MAZDA 232 1990 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 181 of 677

F2 CUNTRULSYSTEM

‘erminal Input Output i Connected to Test condition Correct voltage Remark

2A - - ’ Ground {Injector)

Constant OV -

2B - - I Ground (Output)

Constant OV -

2c , - - 1 Ground (CPU)

Constant OV - 20

-i- Ground (Input) Constant

OV -

2E ’ 0 1 Distributor I

Ignition switch ON Approx. OV

(Ne-signal)

or 5v -

Idle Approx. 2V

2F -j- - - - -

2G 0

Distributor ignition switch ON Approx. OV

(G-stgnal) or 5V

Idle Approx. I.3

2t-I - - -

- - -

21 - - - - - -

2J C

Knock control unit

Idle Approx. 4. OV -

2K 0

Thronle sensor/ Constant . 4.5--5.W

Airflow meter

-

2L

- -

- - - -

I

2M 0 Throttle sensor

Accelerator pedal released Approx. 0.W

-

Accelerator pedal fully depressed Approx. 4.W

2N 0

20 0

2P 0

1

2Q ! 0

2R Oxygen sensor

Airflow meter

Intake air

thermosensor

Water

thermosensor 0

’ Turbocharge

indicator Ignition switch ON

f OV

Idle (Cold engine) ov

Idle (After warm-up) O-l .ov -

Increasing engine speed [After warm-up) 0.5-I .ov

Deceleration o-0.4v

ignition switch ON

’ Idle Approx. 3.8V

-

Approx. 3.OV

Ambient air temperature 20°C (68OF) Approx. 2SV In airflow meter

Engine coolant temperature 20°C (68OF) Approx. 2.5V

-

After warm-up

Below 03

Ignition switch ON

Approx. f2V

-

F2-64

Page 182 of 677

CUNTRUL SYSTEM F2

Incorrect voltage Possible cause

I

Above Ok’ l Poor contact at ground terminal l Open crrcurt in wiring from ECU to ground

Always approx. OV or approx. 2V

l Refer to Code No.02 Troubleshooting -

Always approx. OV or approx. ISV - l Refer to Code No.03 Troubleshooting

Always OV

Always OV -

- -

-

l Refer to Code No.05 Troubleshooting

l . Short circutt in wiring from ECU termrnal 2K to throttle sensor, or airflow

meter

l Poor connection at ECU connector l ECU malfunctron

Below 4-W or above 5.5V

Always OV

l ECU malfunction

l Throttle sensor malfunction l Short circurt in wiring from ECU terminal 2L to throttle sensor l Poor connection at ECU connector

l ECU malfunction

Always approx. 5V

Always constant

Always above f V

OV after warm-up

Always approx. IV after warm-up . Throttle sensor m&adjustment

l Open circuit in wiring from ECU terminal 2L to throttle sensor l Open circuit in wiring from ECU terminal 2t to ECU terminal 20

l Open circuit in wiring from ECU terminal 2M to throttle sensor l Open circuit in wiring from ECU terminal 2K to throttle sensor l Open circuit in wiring from ECU terminal 2D to throttle sensor

l Throttle sensor m&adjustment

l Refer to Code No.15 Troubleshooting

l Refer to Code No.1 7 TroubleshootIng

Always OV or approx. 5V l Refer to Code No.08 Troubleshooting

-

Always OV or approx. 5V

Always OV or approx. 5V

l Refer to Code No.1 0 Troubleshootrng

1

l Refer to Code No.09 Troubfeshooting

Always OV . Indicator broken

l Open or short circuit rn wirinq from ECU 2R to rgnition swatch

F2-65

Page 183 of 677

F2 CONTROLSYSTEM

Terminal I Input Output Connected to Test condition Correct voltage Remark

25 0

Overboost warning lgnltion switch ON Approx. 12V

-

buzzer

2T 0 1 Solenoid valve 180 seconds atter engine started when Below 1 SV

(Pressure regulator) engine coolant temperature above 90%

(I 94OF) and Intake air temperature above -

58OC (13WF)

1 Other condition at Idle Approx. 12V

2u 0 Injector (Nos. I 1 3) Ignrtion switch ON Approx. 12V * Engine Signal

Idle Approx. 12V’ Monitor: Green

and red lamps

Engrne speed above 2,000 rpm on de- Approx. f2V

flash

celeratlon (Atter warm-up)

2v 0 Injector (Nos. 2, 4) lgnitlon swrtch ON Approx. 12V

Idle Approx. 12V’

Engine speed above 2,000 rpm on de- Approx. 12V

ceieration (After warm-up)

2W 0

ISC valve Ignition switch ON Approx. 7V

-

Idle Approx. 9V

2x 0 Solenoid valve Ignition switch ON Approx. 12V

(Purge control)

t Idle -

Approx. f2V

t

2Y 0 Cmxit opening Ignition switch UN Approx. 12V

-

relay

Idle Below 1 .OV

22 - - - - - -

-L J

u-

v I U-1 l-

2y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2C

2A 1U 1S IQ 10 1M 1K 11 1G 1E IC 1A

22 2X 2V 2T 2R 2P 2N 2L 2.J i’t-( 2F 2D 2B 1V 1T 1R tP IN IL I..! ItI IF

tD 18

F2-66

Page 184 of 677

CONTROLSYSTEM F2

I

7

Incorrect voltage Possible cause

Always OV l Open or short circuit in wjring from ECU terminal 2s to buzzer

Always OV or approx. 12V

1 l Refer to Code No.25 Troubieshootlng

Always OV

1

l Marn relav (FUEL INJ relay) malfunction

/ l Open or shbrt circuit in wi&g from injector to ECU terminal 2U or 2V

Always approx. 12V

l ECU malfunctron

Always OV or approx. t2V

l Refer to Code No.34 TroubleshootIng

Always OV or approx. 12V

l Refer to Code No.26 Troubleshooting

Always OV

l Open or short circuit KI wiring from ECU terminal 2Y to relay

f2-67

Page 185 of 677

![MAZDA 232 1990 Workshop Manual Suplement F2 CONTROL SYSTEM

93GOF2-79; 2

93GOF2-793

93GOFZ794

1

OXYGEN SENSOR [BP TURBO]

Inspection

Sensor

1. Warm up the engine to normal operating temperature.

2. Disconnect the oxygen sensor connect MAZDA 232 1990 Workshop Manual Suplement F2 CONTROL SYSTEM

93GOF2-79; 2

93GOF2-793

93GOFZ794

1

OXYGEN SENSOR [BP TURBO]

Inspection

Sensor

1. Warm up the engine to normal operating temperature.

2. Disconnect the oxygen sensor connect](/img/28/57056/w960_57056-184.png)

F2 CONTROL SYSTEM

93GOF2-79; 2

93GOF2-793

93GOFZ794

1

OXYGEN SENSOR [BP TURBO]

Inspection

Sensor

1. Warm up the engine to normal operating temperature.

2. Disconnect the oxygen sensor connector.

3. Connect a voltmeter to the oxygen sensor terminal @.

4. Run the engine at 4,500 rpm untiI the voltmeter indicates

approx. 0.7V.

5. Increase and decrease the engine speed suddenly and

measure the vottage.

Voltage

Engme speed Voltage (v-)

Decelerating o-0.4

Accelerating 0.5-l .o 6. Connect the

SSTs to the diagnosis connector.

7. Set the system selector select switch to 1 and the test switch

to 02 MONITOR.

8. Increase the engine speed to

between 2,000 and 3,000

rpm, and verify that the monitor lamp flashes for 10 seconds.

Specification:

Monitor lamp flashes more than 8 times/IO sec.

Heater 1. Disconnect the oxygen sensor connector.

2. Check resistance between oxygen sensor connector ter-

minals @ and 0.

Resistance: Approx.-6& [at 20°C (68OF)]

Replacement 1. Disconnect the oxygen connector. ’

2. Remove the oxygen sensor.

3. Install the new oxygen sensor and new washer.

4. Tighten the oxygen sensor to specified torque.

Tightening torque:

29-49 N-m (3-5 m-kg, 22-36 ft-tb)

Page 186 of 677

CONTROLSYSTEM F2

KNOCK SENSOR

!, -

l The knock sensor and knock control unit cannot be

inspected

individually.

When

a malfunction code number 05 is indicated,

replace.

Replacement

I_ Disconnect the knock sensor connector.

2. Raise the vehicle and support it WI safety stands.

1 93GOF2-797 3. Remove the knock sensor with using the SST

4. Install it in the reverse order of removal.

Tightening torque:

20-34 Nm (2.0-3.5 m-kg, 14-25 ft-lb)

F2-69

Page 187 of 677

Page 188 of 677

G

ENGINE ELECTRICAL SYSTEM

INDEX . ..I 1.. . . . . . . . . . . . . . . . . . . . . . . ..*. . . ..I..... . . . . . ..I...

G- 2

j FEATURES 1

OUTLINE . . . . . . . . . ...*....* .I.............. .I . . . . . . . . . . . . . .

G- 3

OUTLINE. OF CONSTRUCTION ..I... . . . . . . . . . . . G-

3

SPECtFICATiONS . . . . . . . . . . . . ..I............... . . . . . .

G- 3

1 SERVICE 1

SUPPLEMENTAL SERVICE INFORMATION . . G- 4

STARTING SYSTEM

. ..I. . . . . . . . . a.. . . . . . . . . . . . . . . . . . . G- 4

STARTER

l ..I.... . . . . . . . . . . . . . . . . . . l .*.....* .I....... . . . G- 4

CHARGlNG SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G- 5

PREPARATION

. . . . . . . . . . . . ..I..-... . . . . l . . . . . . . . 1. . . . . G- 5

ALTERNATOR (RHD)

. . . . . . . . . . . . . . . . . . . . . . . . . . ...*. G- 5

93GOGX-701

Page 189 of 677

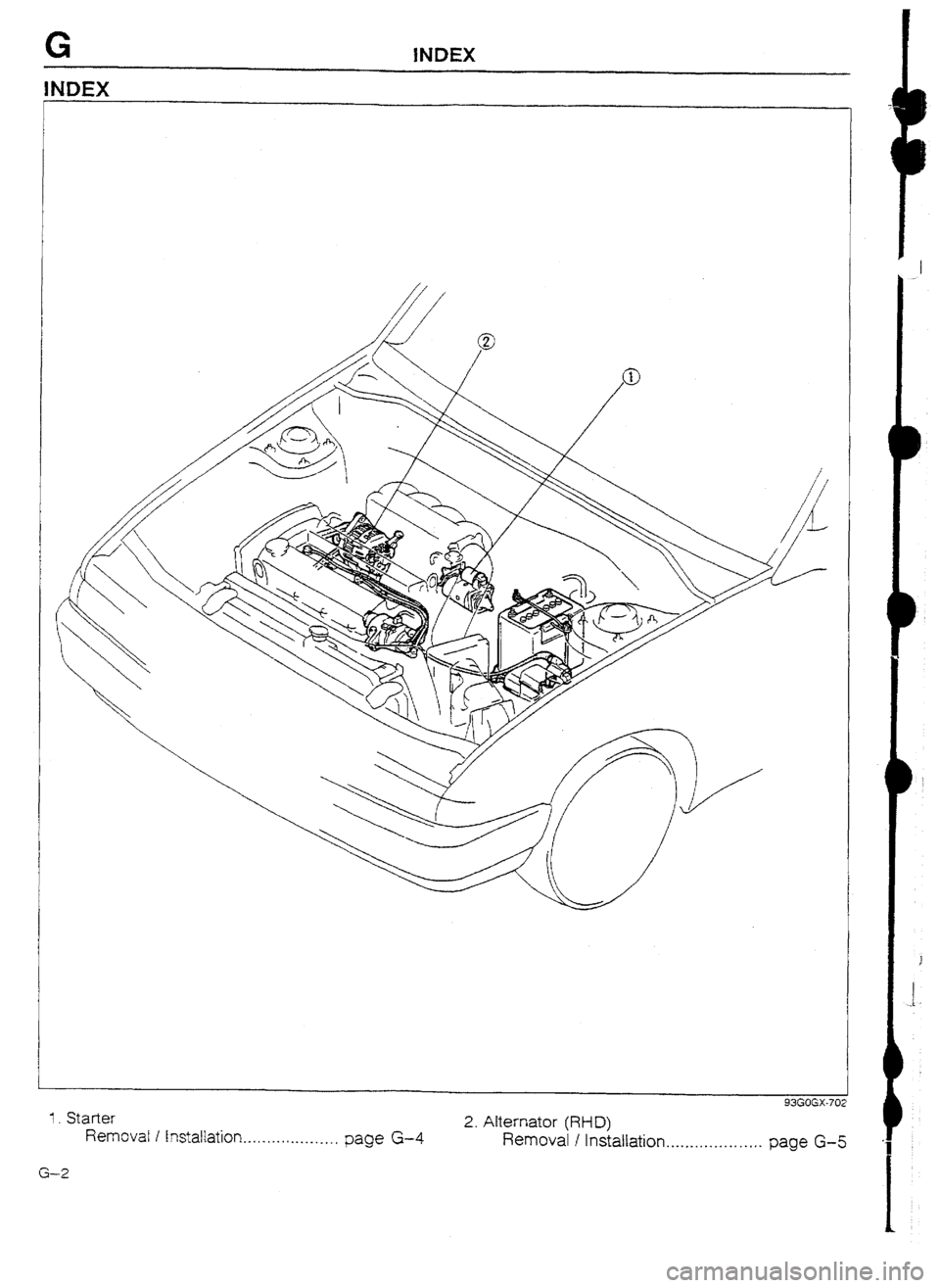

G INDEX

1. Starter 93GOGX-702

Removal I Instaltation... ._. . . . . . . , . . ._._, page G-4 2. Alternator (RFD)

Removal I Installation. . . .._.. . . . . . . . . . . . .

page G-5

G-2

Page 190 of 677

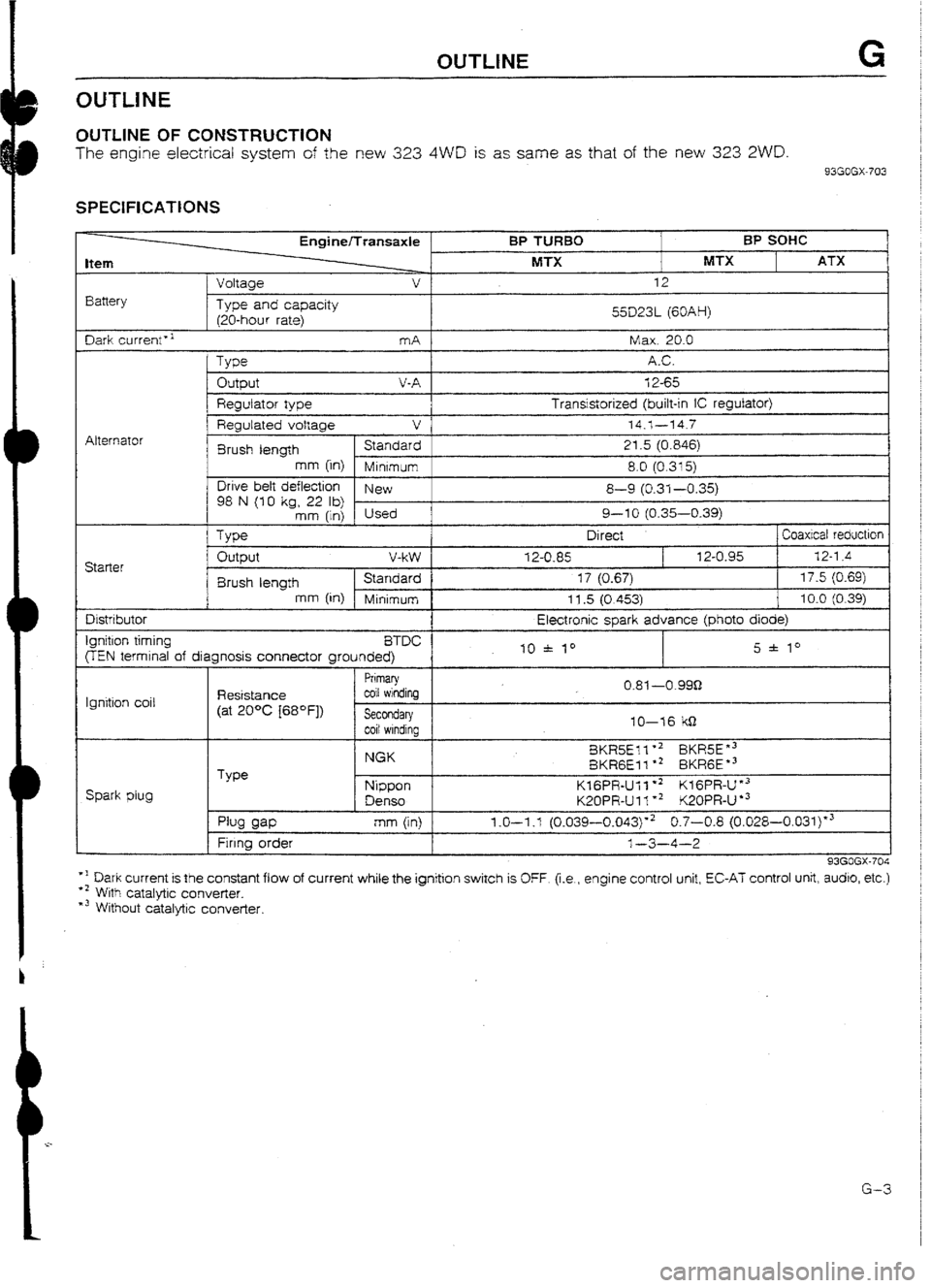

OUTLINE G

L

i i-

OUTLINE

OUTLINE OF CONSTRUCTION

The engine electrical system of the new 323 4WD is as same as that of the new 323 ZWD.

93GOGX-703

SPECIFICATIONS

Item

Battery t

Voltaae EnginelTransaxle

v

Type and capacity

120-hour rate) BP TURBO

MTX BP SOHC

MTX ATX 12

55D23L (60AH)

I

Dark current” mA 1 Max. 20.0

Alternator

Output V-A 12-65

Regulator type Transistorized (built-in iC regulator)

1 I Regulated voltage v

74.1---14.7

Brush length Standard 21.5 (0.846)

mm (in)

Minrmum 8.0 (0.315)

Drive belt deflection

New

98 N (10 kg, 22 lb) 8-9 (0.31-0.35)

mm (in) Used 9-l 0 (0.35-0.39)

Type Direct ] Coaxicat reductron Starter Output V-W

12-U-85 12-0.95 32-l .4

8rush length Standard 17 (0.67) 17.5 (0.69)

mm [in) Minimum 11.5 (0.4531 10.0 (0.39) Distributor

Ignition timing

BTDC

FEN termrnal of diagnosis connector grounded) Electronic spark advance (photo

diode)

10 * I0 5 f lo

Ignition coil Resistance

(at 20°C [68OFj)

I

Primary

coil windinq

I

Spark plug Type I

Secondary 1

f coil windina 1

NGK

Nippon

Denso 10-76 kS-l

8KR5Ell +2 BKR5E”3

BKRGEI 1 l * BKRGE *3

KIGPR-Ull *2 KfGPR-I-Y3

K20PR-Ul l ** K20PR-U

l 3 0.81 ---o-999

pw am

Firrng order

I mm (in) 1.0-I .l (0.039-0.043)“2 0.7-0.8 (0.028-0.03i)*3

l-3-4-2

93GOGX-704

*I Dark current is the constant flow of current while the ignition switch is OFF. (i.e., engine control unit, EC-AT control unit, audro, etc.)

+’ With catalytic converter.

*3 Without catalytic converter.

G-3