service MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 66 of 279

![MAZDA 323 1992 Suplement Owners Manual TROUBLESHOOTING GUlbE F3 1

14 IDLE MOVES UP AND DOWN/IDLE HUNTS

IESCRLP-

l Engine speeds up and down periodically at idle

UON

TROUBLESHOOTING HINTS]

B Idle switch (En throttle sensor) OFF at idl MAZDA 323 1992 Suplement Owners Manual TROUBLESHOOTING GUlbE F3 1

14 IDLE MOVES UP AND DOWN/IDLE HUNTS

IESCRLP-

l Engine speeds up and down periodically at idle

UON

TROUBLESHOOTING HINTS]

B Idle switch (En throttle sensor) OFF at idl](/img/28/57055/w960_57055-65.png)

TROUBLESHOOTING GUlbE F3 1

14 IDLE MOVES UP AND DOWN/IDLE HUNTS

IESCRLP-

l Engine speeds up and down periodically at idle

UON

TROUBLESHOOTING HINTS]

B Idle switch (En throttle sensor) OFF at idle

3 Air leakage

3 Fuel injection amount Inconstant

. Poor contact point inside airflow meter

9 Poor ignitron

rEP[ INSPECTION

I is “00” displayed on Self-Dragnosis Checker

with ignrtron swatch ON?

SYSTEM SELECT: i I ACTfON

Yes Go to next step

NO Service Code No. displayed

Check for cause (Refer to specified

check sequence) c=;r page F3-16

“86” flashes

Check ECU terminal IF vottage csr page F345

Voltage: Battery voltage

W: SELF TEST (ignition switch ON)

SELECT SW: A

.d P/ e If OK, replace ECU CT page F3-3

c3 If not OK, check wrrjng

(ECU - Self-Dlagnosls Checker)

2 Is intake manrfold vacuum correct at idle? Yes Go to next step

Intake manifold vacuum:

More than 450 mmHg { 17.7 inHg )

No Low vacuum

Check for air leakage at intake air

system

3 Is air cleaner element clean? Yes Go to next step

No Replace abr cleaner element

4 Disconnect each hrgh-tension lead at idie; does Yes Go to next step

engine speed decrease equally at each cylinder?

No Go to Step 8

5 Are ECU terminal voltages OK? Yes Go to next step

(especially 20, 2Q, 20) -

rI7 page F345 No

Check for cause

6 Connect System Selector to diagnosis connector Yes Go to next step

and set Test Switch to SELF TEST; is ignition

timing at idle correct after warm-up?

Ignition timing (BTDC): f 0 f la

No Adjust ignition timing

._

. F3-33

Page 68 of 279

![MAZDA 323 1992 Suplement Owners Manual TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe MAZDA 323 1992 Suplement Owners Manual TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe](/img/28/57055/w960_57055-67.png)

TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne speed drops too much when releasrng accelerator

3 Idle-speed misadjustment @I Loose connector disconnected by force of deceleration

3 Fuel-cut contrd malfunction

TEP lNSPECTlON ACTION

1 1s idle condition normal? Yes Go to next step

tdle speed: 800 f 50 rpm (in neutral)

NO Adjust or perform Troubleshooting, Nos.

8-I 1 “ROUGH IDLE”

(Refer to Workshop Manual

(1203-I o-89F))

2 Is “00” displayed on Self-Diagnosis Checker Yes Go to next step

with ignition switch ON?

SYSTEM SELECT: 1 NO Service Code No. displayed

Check for cause (Refer to specified

check sequence) ET page F3-16

“88” flashes

Check ECU termrnal 1 F voltage

Voltage: Battery voltage

(ignition switch ON) r;r page F346

W:SELFTEST

e If OK, replace ECU CI page F3-3

4 If not OK, check wirtng

(ECU - Self-Diagnosis Checker)

3 Does Self-Diagnosis Checker Monitor Lamp with Yes Go to next step

lgnttlon switch UN show that switches operate

correctly?

NO Lamp not ON or OFF with specified

switch

Check for cause (Refer to specified

check sequence)

W: SEtF TEST Lamp slways ON

Check wiring between

(ECU terminal 1 D - Self-Diagnosis

Checker)

4 Are ECU ?erminal voltages OK? Yes Go to next step

(especially IV, 20, 20, ZU, 2V.

and 20) v page F346 No

Check for cause

5 Check for poor connection of foltowing parts YC?S Repair or replace

l ignrtion coil l Igniter l Olstribdor l High-tension lead

NO Go to next step l Injector. l Injector resistor l Ctrcuit-opening relay . l ECU

F3-35

Page 69 of 279

F3 TROUBLESHOOTING GUIDE

STEP INSPECTION ACTlON

6 Is dashpot correctly adjusted? Yes Go to next step

c

Dashpot set speed: Approx. 3,500 rpm

No Adjust dashpot

7

Try known good ECU; does condition

Improve?

w page F3-3

13EOF3-336

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP.

l Engine intermittently stops running

TION l Before stalling, engine conditron is OK

TROUBLESHOOTING HINTS]

@ intermittently no spark or no fuel injection caused by ve-

hlcle vibratron, acceleratton, or deceleration

l Poor connectlon in wiring harness

iTEP INSPECTION ACTfON

1 Is “00” displayed on Self-Oiagnoss Checker Yes Go to next step

with lgnltlon swrtch ON?

NO Service Code No. displayed

Check for cause (Refer to speclfled

check sequence).

Note CT page F3-16

l When checking wiring harness and

connectors, tap, move, and wiggle

suspect sensor and/or harness to

recreate problem

“88” flashes ’

Check ECU terminal IF voltage

Voltage: Battery voltage

{ignition swttch ON) w page F3-45

4 If OK, replace ECU

4 If not OK, check wiring

(ECU - Self-Diagnosis Checker)

2 Check for poor connection of foliowrng parts

Yes Reparr or replace

l lgnltfon coil l Igniter l Distributor l t-flgh-tensron lead

No Go to next step l Injector l Injector reststor l Circutt-opening relay l ECU

3 Are ECU terminal voltages OK? Yes Go to Troubleshbotrng No. 2

(especially 16, 2A, 2B, and 2C) .“CRANKS NORMALLY BUT WILL NOT

w page F3-45 START (NO COMBUSTION)”

w page F3-20

Note

. No Check for cause

l When. checking voltages, tap, move, and

wiggle harness and connector to recreate

problem

* lrlrl m-7

F3-36

7.8-l

Page 79 of 279

F3 CONTROL SYSTEM

Terminal voltage

Reference date

Vs: Battery voltage

‘em&al Input Output Connected to Test condition Correct voltage Remark

1A - - Battery Constant VB

For backup

18 0 Main relay

Ignition switch OFF ov

(FUEL INJ relay) -

ON

V8

1C 0 lgnitlon switch While cranking Approx. 1 OV

(START) -

Ignition switch ON ov

10 0 Self-Diagnosis Test switch at SELF TEST

Wtth Self-

Checker Lamp illuminated for 3 sec. after ignition Approx. 5V

(monitor lamp) switch OFFdON Diagnosis Check-

er and System

lamp not iltuminated after 3 sec. V8 Selector

Test switch at 02 MONITOR with engine

idling Approx. 5V

Monitor lamp illuminated

Test switch at 02 MONITOR with engine

idling Vi3

Monitor lamp not illuminated

IE - - - - - -

IF

0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2SV

l With Seif-

Checker switch OFF-+ON

Diagnosis

(service code)

Buzzer not sounded after 3 set V0 ’ Checker and

Buzzer sounded Below 2.5V System Selector

l With System

Buzzer not sounded VB Selector test

switch at SELF

TEST

1G 0 igniter tgnition switch ON

ov

-

Idte

Approx. 0.2V

It-l 0

Solenoid valve Ignition switch ON

VB

(wastegate)

Idle

Approx. 2V ’ -

II

0 Fuel pump While cranking

Approx. 1 OV

resistor/relay -

Idle

8etow 1.5V

IJ 0 NC relay Ignition switch ON

VB

A/C switch UN at idle

Below 2.5V

. NC switch OFF at idle V3

-

IK 0 Diagnosis

connector

(TEN terminal) System Selector test switch at

02 MONITOR

System Selector test switch at

SELF TEST V0

-

8elow l*OV

1L - - - - - -

I

1M - - - - -

I -

lr ‘- l-7

f L.-

r

20 20 2M 2K 21 2G 2E 2c 2A IU 1S 10 10 ltvl tK II Ir; tE 1~ IA

1

22 2x 2v 2T ZR 2P 2N 2L 25 2H 2F 20 2B 1V IT 1R tP 1N IL 1J 1H IF 1~ 1~

1

J=3-46 --

4lways 4

--

AIways 4

--

Atways 1

--

Always 1

-a

Always ’

--

Always i

-e

Always I

2.5v

Always

Always (

-m

Always f

-a

Always 1

Always (

--

Always I

2.5V

Always 1

Always t

Always

--

Page 87 of 279

ENGINE ELECTRICAL SYSTEM

OUTLINE ................................................... G- 2

SPECIFICATIONS .................................... G- 2

SUPPLEMENTAL SERVICE tNFORMATlON .m G- 2

13EOGX-30 t

G

Page 88 of 279

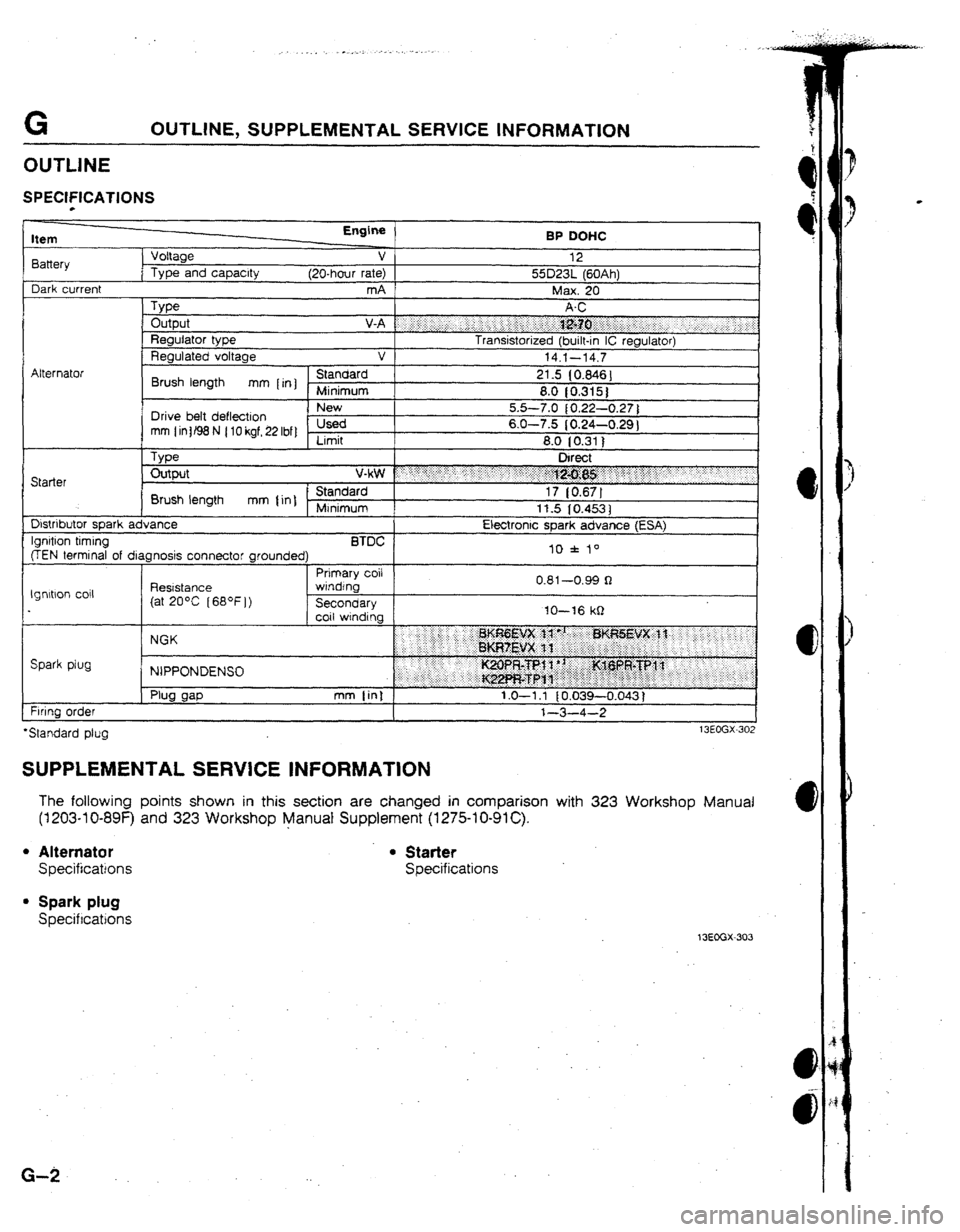

G OUTLINE, SUPPLEMENTAL SERVICE INFORMATION

SPECIFfCATfUNS

Item

8attery

Dark current Voltage

Type and capacity Engine

v

(20-hour rate)

mA BP DOHC

12

55D23L (60Ah)

Max. 20

Type Output V-A f “‘i j.,: i .:.. ‘:.. ,, j j.: i.‘: ;:;:i :j;&?.:. .: .:.

__ : . . s.i-....‘:‘:. _.. j ;.’

Regulator type Transistorized (built-in IC regulator)

Regulated voltage v

14.1-14.7

I

C?*..*rlrrrl

Brush length mm [rn] }e 21.5 (0.846)

8.0 10.315)

I Drive belt deflection I 5.5-7.0 { 0.22-0.27 )

mm (intB8N (lOkgf,22Ibf) usea 6.0-7.5 (0.24-0.29 1

Limit 8.0 (0.311

, Type Direct

Starter Output v*$# : : ;..;. ‘:‘.. ._ .; : :‘: 7.:

.. .::“:.:j 1 ,5

. . . . .j$$g;g$y .“. :yy

Brush length mm {in] - Standard 17 [0.67]

Minimum

11.5 IO.4531

Dlstnbutor soark advance Electronic soark advance (ESA)

@EN termind of diagnosis connector grounded) II) f lo

I 1 Prtmary coil

**4 nn*

Ignltbon co11 Reststance 3

(at 20°C [68*F])

in IO-16 kQ lgnrtlon timing BTDC f ar

wrndfnb

I

Secondary 1

coil WindIn.. v.0 I

--v.yy 1

Spark plug NGK

NIPPONDENSU

Firing oraer

*Standard pfug

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop Manual

(1203-l O-89F) and 323 Workshop Manual Supplement (I 275-l O-91 C).

l Alternator . Starter

Specifications Specifications

l Spark plug

Specifications

13EGGX-303

G-2

Page 92 of 279

OUTLCNE

OUTLDJE OF CONSTRUCTION

. The 323 GT-R is added to the 323 BP DOHC turbo model lineup.

l All GT-R modek are equpped with the G25MX-R (GSMX-R) manual transaxle and transfer unit.

l The transaxle and transfer unit is the same as in the 323 BP DOt-tC turbo models, except that the speedo-

meter gear ratio is changed.

Note

l Transaxk code is as shown.

G25MX-R

--r--r T

13EOJ3-302

SPECIFtCATIONS

Transaxle and Transfer Unit

Item

Transaxte control

Synchromesh system

Gear ratio Model/Engine

Forward

Reverse

1 st

2nd

3rd

4th

1 5th

Reverse

FInal gear rat10 I

Speedometer gear ratio f

Type

Number of rrng Outer

gear teeth

Inner

Center diff erentlal Number of plnion Outer

gear teetn

Inner

Numbef of sun Pinion gear side

gear teeth

idler gear side

Number of idler gear teeth

Grade

Oh Vtscosity All-season

Above -18OC { O°F 1

Capacity t ( LB qt, Imp qtl 323 GT-R

0.717 I Other

3.166 323 4WD

BP DOHC turbo

Floor shift

Synch romesh

Setecttve slrdrng and synchromesh

3.454

1.833

I.310

0.970

4.214

1.045

I 1 .OUU

Pfanetary carrier

59

I

75

14

14

43

43

37

API service U-4

ATF Dexron@II or M-III

SAE 75W-90

2.6 (2.7, 2.2)

13EOJ3-303

Transfer Carrier

Number

Orl of

- teeth

Grade

Viscosity

CaDacitv Rung gear

Pinron gear

Above -18OC fO°F]

Below -t8OC I PF 1

L I US at. imn at 1 37

31

API service ‘Gt-5

SAE 90

SAE BOW

0 5 10.53. 0.44 t

J3-2 ._

Page 93 of 279

FRONT AND REAR AXLES

INDEX ..*** . . . . . l . . . ...* . . . . . . . ..**...I* . . . . . .*..*.* . . . . . . . M- 2

1 FEATURES 1

OUTIJNE .................................................

M- 3

OUTLINE Of CONSTRUCTION

................. M- 3

SPECIFICATIONS ....................................

M- 3 t

SUPPLEMENTAL SERVICE INFORMATION.. M- 4

FRONT AXLE

l ,..,..,..............,.....*.............. M- 5

PREPARATION . . . . . . . . ..*.*...........m..........*... M- 5

WHEEL HUB, STEERING KNUCKLE . . . ..I.... M- 6

REAR AXLE *...............*............................ M-l 1

PREPARATION

l . . . . ..*..*...................*..*..... M-l 1

WHEEL HUB, KNUCKLE . . . . . . . . . . . . . . . . . . . . . . . . .

M-12

)I

13EOMX.301

q

Page 95 of 279

OUTLINE M

OUTttNE

OUTLiNE OF CONSTRUCTION

l TKe construction and operation of the front and rear axles are basically the same as previous models.

l Because of the use of a high power engine, the following parts are modified to improve rigidity.

(I) Larger front and rear bearings are used.

(2) Larger front and rear knuckles are used.

(3) A five-stud wheel hub is used.

l An ice scraper is newly installed on the rear knuckle to prevent ice from building up on the brake caliper.

(Refer to page M-14.)

13EOMX-303

SPECIWCATIONS

Hem Speclficatlons

Front driveshaft

Joint type inside

Double offset joint

Outsrde Bell joint

Length of joint (between center of joint) Right

392 I15.4)

mm lrn)

Left 306 IO.831

Shaft drameter mm fin)

21.0 (0.83)

Rear driveshaft

Inside

Joint type Double offset joint

Outside 5ell joint

Length of joint (between center of joint) Right

519.5 [ 20.5 1

mm [in]

Left.

489.5 ( 19.3 )

Shaft diameter mm (in) 21.0 [O&3]

Joint shaft

I

Length of joint

Shaft diameter

Front axle

mm jin] 357.2 114.11

mm {in] 21.0 {0.83]

4

Bearing play axial direction mm tin)

0.05 IO.002 ]

I

Rear axle

Bearing play axial direction mm (inj

Rear dtfferentlal (viscous limited slip differential) 0.05 (0.002 1

Reduction aear Hypoid gear

Differentral gear

Drfferential ratio Straight bevel gear

3.909

Number of teeth Ring gear .

Drive binion aear

43

If

Fluid I Grade API Service GL-5

Above -t8*C (O*F) SAE 90

Viscosity .

Below -18*C i O*Fl SAE 8OW

1 I Capacity L I US qt, imp stl 1 0.65 !O.SS, 0.571

1

13EOMX-304

M-3

Page 96 of 279

M SUPPLEMENTAL SERVICE INFORMATION

SUPPLEMENTAL SERVICE INFORMATION

The foIlowIng points in this section are changed in comparison with Mazda 323 Workshop Manuals

(1206-f O-89F) and (1229-l O-89L).

Front axle

l Removal I Inspection I Installation

l Disassembly I Inspection / Assembly

Rear axle

l Removal / Inspection I Installation l Disassembly / Inspection I Assembly

13EOMX-305

t

,

c

.

c!

M-4

.

r&

-s

FRC

PREF

SST

-m

49 0’

Pulle

--

49 Gl

Atkd

(Part

49 Gc

--

49 FC

I n.stail beam

--

49 F3

Attact

:Part

t 49 FO

--

49 Frl

4ttac P 58 8 : Part < $9 Fcl,

--

a9 G3

nstallt