fuel MAZDA 6 2002 Suplement Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 197 of 909

FUEL SYSTEM

F2–45

F2

BEFORE REPAIR PROCEDUREA6E401201006203

Warning

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leads are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the following “Fuel

Line Safety Procedures”.

Fuel Line Safety Procedures

Note

•Fuel in the fuel system is under high pressure when the engine is not running.

1. Avoid fuel line spills and leaks by completing the following procedures.

(1) Remove the fuel-filler cap and release the pressure in the fuel tank.

(2) When disconnecting a fuel line hose, wrap a rag around it to protect against fuel leakage.

(3) Plug the hose after removal.

End Of Sie

AFTER REPAIR PROCEDUREA6E401201006204

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. When installing the fuel hose, observe “Fuel Hose Installation” described below.

Fuel Line Air Bleeding

Caution

•Continuously cranking the engine for over 30 s can damage the battery and the starter.

1. Continue cranking the engine for 30 s and stop for 5—10 s until the engine starts.

Fuel Hose Installation

1. Verify that there is no damage or deformation on the fuel hose and fuel pipe when installing.

End Of Sie

FUEL TANK REMOVAL/INSTALLATIONA6E401242110201

Warning

•Repairing a fuel tank that has not been properly steam cleaned can be dangerous. Explosion or

fire may cause death or serious injury. Always properly steam clean a fuel tank before repairing it.

•Fuel line spills and leakage are dangerous. Fuel can also irritate skin and eyes. To prevent this, do

not damage the sealing surface of the fuel gauge sender unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

FUEL SYSTEM

Page 198 of 909

F2–46

FUEL SYSTEM

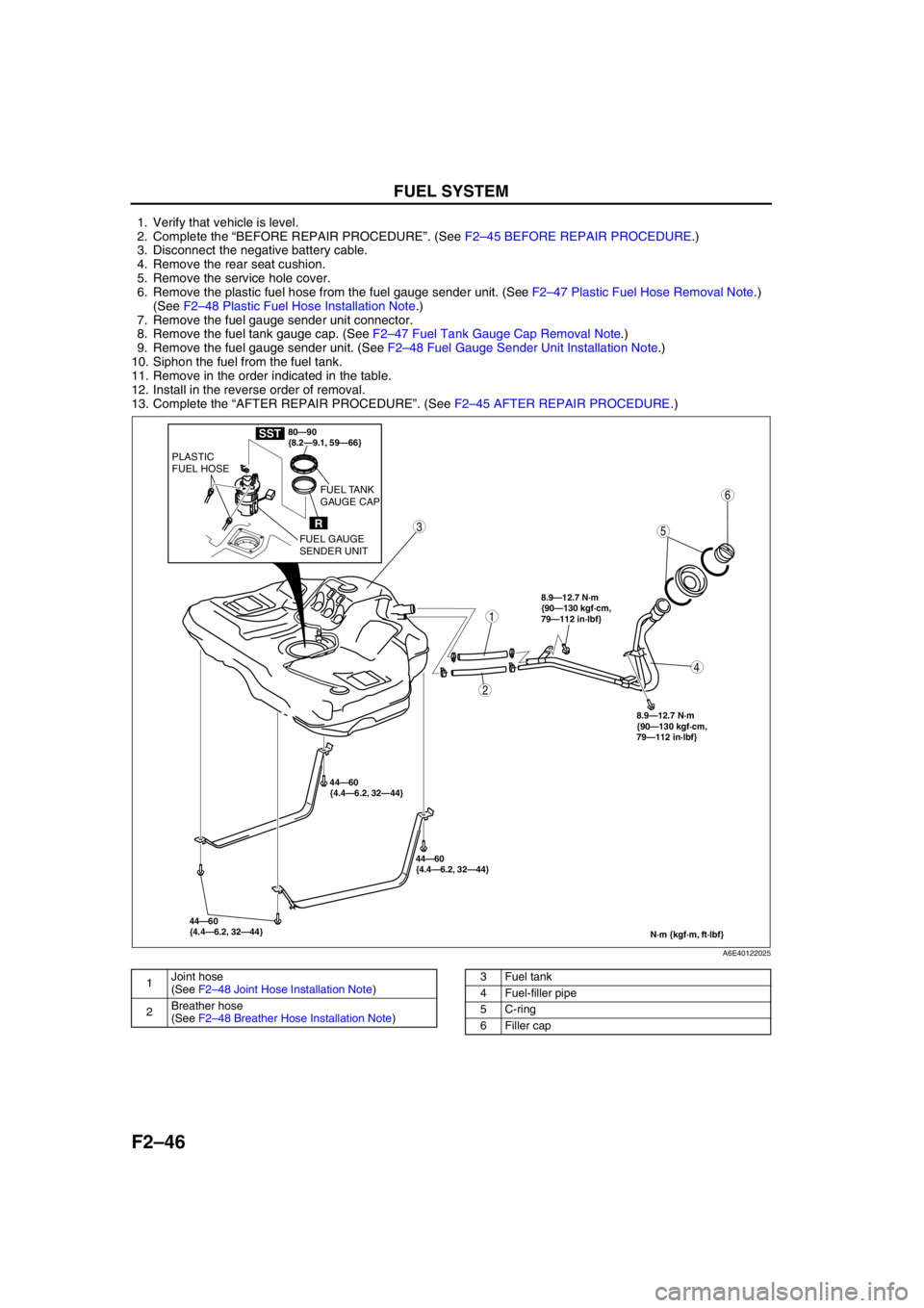

1. Verify that vehicle is level.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Disconnect the negative battery cable.

4. Remove the rear seat cushion.

5. Remove the service hole cover.

6. Remove the plastic fuel hose from the fuel gauge sender unit. (See F2–47 Plastic Fuel Hose Removal Note.)

(See F2–48 Plastic Fuel Hose Installation Note.)

7. Remove the fuel gauge sender unit connector.

8. Remove the fuel tank gauge cap. (See F2–47 Fuel Tank Gauge Cap Removal Note.)

9. Remove the fuel gauge sender unit. (See F2–48 Fuel Gauge Sender Unit Installation Note.)

10. Siphon the fuel from the fuel tank.

11. Remove in the order indicated in the table.

12. Install in the reverse order of removal.

13. Complete the “AFTER REPAIR PROCEDURE”. (See F2–45 AFTER REPAIR PROCEDURE.)

.

44—60

{4.4—6.2, 32—44}44—60

{4.4—6.2, 32—44} 44—60

{4.4—6.2, 32—44}

N·m {kgf·m, ft·lbf}

8.9—12.7 N·m

{90—130 kgf·cm,

79—112 in·lbf}

8.9—12.7 N·m

{90—130 kgf·cm,

79—112 in·lbf}

5

4

3

2

1

6

80—90

{8.2—9.1, 59—66}

R

PLASTIC

FUEL HOSE

FUEL GAUGE

SENDER UNITFUEL TANK

GAUGE CAP

SST

A6E40122025

1Joint hose

(See F2–48 Joint Hose Installation Note)

2Breather hose

(See F2–48 Breather Hose Installation Note)3 Fuel tank

4 Fuel-filler pipe

5 C-ring

6 Filler cap

Page 199 of 909

FUEL SYSTEM

F2–47

F2

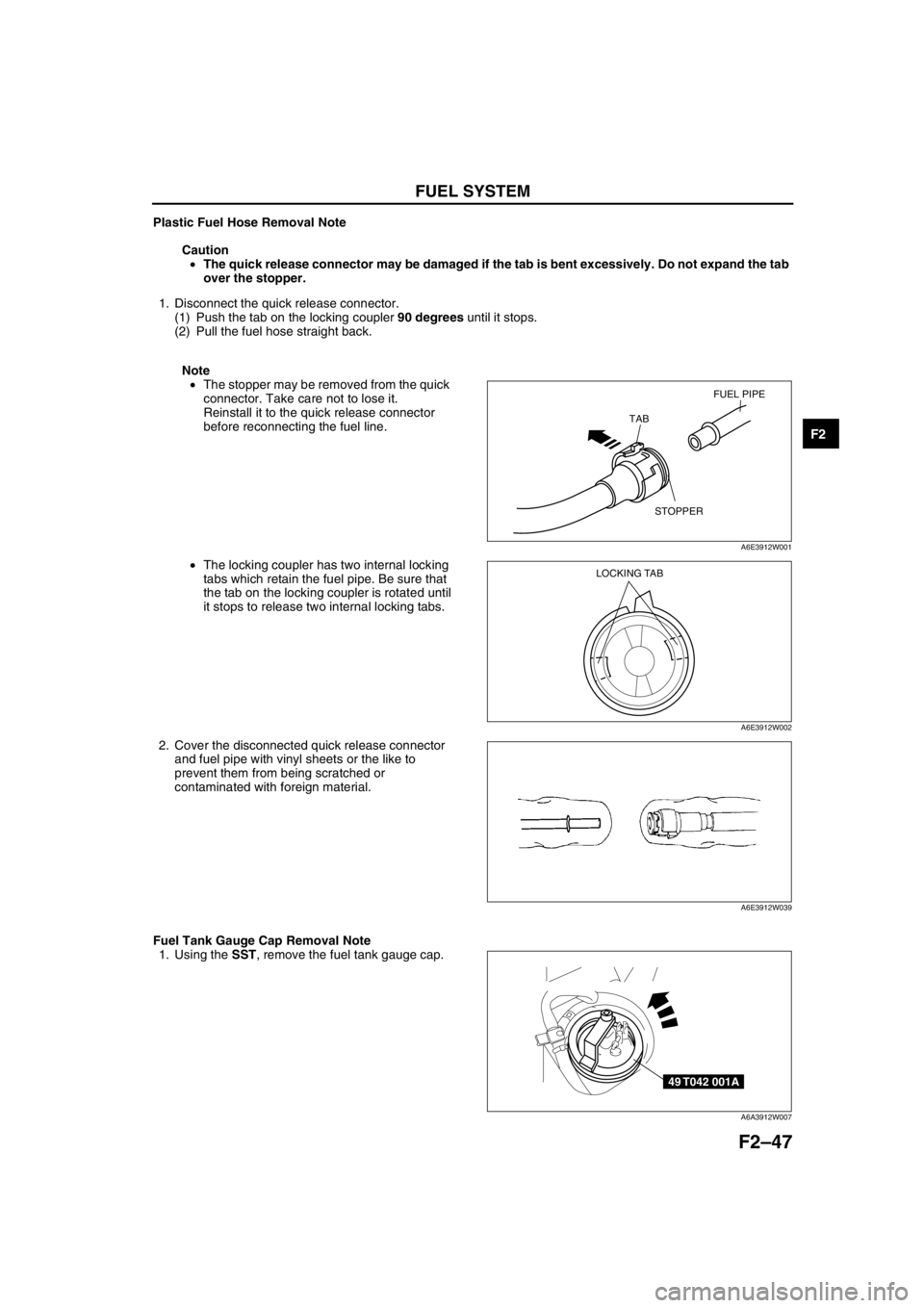

Plastic Fuel Hose Removal Note

Caution

•The quick release connector may be damaged if the tab is bent excessively. Do not expand the tab

over the stopper.

1. Disconnect the quick release connector.

(1) Push the tab on the locking coupler 90 degrees until it stops.

(2) Pull the fuel hose straight back.

Note

•The stopper may be removed from the quick

connector. Take care not to lose it.

Reinstall it to the quick release connector

before reconnecting the fuel line.

•The locking coupler has two internal locking

tabs which retain the fuel pipe. Be sure that

the tab on the locking coupler is rotated until

it stops to release two internal locking tabs.

2. Cover the disconnected quick release connector

and fuel pipe with vinyl sheets or the like to

prevent them from being scratched or

contaminated with foreign material.

Fuel Tank Gauge Cap Removal Note

1. Using the SST, remove the fuel tank gauge cap.

FUEL PIPE

STOPPER TAB

A6E3912W001

LOCKING TAB

A6E3912W002

A6E3912W039

49 T042 001A

A6A3912W007

Page 200 of 909

F2–48

FUEL SYSTEM

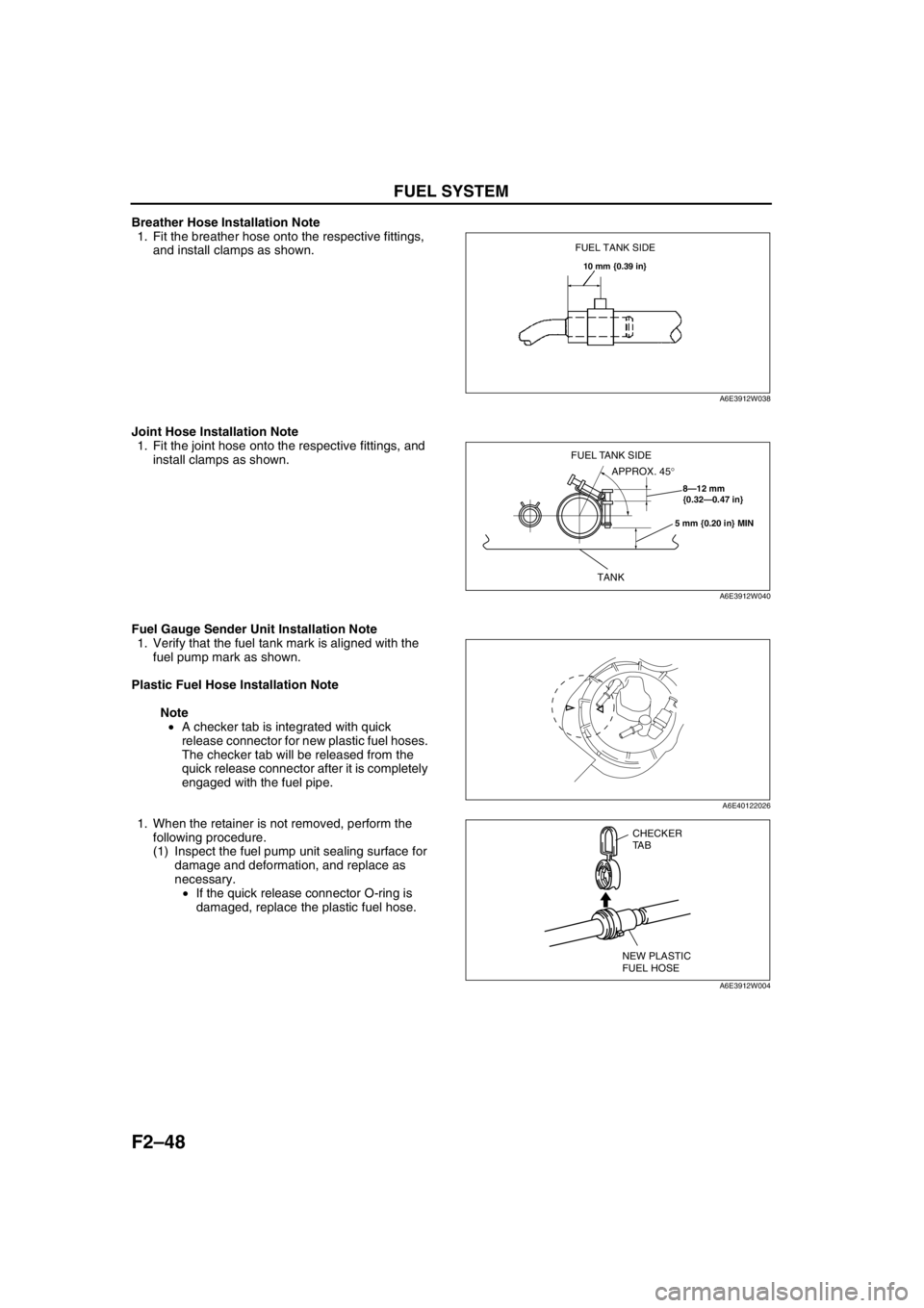

Breather Hose Installation Note

1. Fit the breather hose onto the respective fittings,

and install clamps as shown.

Joint Hose Installation Note

1. Fit the joint hose onto the respective fittings, and

install clamps as shown.

Fuel Gauge Sender Unit Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel pump mark as shown.

Plastic Fuel Hose Installation Note

Note

•A checker tab is integrated with quick

release connector for new plastic fuel hoses.

The checker tab will be released from the

quick release connector after it is completely

engaged with the fuel pipe.

1. When the retainer is not removed, perform the

following procedure.

(1) Inspect the fuel pump unit sealing surface for

damage and deformation, and replace as

necessary.

•If the quick release connector O-ring is

damaged, replace the plastic fuel hose.

FUEL TANK SIDE

10 mm {0.39 in}

A6E3912W038

8—12 mm

{0.32—0.47 in}

5 mm {0.20 in} MIN

TANK

APPROX. 45° FUEL TANK SIDE

A6E3912W040

A6E40122026

CHECKER

TA B

NEW PLASTIC

FUEL HOSE

A6E3912W004

Page 201 of 909

FUEL SYSTEM

F2–49

F2

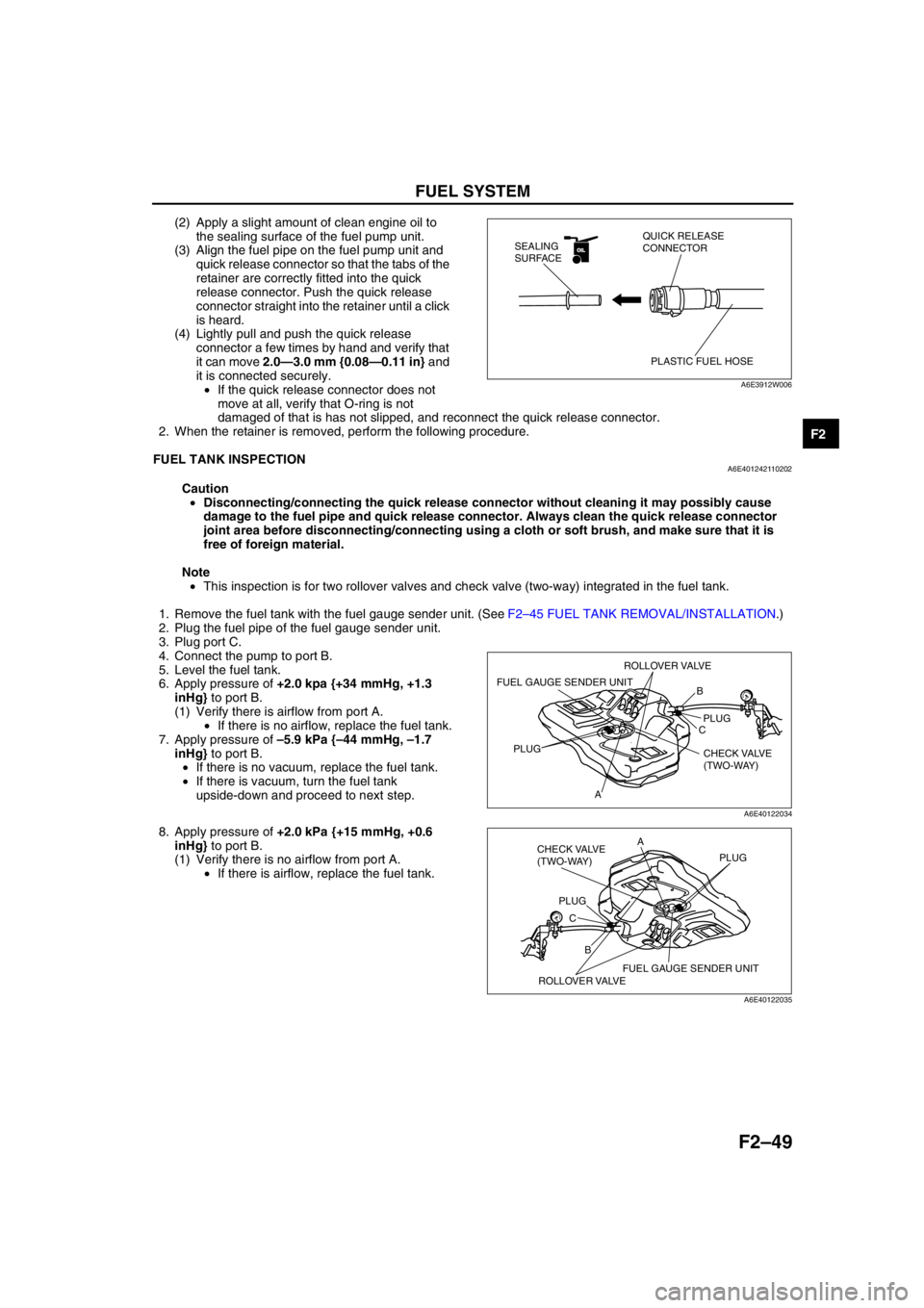

(2) Apply a slight amount of clean engine oil to

the sealing surface of the fuel pump unit.

(3) Align the fuel pipe on the fuel pump unit and

quick release connector so that the tabs of the

retainer are correctly fitted into the quick

release connector. Push the quick release

connector straight into the retainer until a click

is heard.

(4) Lightly pull and push the quick release

connector a few times by hand and verify that

it can move 2.0—3.0 mm {0.08—0.11 in} and

it is connected securely.

•If the quick release connector does not

move at all, verify that O-ring is not

damaged of that is has not slipped, and reconnect the quick release connector.

2. When the retainer is removed, perform the following procedure.

End Of Sie

FUEL TANK INSPECTIONA6E401242110202

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

Note

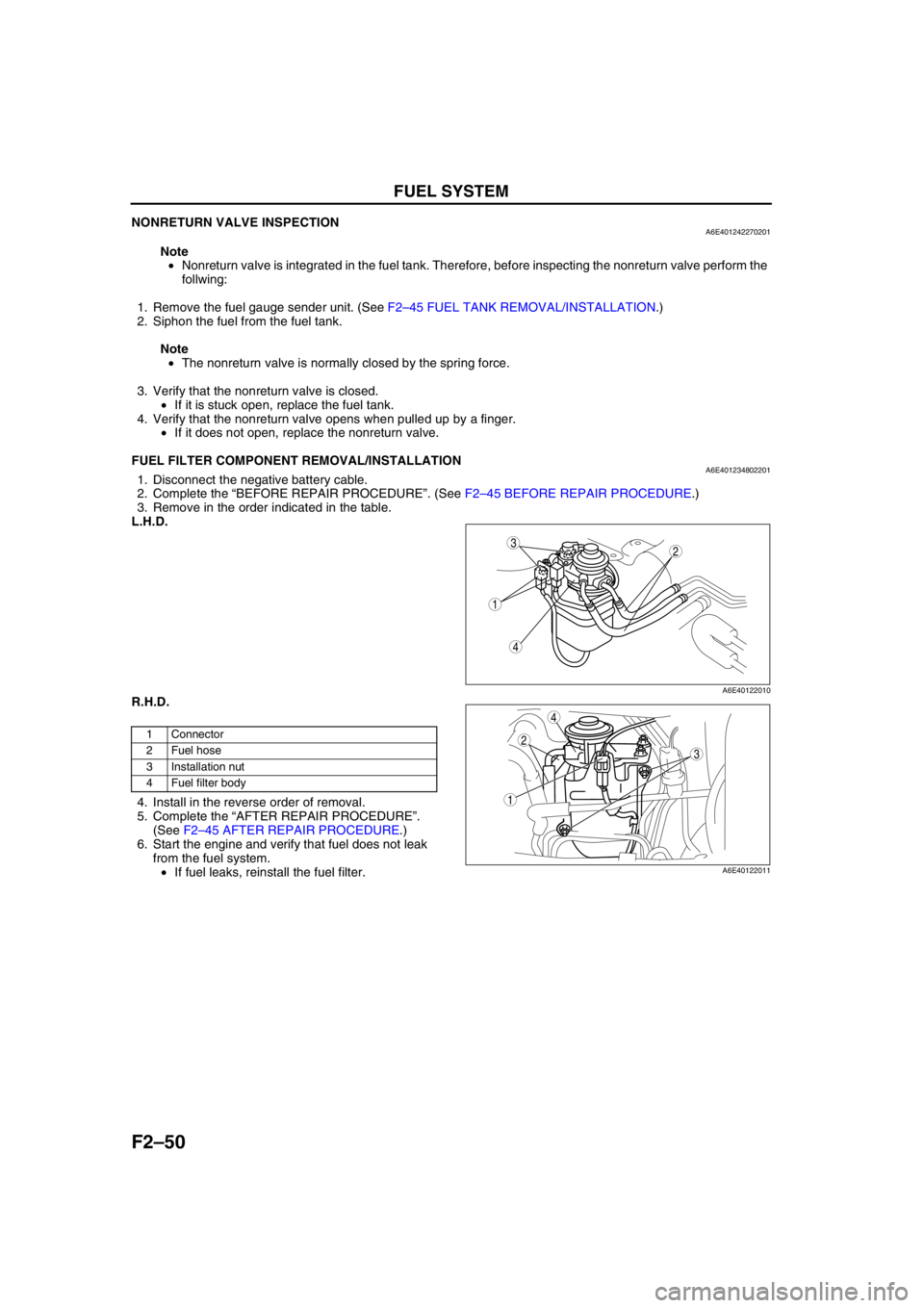

•This inspection is for two rollover valves and check valve (two-way) integrated in the fuel tank.

1. Remove the fuel tank with the fuel gauge sender unit. (See F2–45 FUEL TANK REMOVAL/INSTALLATION.)

2. Plug the fuel pipe of the fuel gauge sender unit.

3. Plug port C.

4. Connect the pump to port B.

5. Level the fuel tank.

6. Apply pressure of +2.0 kpa {+34 mmHg, +1.3

inHg} to port B.

(1) Verify there is airflow from port A.

•If there is no airflow, replace the fuel tank.

7. Apply pressure of –5.9 kPa {–44 mmHg, –1.7

inHg} to port B.

•If there is no vacuum, replace the fuel tank.

•If there is vacuum, turn the fuel tank

upside-down and proceed to next step.

8. Apply pressure of +2.0 kPa {+15 mmHg, +0.6

inHg} to port B.

(1) Verify there is no airflow from port A.

•If there is airflow, replace the fuel tank.

End Of Sie

OILOIL

PLASTIC FUEL HOSE QUICK RELEASE

CONNECTOR SEALING

SURFACE

A6E3912W006

B

C

APLUG

PLUG

CHECK VALVE

(TWO-WAY)

FUEL GAUGE SENDER UNIT

ROLLOVER VALVE

A6E40122034

B CA

PLUGPLUG

CHECK VALVE

(TWO-WAY)

FUEL GAUGE SENDER UNIT

ROLLOVER VALVE

A6E40122035

Page 202 of 909

F2–50

FUEL SYSTEM

NONRETURN VALVE INSPECTIONA6E401242270201

Note

•Nonreturn valve is integrated in the fuel tank. Therefore, before inspecting the nonreturn valve perform the

follwing:

1. Remove the fuel gauge sender unit. (See F2–45 FUEL TANK REMOVAL/INSTALLATION.)

2. Siphon the fuel from the fuel tank.

Note

•The nonreturn valve is normally closed by the spring force.

3. Verify that the nonreturn valve is closed.

•If it is stuck open, replace the fuel tank.

4. Verify that the nonreturn valve opens when pulled up by a finger.

•If it does not open, replace the nonreturn valve.

End Of Sie

FUEL FILTER COMPONENT REMOVAL/INSTALLATIONA6E4012348022011. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Remove in the order indicated in the table.

L.H.D.

R.H.D.

.

4. Install in the reverse order of removal.

5. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

6. Start the engine and verify that fuel does not leak

from the fuel system.

•If fuel leaks, reinstall the fuel filter.

End Of Sie

1

4

23

A6E40122010

1 Connector

2Fuel hose

3 Installation nut

4 Fuel filter body

4

1

2

3

A6E40122011

Page 203 of 909

FUEL SYSTEM

F2–51

F2

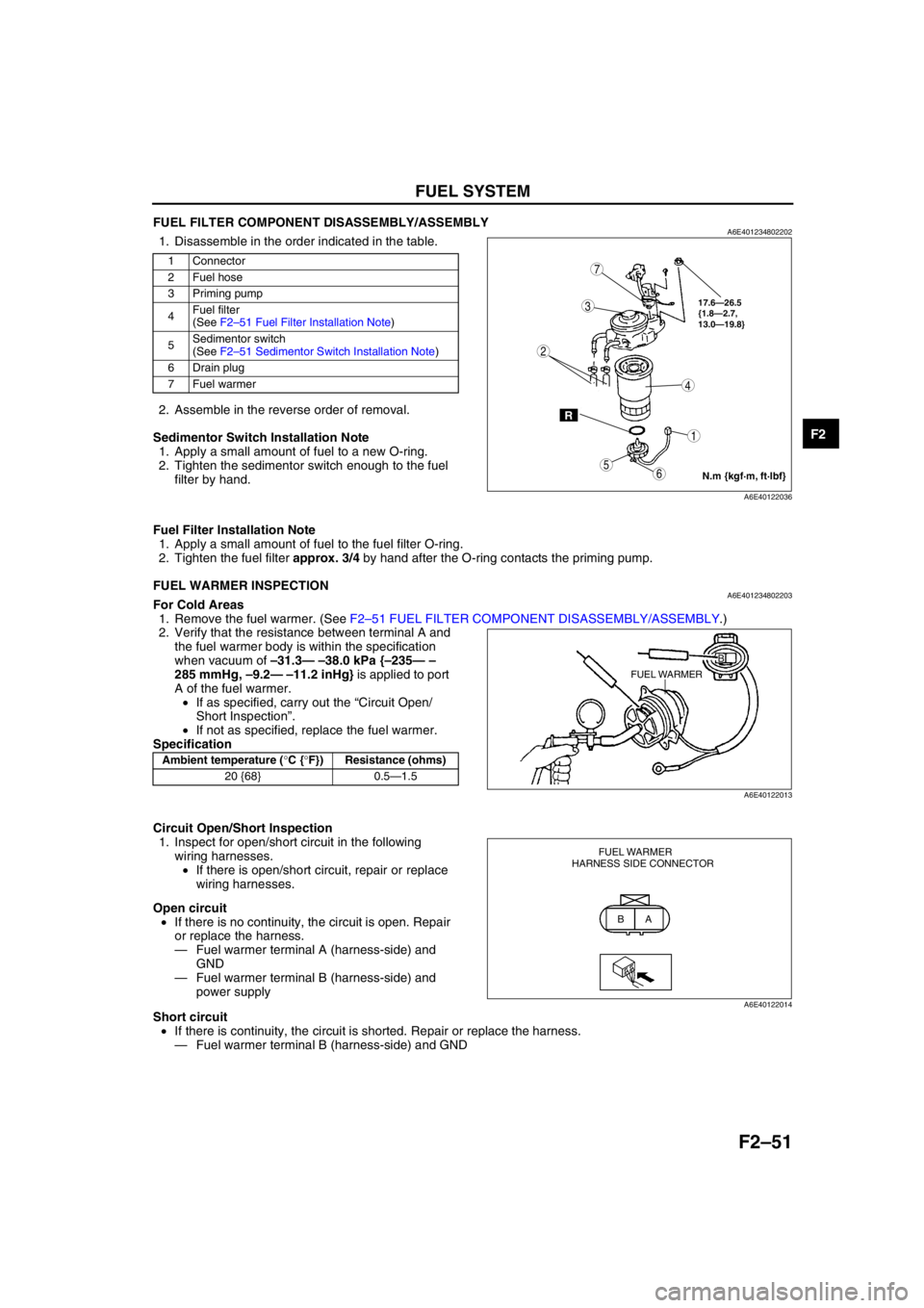

FUEL FILTER COMPONENT DISASSEMBLY/ASSEMBLYA6E4012348022021. Disassemble in the order indicated in the table..

2. Assemble in the reverse order of removal.

Sedimentor Switch Installation Note

1. Apply a small amount of fuel to a new O-ring.

2. Tighten the sedimentor switch enough to the fuel

filter by hand.

Fuel Filter Installation Note

1. Apply a small amount of fuel to the fuel filter O-ring.

2. Tighten the fuel filter approx. 3/4 by hand after the O-ring contacts the priming pump.

End Of Sie

FUEL WARMER INSPECTIONA6E401234802203For Cold Areas

1. Remove the fuel warmer. (See F2–51 FUEL FILTER COMPONENT DISASSEMBLY/ASSEMBLY.)

2. Verify that the resistance between terminal A and

the fuel warmer body is within the specification

when vacuum of –31.3— –38.0 kPa {–235— –

285 mmHg, –9.2— –11.2 inHg} is applied to port

A of the fuel warmer.

•If as specified, carry out the “Circuit Open/

Short Inspection”.

•If not as specified, replace the fuel warmer.

Specification

Circuit Open/Short Inspection

1. Inspect for open/short circuit in the following

wiring harnesses.

•If there is open/short circuit, repair or replace

wiring harnesses.

Open circuit

•If there is no continuity, the circuit is open. Repair

or replace the harness.

—Fuel warmer terminal A (harness-side) and

GND

—Fuel warmer terminal B (harness-side) and

power supply

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Fuel warmer terminal B (harness-side) and GND

End Of Sie

1 Connector

2 Fuel hose

3 Priming pump

4Fuel filter

(See F2–51 Fuel Filter Installation Note)

5Sedimentor switch

(See F2–51 Sedimentor Switch Installation Note)

6 Drain plug

7 Fuel warmer

R

17.6—26.5

{1.8—2.7,

13.0—19.8}

7

5

4

3

6

1

2

N.m {kgf·m, ft·lbf}

A6E40122036

Ambient temperature (°C {°F}) Resistance (ohms)

20 {68} 0.5—1.5

FUEL WARMER

B

A6E40122013

A B FUEL WARMER

HARNESS SIDE CONNECTOR

A6E40122014

Page 204 of 909

F2–52

FUEL SYSTEM

SEDIMENTOR WATER DRAININGA6E4012348022041. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Loosen the drain plug located at the bottom of the fuel filter.

4. Pump the priming pump and drain the water.

5. After all the water has been drained, tighten the drain plug.

6. Complete the “AFTER REPAIR PROCEDURE”. (See F2–45 AFTER REPAIR PROCEDURE.)

7. Reconnect the negative battery cable.

End Of Sie

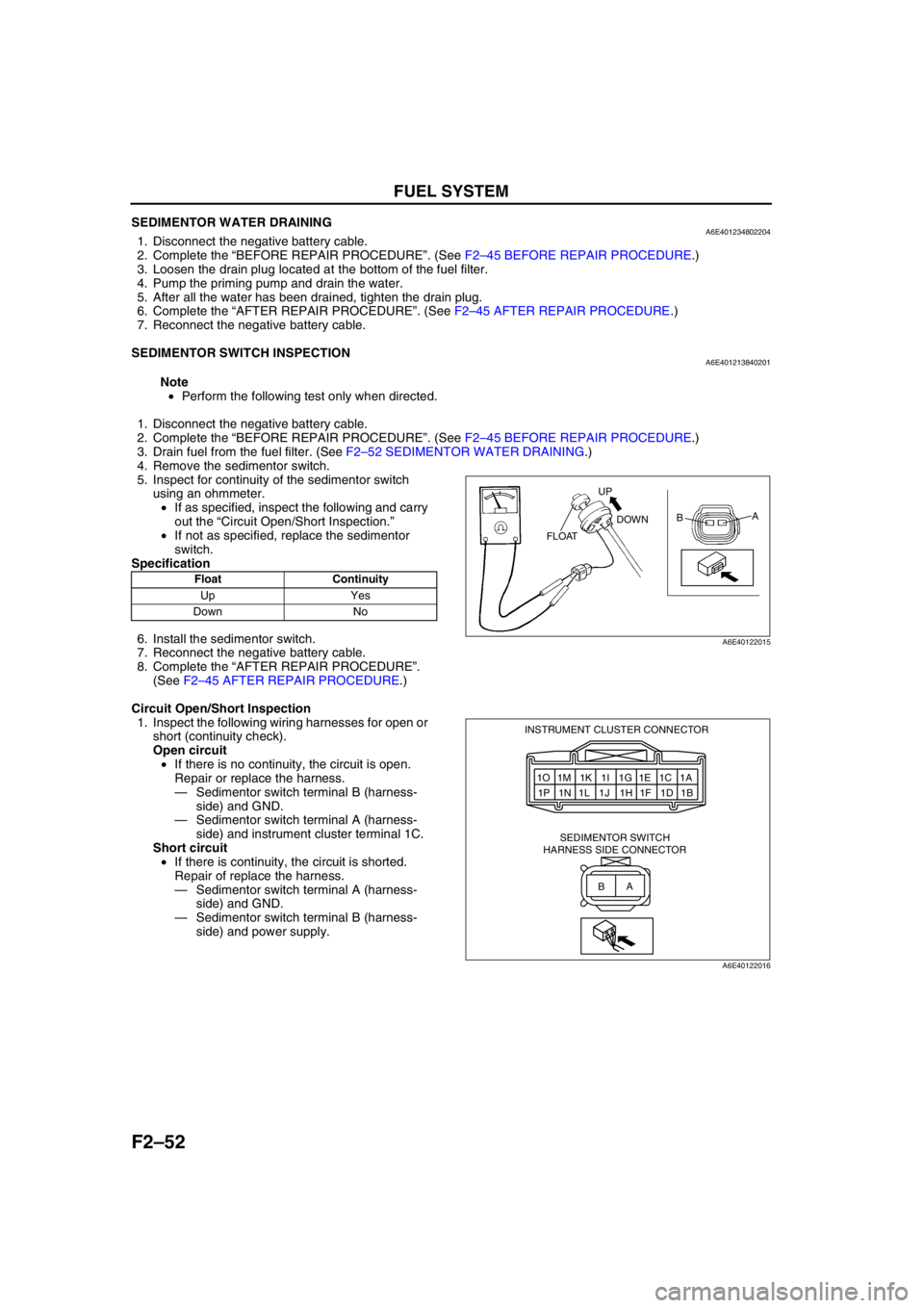

SEDIMENTOR SWITCH INSPECTIONA6E401213840201

Note

•Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Drain fuel from the fuel filter. (See F2–52 SEDIMENTOR WATER DRAINING.)

4. Remove the sedimentor switch.

5. Inspect for continuity of the sedimentor switch

using an ohmmeter.

•If as specified, inspect the following and carry

out the “Circuit Open/Short Inspection.”

•If not as specified, replace the sedimentor

switch.

Specification

6. Install the sedimentor switch.

7. Reconnect the negative battery cable.

8. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

Circuit Open/Short Inspection

1. Inspect the following wiring harnesses for open or

short (continuity check).

Open circuit

•If there is no continuity, the circuit is open.

Repair or replace the harness.

—Sedimentor switch terminal B (harness-

side) and GND.

—Sedimentor switch terminal A (harness-

side) and instrument cluster terminal 1C.

Short circuit

•If there is continuity, the circuit is shorted.

Repair of replace the harness.

—Sedimentor switch terminal A (harness-

side) and GND.

—Sedimentor switch terminal B (harness-

side) and power supply.

End Of Sie

Float Continuity

Up Yes

Down No

UP

DOWN

FLOATA

B

A6E40122015

1O 1M 1K 1I 1G 1E 1C 1A

1P 1N 1L 1J 1H 1F 1D 1B INSTRUMENT CLUSTER CONNECTOR

SEDIMENTOR SWITCH

HARNESS SIDE CONNECTOR

A

B

A6E40122016

Page 205 of 909

FUEL SYSTEM

F2–53

F2

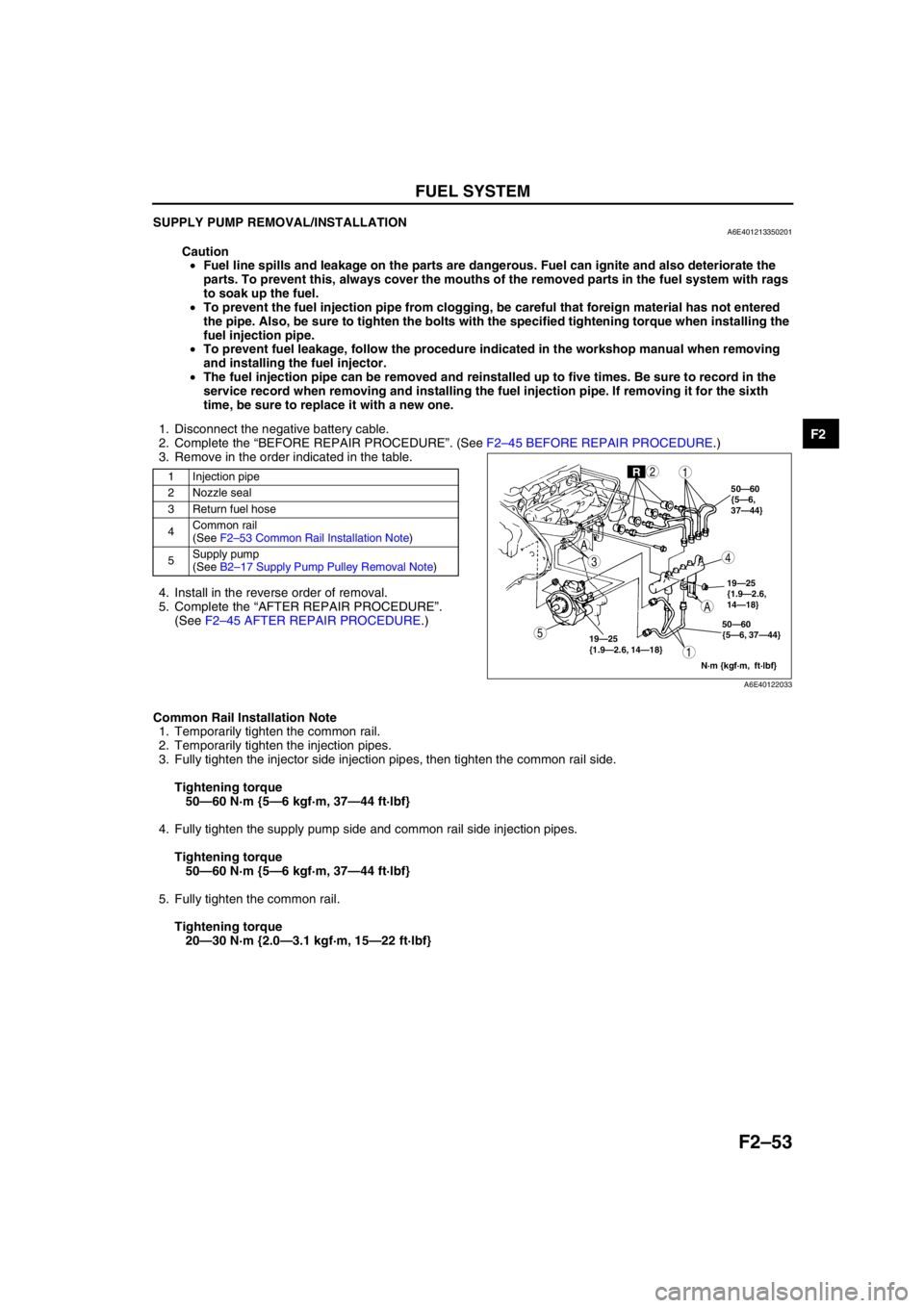

SUPPLY PUMP REMOVAL/INSTALLATIONA6E401213350201

Caution

•Fuel line spills and leakage on the parts are dangerous. Fuel can ignite and also deteriorate the

parts. To prevent this, always cover the mouths of the removed parts in the fuel system with rags

to soak up the fuel.

•To prevent the fuel injection pipe from clogging, be careful that foreign material has not entered

the pipe. Also, be sure to tighten the bolts with the specified tightening torque when installing the

fuel injection pipe.

•To prevent fuel leakage, follow the procedure indicated in the workshop manual when removing

and installing the fuel injector.

•The fuel injection pipe can be removed and reinstalled up to five times. Be sure to record in the

service record when removing and installing the fuel injection pipe. If removing it for the sixth

time, be sure to replace it with a new one.

1. Disconnect the negative battery cable.

2. Complete the “BEFORE REPAIR PROCEDURE”. (See F2–45 BEFORE REPAIR PROCEDURE.)

3. Remove in the order indicated in the table.

.

4. Install in the reverse order of removal.

5. Complete the “AFTER REPAIR PROCEDURE”.

(See F2–45 AFTER REPAIR PROCEDURE.)

Common Rail Installation Note

1. Temporarily tighten the common rail.

2. Temporarily tighten the injection pipes.

3. Fully tighten the injector side injection pipes, then tighten the common rail side.

Tightening torque

50—60 N·m {5—6 kgf·m, 37—44 ft·lbf}

4. Fully tighten the supply pump side and common rail side injection pipes.

Tightening torque

50—60 N·m {5—6 kgf·m, 37—44 ft·lbf}

5. Fully tighten the common rail.

Tightening torque

20—30 N·m {2.0—3.1 kgf·m, 15—22 ft·lbf}

End Of Sie

1 Injection pipe

2 Nozzle seal

3 Return fuel hose

4Common rail

(See F2–53 Common Rail Installation Note)

5Supply pump

(See B2–17 Supply Pump Pulley Removal Note)

19—25

{1.9—2.6, 14—18}19—25

{1.9—2.6,

14—18} 50—60

{5—6,

37—44}

50—60

{5—6, 37—44}

N·m {kgf·m, ft·lbf}

A

R

A

5

43

12

1

A6E40122033

Page 206 of 909

F2–54

FUEL SYSTEM

SUPPLY PUMP INSPECTIONA6E401213350202

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if any of the following supply pump parts

are possibly malfunctioning.

1. Supply pump inner parts

2. Suction control valve

3. Fuel temperature sensor

End Of Sie

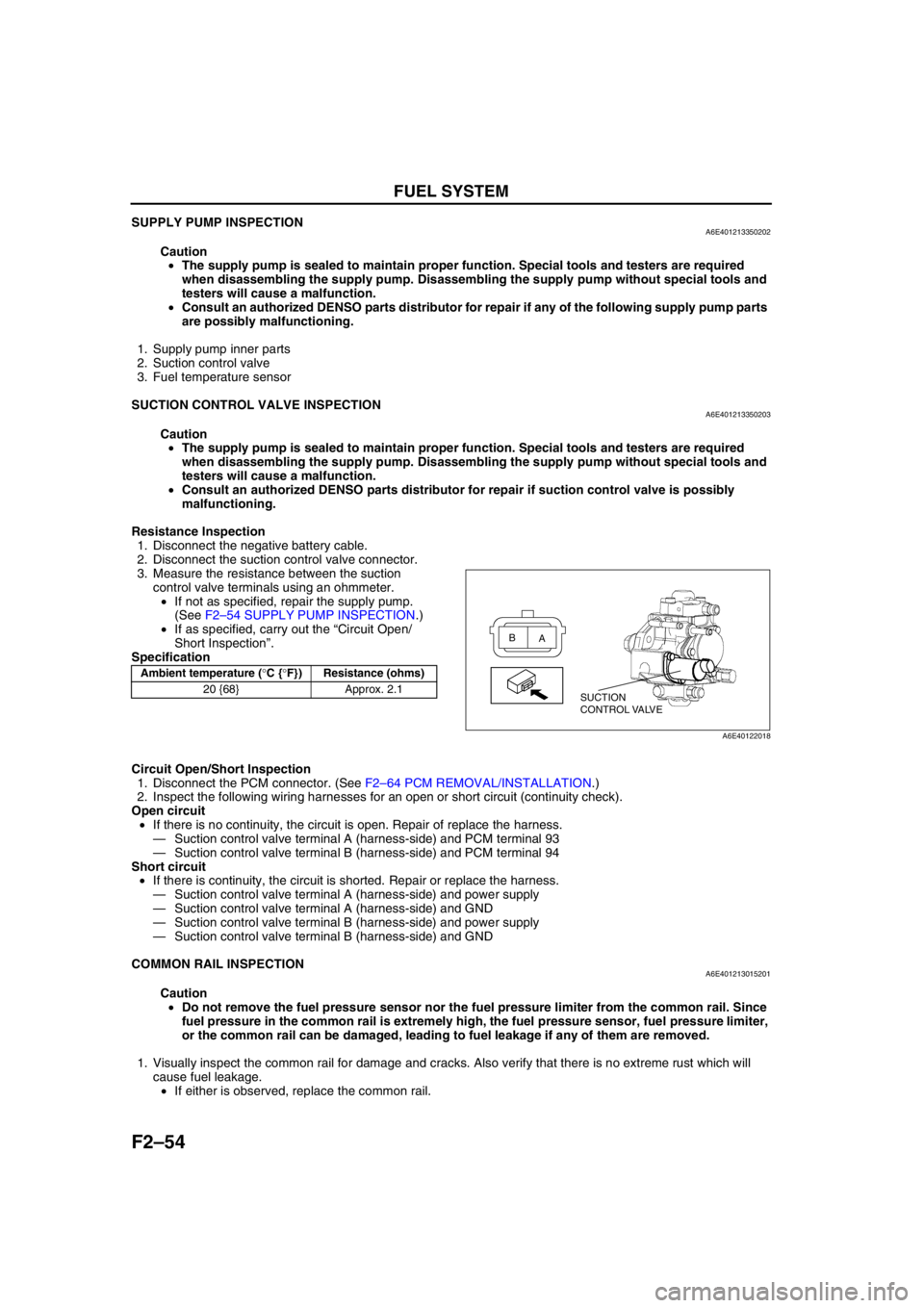

SUCTION CONTROL VALVE INSPECTIONA6E401213350203

Caution

•The supply pump is sealed to maintain proper function. Special tools and testers are required

when disassembling the supply pump. Disassembling the supply pump without special tools and

testers will cause a malfunction.

•Consult an authorized DENSO parts distributor for repair if suction control valve is possibly

malfunctioning.

Resistance Inspection

1. Disconnect the negative battery cable.

2. Disconnect the suction control valve connector.

3. Measure the resistance between the suction

control valve terminals using an ohmmeter.

•If not as specified, repair the supply pump.

(See F2–54 SUPPLY PUMP INSPECTION.)

•If as specified, carry out the “Circuit Open/

Short Inspection”.

Specification

Circuit Open/Short Inspection

1. Disconnect the PCM connector. (See F2–64 PCM REMOVAL/INSTALLATION.)

2. Inspect the following wiring harnesses for an open or short circuit (continuity check).

Open circuit

•If there is no continuity, the circuit is open. Repair of replace the harness.

—Suction control valve terminal A (harness-side) and PCM terminal 93

—Suction control valve terminal B (harness-side) and PCM terminal 94

Short circuit

•If there is continuity, the circuit is shorted. Repair or replace the harness.

—Suction control valve terminal A (harness-side) and power supply

—Suction control valve terminal A (harness-side) and GND

—Suction control valve terminal B (harness-side) and power supply

—Suction control valve terminal B (harness-side) and GND

End Of Sie

COMMON RAIL INSPECTIONA6E401213015201

Caution

•Do not remove the fuel pressure sensor nor the fuel pressure limiter from the common rail. Since

fuel pressure in the common rail is extremely high, the fuel pressure sensor, fuel pressure limiter,

or the common rail can be damaged, leading to fuel leakage if any of them are removed.

1. Visually inspect the common rail for damage and cracks. Also verify that there is no extreme rust which will

cause fuel leakage.

•If either is observed, replace the common rail.

End Of Sie

Ambient temperature (°C {°F}) Resistance (ohms)

20 {68} Approx. 2.1

SUCTION

CONTROL VALVE A B

A6E40122018