12V

I . Poor connection at ECU connector

l ECU matfunction

Always approx. 5V

l ECU malfunction

-

I -

Always below No disptay on Self- . Main relay (FUEL INJ retay) malfunction (Refer to page F3-142)

2.5V Diagnosis Checker l Open circuit in wiring from main relay to diagnosis connector termjnal + B

“88” displayed and

l Open or short circuit in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal 1 F

tinuously

Always approx. 12V

l Poor connection at ECU connector l ECU malfunction

Always OV

l Short circuit in wiring from igniter to ECU terminal tG

Atways OV or approx. 12V

l Refer to Code No.42 Troubleshooting (Refer to page F2-30)

Always approx. 12V

l Fuel pump resistor/relay malfunction

Always OV

l Open or short circuit in wiring from ECU terminal 1 I to resistor/retay

Always below

A/C does not operate

l AJC relay malfunction

23 l Open circuit in wiring from ignition switch to NC relay l Open circuit in wiring from A/C relay to ECU terminal IJ

A/C switch OFF but

l Short circuit in wiring from A/C relay to ECU terminal IJ

AIC operates

l ECU matfunction

Always approx. t2V

Always below 1 .OV

l Poor connection at ECU connector l ECU malfunction

l Short circurt in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always approx. 12V

l Open circutt in wiring from diagnosis connector terminal TEN to ECU termi-

nal lK

l Open c~rcud in wiring from diagnosis connector terminal GND to ground

Always above 1 .OV

I

l Open circuit in wiring from ECU terminal 1 M to ground

F2-61

Page 180 of 677

CONTROL SYSTEM F2

Incorrect voltage

Always below 1 .OV Possible cause

l Throttle sensor misadjustment l Short circuit in wiring from throttle sensor to ECU terminal IN l ECU malfunction

Always approx. f 2V

Atways below 1 .OV (Stopfights OK)

Always below 1 .OV

l Throttle sensor misadjustment l Open circuit in wiring from throttle sensor to ECU terminal IN l Open ctrcuit in wiring from throttle sensor to ECU terminal 20

l Open crrcurt in wiring from stoplight switch to ECU terminal 10

l P/S pressure switch malfunction l Short circuit in wirrng from P/S pressure switch to ECU termrnai 1 P

l ECU malfunction

Always approx. 12V

Atways below 2.5V (Btower fan OK) . P/S pressure switch malfunction

l Open circuit in wiring from P/S pressure switch to ECU terminal I P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunction l Short circuit in wiring from A/C switch to ECU terminal 1 Q l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

l ’ A/C switch malfunction l Open c~rcurt in wiring from NC switch to ECU terminal 1Q l ken circuit H-I winnu from A/C switch to blower control switch

Always below 1.W

l Open or short circuit in wiring from fan relay to ECU terminal IR

(Electrkal cooling fan UK} l ECU malfunctron

Always below 1 .OV (Blower fan OK)

l Short crrcutt in wiring from blower control swrfch to ECU terminal IS l Poor connection at ECU connector l ECU malfunction

Always approx. 12V (Blower fan OK)

Always below Illumination lamp

1.w ON when rear

window defroster

switch ON 1

l Open circurt in wrring from blower control switch to ECU terminat IS

I

l Open or short circuit rn wiring from rear window defroster switch to ECU

terminal 1 T

ftlumination lamp

never ON

l Open circuit in wiring from ignition switch to rear window defroster switch

l Rear window defroster switch malfunction I

Always below 1 .OV (Headlights OK)

l Open or short circurt in wiring from headlight relay to ECU termtnal 1 U

Always below 1 .OV

Always approx. l2V

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

l Neutral switch maifunctton l Clutch switch malfunction l Open circuit in wiring from ECU terminal IV to neutral or clutch swttch

l Poor connection at ECU connector

93GOFZ789

F2-63

Page 182 of 677

CUNTRUL SYSTEM F2

Incorrect voltage Possible cause

I

Above Ok’ l Poor contact at ground terminal l Open crrcurt in wiring from ECU to ground

Always approx. OV or approx. 2V

l Refer to Code No.02 Troubleshooting -

Always approx. OV or approx. ISV - l Refer to Code No.03 Troubleshooting

Always OV

Always OV -

- -

-

l Refer to Code No.05 Troubleshooting

l . Short circutt in wiring from ECU termrnal 2K to throttle sensor, or airflow

meter

l Poor connection at ECU connector l ECU malfunctron

Below 4-W or above 5.5V

Always OV

l ECU malfunction

l Throttle sensor malfunction l Short circurt in wiring from ECU terminal 2L to throttle sensor l Poor connection at ECU connector

l ECU malfunction

Always approx. 5V

Always constant

Always above f V

OV after warm-up

Always approx. IV after warm-up . Throttle sensor m&adjustment

l Open circuit in wiring from ECU terminal 2L to throttle sensor l Open circuit in wiring from ECU terminal 2t to ECU terminal 20

l Open circuit in wiring from ECU terminal 2M to throttle sensor l Open circuit in wiring from ECU terminal 2K to throttle sensor l Open circuit in wiring from ECU terminal 2D to throttle sensor

l Throttle sensor m&adjustment

l Refer to Code No.15 Troubleshooting

l Refer to Code No.1 7 TroubleshootIng

Always OV or approx. 5V l Refer to Code No.08 Troubleshooting

-

Always OV or approx. 5V

Always OV or approx. 5V

l Refer to Code No.1 0 Troubleshootrng

1

l Refer to Code No.09 Troubfeshooting

Always OV . Indicator broken

l Open or short circuit rn wirinq from ECU 2R to rgnition swatch

F2-65

Page 184 of 677

CONTROLSYSTEM F2

I

7

Incorrect voltage Possible cause

Always OV l Open or short circuit in wjring from ECU terminal 2s to buzzer

Always OV or approx. 12V

1 l Refer to Code No.25 Troubieshootlng

Always OV

1

l Marn relav (FUEL INJ relay) malfunction

/ l Open or shbrt circuit in wi&g from injector to ECU terminal 2U or 2V

Always approx. 12V

l ECU malfunctron

Always OV or approx. t2V

l Refer to Code No.34 TroubleshootIng

Always OV or approx. 12V

l Refer to Code No.26 Troubleshooting

Always OV

l Open or short circuit KI wiring from ECU terminal 2Y to relay

f2-67