engine MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 27 of 677

A SCHEDULED MAINTENANCE sERvw3 (Europe)

SCHEDULED MAfNTENANCE SERWCES (Europe)

MAWTENAN CE TABLE (Unlead Fuel Model)

Chati symbols:

I : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

* 1 Major service interval at 12 months120,OOO km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

*2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

“3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). failure to replace the tim-

ing belt may result in damage to the engine.

“4 If the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the &commended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c> Driving for a prolonged periods in cold temperatures or regularly driving only short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more oten

than at usual recommended intervals.

*6 This is a full function check of all electrical systems, i.e, all lights, washers (including condition of blades)

electric windows, sunroof, horn etc.

“7 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-707

A-8

Page 28 of 677

SCHEDULED MAtNTENANCE SERVICES (Europe) A

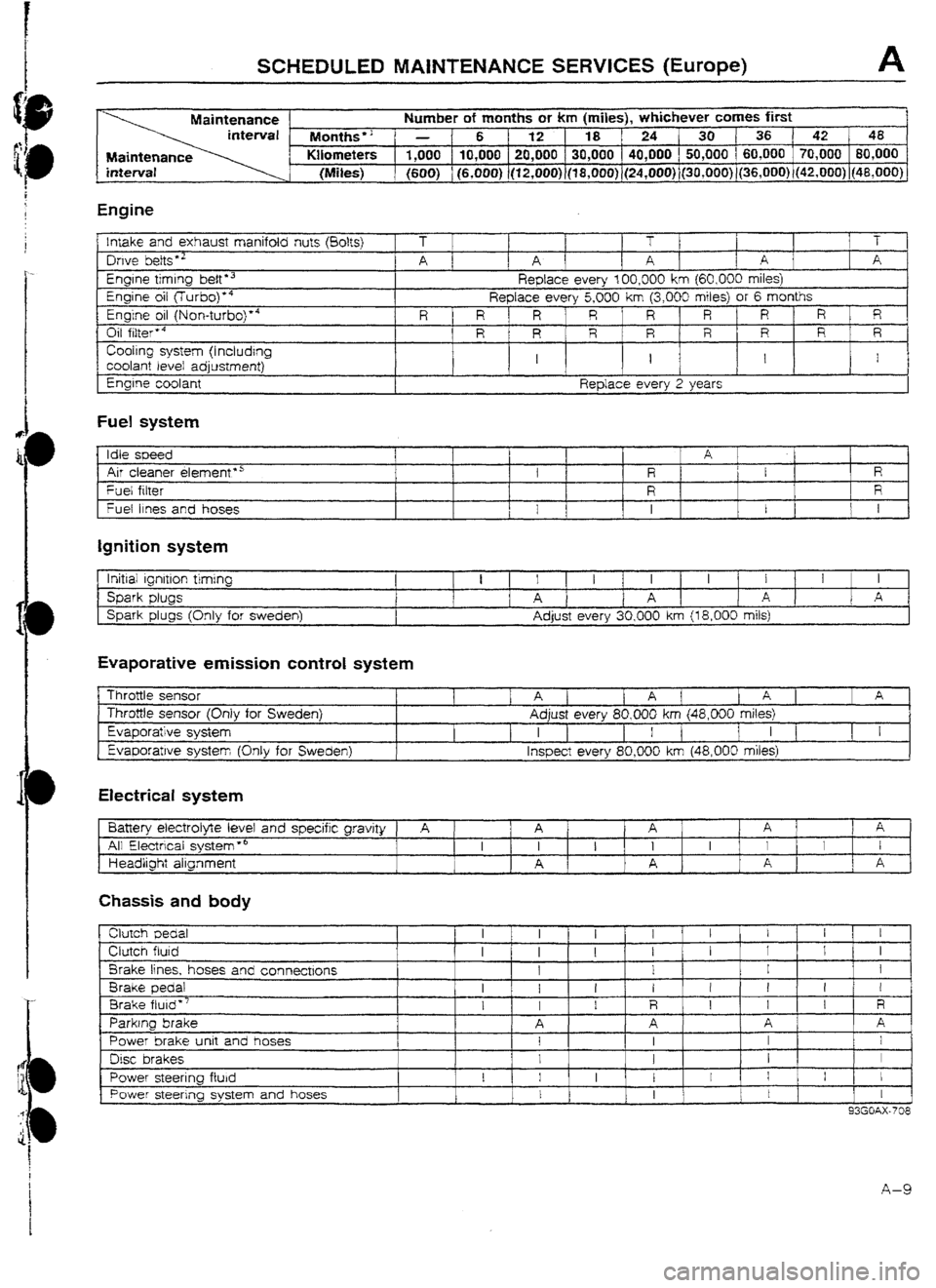

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 ‘24 30136 42 48

Maintenance Kilometers 1,000 10,000 20,000 30,000 40,000 50,000 ( 60,000 70,000 80,000

(Miles) (600) (6,000) (12,OOO)~(l8,0~0) (24,000) (3O,UOO))(36,000) (42,000) j48,OOU)

Engine

!nrake and exhaust manifold nuts (80&j

Owe belts *’

Engrne timing belt l 3

Engine oil flurbo)‘4

Engine oil (Non-turbo)“4

Oil filter’4

Cooling system (I ncludrng

coolant level adjustment)

Engine coolant T 1 T T

A 1 1 A A 1 A A

Reptace every 100,000 km

{60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R 1 R R R R ‘ R R R

R R R R R R R ’ R

I I I I

Replace every 2 years

Fuel system

Idle soeed

I A 1

Air cleaner elemenf*5 I f R E

R

Fuel fitter

R R

fuel 11~s and hoses 1

t 1 I I I I

Ignition system

lrritiai ignition timing

Spark plugs

Spark plugs (Only for Sweden) 1 I I I 1 I I 1 I I 1 I

A 1 A A 1 A

Adjust every 30,000 km {

18,000 mils)

Evaporative emission control system

Throttle sensor

Throttle sensor (Only for

Sweden)

Evaporative system Evaporatwe system Khlv

for Sweden) 1 1 Aj 1 A ( [ A ] 1 A

Adjust every 80,000 km (48,000 miles)

I 1 I [ I 1

I I [ 1 I

lnsoect everv 80.000 km (48.000 miles)

Electrical system

Battery electrolyte level and specific gravity

A 1 A A ’ 1 A ; A *

All Electrical system *’ I I 1 I I I I I I

Headlight alignment A A A I

c I A ,

Chassis and body

clutch Dedal

Clutch fluid

Brake lines, hoses and connectrons

Brake pedal

Brake fluid”’

Parking brake

Power brake unit and hoses

Disc brakes

Power steering fluid

Power steering system and hoses I

I I 1 1 1 I I

I I

I

I I I I 1 1 I

1

1 I I

I I I I t ! I I

I I I R I 1 I R

A A A A

I I I I

I 1 I 1

I 1 I I I I j I ,

I

I 1 I 1

I

93GOAX-708

A-9

Page 30 of 677

91

ENGINE

(SOHC)

INDEX . ..* ..I.... *...*... . . . . . ..I. . . ..‘.I.. . . . . ..I........ Bl- 2

1 FEATURES 1

OUTLINE

................................................ Bf- 3

OUTLINE OF CONSTRUCTION.. .............. BI- 3

SPECIFICATIONS .................................. Bf- 3

lNTERGHANGEABILtP( .......................... Bl- 4

FLYWHEEL

.......................................... Bl- 5

SUPPLEMENTAL SERVICE INFORMATION Bl- 6

REMOVAL

. . . . . . . . . . . . l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I. Bf- 6

PROCEDURE . . . . I..... ..,.... .*...*.. . . . . . . . . . . . . . . . Bl- 6

INSTALLATION . . . . . . I... . . . . . I ,... . ..*..... . . . . . . . . . . Bl-14

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . ..I . . . . . . .I . . . . . . . Bl-14

93GOBl-701

Page 31 of 677

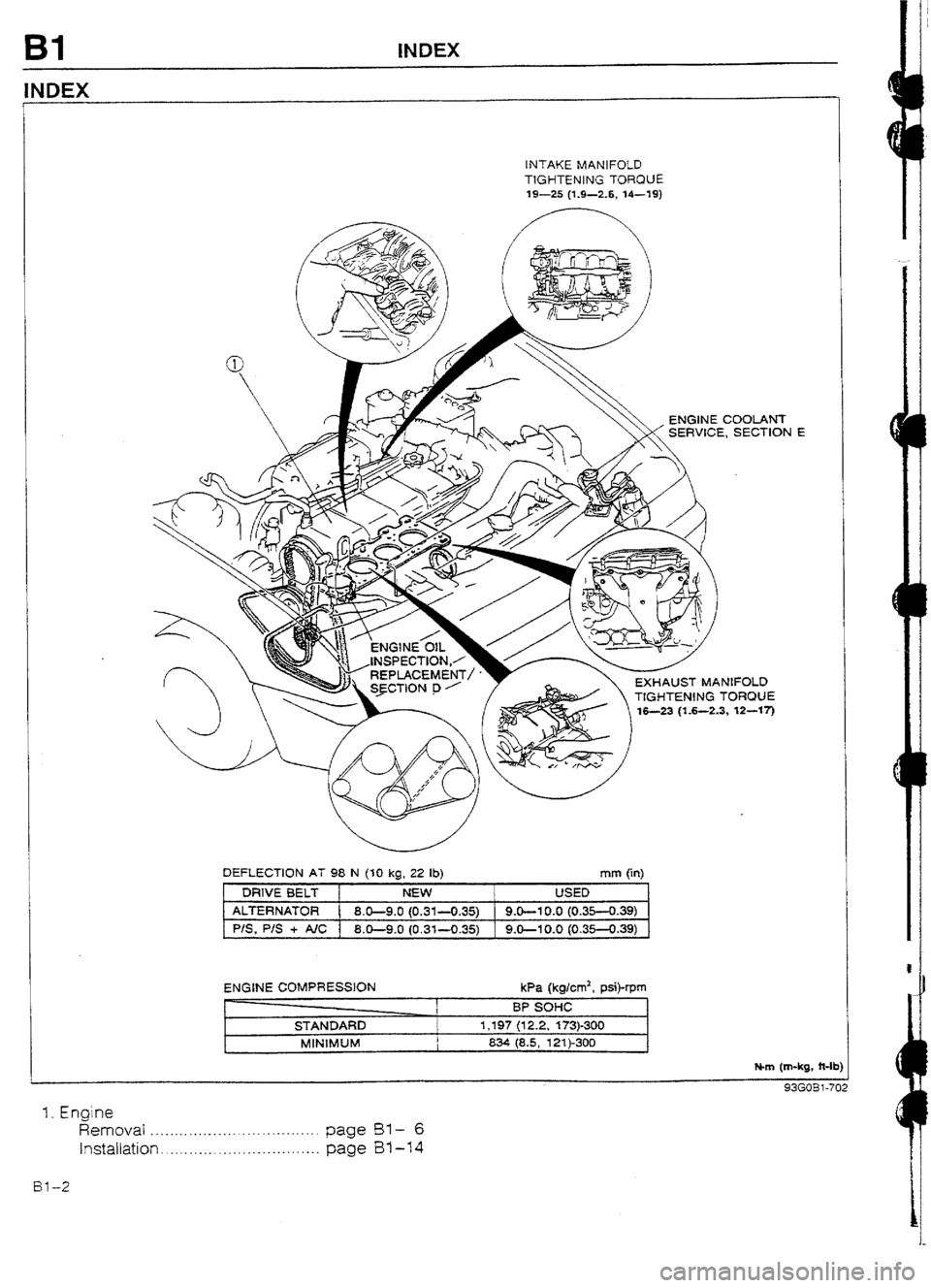

Bl INDEX

INDEX

INTAKE MANIFOLD

TIGHTENING TORQUE

19-25 (1.9-2.6, U-19)

EXHAUST MANIFOLD

TtGHTIEN!NG TORQUE

,3, 12-w-j

DEFLECTION AT 98 N (30 kg, 22 lb)

mm (in)

DRIVE BELT NEW USED

AlTERNATOR

8.0-9.0 (0.31-0.35) 9.0-l 0.0 (0.35-0.39)

PIS, P/S + AIC 1 8.0-9-O (0.31-O-35) 9.0-I 0.0 (0.35-0.39)

ENGINE COMPRESSION

STANDARD

MlNlMUM kPa (kglcm2, psi)-rpm

BP sol-lc

1,197 (12.2, 173)-300

834 (8.5, 121)-300

N-m (m-kg, ?t-It

cIz!f-mRl-71

1. Engine

Removal . . . . . . ..*..*-..............-....... page BY-- 6

Installation . . . . . . ..__. . . . . . . . .._...... . . . .

page B1-14

Bl-2

Page 32 of 677

OUTLINE Bl

UUTLlNE OF CONSTRUCTtON

The BP SOHC engine for the 4WD model is the same as for the 2WD model, except that the flywheel is

shaped differently.

The 3P SOHC engine for the ECE specification (without catatyst) 4WD model is the same as the ECE US83

model, except that the fuel and emission control system and the engine electrical system are modified.

(Refer to Sections Ff and G.)

93G08 i -702

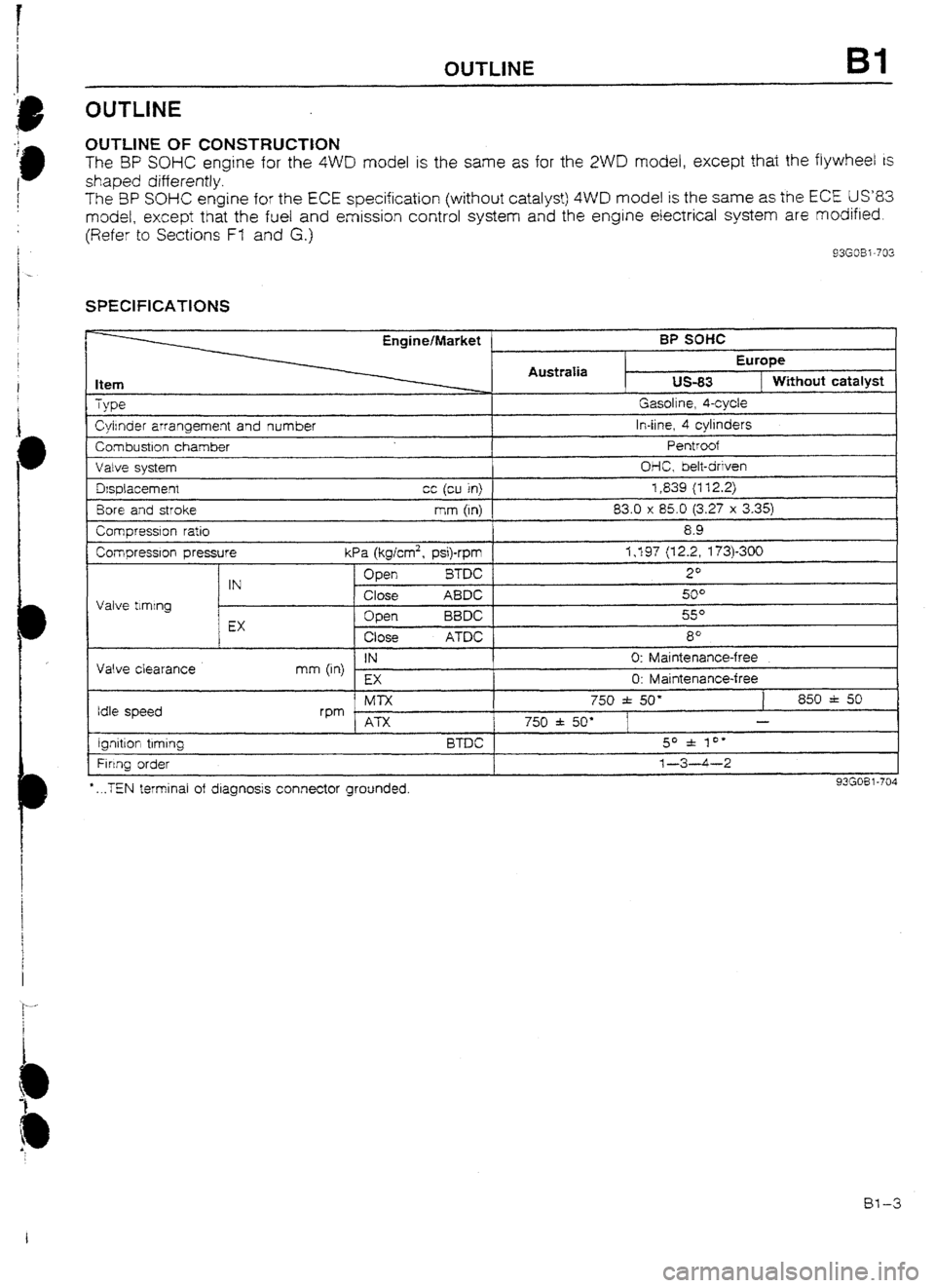

SPEClFlCATlONS

Item

TVDG?

Engine/Market ’

AustraIia BP soffc

Europe us-83

1 Without catalyst Gasoline. 4-cvcle

Cyirnder arrangement and number

Combustron chamber

Valve svstem In-line, 4 cylinders

Pentroof

OI-IC, belt-driven

Fi rtng order *

. ..TEN terminal of diagnosis connector grounded. 1-3-4-2

I 93G08 l-704

IN 0: Maintenance-free

mm (in)

EX

0: Maintenance-free Dsplacemenr cc (cu in) 1,839 (112.2)

Bore and stroke mm (In) 83.0 x 85.0 (3.27 x 3.35)

Comoression ratio

Compressron pressure I 8.9

I I kPa (kglcm2, psi)-rpm 1,197 (12.2, 173)300

Valve tlmtng Open BTDC 2O

IN

Close ABDC 5u”

c

Open BBDC so

EX

Close ATDC 8’

Valve clearance

Idle speed -~

Ml-x 750 f 50’ 850 f 50

rpm . I ATX 750 f 50” - I I I ignrtton trming BTDC 1 50 f 10’

1

Bl-3

Page 33 of 677

BI OUTIAlE

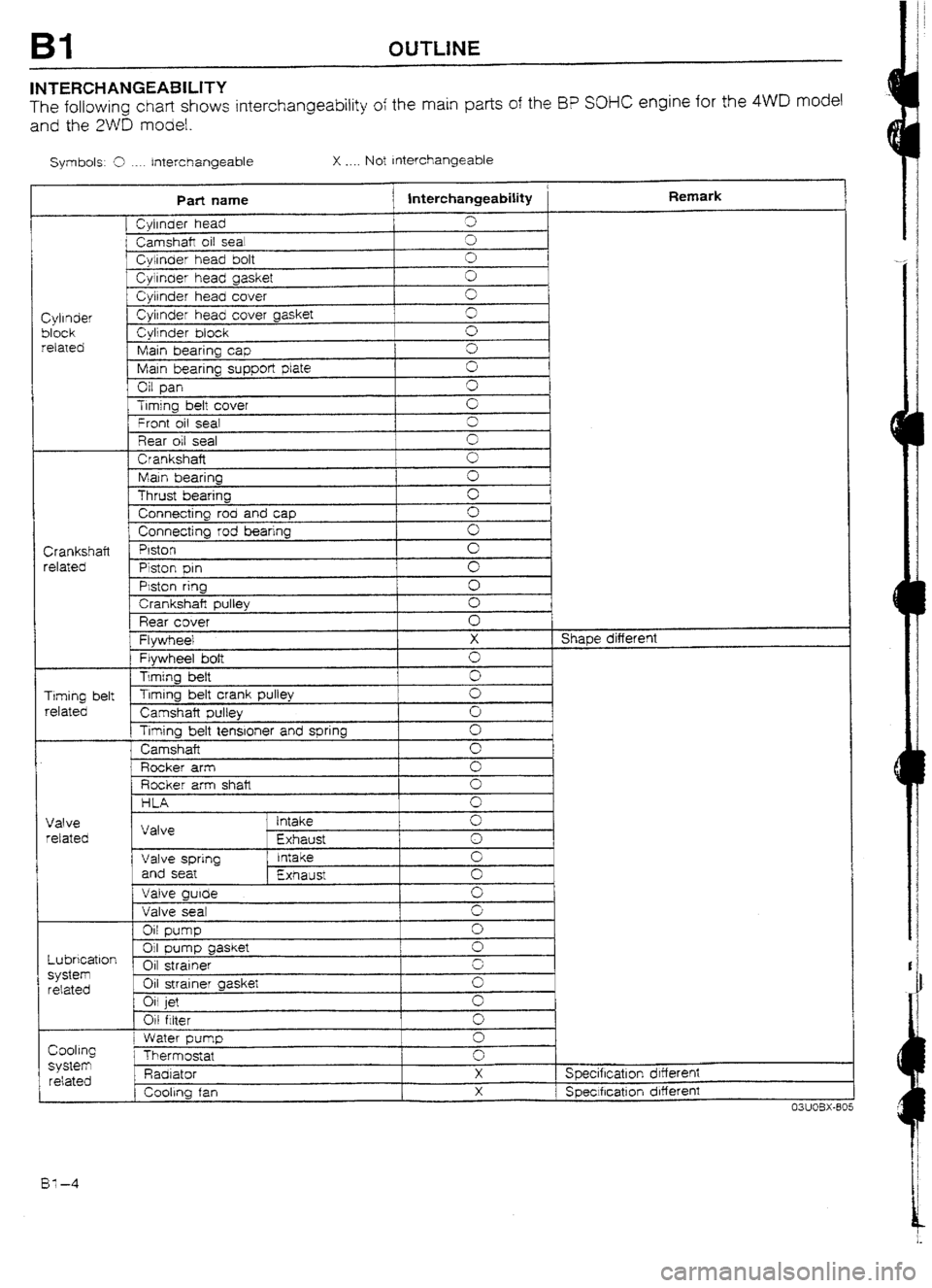

INTERCHANGEABILITY

The following chart shows interchangeability of the main parts of the I3P SOHC engine for the 4WD model

and the 2WD model.

Symbols: 9 ._.. Interchangeable X . . . . Not Interchangeable

Part name

j lnterchangeabiIity Remark

[ Cyirnder head 3

i Camshaft oil sea! cl

f Cylinder head bolt 0

Cyirnaer head gasket 0

Cylrnder head cover 0

Cylinder Cylrnder head cover gasket 3

block Cylinder block 0

related

Main bearing cap 0

Main bearing supper!

plate 0

Oil pan G

Trmjng bett cover

’ Front oil seal G

3

Rear oil seal 0

Crankshaft

0

Main bearing 0

Thrust bearing c

Connecting rod and cap 0

1 Connecting rod bearing 0

Crankshaft Piston

0

related

Piston pm cl

PMon ring

0

1 Crankshaft pulley 0

Rear cover 0

Flywheel X Shape different

Flywheel bolt 0

Timing heft

0

Timing belt Timing belt crank pulley

0

related

Camshaft pulley 0

Timing belt tenstoner and spring Cl

Camshaft

0

Rocker arm 0

Rocker arm shalt 0

HLA 0 I

Valve

retated

Lubrication

system

related Valve ’ intake

Exhaust 0

1

0

Valve spring Intake 0

and seat

Exhaust 0

Valve guide

0

Valve seat 9

Oil pump

0

01 gasket pump

0

Oil strainer r.

Oil strainer gasket G

Oil jet

0

Oil filter 0

Cooling

SyStem related

1 I Water pump

Thermostat

Padi ator

, Cooling fan 0

0

X

X Specification drffereni

1 Speclfrcatlon different

03UOBX-805

BY-4

Page 35 of 677

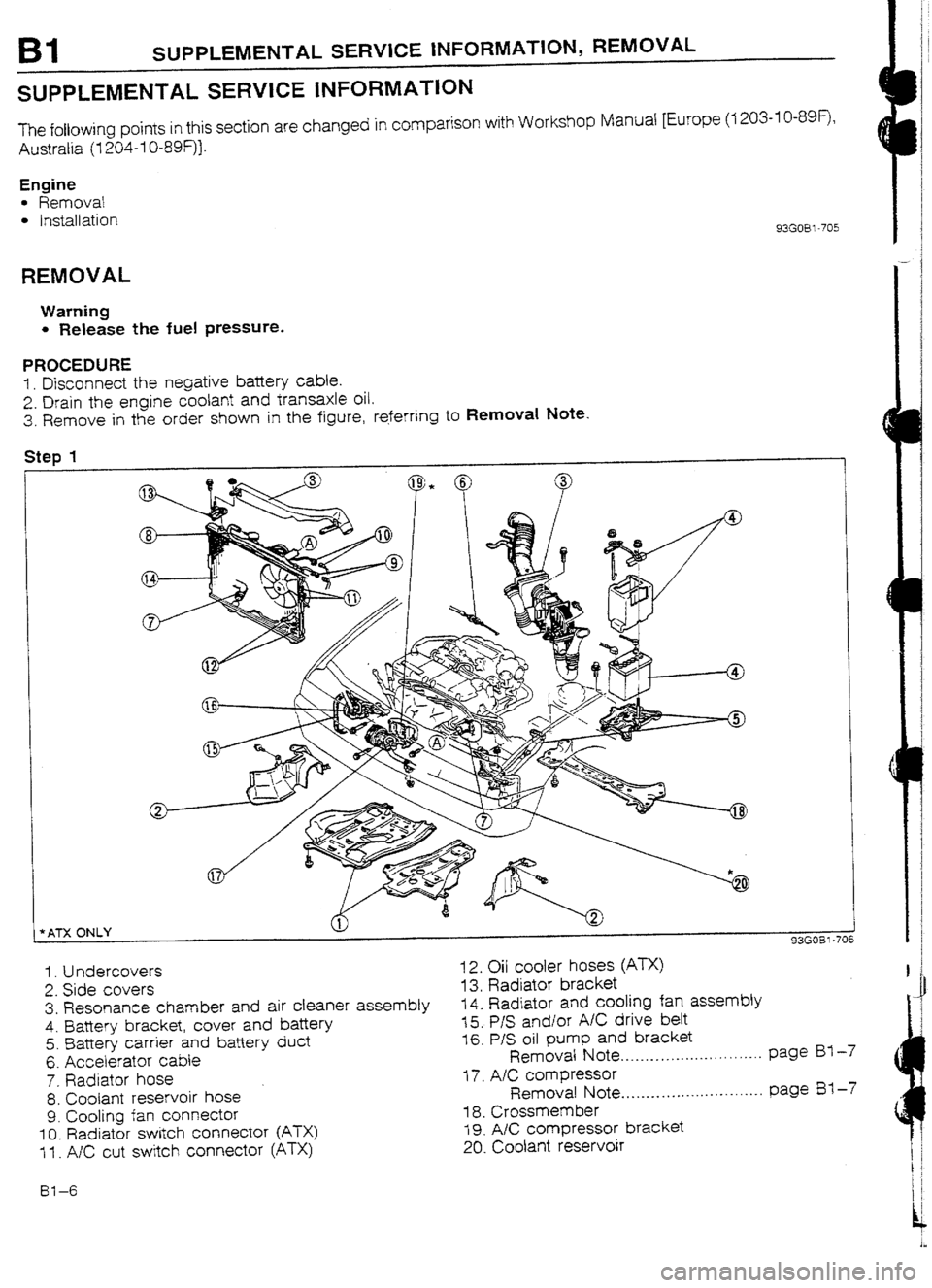

Bl SUPPLEMENTAL SERVICE tNFORMAT1ON, REMOVAL

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison with Workshop Manual [Europe (I 203-I U-89F),

Australia (1204- 1 O-89!=)].

Engine

l Removal

l Installation 93GOF31-705

REMOVAL

Warning

w Release the fuel pressure.

PROCEDURE

1. Disconnect the negative battery cable.

2. Drain the engine coolant and transaxle oil.

3. Remove in the order shown in the figure, referring to Removal Note.

Step 1

t

I

*ATX ONLY 1

93GOBl-706

1. Undercovers

2. Side covers

3. Resonance chamber and air cleaner assembly

4. Battery bracket, cover and bafiery

5. Battery carrier and battery duct

6. Accelerator cable

7. Radiator hose

8. Coolant reservoir hose

9. Cooling fan connector

IO. Radiator switch connector (ATX)

1 f . A/C cut switch connector (ATX) 12. Oil cooler hoses (ATX)

13. Radiator bracket

14. Radiator and cooling fan assembly

15. P/S and/or A/C drive belt

16. P/S oil pump and bracket

Removal Note .._...._...__......... . . . . . . . page BY -7

17. A/C compressor

Removal Note.. . . . . . . . . . . . . . .._. . . . . . . . ._. page Es1 -7

i 8. Crossmem ber

19. A/C compressor bracket

20. Coolant reservoir

61-6

Page 36 of 677

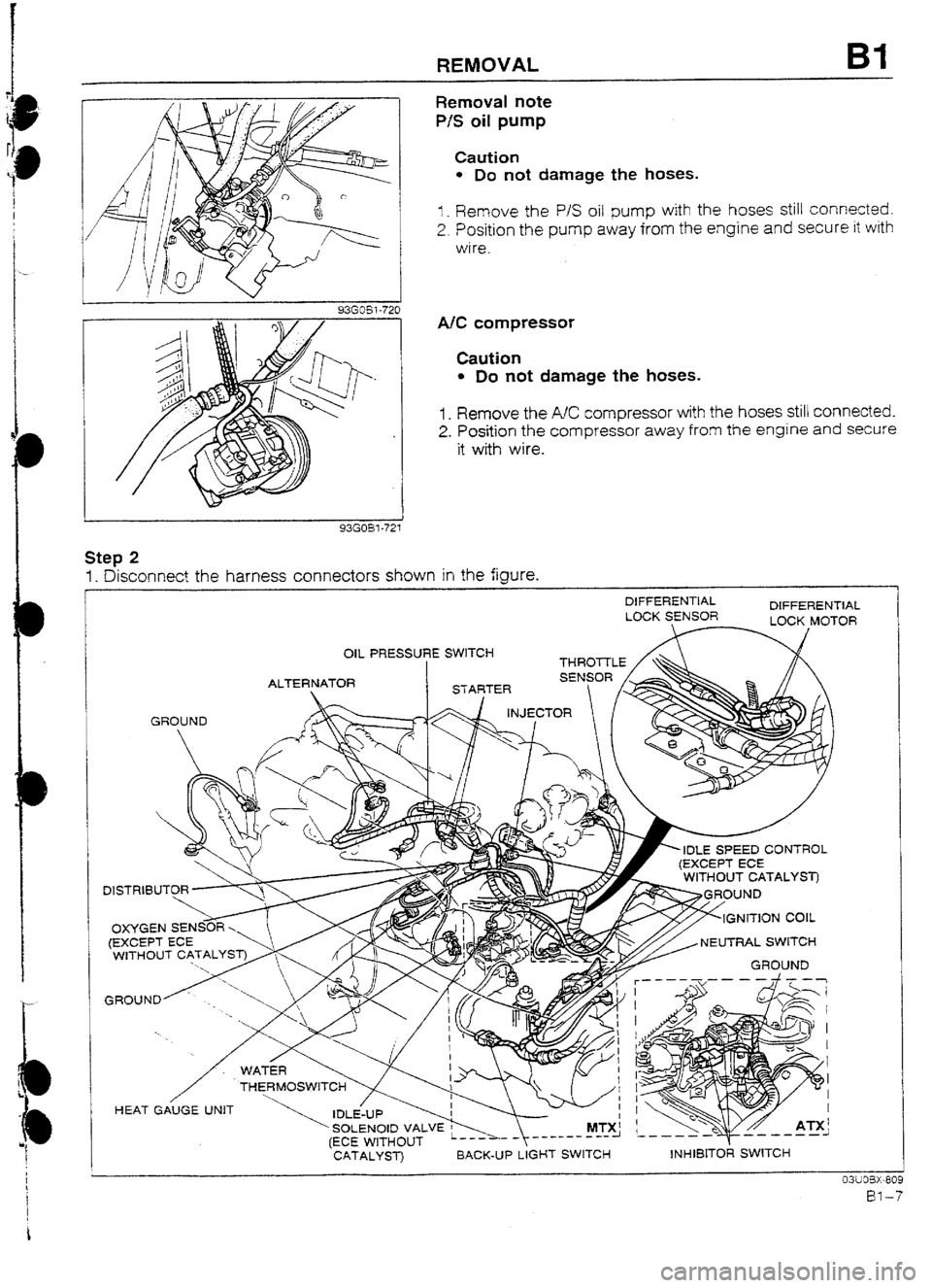

REMOVAL Bl

/

/

93G05? -72t

Removal note

P/S oil pump

Caution

l Do not damage the hoses.

I _ Remove the P/S oil pump with the hoses still connected.

2. Position the pump away from the engine and secure it with

wire.

A/C compressor

Caution

l Do not damage the hoses.

1. Remove the AC compressor with the hoses still connected.

2. Position the compressor away from the engine and secure

it with wire.

Step 2

1. Disconnect the harness connectors shown in the figure.

DIFFERENTIAL

DIFFERENTIAL

LUCK SENSOR

OIL PRESSURE SWITCH --- -

GROUND

r, IDLE SPEED CONTROL

NEUTRAL SWITCH

’ SOLENOID VALVE w MTX!

(ECE WITHOUT _--------I

CATALYST) BACK-UP LIGHT SWITCH

\‘C

Y ~55 ATX’

d ---a-- ,-,---1

INHIBITOR SWITCH

Page 40 of 677

t

REMOVAL 81

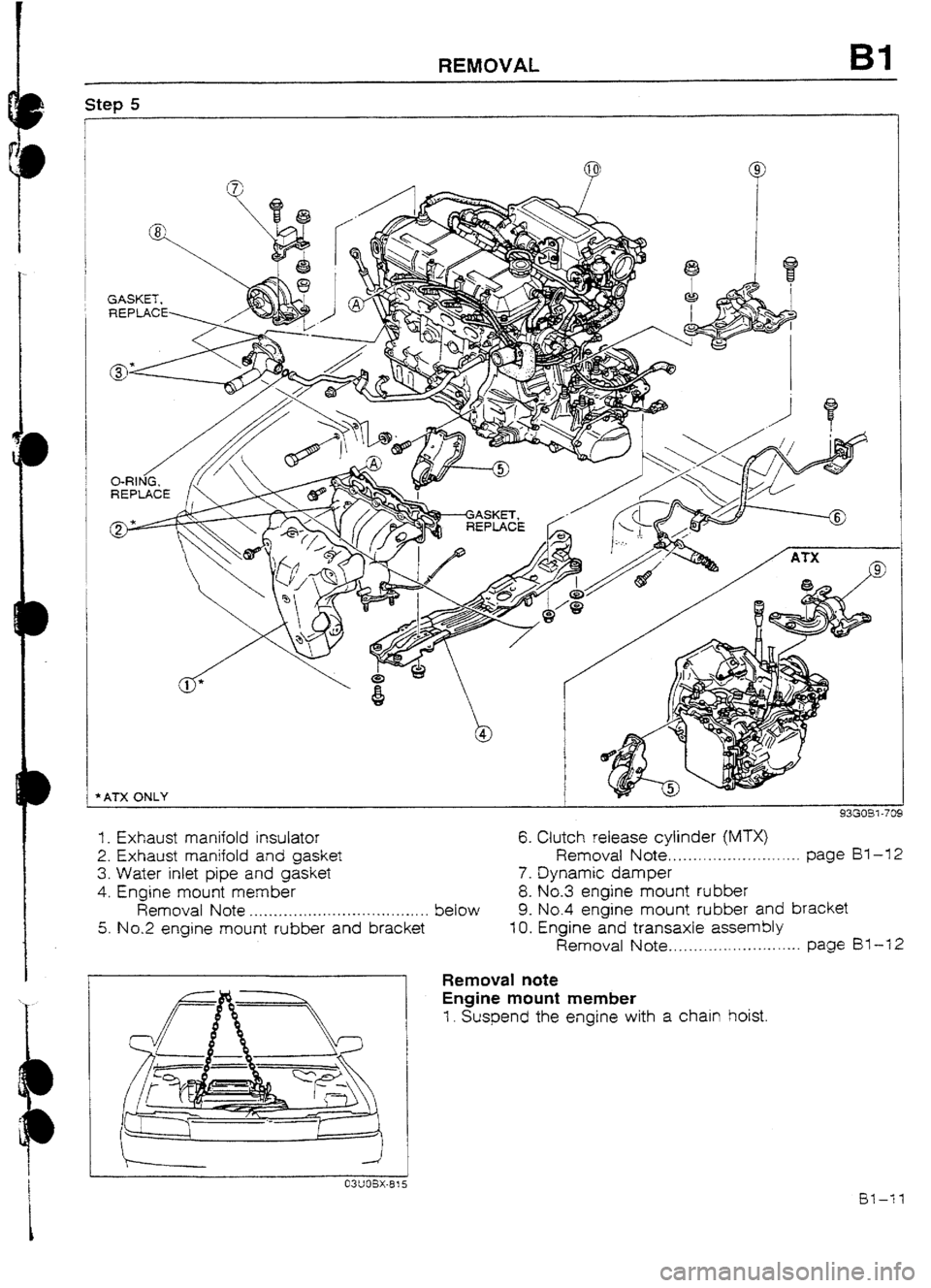

1. Exhaust manifold insulator 6. Clutch release cylinder (MTX)

2. Exhaust manifold and gasket Removal Note ,...........-.....a........ page BY -12

3. Water inlet pipe and gasket 7. Dynamic damper

4, Engine mount member

8. No.3 engine mount rubber

Removal Note . . . . . . . . . . . . . . .._.................. . . below 9. No.4 engine mount rubber

and bracket

5. No.2 engine mount rubber and bracket f 0. Engine and transaxle assembly

Removal Note . . . . . . .._....._... . . . . . . . . . page Bl-12

Removal note

Engine mount member

1. Suspend the engine with a chain hoist.

Page 41 of 677

Bl REMOVAL

93GOBl-72:

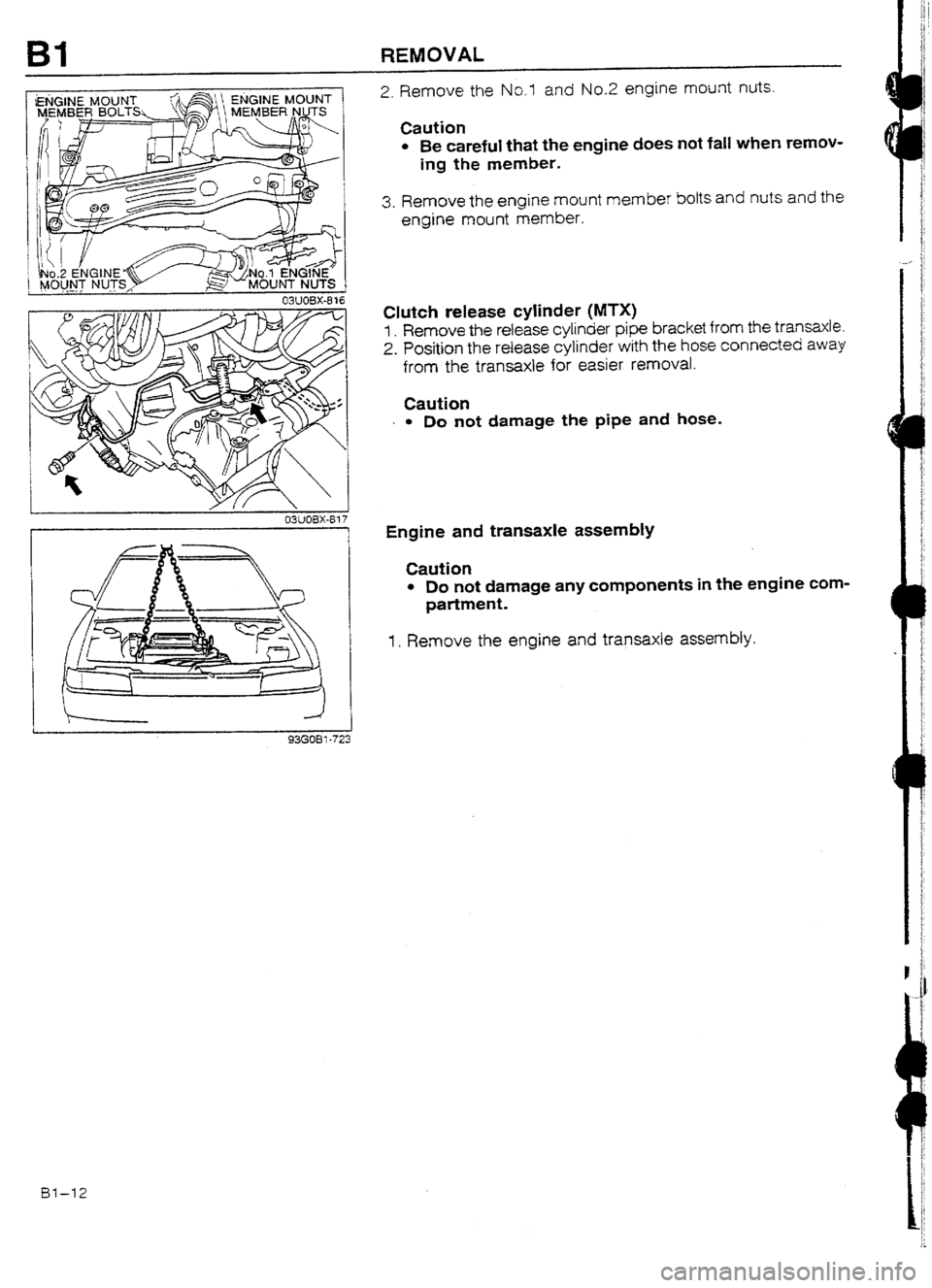

2. Remove the No.1 and No.2 engine mount nuts.

Caution

l Be careful that the engine does not fall when remov-

ing the member.

3. Remove the engine mount member bolts and nuts and the

engine mount member.

Clutch release

cylinder (MTX)

f . Remove the release cylinder pipe bracket from the transaxle.

2. Position the release cylinder with the hose connected away

from the transaxle for easier removal.

Caution

I

l Do nut damage the pipe and hose.

Engine and transaxle assembIy

Caution

l Do not damage any components in the engine com-

partment.

1. Remove the engine and transaxle assembly.

Bl-12