light MAZDA 323 1992 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 143 of 279

S

FRONT BUMPER FRONT BUMPER

COMPONENTS

Rem’ovat ! Installation

1. Removal in the order shown

2. Install in the reverse order of

1 in the figure.

removal.

-9-9.8 Nm 170-100 kgfem,

U-87 h.lbfJ

f4-m Ikgf-m, ft-lbf J

13EOSX-312

4. Front bumper

Disassembly / Assembly

. . . . . . . . . ..m... page S-9 1. Radiator grille

2. Front conbination light

3. Headlight

5-8

Disassembh

I . Disassemi

2. Assemble

t

1. Fog lights

-

a

-I. 2. Bumper rear

3. Bumper me

Page 144 of 279

FRONT BUMPER S

Disassembly / Assembly

I. Disassemble in the order shown in the figure.

2. Assemble in the reverse order of disassembly.

i

1, Fog lights

2. Bumper reinforcement

3. Bumper mesh 4. Hook cover

5. Bumper fascia

Page 148 of 279

WHEEL ARCH MOLDING

Installation

Note

S

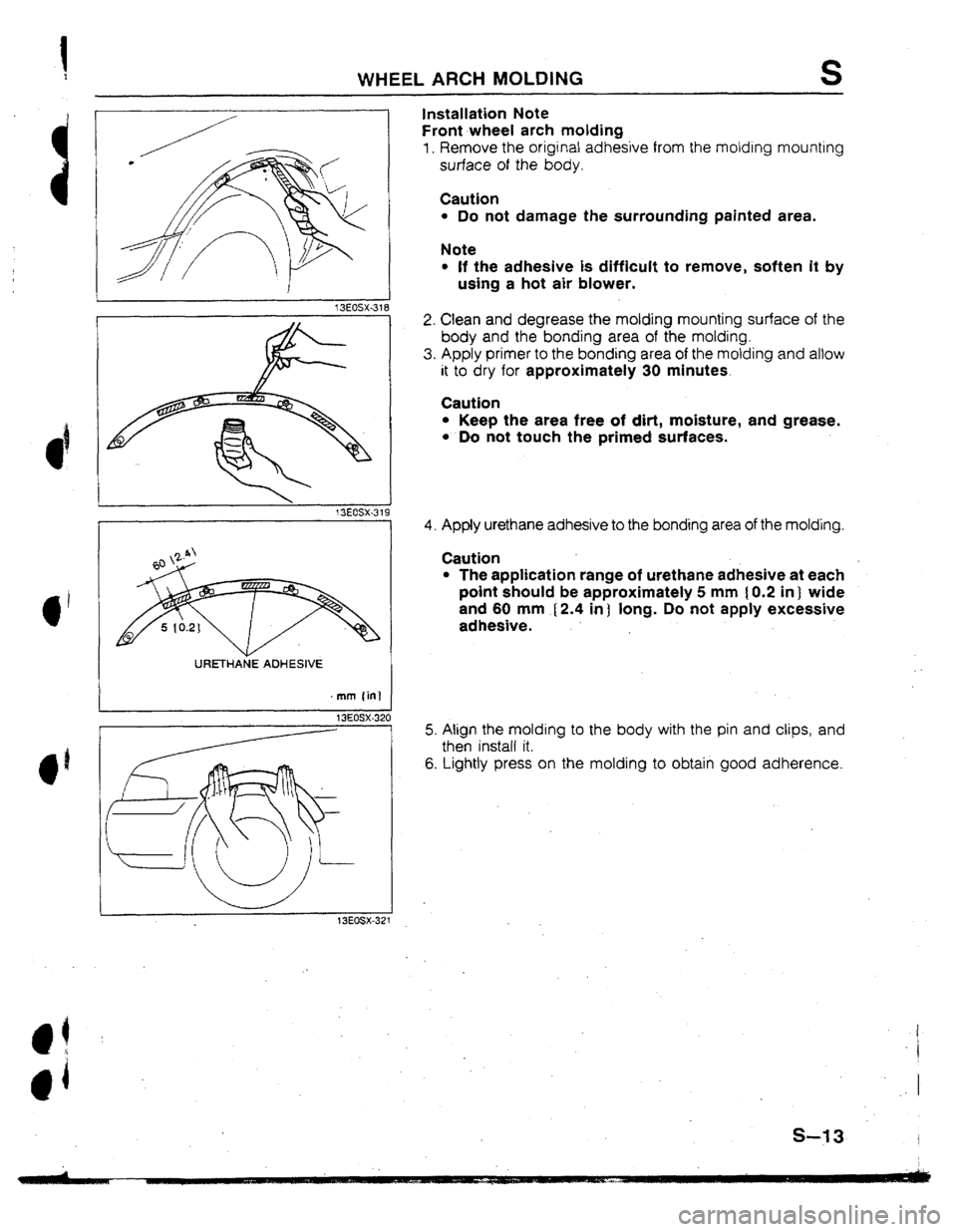

Front wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

Caution

l Do not damage the surrounding painted area.

Note

l If the adhesive is difficult to remove, soften it by

using a hot air blower.

I URETHAtiE ADHESIVE

I

13EOSX-320

13EOSX-321

2. Clean and degrease the molding mounting surface of the

body and the bonding area of the molding.

3. Apply primer to the bonding area of the molding and allow

it to dry for approximately 30 minutes.

Caution

l Keep the area free of dirt, moisture, and grease.

l Do not touch the primed surfaces.

4. Apply urethane adhesive to the bonding area of the molding.

Caution

l The application range of urethane adhesive at each

point should be approximately 5 mm [ 0.2 in 1 wide

and 60 mm [ 2.4 in 1 long. Do not apply excessive

adhesive.

5. Align the molding to the body with the pin and clips, and

then install it.

6. Lightly press on the molding to obtain good adherence.

1

i

1

S-f 3 I

Page 149 of 279

![MAZDA 323 1992 Suplement User Guide S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C MAZDA 323 1992 Suplement User Guide S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

C](/img/28/57055/w960_57055-148.png)

S WHEEL ARCH MOLDING

13EOSX-323

r

ADHESIVE TAPE

mm fin]

f 3EOSX-324

13EOSX.325

s-14.

Rear wheel arch molding

1. Remove the original adhesive from the molding mounting

surface of the body.

Caution

l Do not damage the surrounding painted area.

Note

l tf the adhesive is difficult to remove, soften it by

using a hot air blower.

2. Clean and degrease the molding mounting surface of the

body and the bonding area of the molding.

3. Apply primer to the bonding area of the molding and allow

it to dry for approximately 30 minutes.

Caution

l Keep the area free of dirt, moisture, and grease.

l Do not touch the primed surfaces.

4. Apply strips of double-coated adhesive tape to the bond-

ing area of the molding.

Note

l Use 40 mm I-1.6 in) lengths of tape.

5. Apply urethane adhesive to the bonding area of the molding.

Caution

l The application range of urethane adhesive should

be approximately 5 mm f 0.2 iii ) wide and 60 mm

(2.4 in) long. Do not apply excessive adhesive.

6. Peel the protection paper from the double-coated adhesive

tape.

7. Align the molding to the body with the pin, and then install it,

8. Lightly press on the molding to obtain good adherence.

9. tnstall the fasteners.

Page 150 of 279

T

BODY ELECTRICAL SYSTEM

INDEX .*,........,..............*....*...*.........*....*.*.

T- 2

jFEATURESl

OUTLINE . . . . . . ..*.....*..*...~.=.........*.*........*~...~

T- 3

FEATURES .e . . . . . *..* . . . . . . * . . . . . . * . . . . . . . *..I . . . . . . . . .

T- 3

LIGHTING SYSTEM .,....*.*..m...*..,...,a*..*.*..,..

T- 3

SPECIFICATDNS .I..*.*...*....*....*.............,.

T- 3

SUPPLEMENTAL SERVICE

INFORMATlON I . . . . . . . . . . . . . . . . . *.*.a=..* . . . . . . . *..*.s

T- ,4

EXTERlOR LlGHTlNG SYSTEM . . . . .

l . . ..e.am..a.. T-

4

FRONT FOG LIGHT

. . . . . . n .* . . . . . l ...* . . . . . s* .,..I..

T- 4

f3EOTX-301

H .

Page 151 of 279

T INDEX

NDEX

1 SEOTX-302

1. Front fog light

Removal I lnstallatron . . . . .._. . . . . . . _._. page T-4

OUTLINE

FEATURES

/Toimprov

jToimprov

t

SPECiFICi

1 Front fOQ II!

T-i

Page 152 of 279

OUTLINE, IXHTING SYSTEM

.’ I

Ad T

FEATURES

t3EOTX-303

0. 4.

LlGHTlNG SYSTEM

FRONT -FOG LlGHT

t

SPEClF1CATIONS

@ 4 1

: Item Wattage (w)

Front fog light 55x2 l!.‘i

1

T-3.

Page 153 of 279

T ~WPe~MENTAL SERVICE INFORMATION, EXTERIOR LIGHTING SYSTEM

SUPPLEMENTAL SERVICE INFORMATION

The following points shown in this section are changed in comparison with 323 Workshop manual supple-

menP(1229-1 O-89t) and 323 Workshop manual supplement (1275-l O-91 C>.

Front fog light

l Removal I Installation

13EOTX-305

EXTERIOR LIGHTING SYSTEM

FRONT FOG LIGHT

Removat / tnstaitation

I. Remove in the order shown in the figure.

2. Install in the reverse order of removal.

I. Radiator grille

2. Front combination light

3. Headlight 4. Front bumper

5. Front fog light

T-4

Page 166 of 279

![MAZDA 323 1992 Suplement User Guide SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k MAZDA 323 1992 Suplement User Guide SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ k](/img/28/57055/w960_57055-165.png)

SUSPENSION i

TECHNICAL DATA TD

I

Item

Specifications

Front suspension

Suspension type

strut

Sprrng type

Coil spring

Type Oil 1

Shock absorber

Damping force Extended

1,470 1150, 3N]

N [ kgf, Ibf ] at 0.3 mls

Compressed 1

686 (70, 154)

Stabilizer Type Torsion bar

Oiameter mm {in]

23.0 (0.91 )

Total toe-in mm (in>

2 f 3 (0.08 f 0.12)

degree

0*12’ f 18’

Front wheel Turning angle Inner

38* f 3*

alignment

degree Outer

300 f 30

(* Unladen)

Camber angle degree

-u045’ f 45’

Caster angle degree

2035 f 45’

Kingpin angle

degree 12010’

Rear suspension

Suspension type

I Strut

Spring type

Coil spring

Type Oil

Shock absorber

Damping force Extended

882 (90. 1981

N I kgf, Ibf t at 0.3 mis Compressed

392 140, 88 1

Stabilizer , Type Torsion bar

Diameter mm [in] ?9.? { 0.75 1

Rear wheel

Totat toe-in mm {ini

2 f 3 (0.08 f 0.12)

alignment degree

0°t2’ f 18’

(‘Unladen)

Camber angle degree

-0020’ f 45’

l Fuel tank Ml; radiator coolant and engrne oil at speciffed levels; and spare tire, jack, and tools in designated poations.

Coil Spring Specifications

Item Wire diameter Coil center diameter Free length Coil identification mark coler

mm [in] mm (in) mm (in] number

M” Ae2

Front With sunroof 14.5

IO.57 1 l32.5-158.5 15.22-6.24 ) 271.5 1 IO.69 ] 3.35 Pink

Green

.

WIthout sunroof 14.4 IO.561 1 132.6-158.6 (5.22-6.241 267.0 I IO.51 ] 3.24 Light blue Red

With sunroof 8.8-l 2.5

[ 1 0.34-0.49 128.5-131.2 15.0~5.17) 334 { 13.151 6.19 Cream -

Rear .

I 1 Without sunroof I ff;;y;4”81 I t28.6-13t.j [5.06--5.16) / 335 113.19) 1 6.23 1 Pink 1 - I

l I Main rdentrficatlon mark color: Indicated on second coil from bottom.’ l 2 Auxiliary identification mark color: Indicated on third coil from buttom.

TD-13

Page 167 of 279

TD TECHNlCAt DATA -

BODY EtECTRtCAL SYSTEM

ttem

Headlight

Front fog light

Front turn signat light

Parking light

Front side turn light

StocYlailliaht Specifications (w)

ECE

I Swiss

60155

55

21

5

5

2115

Exterior tamps

Taillight &8) 5

Rear turn single tight 21

Back-up light

21

License plate light

5

Flash-to-pass light 55 (Austrra)

I -

Running Ilght

55 (Sweden, Norway, Iceland)

Rear fog light 21

Interior and spot lamp Interior 10

Spot 6

Interior Iamps

Interior lamp 10

Spot tamp (in overhead console) 8

Cargo compartment lamp

5

High beam

3.4

Turn light

3.4

Brake 3

Hold 3

Charge 3

011 pressure 3 -.

lndcator and n Washer 3

warning Iamps TUF~O 3

Fuel

1 3

Rear fog

I

! 3

1

ABS

Parktng brake

Illumination I 3

3 .

3.4

Rear

Cliff. lock f 3

3 I STANDARD BOLT AND NUT TIGHTENING TORQUE

! Diameter Pkh I 41

8T f&lb N-m I 81 mm {tn] mm fin] N-m 1 m-kg

dsf Wtb 1 Nm

mkg ft4b 6 IO.2361 1 {0.039] 4.2-6.2 /0.43-O-63 3.1-4.6

6.9-9.8 0.7-1.0 5.0-7.2 7.8-11.8 O-8-1.2 5.8-8.8

8 IO.3151 1.25 (0.049) 9.8-14.7 1 1.0-1.5 7.2-10.8 16-23 1 1.6-2.3 12-17 18-26 1.8-2.7 13-20

10 IO.3941

It.25 10.04911 20-28 1 2.0-2.9 1 14-21 31-46 1 3.2-4.7

23-34 36-54 3.7-5.5 27-40

I r

12 IO.4721

1.5 lO.OSSj 34-50 3.5-5-l 25-37 1 55-80

5.6-8.2 41-59 63-93 6.4-9.5 46-69

14 {0.551] 1.5 IO.059) - - - 75-103 7.7-10.5 56-76 102-137 lo-14 75-101

16 #0.630] 1.5 {O.OSSl - -

- f16-157 12-16 85-116 156-211 16-22 115-156

t8 (0.709) 1.5 [0.059] - - - 167-225 17-23

123-166 221-299 23-31 163-221

20 IO.7871 I,5 {0.059]

- - - 231-314 24-32 171-231 308-417 31-43

227-307

22 (0.866) 1.5 IO.0591

- 1 - - 334-423 32-43 231-312 417-564 43-58

' 307-416

24 10.945) 1.5 10.059) - 1

- - 1475-5461 41-56 298-403 1536-7261 55-74

396-536

c)

c) I

-.

c’

c .

4