light MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 5 of 279

GI tMPORTANT INFORMATION

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have certarn special tools that are necessary for the safe and

efficient performance of service operations on Mazda vehicles and that you know how to use them properly.

It also assumes that you are familiar with automobile systems and basic service and repair procedures.

YOU should not attempt to use this manual unless these assumpttons are correct and you understand the

consequences described below.

SAFETY RtSK

This manual contains certain notes, warnings, and other precautionary information that you should care-

fully read and follow to reduce the risk of personal injury to yourself or others and the risk of improper

service that may damage the vehicle or render it unsafe. If there IS no such information in regard to any

specific service method, this does not mean there is no possibility that personal safety or vehicle safety

wili be jeopardized by the use of incorrect methods or tools.

POSStBLE LOSS OF WARRANTY

The manufacturer’s warranty on Mazda vehicles and engines can be voided if improper service or repairs

are performed by persons other than those at an Authorked Mazda Dealer.

WARNtNG ON LUBRtCANTS AND GREASES

Avoid all prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated

during service (e+g., engine sump oils) are more irritating and more likely to cause serious effects, includ-

ing skin cancer, in the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving 011.

Protective hand cleaners may be of value provided they can be removed from the skin with water Do

not use gasoline, paraffin, or other solvents to remove oil from the skrn.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or protonged skin contact shoutd be avoided by wearing protective clothing if necessary. Par-

ticular care should be taken with used oils and greases containing lead. Do not allow work clothing .to

be contaminated with oil. Dry clean or launder such clothing at regular intervals.

9MtlGIX-002

Gt-2 REP/

I. Mc

pai

2. &

illu:

3. Put

vir:

Exarr

SHOI

EXPE

PART

SHOW

REUl

PAGE

SEWI

‘1: T

*2: c

Page 18 of 279

CAUTION GI

HANDLING CONNECTORS

Caution

*‘Be sure to grasp the connectors, not the wires, when disconnecting them.

1. Raise the rear

2. Lift the tab with a

thin piece of metal

and remove the

poor termrnat contact.

Lift the tab with a thin

When using a matching Make sure the termmals

male terminal, make are

not pushed out of

sure there

IS no

c Round connectors >

1. Raise the cover.

2. Lift the termrnal to

3. Make sure the

terminal is securely

mounted in the

Pull lightty on individual

wires to check that they

are secured rn the 1. Raise the cover.

2. Remove A.

3. Lift the tab with a

thin piece of metal

and remove the

Page 19 of 279

:

.

GI CAUTION

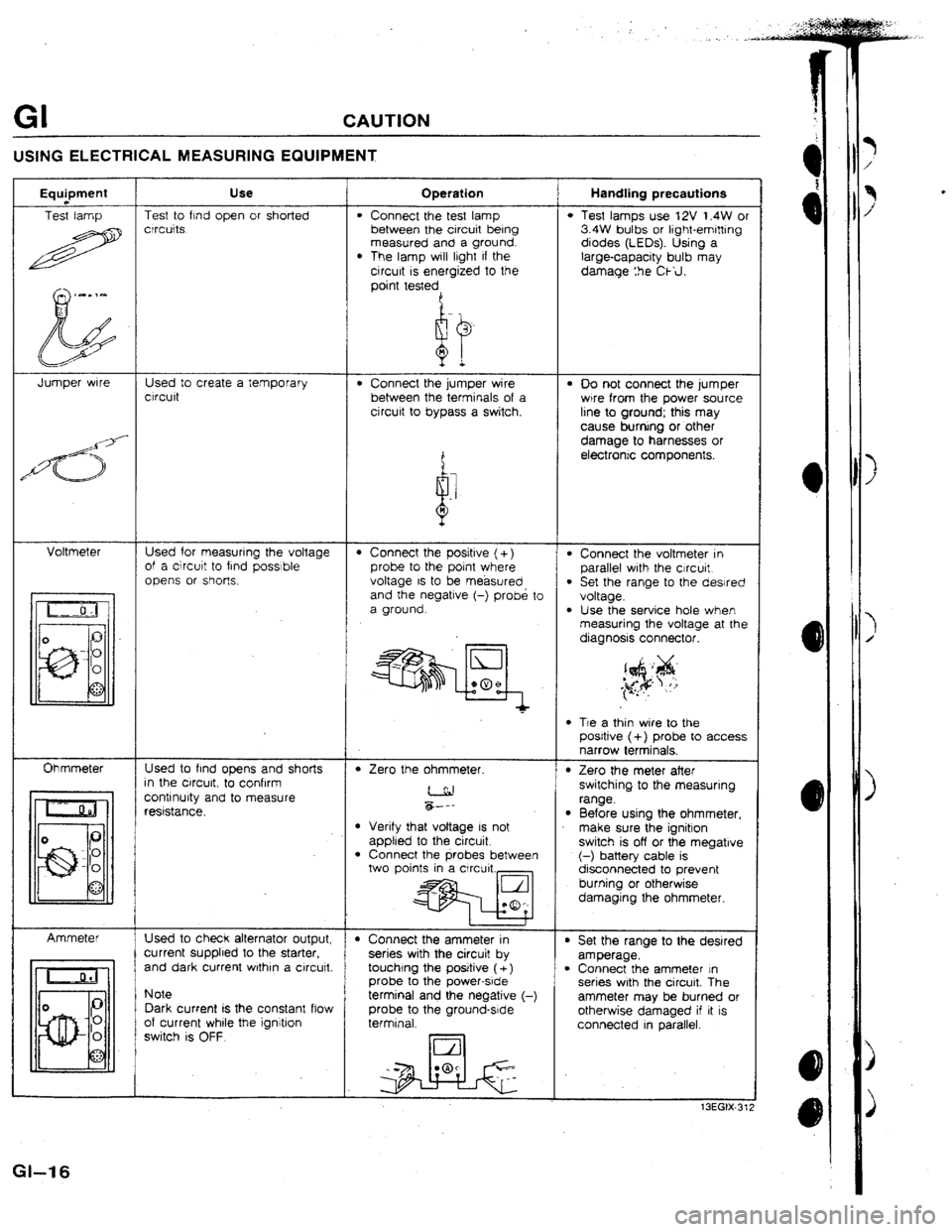

USING ELECTRICAL MEASURING EQUIPMENT

Use Handling precautions Operation Equpment

Test lamp Test to find open or shorted

crrcuits

l Connect the test lamp

between the circuit being

measured and a ground.

l The lamp will lrght if the

circurt is energized to the

point testedA

l Test lamps use 12V t.4W or

3.4W bulbs or light-emitting

diodes (LEOs). Using a

large-capacity bulb may

damage :he Ckil.

Jumper wrre Used to create a temporary

ctrcult . Connect the jumper wire

between the terminals of a

cjrcurt to bypass a switch. l 00 not connect the lumper

wrre from the power source

line to ground; this may

cause burning or other

damage to harnesses or

electrontc components.

Voltmeter Used for measuring the voltage

of a circutt to find possible

opens or shot-k.

l Connect the voltmeter in

parallel wrth the cjrcurt.

l Set the range to the dewed

voltage.

l Use the service hole when measuring the voltage at the

diagnosis connector.

l Connect the positive (+)

probe to the point where

voltage IS to be. measured

and the negatrve (-) probe to

a ground.

l Tie a thin wire to the

posrtive (+) probe to access

narrow terminals.

Ohmmeter Used to find opens and shorts

In the ctrcurt, to confrrm

contrnurty and to measure

reststance.

l Zero the ohmmeter. l Zero the meter after

switching to the measuring

range.

l Before using the ohmmeter,

make sure the ignitron

switch is off or the megatrve

(-) battery cable is

disconnected to prevent

burning or otherwise

damaging the ohmmeter. &--- l Verify that voltage IS not

applied to the circuit

l Connect the probes between

two points in a Circuit.,

t I t

+ Connect the ammeter in

series with the circuit by

touchtng the positive ( +)

probe to the power-srde

terminal and the negative (-

probe to the ground-srde

terminal. Ammeter

Used to check alternator output,

current supplied to the starter.

and dark current wrthrn a circutt. l Set the range to the desired

amperage.

l Connect the ammeter In

series with the circuit. The

ammeter may be burned or

otherwise damaged if it IS

connected in parallel. Note

Dark current IS the constant flow

of current whrle

the ignitron

switch is OFF.

13EGIX-31;

Gl-t 6

Page 21 of 279

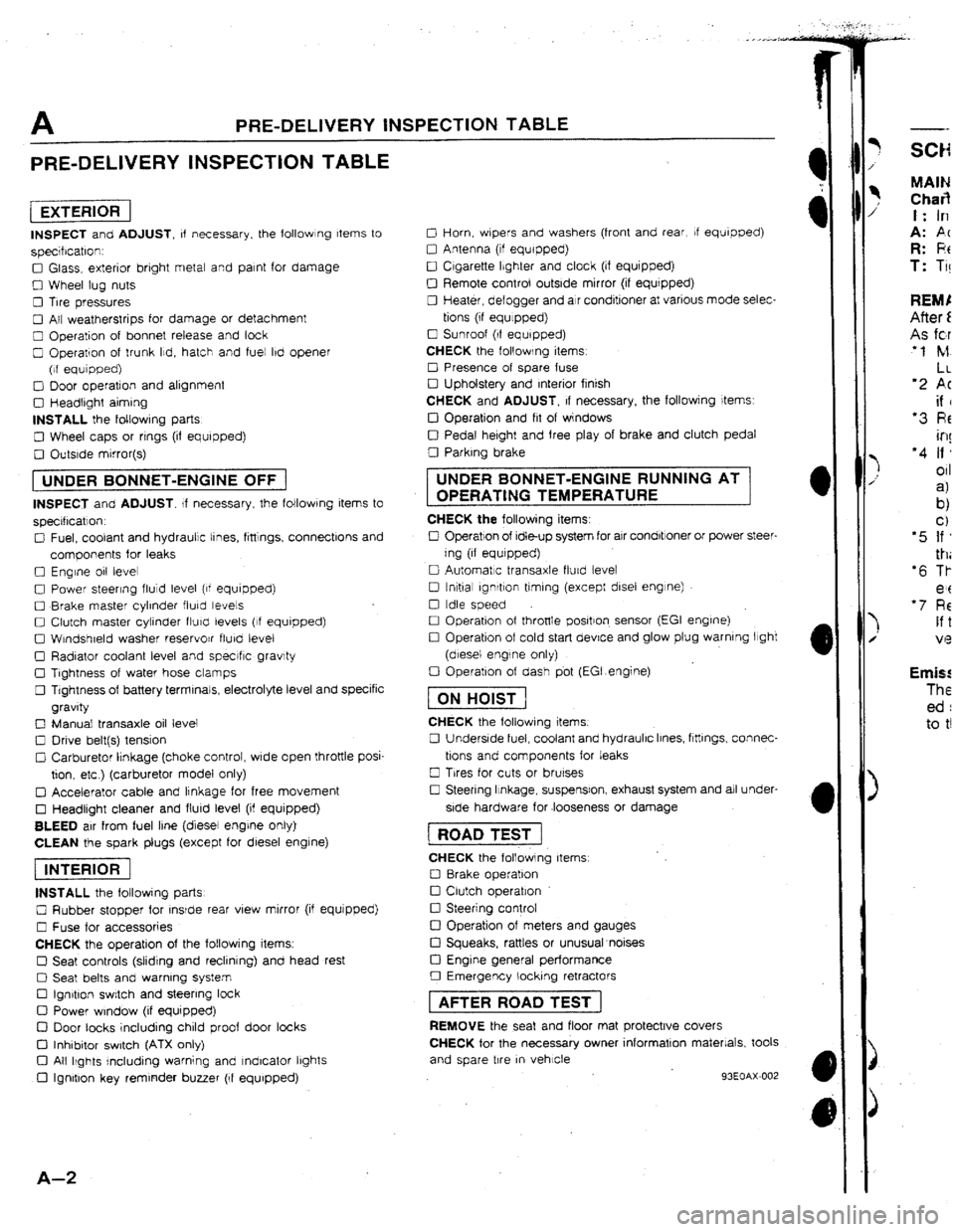

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 23 of 279

A SCHEDULED MAtNTENANCE SERVtCES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 12 18 24 30 36 42 48

Kllometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000

{Miles)

(600) (6,000) f[t2,000) (18,000) (24,000) (3U,OOO) (36,000) (42,000) {48,000), Engine

Intake and exhaust manrfold nuts (Bolts)

Drive belts”

i Engine trmlng beltW3

Engine oil (Turbo)‘4

01 filter

l *

Cool!ng system (Includtng

coolant level adlustment)

Engrne coolant T T T

A A A

A A

Replace every 100,000 km (60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R R R R 1 R R R

I I I I

I

Replace every 2 years Fuel system

Idle speed

Air cleaner element * 5

Fuel

falter

Fuel Ilnes and hoses Ignition system

A f 1

I R I R

R R

I I f t I ~

lnlttal rgnrtloh trmlng 1 I I I I I I I I

Spark plugs A

A. A A

Spark plugs (Only for Sweden) Adjust every 30.000 km (t8.000 mrls) Evaporative emission control system

Throttle sensor Throttle sensor (Only for Sweden)

Evaporative system

Evaporatrve system (Only for Sweden) 1 A 1 1 A 1 1 A 1 ) A

Adjust every 80,000 km (48,000 miles)

1 I 1 1 I’ 1 1 I 1 1 I

Inspect every 80,000 km (48,000 mites) Electrical system

Battery electrolyte level and specific gravity 1 I f I I I

All Electrical system

l ’ 1 I

I 1 I I I

1 . 1 I I

Headlight alrgnment 1 A A A . A. Chassis and body

t 3EOAX-303

A-4 Chas

SW31 Rear

Tires

Hing

Seat

Page 52 of 279

F3 TROUBLESHUOTING GUIDE

TROU8LESHOOTlNG GUIDE

RELATIONSHIP CHART

.

OUTPUT DEVICE

INPUT DEVICE

w

3

s

s

KNOCK SENSOR

0

0 0 0 DtAGNOStS CONNECTOR

(TEN TERMINAL)

0 0 0 IGNITION SWlTCH

(START POSITION) 0 0

0

0

0 0

0 0

0 0

0

0

0

0

0 0 0 0

E/L SIGNAL* 0

P/S PRESSURE SWITCH 0

0

A/C SWtTCH

NEUTRAL AND CLUTCH

SWITCHES

STOPLIGHT SWITCH

ATMOSPHERIC PRESSURE

SENSOR (IN ECU)

THROTTLE SENSOR

0 0 0 0

0

0

0 0’

0

0 0

0

0 0

0

’ 0

0

0 0 0 0 0 0 0

0 I

0 ~ INTAKE AIR THERMOSENSOR 0 0 0 0

0 -~

OXYGEN SENSOR

0 0 0 0 WATER THERMOSENSOR

A

0

* 0 0 0 c 0

13

3F3-32 IN, o . E/L SIGNAL: Blower fan control switch second position or higher, electric cooling fan operating, headlights

rear window defroster ON.

F3-19

i

Page 81 of 279

F3 CONTROL SYSTEM

Ve: Battery voltage

Termina

1N ’

10

1P

IQ

IR

IS

1T

tlJ

IV Jnput Outpul

0

0

0

0

0

0

0

0

0 Connected to

Throttle sensor

(idle switch) Test condition

Correct voltage Remark

Accelerator pedal released

Below 1.0V

lgnltlon switch

Accelerator pedal depressed

VI3 ON

Foglrght relay

P/S pressure

switch Fogtight switch ON

Fogfight switch OFF

Ignition switch ON

P/S pressure switch ON at Idle

PIS pressure switch OFF at idle Va

ov

V3

Below 1 .OV

VB -

-

A/C switch A/C switch ON

A/C switch OFF Below 23 Ignition switch

Va ’ ON and blower

motor ON

1 f Ekctrtc cooltng fan Fan operating (coolant temperature over

Below 1 .OV

switch

97OC 1207OF 1 or diagnosis connector

terminal TFA grounded) -

Fan not operating (Idle)

VI3

Blower control Blower control switch OFF or 1st position

.Va

swbtch Ignitton switch

Blower control switch 2nd or hjgher po-

Below 1 .OV ON

sition

Rear window

defroster switch Rear window defroster OFF

Rear window defroster ON Below 1 .OV Ignition switch

V0 ON

Headlight switch

Headfights ON Va

Headlights OFF -

Below 1.OV

Neutral/Clutch

Neutral position or clutch pedal

9eJow I .OV

switches

depressed

Others

Va

7

r u-.

I-I-I

f

2y 2w 2u 2s 20 20 2M 2K 21 2G 2E 2C 2A 1U 1s 10 10 1M 1K 11 rG IE tC ;A

22 2% 2V 2T 2R 2P ZN 2L 25 2H 2F 2D 28 tV 1T ‘IR IF 1N It ;J. IH IF ID 18

i

A

F3-48

-- Alwa@

Always

Always

Always

--

Always

--

Always

--

Always

--

Always

--

Always

(electric

--

Alway<;

--

Always

-e

Afway?;

I .ov

Always

--

Always

--

Alway:;

--

Page 82 of 279

-. _.. . . . . . _ - ._.

-w

CONTROL SYSTEM F3

I .

-.

Ve: Battery voltaae I

Incorrect voltage

Atwafi below 1 .OV

Always VB

Always VS (foglight switch OK)

Always below 1 .OV

Always below 1 .OV

Always Vs

Always

below 23 (blower fan OK)

Always VB (blower fan OK)

Always below 1 .OV

(electric cooling fan OK) -

1-

Possible cause

l Throttle sensor mrsadjustment l Short circuit in wtrrng from throttle sensor to ECU terminal 1 N l ECU malfunction

l Throttle sensor mrsadjustment l Open circuit in wiring from throttle sensor to ECU terminal fN l Open circuit in mnng from throttle sensor to ECU terminal 20

l Foglight relay malfunctron

l Foglrght relay malfunction

l P/S pressure switch maltunctron l Short crrcurt In wrrlng from P/S pressure switch to ECU terminal 1 P l ECU malfunction

l P/S pressure switch malfunction l Open circuit in wlnng from P/S pressure switch to ECU terminal 7 P l Open circuit in wiring from P/S pressure switch to ground

l A/C switch malfunctron l Short circuit tn wiring from A/C switch to ECU terminal 1Q l Poor connection at ECU connector l ECU malfunction

l #C swatch malfunction l Open circuit in wiring from A/C switch to ECU terminal 1Q l Open circuit in wiring from A/C switch to blower control switch

l Open or short circuit in wiring from fan relay to ECU terminal 1R l ECU matfunction

Always below 1 .OV (blower fan OK}

Always Vs (btower fan OK)

Always betow illumination lamp

1 .ov ON when rear

window defroster

switch ON

Illumination lamp

never ON

Atways below 1 .OV (headttghts OK)

l Short circuit in wrrtng from blower control switch to ECU terminal IS l Poor connection at ECU connector l ECU m&function

l Open crrcuit in wrrrng from blower control switch to ECU terminal 1s

l Open or short crrcuit In wiring from rear window defroster switch to ECU

terminal t T

l Open circuit in wiring from ignitron switch to rear window defroster switch l Rear window defroster switch malfunction

l Open or short circuit in wiring from headlight relay to ECU terminal 1 U

Always below 1 .OV

l Neutral switch malfunction l Clutch switch malfunction l Short circuit in wiring from ECU terminal IV to neutral or clutch switch

Always VB

l Neutral switch malfunction l Clutch switch malfunction l Open circuit in wiring from ECU terminal 1V to neutral or clutch swdch l Poor connection at ECU connector

13FOl=3-36 .

F3-49

.:i

Page 139 of 279

UUTLINE

RADfATOR GRfLtE

l The air inlet area of the radiator grille is enlarged for improved cooling efficiency.

FRONT BUMPER

l The large front bu,mper includes fog lights and bumper mesh to give the vehicle a dynamic appearance.

l tight and rigid polyurethane is used for the bumper fascia.

l The air inlet area is adopted for improved cooling efficiency.

s-4

REAR SKI

l The rear 5

l Light and

WHEEL AR4

l Wheel arc

Page 140 of 279

OUTLINE S

REAR SKIRT

13EOSX-308 l The rear skirt is added for improved vehicle aerodynamics.

l Light and rigid polyurethane is used.

WHEEL ARCH MOLDING

13EOSX-30E a Wheel arch moldings are fitted to the front and rear fenders to give the vehicle an aggressive look.