MAZDA 232 1990 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 211 of 677

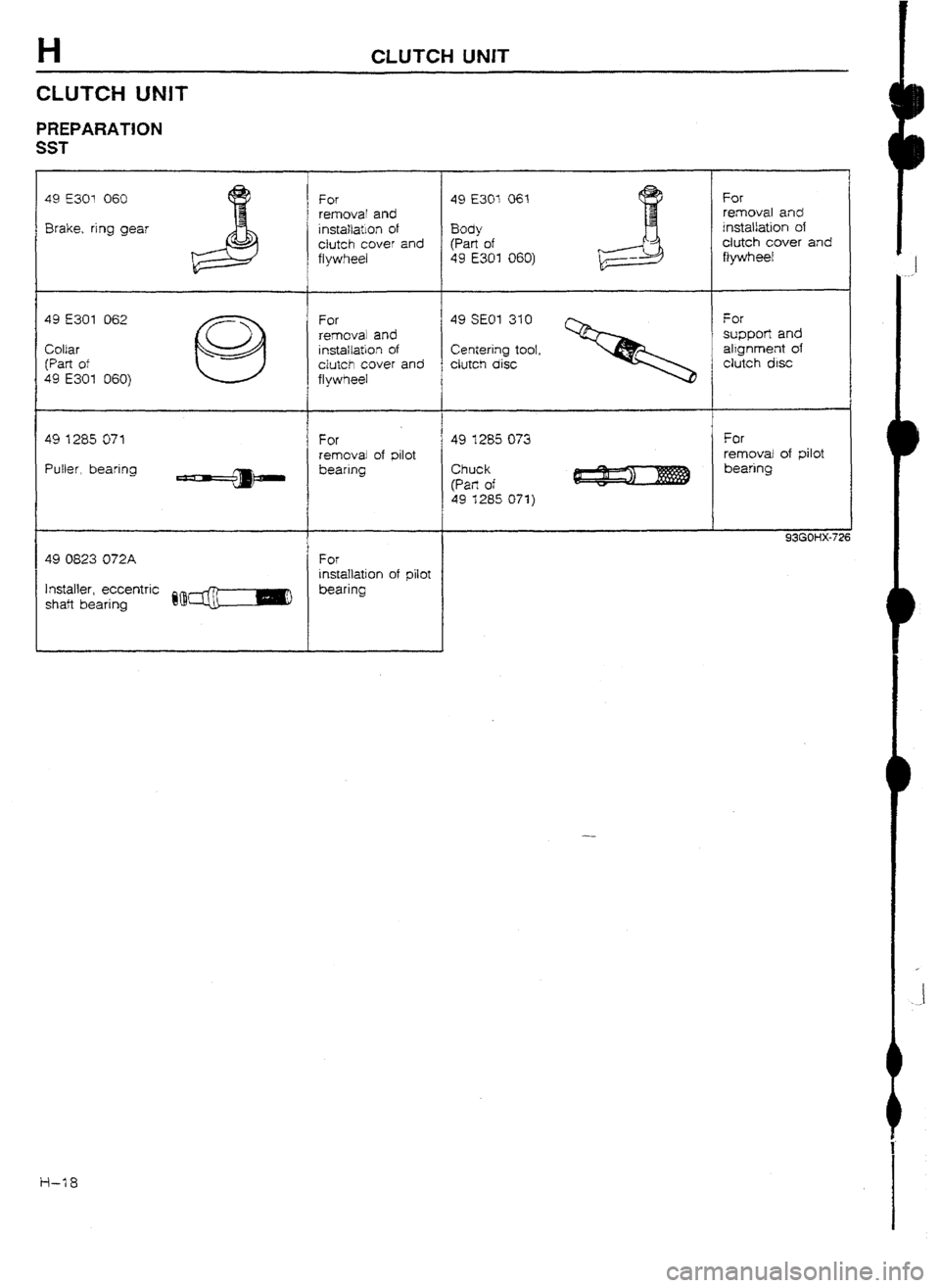

H CLUTCH UNIT

PREPARATION

SST

49 E301 060

Brake, ring gear

For removal and

i nstaI\abon of

c!utch cover and

flywl-leel

49 E301 062

Collar

(Part

of 49 E301 060) For

removal and

installation of

cIutch cover and

flywheel

49 1285 071 For

I removal of blot

Puller, bearing

Lj , - e bearing

49 0823 U72A 1 For

I installation of pilot 49 E3OI 061

Body

(Part

of 49 E301 060)

49 SE01 310

Centering tool,

clutch disc

49 1285 073

Chuck

(Part of

49 1285 071)

Installer 1 eccentric

shaft bearing @@D bearing -

For

removal and

installation of

dutch cover and

flywheel

For

support and

alrgnment of

clutch disc 7

For

removal of pilot

bearing

93GOHX-726

H-18

Page 212 of 677

t .-

1

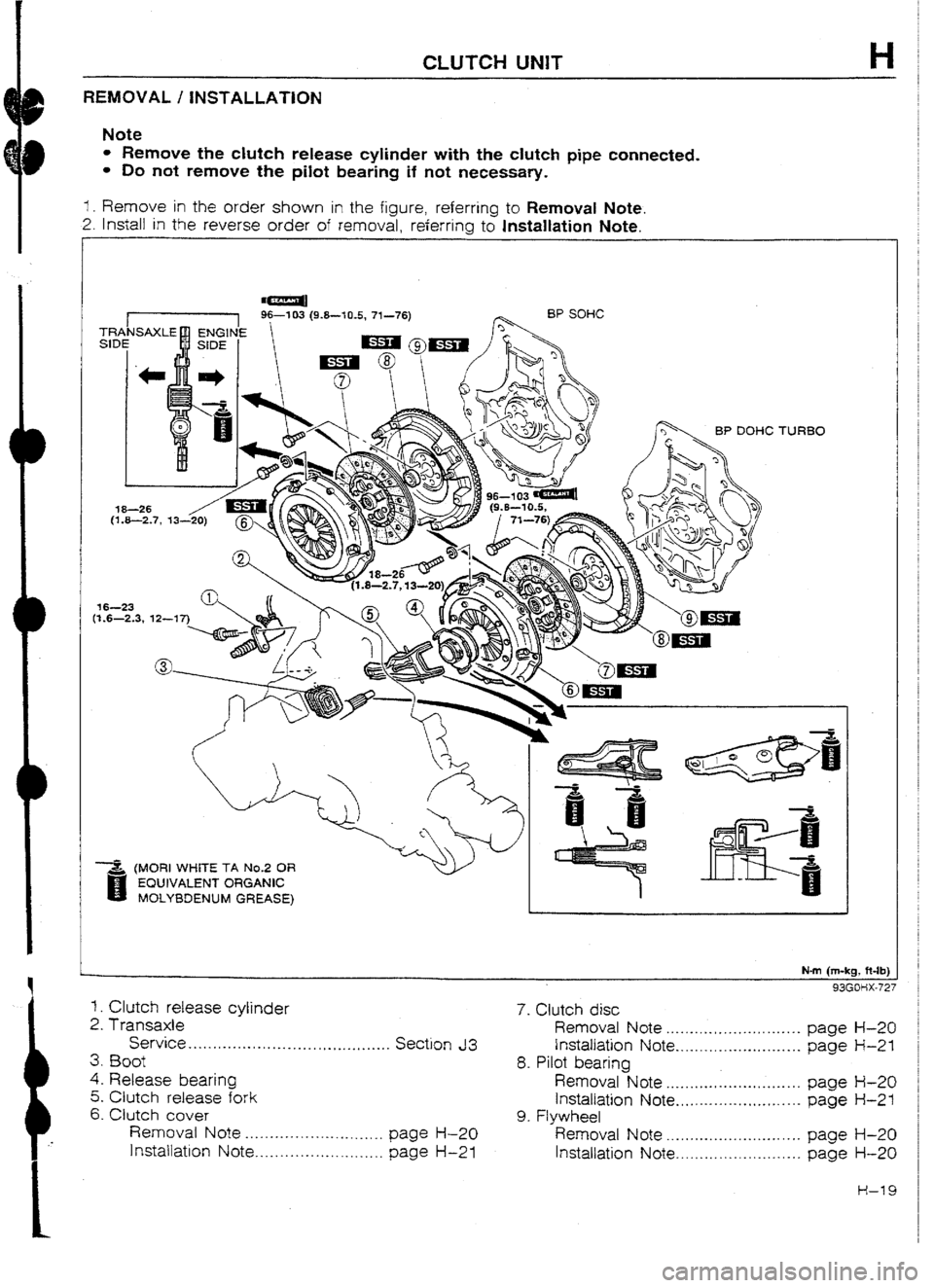

CLUTCH UNIT H

REMOVAL I fNSTALLATION

l Remove the clutch release cylinder with the clutch pipe connected.

- Do not remove the pilot bearing if not necessary.

f . Remove in the order shown in the figure, referring to Removal Note.

2. Instal! in the reverse order of removal, referring to Installation Note.

-761 BP SOHC

,E+--l BP DOHC TURBO

-; (MORI Wl-llTE TA No.2 OR

B EQUIVALENT ORGANIC

MOLYBDENUM GREASE)

1. Clutch release cylinder

2. Transaxle

Service ~......-...tl.*I.*-......*,,.**..l....... Section J3

3. Bout

4. Release bearing

5. Clutch release fork

6. Clutch cover

Removal Note _....._._._.-..._....___.._. page H-20

lnstaflation Note .._.......-..._.. . .._..._. page H-21 7. Clutch disc

Removal Note . . . . . . . .._...

Installation Note.. . . . . . . . . .

8. Pilot bearing

Removal Note . . . . . . . . . .._.

1 nstatlation Note.. . . . . __ . _.

9. Flywheel

Removal Note . . . . . . . . . . . . .

Installation Note . . . . . . . . . . . *..*.

w....

*.*..

-....

. . . . .

. . . . ..*.a.*.

page H-20

.,..I.._ page H-21

.**-. ..- page H-20

.,..... -

page H-21

. ..*.-.- page H-20

_...a-.. page H-20

H-19

Page 213 of 677

C1UTCf-f UNtT

9MUOHX-032

I

03UOf-lX-028

I

93GOHX-729

I

i

Removal Note

Clutch cover and disc

1. Install the SST.

2. Loosen each bolt one turn at a time in a crisscross pattern

until spring tension is released. Then remove the ciutch cov-

er and disc.

Pilot bearing

1. Remove the pilot bearing with the

SST if necessary.

Flywheel

Note

l After removing the flywheel, inspect for oil leakage

past the crankshaft rear oil seal.

If necessary, replace the oil seal.

1. Hold the flywheel with the SST.

2. Remove the flywheel.

Instalfation Note

Flywheel

1 -Wipe the bolts clean and apply sealant to the bolt threads.

2. Install the flywheel and SST.

3. Tighten the bolts evenly and gradually in the pattern shown.

Tightening torque:

96403 Nmm (9.8-10.5 m-kg, 71-76 ft.lb)

PiIot bearing

Note

l Install the pilot bearing ftush with the flywheeL

I_ Install the new bearing with the SST.

03UOHX-030

H-20

Page 214 of 677

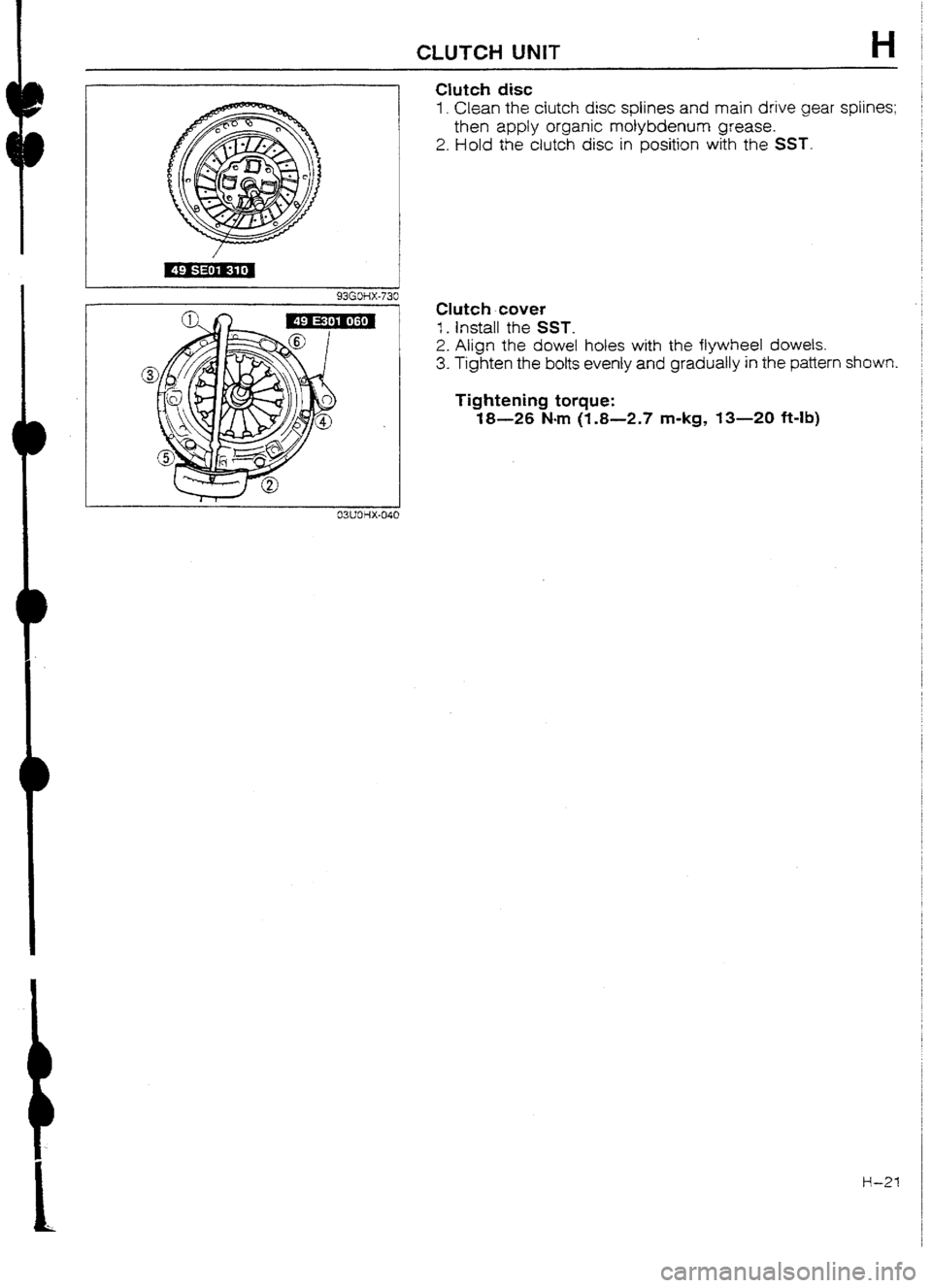

CLUTCW UNIT

Clutch disc

1. Clean the clutch disc splines and main drive gear spIines;

then apply organic molybdenum grease.

2. Hold

the clutch disc in position with the SST.

Clutch cover

1. Install the SST.

2. Align the

dowel holes with the flywheel dowels.

3. Tighten the

botts evenly and gradually in the pattern shown.

Tightening torque:

18-26 N-m (1.8-2.7 m-kg, 13-20 ft-lb)

EWOHX-040

Ii-21

Page 215 of 677

I

Page 216 of 677

![MAZDA 232 1990 Workshop Manual Suplement J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION .. MAZDA 232 1990 Workshop Manual Suplement J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION ..](/img/28/57056/w960_57056-215.png)

J3

MANUAL TRANSAXLE AND

TRANSFER UNIT (GSMX-R)

INDEX .........................................

J3- 2

/FEATURES] I

OUTLINE .....................................

J3- 4

OUTLINE OF CONSTRUCTION ..... J3- 4

SPECIFlCATtUNS ....................... J3- 5

TRANSAXLE AND TRANSFER UNIT J3- 5

STRUCTURAL VIEW.. ................. J3- 6

TRANSAXLE ................................ J3- 8

DOUBLE CONE SYNCHRU

MECHANlSM ........................... J3- 8

SHIFT FORKS AND SHIFT RODS . . J3- 10

iNTERLUCK MECHANISM ......... ., J3- 11

TRANSFER UNtT

.......................... J3- 12

CENTER DIFFERENTIAL ............. J3- 14

VISCOUS COUPLING

(BP DOHC TURBO). .................. J3- 20

CENTER DlFFERENTIAL LUCK

SYSTEM (MANUAL) .................. J3- 23

CENTER DIFFERENTIAL LOCK

SYSTEM (ELECTRICAL) ............. J3- 24

CENTER DIFFERENTIAL LOCK

CONTROL SWITCH ................... J3- 28

CENTER DIFFERENTIAL LUCK

ASSEMBLY

.............................. J3- 29

CENTER DIFFERENTIAL LOCK

SENSOR SWlTCH.. ................... J3- 31

IDLER GEAR SHAFI- ................... J3- 33

POWERFLOW .............................. J3- 34

TROUBLESHOOTING GUIDE ......... J3- 35 TRANSAXLE OIL .......................... J3- 36

INSPECTlON ............................. 33- 36

REPLACEMENT.. ....................... J3- 36

TRANSFER CARRIER CM .............

339 36

INSPECTION ............................. J3- 36

REPLACEMENT. ........................ J3- 36

TRANSAXLE AND

TRANSFER UNIT ........................ J3- 38

PREPARATION .......................... J3- 38

REMOVAL ................................. J3- 42

DISASSEMBLY

........................... J3- 48

INSPECTION ............................. J3- 72

ASSEMBLY ............................... J3- 75

INSTALLATION

.......................... J3-I I2

SHIFT MECHANISM.. .................... J3-119

OVERHAUL ............................... J3-119

CENTER DIFFERENTIAL

LOCK SYSTEM ........................... J3-121

SYSTEM DIAGRAM ..................... J3-121

INSPECTION ............................. J3-122

CENTER DIFFERENTIAL

LOCK MOTOR ............................ J3-123

INSPECTDN ............................. J3-123

REPLACEMENT ......................... J3-123

4x4 CONTROL UNIT.. ................... J3-126

INSPECTION ............................. 53-l 26

REPLACEMENT.. ....................... 53-l 26

CENTER DIFFERENTIAL

LOCK SWITCH ........................... J3-126

INSPECTION ............................. J3-126

REPLACEMENT ......................... J3-127

CENTER DIFFERENTIAL

LUCK SENSOR SWITCH ............. J3-127

INSPECTION ............................. J3-127

REPLACEMENT ......................... J3-127

93GOJ3-701

Page 217 of 677

J3 INDEX

JNDEX

LHD

// /

vIscOsIn:

ALL SEASON DEXRON-II, \_\;/ M-III

ABOVE -18OC @OF): ?5W-90

CAPACITY: 2.6 liters

(2.7 us qt, 2.2 Imp qt) ABOVE -18OC (UOF): 90

BELOW --t8OC (UOF): 8UW

CAPACITY: 0.5 liter

IO.53 US qt, 0.44 Imp qt 1. Transaxle oil

Inspection.. ._._.. . . . . . . . . . . . . . . . . . . . . . . . . page J3- 36

Replacement -.._.......-............... page J3- 36

2. Transfer carrier oi!

Inspection

. . . ..-*..-.*a. . . . . * . . . . . . . . . . . . . page J3- 36

Replacement . . ..-...Ir.....*....~......

page J3- 36 3. Transaxle and transfer unit

Removal . . . . . . . ..-.-........-._._._....... page J3- 42

Disassembly, .._. . . .-. ._. .-. . . . . . . . . . . . . page J3- 48

Inspection.. . . . . . . ._. .-. .-. .-. . ._. . . . ._. . . page J3- 72

Assembly _.._..._.__._......._._..._...._ page J3- 75

Installation _.._.._.._._..._. . . . . . . . . .._.._ page J3-1 I 2

4. Shift mechanism

Overhaul ,._.._... . . . . . . . . . . . ._..._......_ page

J3-1 19 J3-2 Inspection . . . . . . . . . . . . . .._......._._...... 5. Center differential lock motor

page J3-I 23 Replacement .,-.....,..._..............

page J3-123 6.4x4 Control unit

Inspection ,.......... ~ ....._._._........I- page J3-I 26

Replacement ..*...** . . . . *.*...- . . . . . . . - page J3-126 7. Center differential lock switch

1 nspection ..,....*.....*.. *.*.* . . . . -.- . . . . page J3-126

Replacement ..~ ..,....._.........._,... page 33-l 26

8.

Center differential lock sensor switch

Inspection.. . . . . . . _ _ _ . . . _. . . _. _ _ _. __. . . . _ _ page J 3- 128

Replacement ..,.. . . . . . . . . . . . . . .._...... page J3-128

Page 218 of 677

t

1

lNDEX J3

GRADE: API SERVICE GL-5

ABOVE -18OC (OOF): 90

BELOW -18°C (OOf): 80W

CAPACITY: 0.5 liter

(0.53 us qt, 0.44 Imp qt)

SERVICE, SECTiON T

GRADE: API SERVICE Gt4

ALL SEASON DEXRON-II, M-D

ABOVE -18OC (OOF): 75W-90

CAPACITY: 2.6 liters

(2.7 US qt, 2.2 Imp qt)

I. Transaxle oil

Inspection . . . . .._........_................ page J3-

36

Reptacement . . . . . . . . . _,. . . . ._. . . . . . . . . .

page J3-

36

2. Transfer carrier oil

Inspection.. . .._. . . .._ ._. ._.. . . . . . . . . . . . . .

page

J3- 36

Replacement . . . . . . . . . . ..l._............ page J3-

36

3. TransaxIe and transfer unit

Removal .I...............~.......~......__

page J3- 42

Disassembly .**.,.--......-.**.....,.._.

page J3- 48

t nspection . . .._........*...*I.-..-........

page J3- 72

Assembly . .._....._.....--......-........ page J3- 75

lnstaliation . . . . ._. . . _ .-. . . . . . ..-. . . .._., . _ page J3-I 12

4. Shift mechanism

Overhaul . . . ..*..-.*._.........-..........

pageJ3-119 5. Center differential lock motor

Inspection . . . . . . . . . . . . . . . . . . .._..._....... page J3-123

Replacement . . . _ , . . . . . . *. . . . . _ . _. . . . _ . .

page J3- 123

6. 4x4 Control unit

Inspection . . . . . . . . . . . . .._...._......._....

page J3-126

Replacement . . . .._......_........ . . . . . .

page J3-126

7. Center differential lock switch

Inspection.. . _ . _ . _. _. . _. . . . . _ . . . _ . . . . . . . . .

page J3-f 27

Replacement . . . . . .._...._........_..... page 33-l 27

8. Center differential lock sensor switch

Inspection . . . . . . . . . . . . . . ** .-... 1*..**-.I..

pageJ3-128

Replacement

. . ..=......-.... -* . . . . -..-. page J3-I 28

J3-3

Page 219 of 677

J3 OUTLtNE

OUTLINE OF CONSTRUCTION

l Full-time 4-wheel drive, incorporating a viscous coupling is used on the BP DUHC Turbo model. BP SUHC

engine equipped models are fitted with an electronically controlled, lockable center differential.

With this system all driving conditions are easily contended with; from good roads to bad roads and

ad-

verse weather conditions.

l The transaxle and transfer unit were developed based on the GSM-R type transaxle.

The transaxle, center differential, viscous coupling, and front differentia! are a single, compact unit.

l The center differential employs a planetary carrier. system and a viscous coupling, and functions to distrib-

ute the driving force to the front and rear differentials as needed.

Through the use of this center differential, tire scuffing common to 4-wheel drive vehicles during tight cor-

nering, is eliminated.

l The speedometer driven gear (for detection of vehicle speed) is installed in the transfer carrier and detects

the speed of the rear wheels.

l Lubrication oil of the transaxle and transfer unit and of the carrier is contained separately.

93GOJ3-704

J3-4

Page 220 of 677

OUTLINE 33

SPECIFICATIONS

TRANSAXLE AND TRANSFER UNIT

Item Engine model

Transaxle control

Forward

Synchromtsh system

Reverse

I St

2nd

3rd

Gear ratlo 4th

5th

Reverse

Final gear ratio

Speedometer gear ratlo

Type

Number of ring Outer

gear teeth

Inner

Center differential

gear teeth

Inner

Number of sun Pinion gear side

gear teeth

Idler gear side

Number of idler gear teeth

Type

011

Capacity BP DOHC turbo BP SOHC

Floor shift

Synchromesh

Selectrve sfiding and synchromesh

3.454 3.307

1.833

I.310 1.233

0.970 Cl.91 4

0.717

3.166 L

4.214 4.388

1 .oo

Planetary carrier

59 79

75 66

14

14

43 33

43

37

ATF: DEXRON-II, M-III Above -18OC (O°F)

API servie GL-4 SAE 75W-90

2.6 liters (2.7 US qt, 2.2 Imp qt)

93GOJ3-305

Transfer Carrier

Number of teeth Ring gear

Pinion gear 37

11

API service GL-5

Oil Type

Capacity Above -18OC tOoF) SAE 90

Below -18OC tOoF) SAE 8OW

0.5 liter (0.53 US qt,

0.44 Imp qt)

93GOLl3-776 -

J3-5