fuel MAZDA 323 1992 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 42 of 279

OUTLINE F3

SPEClFiCATlONS

Iten

Idle speed’

tgnltion trming * Engine

m

BTDC BP TURBO

800 f 50

IO f 10

Fuel pump

Maximum output pressure kPa { kgflcm’, psi 1 1 490-736 {SO-7.5, 7t-110)

Transfer pump

Maximum output pressure

Fuel filter kPa { kgf/cm2, psi ) 1 , 39 10.4, 5.7 1 or higher

Nylon element (in fuel pump)

Idle-speed control (fSC) valve

Type

Resistance I Rotary

nt

11-13 [at 2O*C [68*F)]

Solenoid va tve (purge contra I)

,I

Resistance -2o*c I -4Of 1 14.6-I 7.8

2.21-2.69

.kQ , 2o”c { 68OF)

40% f104*f 1 1.0-l .3

Resistance

Fuel tank

Capacity

Air cleaner

Etement type

Fuel

Specification L {US gal, Imp gal) [ Approx. 6 [at 20°C f 68*FJ]

60 (15.9, 13.2)

01 permeated

Unleaded premium (RON 95 or higher)

11FrlC?.7 11

l TEN terminal of diagnosis connector grounded.

The I; mark indicates newly equipped Parts. l”L”l “VI I

F3-9

Page 45 of 279

F3 FUEL SYSTEM

FUEL

SYSTEM

OUTLINE

l Thspressure regulator has two vacuum ports for its two-stage operation. (Refer to page F3-43.)

l The injectors are changed from high-ohmic type to low-ohmic type for improvement of the supply of fuel

during high-speed engine operation.

l To decrease the current in the injectors, an external resistor is equipped and is mounted on the aircleaner

housrng .

13EOF3315 Pressur regulator

VACUUM PORTS

F3-12 13EOF331;

Page 46 of 279

:

:

1 , ._.s_ , -. _ ._>_ ‘r--A.-

_, . :. . . . . .-

CONTROL SYSTEM F3

CONTROL SYSTEM

STRUCTURAL VtEW

SOLENOID VALVE

PRESSURE RE

LUTCH SWlTCH

FUEL INJ RELAY

NTAKE AIR THERMOSENSOR

AIRFLOW METER)

WATER THERMOSENSOR

F3-13

Page 47 of 279

F3 CONTROL SYSTEM

PRESSURE REGULATOR CONTROL SYSTEM

SOLENOID VALVE TO MAIN RELAY

(PRC HIGH TEYP.)

t ECU

I

PRESSURE REGULATOR

// VACUUM

IJ WATER

THERMOSENSOR

F----------- lNTAKE AIR

THERMOSENSOR

SWITCH SOLEltolD VALVE

(PRC LOW TEMP.)

TO FUEL TANK

13EOF3-31 To prevent vaporlock in the fuel system during hot restart idle, a two-stage pressure regulator is adoped

to the new 323 4WD.

Low temperature operation: The vacuum to the pressure regulator (A and B ports) is cut (solenoid valve

[low temp.] UN), and the fuel injection pressure is increased to 284 kPa (2.90 kgf/cm2, 41 psi ) ,

High temperature operation: The vacuum to the pressure regulator (A port) is cut (solenoid valve [high

temp.] ON), and the fuel injection pressure is increased to 343 kPa [ 3.5 kgf/cm2, 49 psi 1.

Condition and operation

Condition Operation

1

coolant Intake alt Solenoid vrlve Solenoid vatve Opemtlon

I temperature temperature Engine (Idw temp.)

(high temp.) time Operation 40% [fU40f)-

Above 90°C 5U°C (t22OFI ON OFF 180s Low temp.

f f940Fj No load

Above 5O*C

I122OF) OFF ON 210s t-ltgh temp.

3

t3EOF3-319

F3-14 Wast

l Ins fuel

l In:; InJeci

l In:;

l Vol Injecl

l In:;

Presr

l SCI Engir

l InsI

Page 48 of 279

![MAZDA 323 1992 Suplement User Guide SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Inst MAZDA 323 1992 Suplement User Guide SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Inst](/img/28/57055/w960_57055-47.png)

SUPPLEMENTAL SERVICE INFORMATION .

I

The following points in this section are changed in comparison to the Mazda 323 4-Wheel Drive Work-

shop Manual [I 229-l O-89t].

Turbocharger

l Removal / Installation

Wastegate solenoid valve

l Inspection

htercooter

l Removal I Installation

Fuel pump (main)

l Inspection

Fuel pump resistor/relay

l System operation

l Inspection

Injector

l Inspection

l Volume test

Injector resistor

l Inspection

Pressure regulator control system

l Solenoid valve (pressure regulator control}

Engine control unit (ECU)

l Inspection 13EOF3.320

F3-I 5

Page 51 of 279

F3 SELF-DIAGNOSIS FUNCTION

:ODE NO. 25 {SOLENOlD VALVE - PRESSURE REGULATOR CONTROL) (Low temperature opoeration)

INSPECTION ACTION

Disconnect connector from ECU; IS there battery Yes Check ECU termrnal connector for poor

voltage at ECU terminal 2T (G/C) wrth Ignition connection

switch ON?

4 If OK, replace ECU

CT page F3-2

c3 If not OK, repatr or replace connector

NO Go to next step

2 In same condition as rn Step 1. is there battery Yes Repair or replace wlrrng harness (G/O)

voltage at sofenord vatve (PRC low temp.) con-

nector termrnal wrre (G/O)?

NO Go to next step

3 Is solenord valve (PRC low temp ) UK7 Yes Check for a short or open crrcuit in WII-

CT page F343 ing harness (main relay [FUEL INJ re-

lay] - solenoid valve [PRC low temp.])

NO Replace solenord valve (PRC tow temp.)

1

t3EOF3-323

CODE NO. 35 (SOLENOID VALVE - PRESSURE REGULATOR CONTROL) (High temperature opoeration)

STEP lNSPECTlON ACTlON

1 Disconnect connector from ECU: is there battery Yes Check ECU terminal connector for poor

voltage a? ECU terminal 22 (G) with rgnttlon connection

swttch ON7

4 If OK, replace ECU

J page F3-2

e If not OK, repair or replace connector

No Go to next step

2 In same condrtron as In Step 1, is there battery Yes

voltage at solenoid valve (PRC high temp.) con- Repair or replace wiring harness (G)

nector terminal wire (G)?

No Go to next step

3 Is solenoid valve (PRC high temp ) OK7 Yes Check for a short or open circuit In wir-

r;r page F343 ing harness (marn relay [FUEL INJ re-

WI - sofenord valve [PRC high temp.])

No Replace solenoid valve

(PRC high temp.)

f3EOF3-324

Circuit Diagram

ECU

I

2T 22 I

G

TO MAIN RELAY

I SOLENOID

VALVE

(PRC HIGH TEMP.)

F3-18 :3EOf3 32 5

--

TRW

RELAT

c

-..

INPUT

--

KNOCH

--

DIAGM

(TEN T

--

IGNITIi

(STAR1

--

E/L SIC

-a

P/S PR

--

A/c SYI

--

NEUTR

SWITCI

--

STUPb

--

ATMDI

SENSQ

-a

THRUI

-..

INfAk.1

--

AlFlFLC

--

UXYGE

--

WATEF

--

DlSfRl

Page 53 of 279

F3 TRUUBtESHOOTlNG GUIDE

IDIAGNOSTiC tNDEX

No. TFtOUBLESHOOTtNG ITEM DESCRIPTtON PAGE

1.

WI/I not crank or cranks slowly Refer to Engine Electrrcal System ‘1

2 Cranks normally but No combustion Engine cranks at normal speed but shows no sign of F3-22

will not start flrlng

3 Partial corn bustlon- Engine cranks at normal speed but shows only par- ‘1

When engine cold tial combustion and will not continue to run

4 Partial combustron- Engine cranks at normal speed and shows partial F3-25

After warm-up combustion but ~111 not continue runnrng after being

hot soaked

Cranks normally but Always Engine cranks at normal speed but rqurres exces- ‘1

hard to start sive cranktng time before starting

When engine cold Same condition as No. 5 when engine IS cold ‘1

Restarts normally after warm-up

After warm-up Same condition as No. 5 after running and betng hot F3-27

soaked

Starts normaNy when cold

1 8 1 Rough idle/

tsl Engine stalls at idle 1 Always [ Engine stalls or vibrates excessively at idle

r - 1 F3-29

r

Before warm-up 1 Engine stalls or vibrates excessively at idle during

I ‘1

10

11

12 After warm-up

When A/C, P/S,

or IX ON

Rough rdle/Englne stalts lus: after starting warm-up

Engine runs normally at idle during warm-up but

stalls or vibrates excessively atter warm-up

Engrne stalls or vtbrates excessrvely at idle when

NC, P/S, or E/L ON

Engine stalts or vibrates excessively lust after starting

tacceleratton from Idle1 F3-3 f

‘1

‘1

I I ’ I

I 13 High Idle speed after warm-up tdle speed excessively hrgh after warm-up ‘1

14 Idle moves up and down/idle hunts Engine speeds up and down periodically at Idle

F3-33

15 Engme stalls on deceleratron Engine unexpectedly stops running durrng or after

F3-35

deceleration

16 Engine statts suddenly (intermrttent) Engine intermittently stops runnrng

F3-36

17 Hesitates/Stumbles on acceleratton Flat spot occurs just after accelerator is depressed,

‘1

or m/Id ierkina occurs dunna acceleration

L I I

t 18 1 Surges while crulsng

1 Unexpected change In engine speed that is usually 1 ‘1

1 repetrtive

19 tack of power

20 Poor acceleration

21 Runs rough durrng deceleration/Backfire

22 Knocktng

23 Fuel odor Performance poor under load when throttle valve IS

wide open

Maximum speed reduced

Performance poor during acceleration

Engtne runs rough during deceleratron, and abnor-

mal combustion occurs in exhaust system

Abnormal combust!on accompanied by audible

“pinging” noise

( Gasoline odor in cabln ‘2

‘2

‘1

‘2

+1

24 Exhaust sulfur smell Exhaust gas has an unusual odor

25 High oil consumption Oil consumption excessive

b

26 Poor fuel economy Fuel economy unsatisfactory

27 A/C does not work

Blower fan operates, but magnetic clutch does not

l 1.. .Refet to 323 Workshop Manual (t 203-l O-89F). l 2...Re#er to 323 4-Wheet Drive Workshop Manual (1229-IO-89L). ‘1

‘2

‘1

l 1

13EOFS327

F3-20 -..

REAR I

--

--

Page 54 of 279

TRUU8LESH00TlNG GUIDE F3

13EOF3-328

13EOF3-329

1

PRECAUTIONS

Fuel Pressure Release and Servicing Fuel System

Fuel

in the fuel system remains under high pressure when the engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

or fire as discribed below.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuet pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the fuel hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l install hose clamps to secure the fuet pressure

gauge to the fuei fitter and the fuel main hose to pre-

vent fuel leakage.

Pinching Hose

When pinching an air hose-or a fuel hose with pliers, wrap

the hose with a rag to prevent damage,

F3-2 t

Page 55 of 279

F3 TROUBLESHOOTING GUIDE

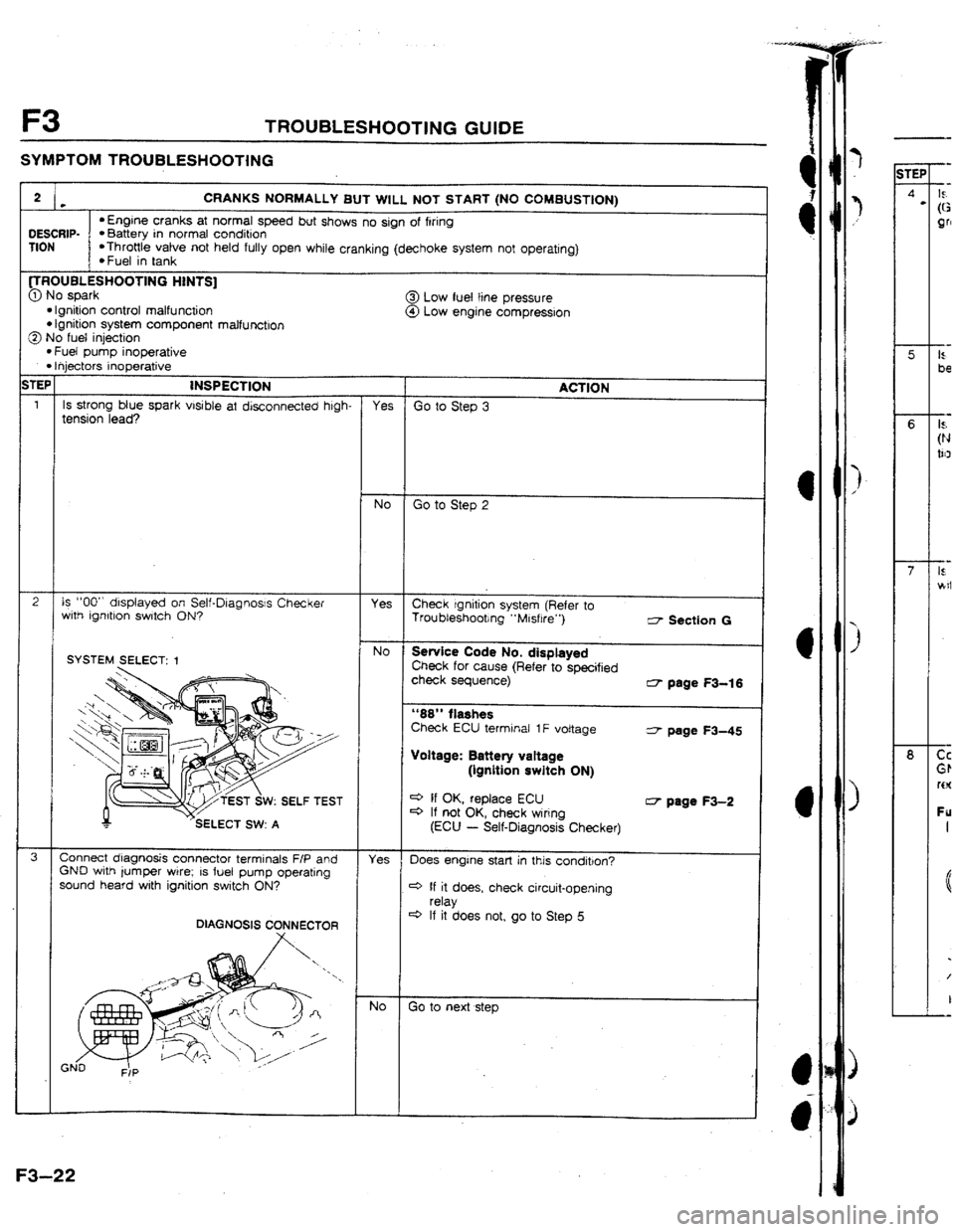

SYMPTOM TROUSLESHOOTING

2 . CRANKS NORMALLY BUT WILL NOT START (NO COMBUSTION)

LIESCRIP-

l Engine cranks at normal speed but shows no sign of firing l Battery in normal condition

TION *Throttle valve not held fufly open while cranking (dechoke system not operating}

l Fuel in tank

UROOBLESHUOTlNG HINTS]

@ No spark

@.I low fuei tine pressure

l Ignition control malfunction @I Low engine compresslon l Ignition system component malfunction

@ No fuel injection

l Fuel pump inoperative l Ihjectors inoperative

;TEP

INSPECTION

I ACTION

1

Is strong btue spark visible at disconnected high- Yes Go to Step 3

tension lead?

NO Go to Step 2

2 Is “00” dlsplayed on Self-Dlagnosjs Checker

Yes

with ignltron switch ON? Check rgnltion system (Refer to

Troubleshooting “Misfire”)

c7 Section G

SYSTEM SELECT: 1 No

Service Code No. displayed Check for cause (Refer to specified

check sequence)

G- page

F3-16

“66” flashes

Check ECU termrnal 1F voltage

3 page W-45

Voltage: Battery vabage

(ignition switch ON)

W: SELF TEST C+ If OK, replace ECU

4 If not OK, check wiring

CT page F3-2

(ECU

- Self-Diagnosis Checker)

3

Connect diagnosis connector terminals F/P and

Yes

GND with jumper wire; IS fuel pump operating Does engine start in this condition?

sound heard wjth ignition switch ON?

4 If it does, check circuit-opening

relay

4 If it does not, go to Step 5

No Go to next step

F3-22

iTEF

6

8

Page 56 of 279

TROUBLESHOOTING GUlDE F3

STEP INSPECTION ACTlON

4

Is there buttery voltage at fuel pump connector Yes

* (G/R) with lgnitron switch ON and F/P terminal Check contmurty of fuel pump

between termrnafs G/R and 8

Check ctrcutt openmg relay

5

Is qector operating sound heard whtle engine IS Yes Go to Step 8

being cranked?

No Go to next step

CcI page F3-45

+ If 0K;check for a short cjrcult rn

wiring harness

(Injector reastor-Injector)

=D If not OK, replace Injector reststor

fuel Line pressure: 265-314 kPa

12.7-3.2 kgflcd, 38-46

psi)

if fuel return hose is clogged or

t, replace pressure

CT psge F3-3

F3-2 3