engine MAZDA 232 1990 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 42 of 677

REMOVAL Bl

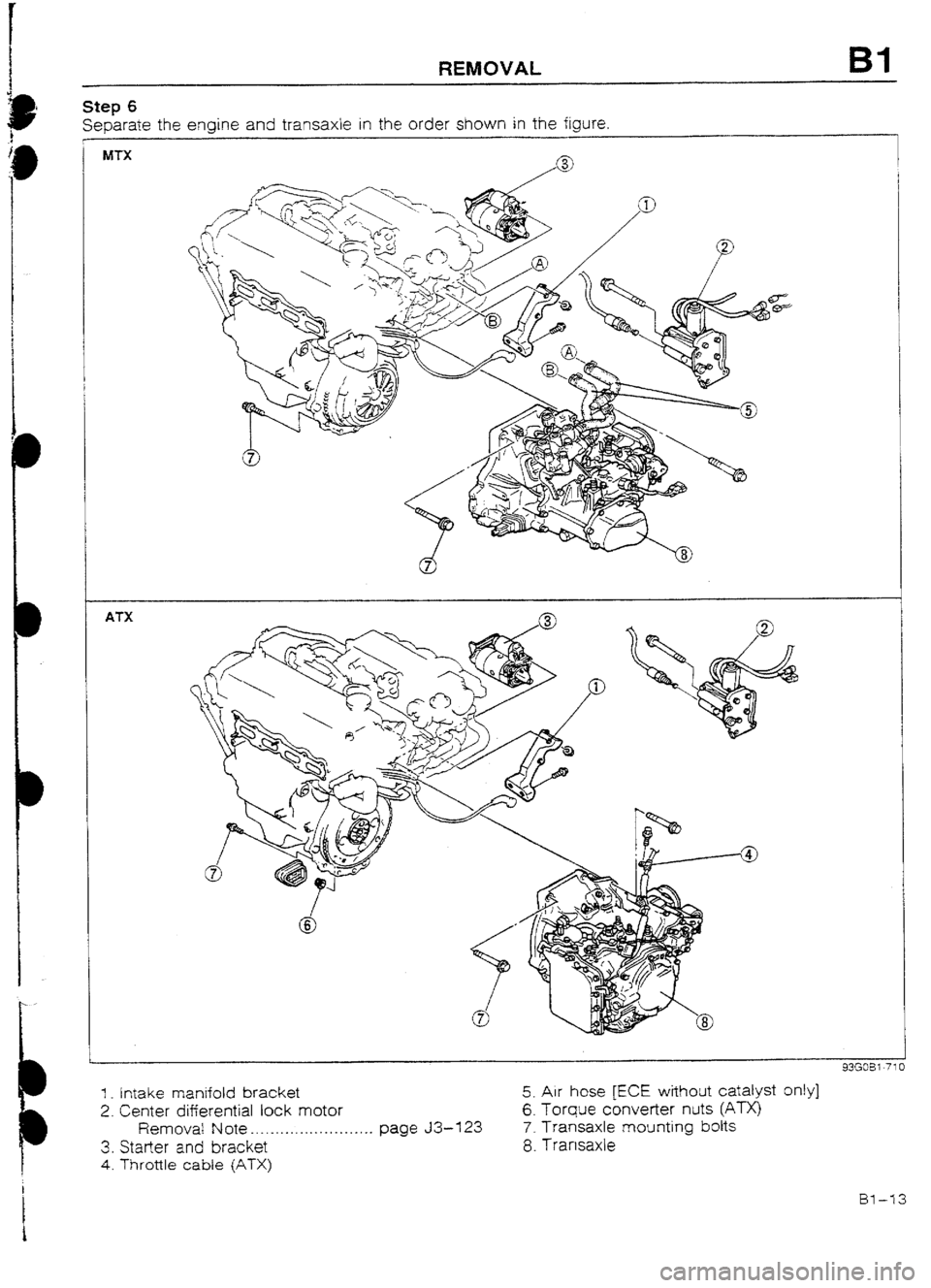

Step 6

Separate the engine and transaxle in the order shown in the figure,

MTX

ATX

43GX3i-71

1 _ Intake manifold bracket 5. Air hose [ECE without catalyst only)

2. Center differential lock motor 6. Torque converter nuts @TX)

Removal Note . . _. _. . . ._. . . . . . . . . . . . . _. page 33-l 23 7. Transaxle mounting bolts

3. Starter and bracket 8. Tramaxle

4. Throttle cable (ATX)

Bl-73

Page 43 of 677

Bl INSTALLATiON

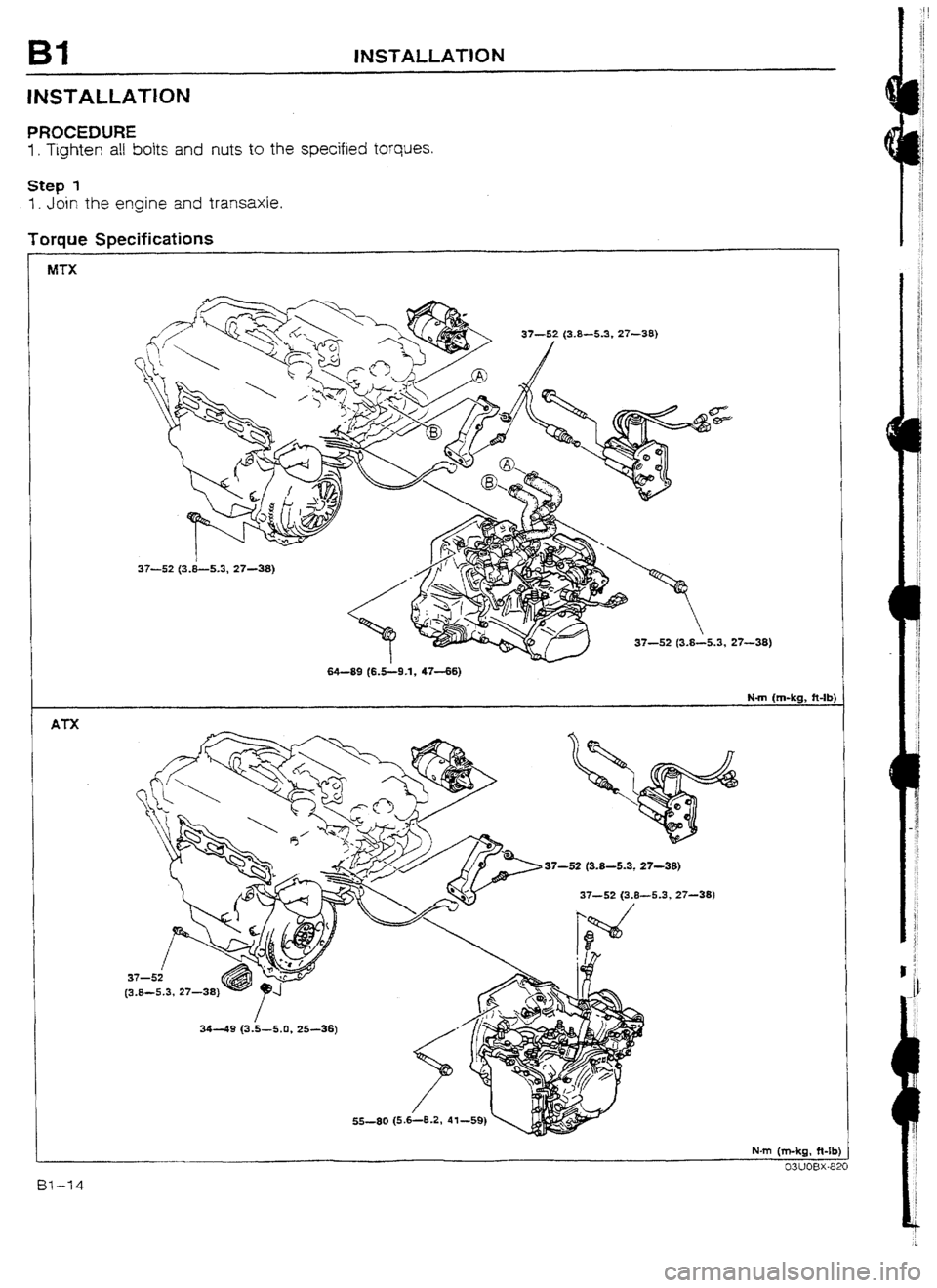

INSTALLATION

PROCEDURE

I. Tighten all bolts and nuts to the specified torques.

Step I

1. Join the engine and transaxle.

Toraue Snecifications

1- - -r--

MTX

37-52 (3.8-5.3, 27-38)

37-52 (3.8-5.3, 27-38)

ATX

64-89 (6 S-9 -1, 4746)

Nm (m-kg, ft-lb)

37-52 (3.8-5.3, 27-38)

55-80 (5.6-8.2, 41-59)

N-m (m-kg, ft-lb

51-14

Page 44 of 677

INSTALLATlON ES1

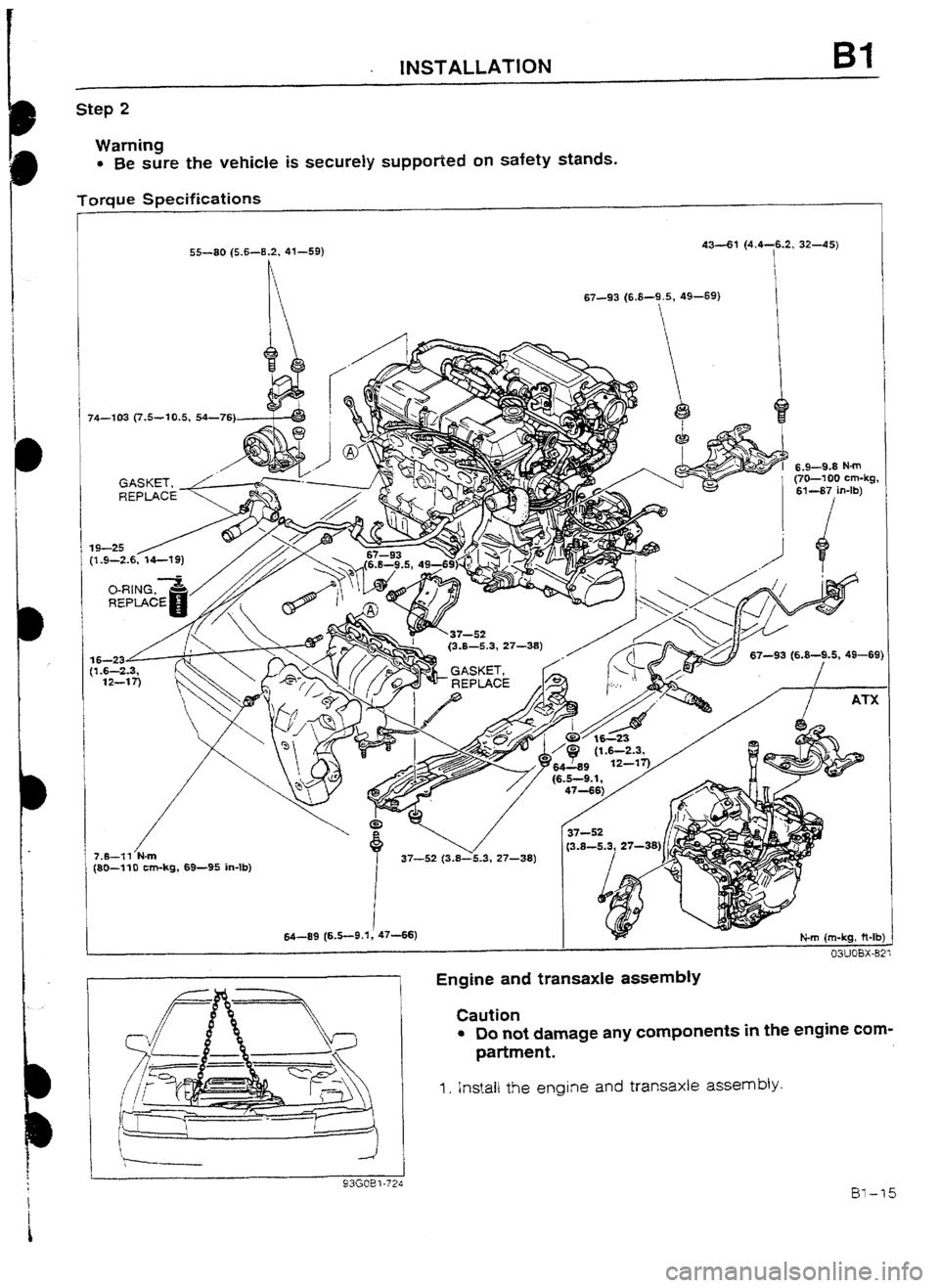

Step 2

Warning

l Be sure the vehicle is securely suppofied on safety stands.

Torque Specifications

I

I i 74-103 (7.5--10.5, 54-76)

/ 7.8-?I N-m

(80--flO cm-kg, 69-95 in-lb) 55-80 (5.fG-8.2, 41-59) 43-61 (4.4-6.2, 32-45)

I

1

I 64-89 (6.5-9.1, 4746) 67-93 (6.8-9.5, 49-69)

7 37-5x 27-38)

Engine and transaxle assembly

Caution

l Do not damage any components in the engine com-

partment.

1. Install the engine and transaxle assembly.

Page 45 of 677

Bl INSTALLATION

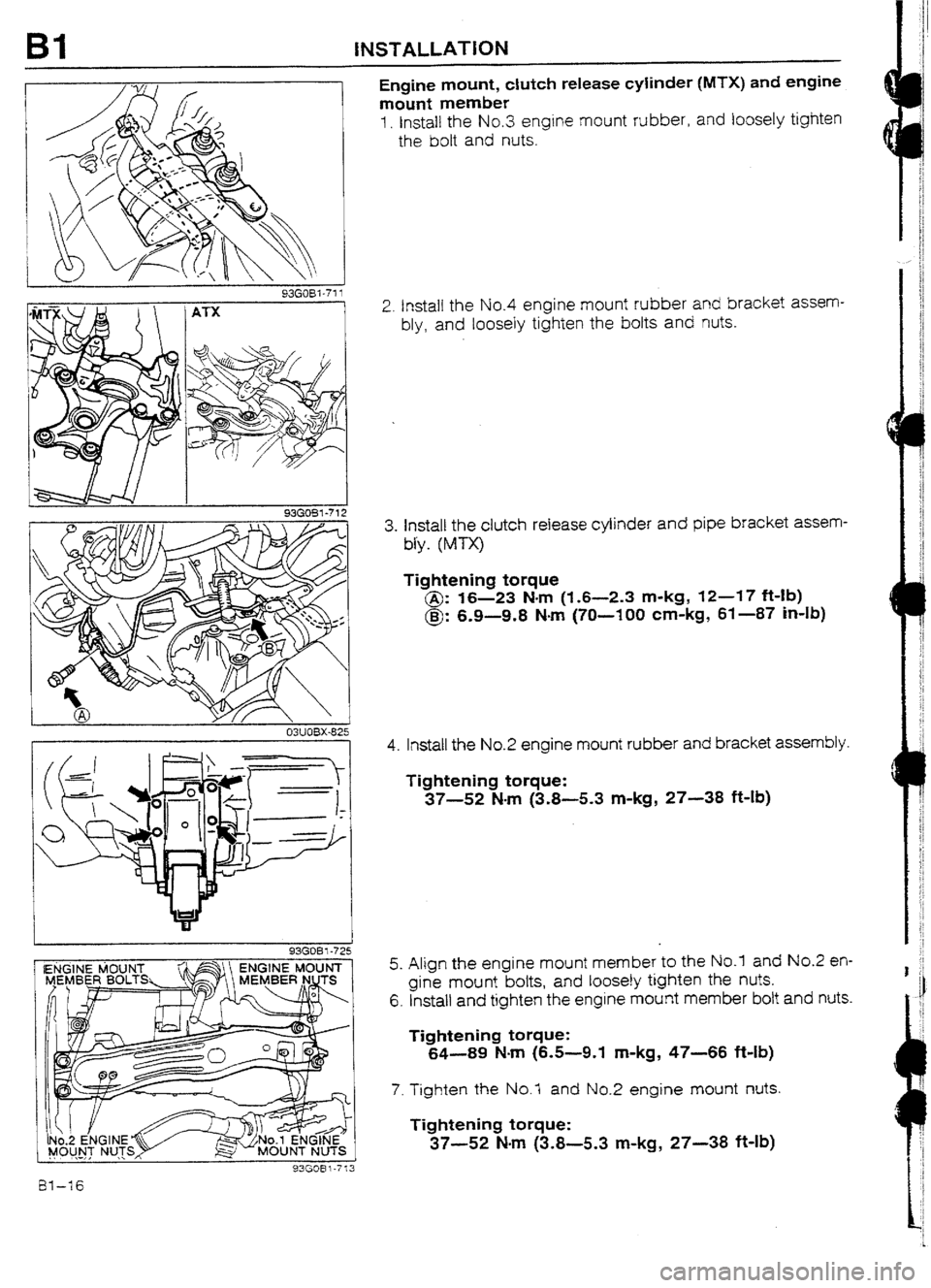

Engine mount, clutch release cyiinder (MTX) and engine

mount member

1. Install the No.3 engine mount rubber, and loosely tighten

the bolt and nuts.

2. Install the No.4 engine

mount rubber and bracket assem-

bly, and loosely tighten the

k~olts and nuts.

3. Install the clutch release cylinder and pipe bracket assem-

U-y.

(MTX)

Tightening torque

@: 16-23 Nm (1.6-2.3 m-kg, 12-47 ft-lb)

@: 6.9-9.8

N-m (70-100 cm-kg, 61-87 Mb)

I

93GOBl-72 J .-, , . . ,.

I

93GOBi-713

4. Install the No.2 engine mount rubber and bracket assembly.

Tightening torque:

37-52 Nm (3.8-5.3 m-kg, 27-38 ft-lb)

5. Align the engine mount member to the No.1 and No.2 en-

gine mount bolts, and loosely tighten the nuts.

6. Install and tighten the engine mount member bolt

and nuts.

Tightening torque:

64-89 N-m (6.5-9.1 m-kg, 47-66

ft-Lb)

7. Tighten the No.7 and No.2 engine mount nuts.

Tightening torque:

37-52 Mm (3.8-5.3 m-kg, 27-38 ft.lb)

Page 46 of 677

INSTALLATlON

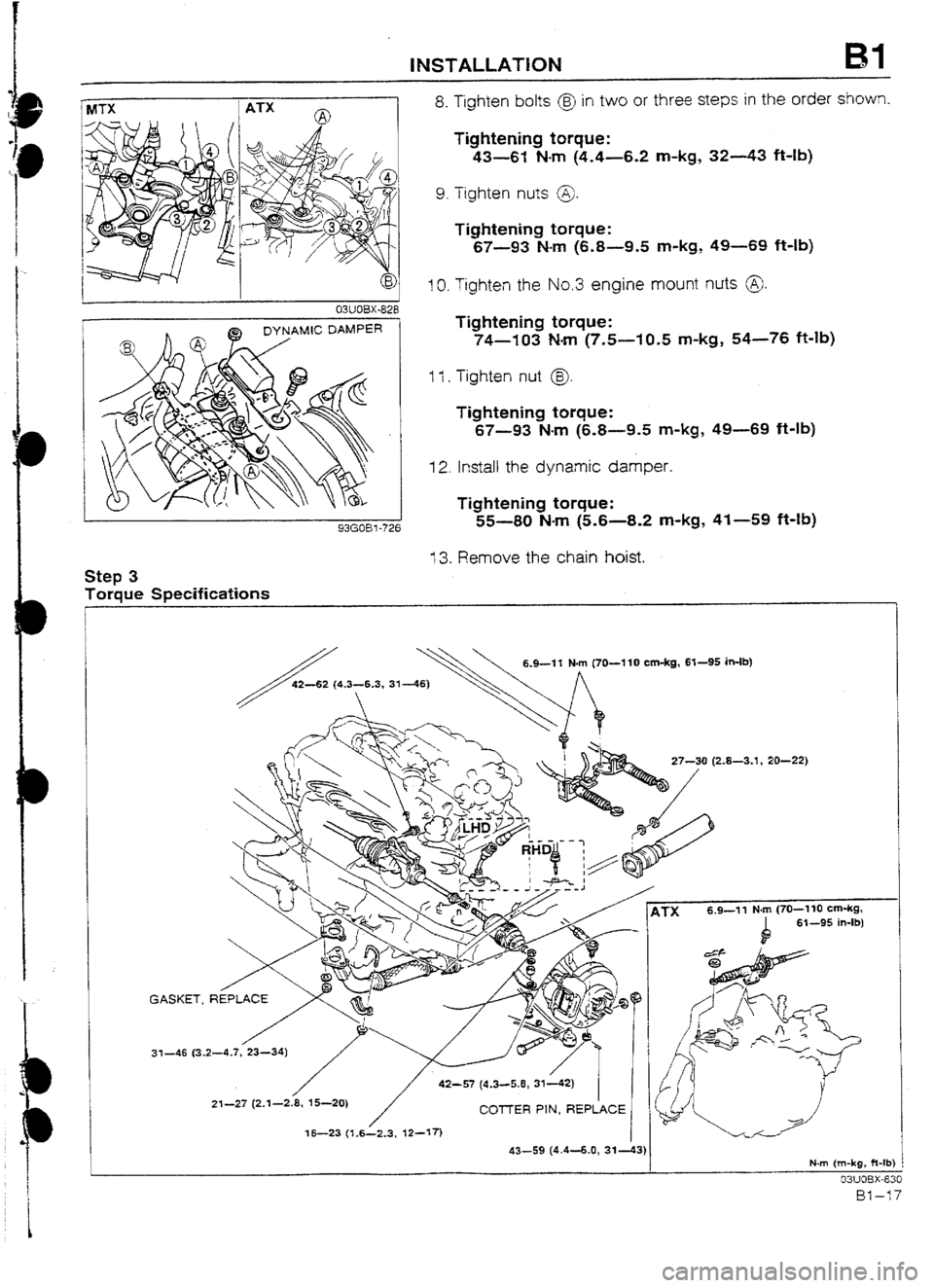

MTX 1 A-I-X

WUOBX-828

43GOBl-72t

Step 3

Torque Specifications 8. Tighten bolts @ in two or three steps in the order shown.

Tightening torque:

43-61 N-m (4.4-6.2 m-kg, 32-43 ft-lb)

9. Tighten nuts @J.

Tightening torque:

67-93 N-m (6.8-9.5 m-kg, 49-69 ft-lb)

IO. Tighten the No.3 engine mount nuts 0.

Tightening torque:

74-103 Nom (7,5--f0,5 m-kg, 54-76 ft-lb)

Ii. Tighten nut @.

Tightening torque:

67-93 N-m (6.8-9.5 m-kg, 49-69 ft-lb)

12. Install the dynamic damper.

Tightening torque:

55-W N-m (5.6-8.2 m-kg, 41-59 ft-Ib)

13. Remove the chain hoist.

6.9-11 N-m (70-l 10 cm-kg, 63-95 in-lb)

-8-3.1, 20-22)

&TX 6.9-11 N-m (70-130 cm-kg,

b 6% -95 in-lb) /

42-57 (4.3~5.8,31142)

21-27 (2.1-2.8, 15-20)

COTTER PIN, REPLACE

16-23 (1.6L2.3, Q-17)

N-m {m-kg, ft-tb

03UOBX-8:

Page 52 of 677

INSTALLATION Bl

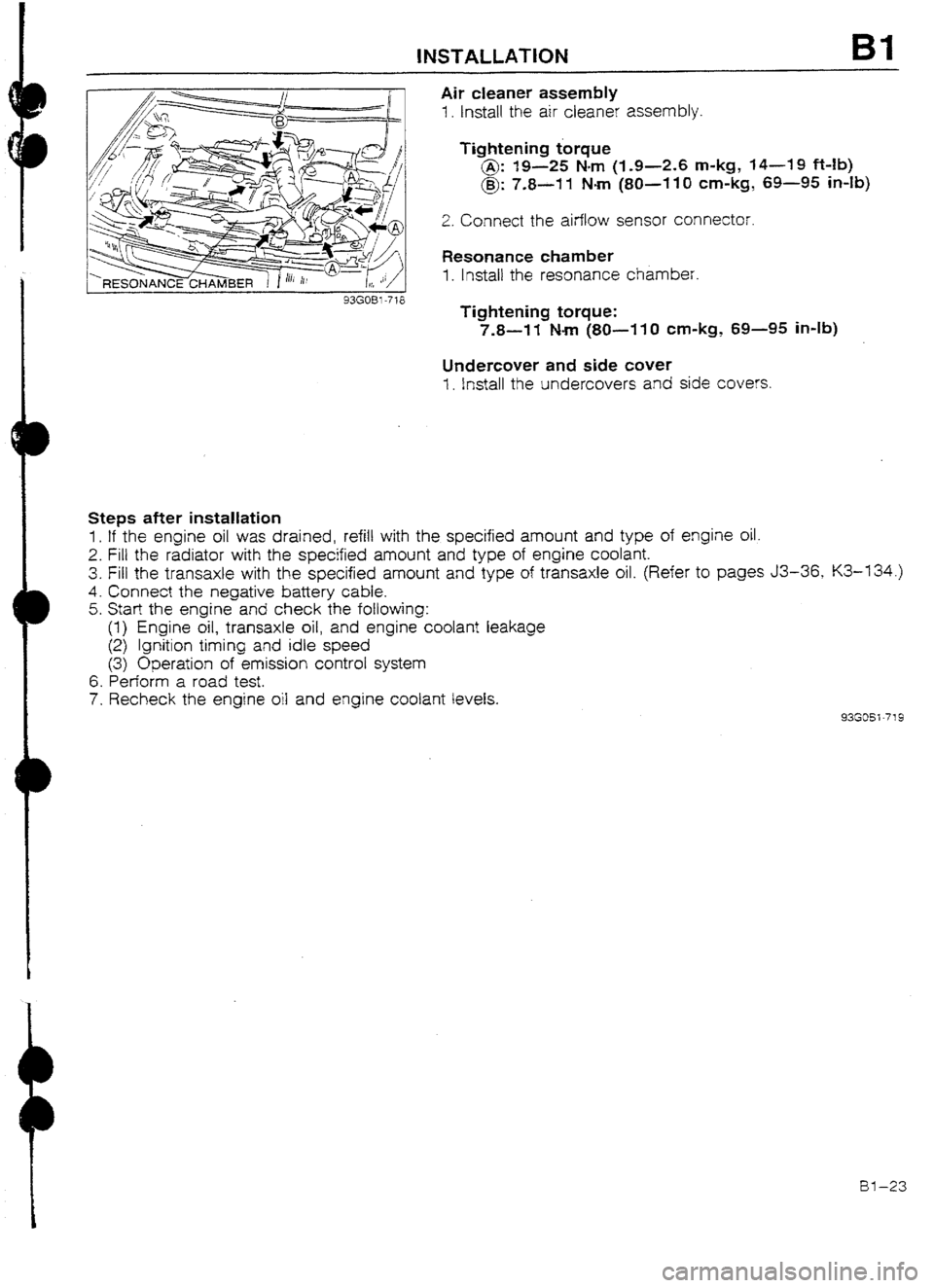

Air cleaner assembly

1. Install the air cleaner assembly.

Tightening torque

@: 19-25 Nm (I-9-2.6 m-kg, 14-19 Mb)

@: 7.8-11 Nm (80~-110 cm-kg, 69-95 in-lb)

2. Connect the airflow sensor connector.

Resonance chamber

1. lnstail the resonance chamber.

Tightening torque:

7.8-W Nm (SO-11 0 cm-kg, 69-95 in-lb)

Undercover and side cuver

1. install the undercovers and side covers.

Steps after installation

1. If the engine oil was drained, refill with the specified amount and type of engine oil.

2. Fill the radiator with the specified amount and type of engine coolant.

3. Fill the transaxle with the specified amount and type of transaxle oil. (Refer to pages J3-36, K3-134.)

4. Connect the negative battery cable.

5. Start the engine and check the following:

(1) Engine oil, transaxle oil, and engine coolant leakage

(2) Ignition timing and idle speed

(3) Operation of emission control system

6. Perform a road test.

7. Recheck the engine oil and engine coolant levels.

93GOSi-719

al-23

Page 54 of 677

B2

ENGINE

(DOHC)

INDEX . . . . . . . ..**......... . . . . . . . ...* . . . . . . . . . . . . . . . . . . . l . BZ- 2

OUTLINE

................................................ BZ- 3

OUTLINE OF CONSTRUCTION.. .............. BZ- 3

SPEClFlCATlONS .................................. BZ- 4

INTERCHANGEABiLITY

.......................... BZ- 5

CYLINDER HEAD

.................................. BZ- 6

CYLINDER BLOCK AND OIL PAN ........... BZ- 7

PISTON ............................................... BZ- 8

FtYWtiEEL .......................................... BZ- 9

CAMSHAFT .......................................... BZ-10

SUPPLEMENTAL SERVICE INFORMATION BZ-11

COMPRESSION

....................................... 82-I 1

INSPECTION ........................................ B2-11

REMOVAL .............................................. BZ-12

PROCEDURE ........................................ BZ-12

ENGINE STAND MOUNTING.. ................... BZ-20

PROCEDURE ........................................ BZ-20

ENGINE STAND DISMOUNTING.. ..............

BZ-21

PROCEDURE ........................................ 82-21

INSTALLATION

....................................... BZ-23

PROCEDURE ........................................ BZ-23

93GOB2-701

Page 55 of 677

B2 INDEX

INDEX

~IMIY~ULU

TIGHTENING TORQUE

19-25 (1.9-2.6, 14-19)

/5--l ENGINE COMPRESSION

STANDARD

MINIMUM kPa (kglcm2, psi)-rpm

BP Turbo

I

1,059 (10.8, 1543-300

1 i-85 (8.0, 114)-300

EXHAUST MANlFOt

TIGHTENING TORQUE

DEFLECTION AT 98 N (IO kg, 22 Ib)

mm (in)

DRIVE BELT 1 NEW USED

ALTERNATOR 1 8.0-9.0 (0.31-U.35) 9.0-I 0.0 (0.35-U.39)

P/S, P/S + AIC ( 8.U-9.0 [O-31--0.35) 9.0-10.0 (0.35-0.39) 3826 3.9-A.?, -28134)

1. Engine

Removal -*-...-..I-*.* . ..wm._..... * e-e... -. page B2--I 2

Engine stand mounting ._.....__... page B2-20

Engine stand dismounting . . . . . . . page B2-21

Installation _ . . . . . . . . . . . . , . . _. . . . . . _. . . . . . . . , page EQ-23

BZ-2

Page 58 of 677

c

OUTLINE B2

INTERCHANGEABILITY

The following chart shows interchangeability of the main park of the BP DOHC Turbo engine for the 4WD

model and the BP DOHC Non-Turbo engine for the 2WD model.

Symbols: 5 . Interchangeabie X . . . . Not Interchangeable

Part name interchangeability Remark

1 Cylinder head Shape different

Camshaft oil sea! :

Cylinder head bolt

3

Cyijnder head gasket cl

C$rnder head cover 0

1

Cylinder Cylinder head cover gasket cl

I

Cylinder block 0

block

related Man bearing cap 0

Main bearing support plate 3

OrI pan x Shape different

Trming belt cuver cl

Seal plate 3

Front oil seal I

3

Rear oil seal cl

Crankshaft ‘3

Main bearing 0

Thrust bearing 0

Connecting rod and cap 0

Connecting rod bearing I

0

Crankshaft [ Prston Shape different

related

Piston pin +-- -

c Piston ring cl

Crankshaft pulley 0

Rear cover 3

I Flywheel X Shape different

Flywheel bolt 0

Timing belt

cl

Timing belt Timing belt crank pulley

cl

Camshaft pulley 0 I

related

f Timing belt tensioner and spring

i 0

1, ldter

Camshaft

; Valve timing different

I-LA

Valve I Make - cl

Valve Exhaust 0

related

Vaive sprtng Intake 0

and seat

Exhaust 0

Valve guide cl

Valve seal 0

Oil pump 0

Oil pump gasket 0

Lubrication Oil strainer

0

system Oil strainer gasket

0

related

Oil cooler

0

Oil jet

0

Oil fitter

0

Water pump cl

Cooling

Thermostat

X system Specificatron drfferent

related Radiator X Specificatron different

Cooling fan

X Specification different

^^-^-^ m^- Ix?-5

Page 59 of 677

B2 OUTLINE

CYLINDER HEAD

INTAKE PORT 1 EXHAUST PORT

ENTlFlCATlON MARK

BP TURBO.. .BP26

BP NON-TURBO...BP05

The cylinder head for the BP DOHC Turbo engine is the same as for the BP DO% Non-Turbo engine! ex-

cept that the intake ports are shaped differently.

The identification mark is cast at the rear of the cyfinder head.

Identification:

BP DUHC Turbo

: BP26

BP DOHC

Non-Turbo: BP05

W-6