ignition MAZDA 6 2002 Suplement Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 612 of 909

TROUBLESHOOTING

K2–197

K2

End Of SieNO.18 EXCESSIVE SHIFT SHOCK IS GIVEN WHEN UPSHIFTING AND DOWNSHIFTINGA6E578001030221

End Of SieNO.19 EXCESSIVE SHIFT SHOCK ON TORQUE CONVERTER CLUTCH (TCC)A6E578001030222

End Of Sie

3•Is line pressure okay?

(See K2–72 Line Pressure Test.)Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

4•Is stall speed okay?

(See K2–74 Stall Speed Test.)Yes Go to next step.

No Go to Step 6.

5•Inspect TR switch and related harness:

vibration, intermittent open/short circuit.

•Is it okay?Yes Go to next step.

No Repair or replace part if necessary.

6•Stop engine and turn ignition switch on.

•Inspect pressure control solenoid circuit.

•Is it okay?Yes•Overhaul control valve body and repair or replace any

defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No•Inspect for pressure control solenoid mechanical stuck.

(See K2–88 SOLENOID VALVE INSPECTION.)

7•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM. STEP INSPECTION ACTION

18 Excessive shift shock is given when upshifting and downshifting

DESCRIPTION•Excessive shift shock felt when depressing accelerator pedal to accelerate at upshifting.

•During cruising, excessive shift shock felt when depressing accelerator pedal at downshifting.

POSSIBLE

CAUSE•Shift shock may worsen when fail-safe is operating. The shift shock has worsen if TP sensor, input/

turbine speed sensor, or VSS signal malfunctions.

—Clutch slipped, burned

•Line pressure low, high

•Incorrect throttle position signal

•Malfunction of VSS

•Malfunction of input/turbine speed sensor

•Malfunction of TFT sensor

•Malfunction of shift solenoid A, B, or C

•Malfunction of TCC solenoid valve

•Misadjustment of throttle cable

•Malfunction of body ground and sensor ground

•Malfunction of control valve body

—Poor hydraulic operation (Malfunction in range change)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

19 Excessive shift shock on torque converter clutch (TCC)

DESCRIPTION•Strong shock felt when TCC engaged.

POSSIBLE

CAUSE•The troubleshooting flow is the same as No.16 “Judder upon torque converter clutch (TCC) operation”.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

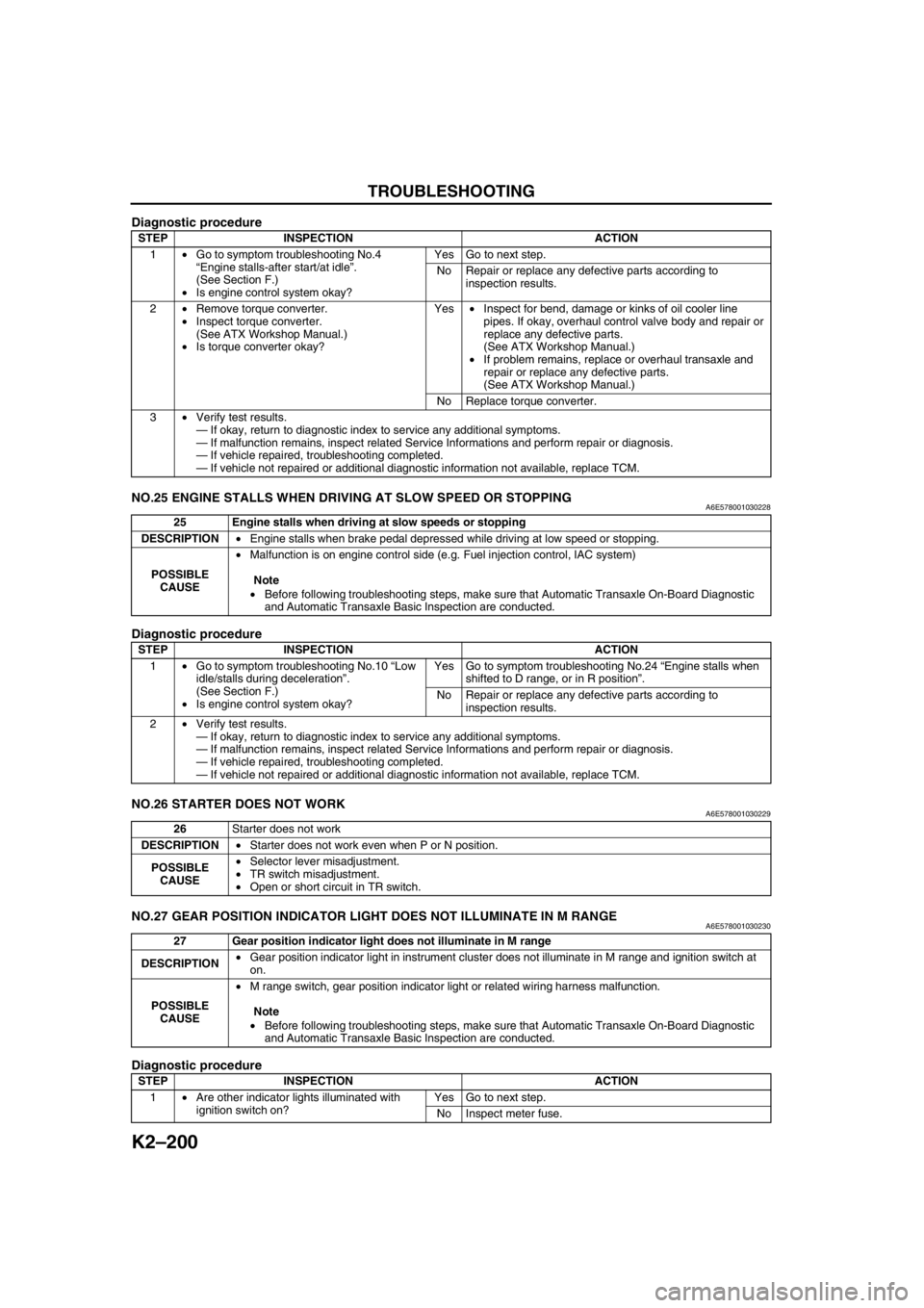

Page 615 of 909

K2–200

TROUBLESHOOTING

Diagnostic procedure

End Of SieNO.25 ENGINE STALLS WHEN DRIVING AT SLOW SPEED OR STOPPINGA6E578001030228

Diagnostic procedure

End Of SieNO.26 STARTER DOES NOT WORKA6E578001030229

End Of SieNO.27 GEAR POSITION INDICATOR LIGHT DOES NOT ILLUMINATE IN M RANGEA6E578001030230

Diagnostic procedure

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.4

“Engine stalls-after start/at idle”.

(See Section F.)

•Is engine control system okay?Yes Go to next step.

No Repair or replace any defective parts according to

inspection results.

2•Remove torque converter.

•Inspect torque converter.

(See ATX Workshop Manual.)

•Is torque converter okay?Yes•Inspect for bend, damage or kinks of oil cooler line

pipes. If okay, overhaul control valve body and repair or

replace any defective parts.

(See ATX Workshop Manual.)

•If problem remains, replace or overhaul transaxle and

repair or replace any defective parts.

(See ATX Workshop Manual.)

No Replace torque converter.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

25 Engine stalls when driving at slow speeds or stopping

DESCRIPTION•Engine stalls when brake pedal depressed while driving at low speed or stopping.

POSSIBLE

CAUSE•Malfunction is on engine control side (e.g. Fuel injection control, IAC system)

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Go to symptom troubleshooting No.10 “Low

idle/stalls during deceleration”.

(See Section F.)

•Is engine control system okay?Yes Go to symptom troubleshooting No.24 “Engine stalls when

shifted to D range, or in R position”.

No Repair or replace any defective parts according to

inspection results.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

26Starter does not work

DESCRIPTION•Starter does not work even when P or N position.

POSSIBLE

CAUSE•Selector lever misadjustment.

•TR switch misadjustment.

•Open or short circuit in TR switch.

27 Gear position indicator light does not illuminate in M range

DESCRIPTION•Gear position indicator light in instrument cluster does not illuminate in M range and ignition switch at

on.

POSSIBLE

CAUSE•M range switch, gear position indicator light or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Are other indicator lights illuminated with

ignition switch on? Yes Go to next step.

No Inspect meter fuse.

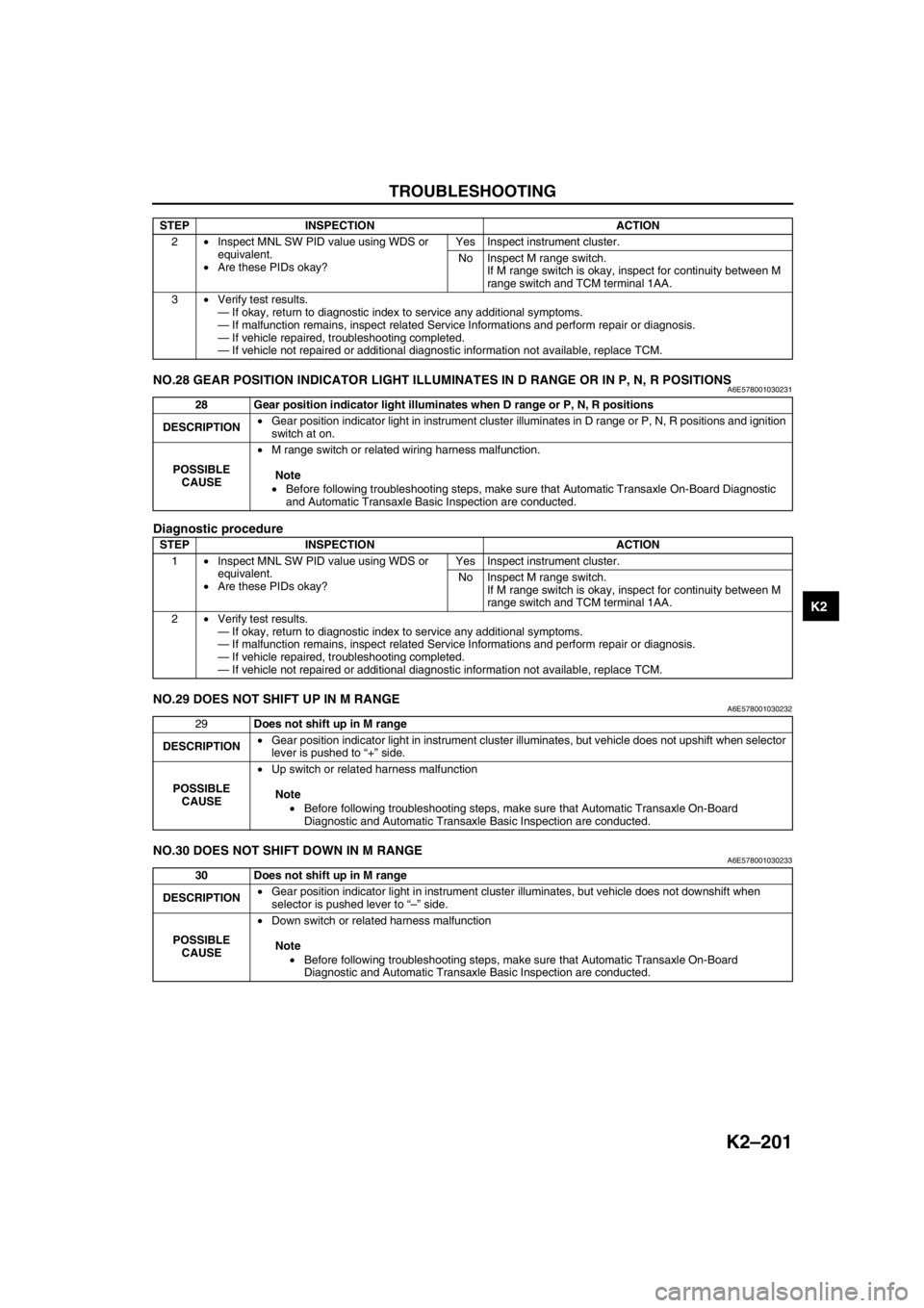

Page 616 of 909

TROUBLESHOOTING

K2–201

K2

End Of SieNO.28 GEAR POSITION INDICATOR LIGHT ILLUMINATES IN D RANGE OR IN P, N, R POSITIONSA6E578001030231

Diagnostic procedure

End Of SieNO.29 DOES NOT SHIFT UP IN M RANGEA6E578001030232

End Of SieNO.30 DOES NOT SHIFT DOWN IN M RANGEA6E578001030233

End Of Sie

2•Inspect MNL SW PID value using WDS or

equivalent.

•Are these PIDs okay?Yes Inspect instrument cluster.

No Inspect M range switch.

If M range switch is okay, inspect for continuity between M

range switch and TCM terminal 1AA.

3•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM. STEP INSPECTION ACTION

28 Gear position indicator light illuminates when D range or P, N, R positions

DESCRIPTION•Gear position indicator light in instrument cluster illuminates in D range or P, N, R positions and ignition

switch at on.

POSSIBLE

CAUSE•M range switch or related wiring harness malfunction.

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board Diagnostic

and Automatic Transaxle Basic Inspection are conducted.

STEP INSPECTION ACTION

1•Inspect MNL SW PID value using WDS or

equivalent.

•Are these PIDs okay?Yes Inspect instrument cluster.

No Inspect M range switch.

If M range switch is okay, inspect for continuity between M

range switch and TCM terminal 1AA.

2•Verify test results.

—If okay, return to diagnostic index to service any additional symptoms.

—If malfunction remains, inspect related Service Informations and perform repair or diagnosis.

—If vehicle repaired, troubleshooting completed.

—If vehicle not repaired or additional diagnostic information not available, replace TCM.

29Does not shift up in M range

DESCRIPTION•Gear position indicator light in instrument cluster illuminates, but vehicle does not upshift when selector

lever is pushed to “+” side.

POSSIBLE

CAUSE•Up switch or related harness malfunction

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board

Diagnostic and Automatic Transaxle Basic Inspection are conducted.

30 Does not shift up in M range

DESCRIPTION•Gear position indicator light in instrument cluster illuminates, but vehicle does not downshift when

selector is pushed lever to “–” side.

POSSIBLE

CAUSE•Down switch or related harness malfunction

Note

•Before following troubleshooting steps, make sure that Automatic Transaxle On-Board

Diagnostic and Automatic Transaxle Basic Inspection are conducted.

Page 638 of 909

M–8

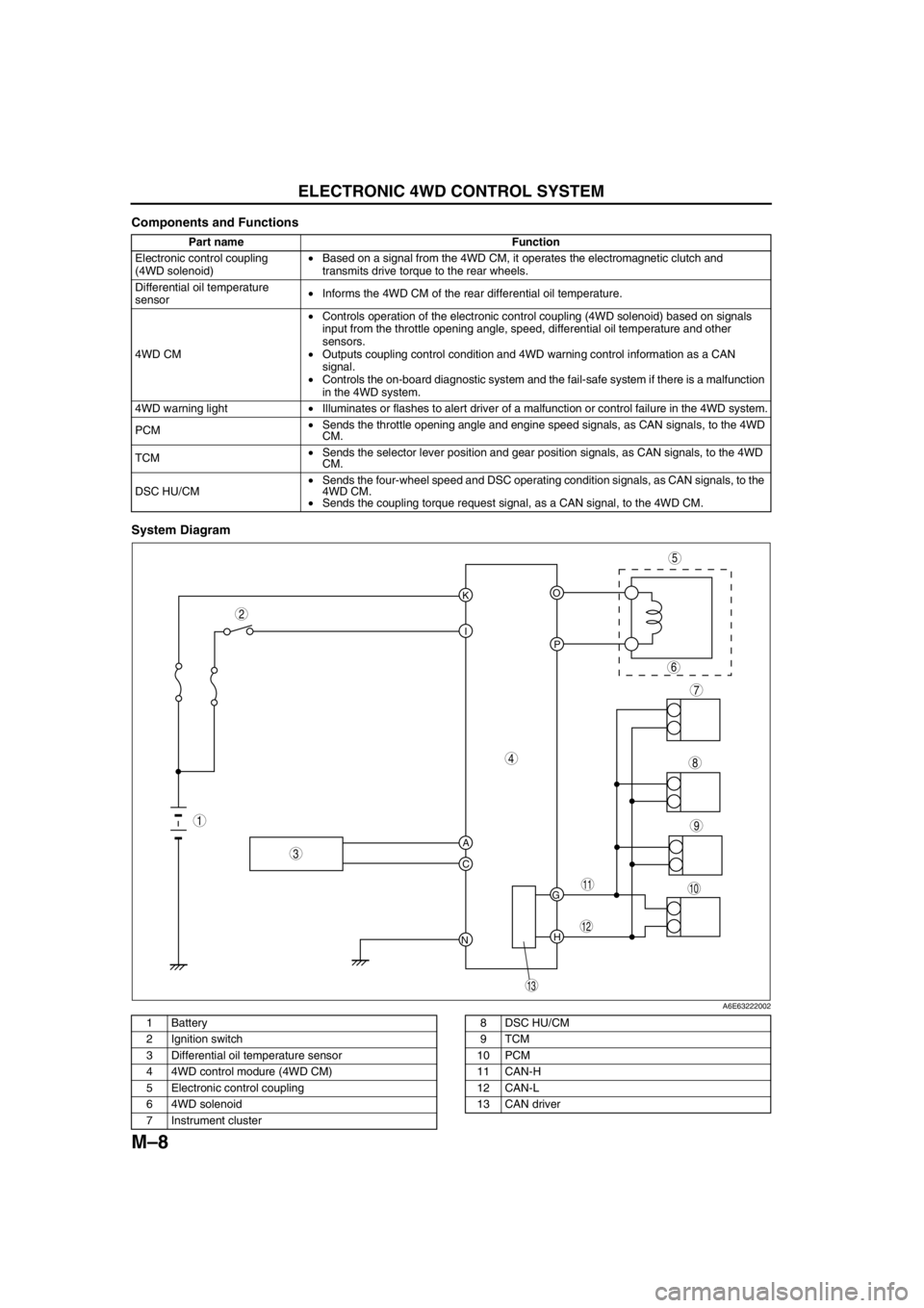

ELECTRONIC 4WD CONTROL SYSTEM

Components and Functions

System Diagram

.

Part name Function

Electronic control coupling

(4WD solenoid)•Based on a signal from the 4WD CM, it operates the electromagnetic clutch and

transmits drive torque to the rear wheels.

Differential oil temperature

sensor•Informs the 4WD CM of the rear differential oil temperature.

4WD CM•Controls operation of the electronic control coupling (4WD solenoid) based on signals

input from the throttle opening angle, speed, differential oil temperature and other

sensors.

•Outputs coupling control condition and 4WD warning control information as a CAN

signal.

•Controls the on-board diagnostic system and the fail-safe system if there is a malfunction

in the 4WD system.

4WD warning light•Illuminates or flashes to alert driver of a malfunction or control failure in the 4WD system.

PCM•Sends the throttle opening angle and engine speed signals, as CAN signals, to the 4WD

CM.

TCM•Sends the selector lever position and gear position signals, as CAN signals, to the 4WD

CM.

DSC HU/CM•Sends the four-wheel speed and DSC operating condition signals, as CAN signals, to the

4WD CM.

•Sends the coupling torque request signal, as a CAN signal, to the 4WD CM.

KO

P I

A

C

NH G

9

8

7

5

4

3

10

13

11

12

6

1

2

A6E63222002

1 Battery

2 Ignition switch

3 Differential oil temperature sensor

4 4WD control modure (4WD CM)

5 Electronic control coupling

6 4WD solenoid

7 Instrument cluster8 DSC HU/CM

9TCM

10 PCM

11 CAN-H

12 CAN-L

13 CAN driver

Page 646 of 909

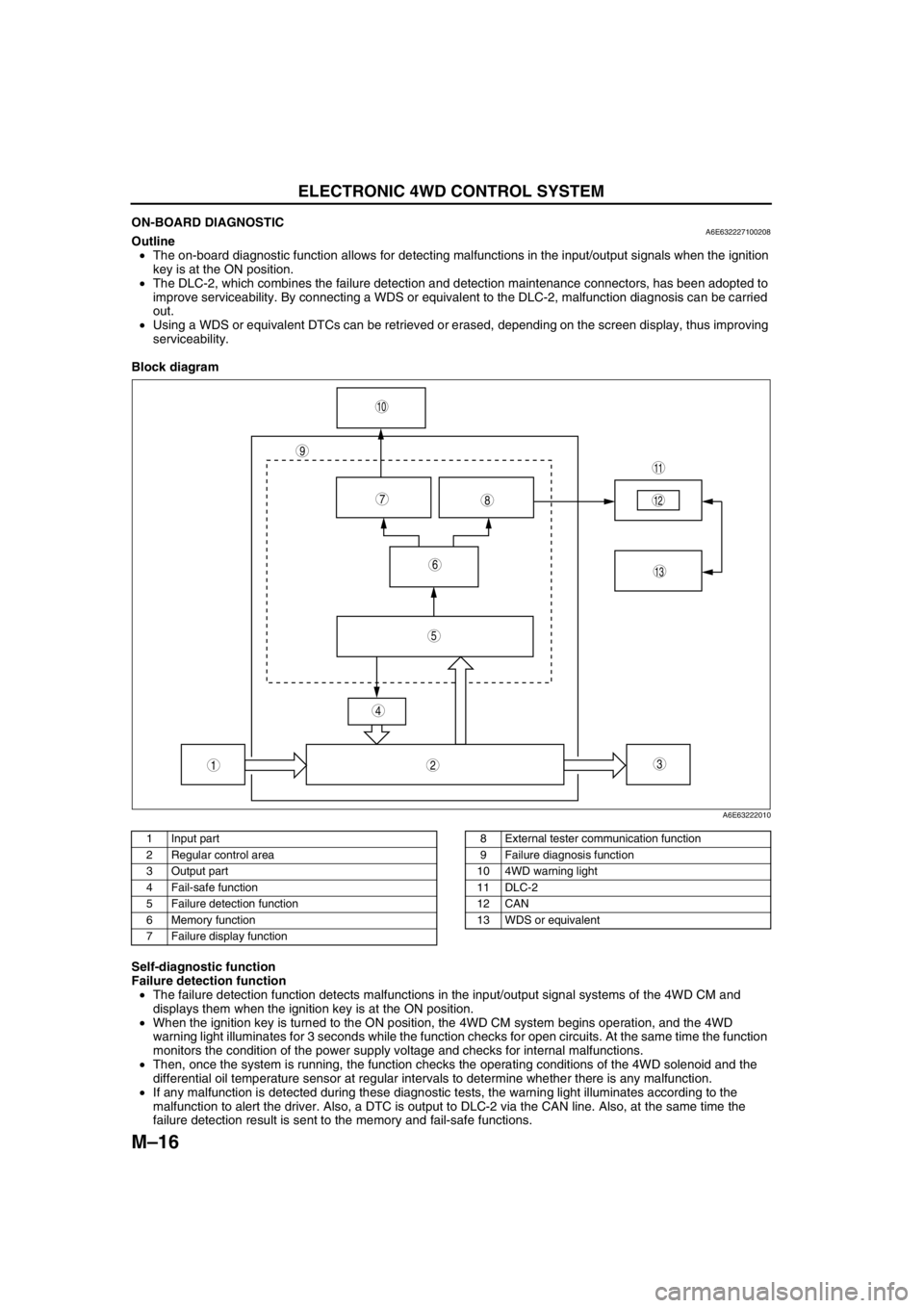

M–16

ELECTRONIC 4WD CONTROL SYSTEM

ON-BOARD DIAGNOSTICA6E632227100208Outline

•The on-board diagnostic function allows for detecting malfunctions in the input/output signals when the ignition

key is at the ON position.

•The DLC-2, which combines the failure detection and detection maintenance connectors, has been adopted to

improve serviceability. By connecting a WDS or equivalent to the DLC-2, malfunction diagnosis can be carried

out.

•Using a WDS or equivalent DTCs can be retrieved or erased, depending on the screen display, thus improving

serviceability.

Block diagram

.

Self-diagnostic function

Failure detection function

•The failure detection function detects malfunctions in the input/output signal systems of the 4WD CM and

displays them when the ignition key is at the ON position.

•When the ignition key is turned to the ON position, the 4WD CM system begins operation, and the 4WD

warning light illuminates for 3 seconds while the function checks for open circuits. At the same time the function

monitors the condition of the power supply voltage and checks for internal malfunctions.

•Then, once the system is running, the function checks the operating conditions of the 4WD solenoid and the

differential oil temperature sensor at regular intervals to determine whether there is any malfunction.

•If any malfunction is detected during these diagnostic tests, the warning light illuminates according to the

malfunction to alert the driver. Also, a DTC is output to DLC-2 via the CAN line. Also, at the same time the

failure detection result is sent to the memory and fail-safe functions.

9

87

5

4

3

10

13

11

12

6

12

A6E63222010

1 Input part

2 Regular control area

3 Output part

4 Fail-safe function

5 Failure detection function

6 Memory function

7 Failure display function8 External tester communication function

9 Failure diagnosis function

10 4WD warning light

11 DLC-2

12 CAN

13 WDS or equivalent

Page 647 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–17

M

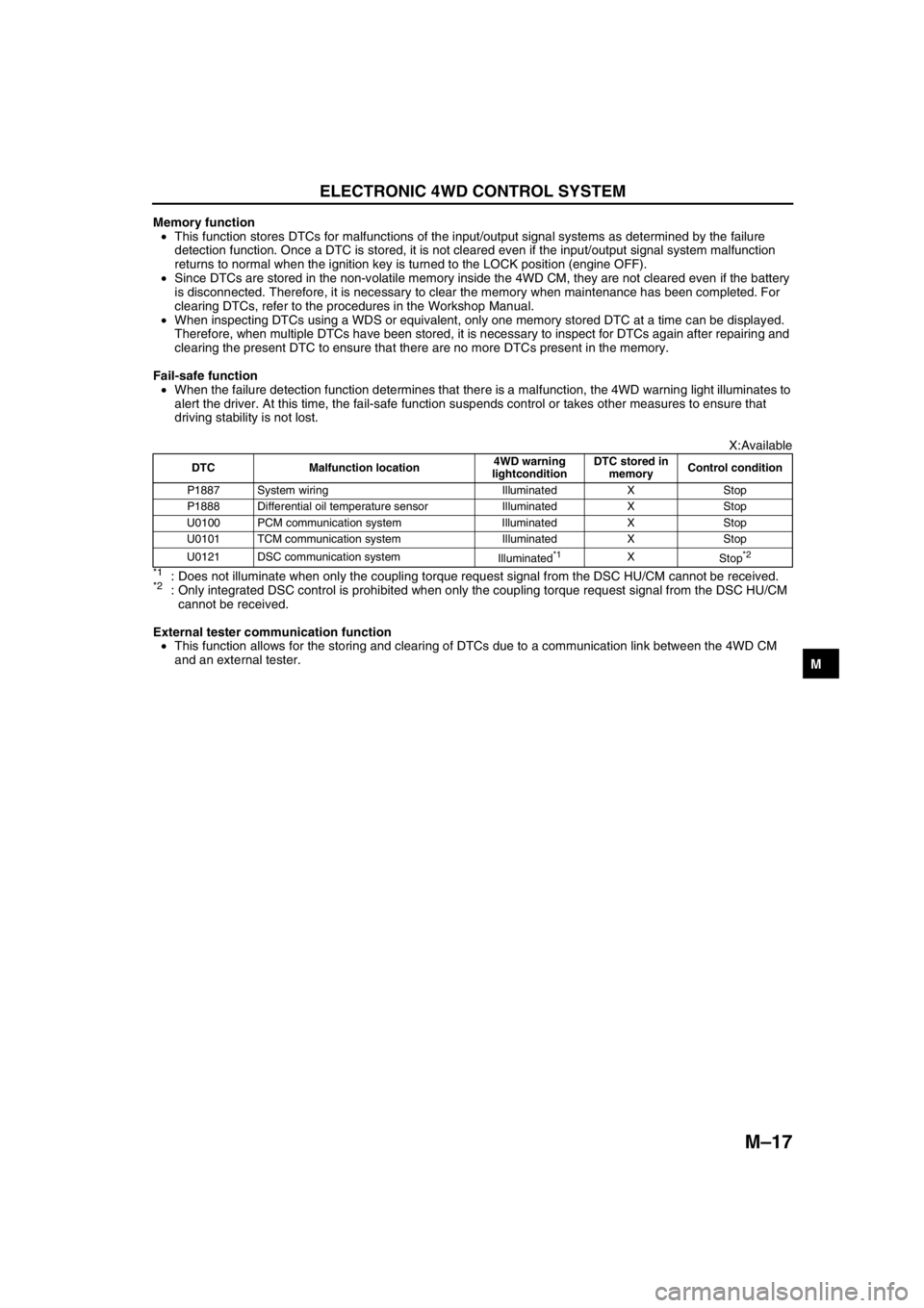

Memory function

•This function stores DTCs for malfunctions of the input/output signal systems as determined by the failure

detection function. Once a DTC is stored, it is not cleared even if the input/output signal system malfunction

returns to normal when the ignition key is turned to the LOCK position (engine OFF).

•Since DTCs are stored in the non-volatile memory inside the 4WD CM, they are not cleared even if the battery

is disconnected. Therefore, it is necessary to clear the memory when maintenance has been completed. For

clearing DTCs, refer to the procedures in the Workshop Manual.

•When inspecting DTCs using a WDS or equivalent, only one memory stored DTC at a time can be displayed.

Therefore, when multiple DTCs have been stored, it is necessary to inspect for DTCs again after repairing and

clearing the present DTC to ensure that there are no more DTCs present in the memory.

Fail-safe function

•When the failure detection function determines that there is a malfunction, the 4WD warning light illuminates to

alert the driver. At this time, the fail-safe function suspends control or takes other measures to ensure that

driving stability is not lost.

X:Available

*1: Does not illuminate when only the coupling torque request signal from the DSC HU/CM cannot be received.*2: Only integrated DSC control is prohibited when only the coupling torque request signal from the DSC HU/CM

cannot be received.

External tester communication function

•This function allows for the storing and clearing of DTCs due to a communication link between the 4WD CM

and an external tester.

End Of Sie

DTC Malfunction location4WD warning

lightconditionDTC stored in

memoryControl condition

P1887 System wiring Illuminated X Stop

P1888 Differential oil temperature sensor Illuminated X Stop

U0100 PCM communication system Illuminated X Stop

U0101 TCM communication system Illuminated X Stop

U0121 DSC communication system

Illuminated

*1X

Stop*2

Page 696 of 909

M–66

ELECTRONIC 4WD CONTROL SYSTEM

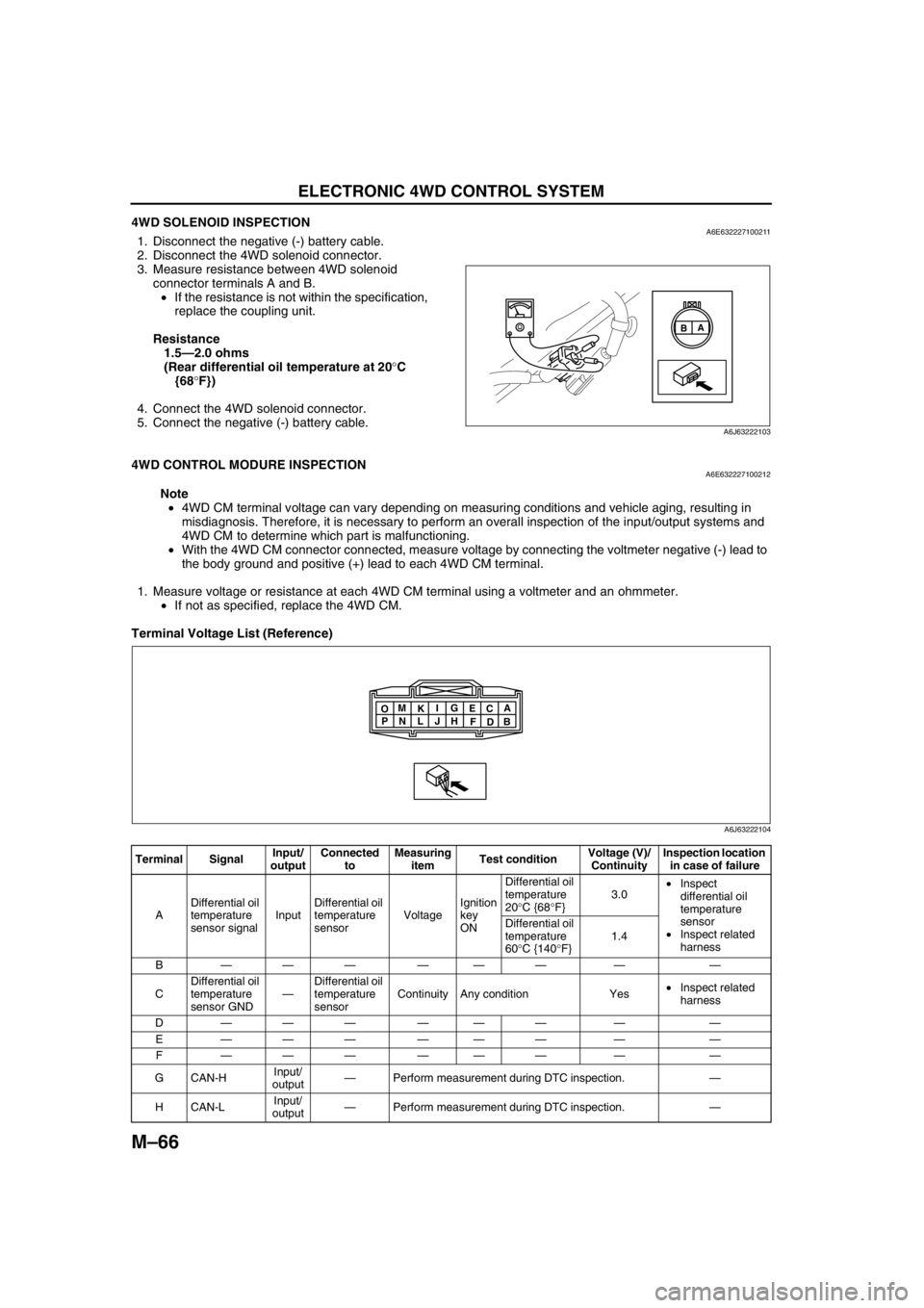

4WD SOLENOID INSPECTIONA6E6322271002111. Disconnect the negative (-) battery cable.

2. Disconnect the 4WD solenoid connector.

3. Measure resistance between 4WD solenoid

connector terminals A and B.

•If the resistance is not within the specification,

replace the coupling unit.

Resistance

1.5—2.0 ohms

(Rear differential oil temperature at 20°C

{68°F})

4. Connect the 4WD solenoid connector.

5. Connect the negative (-) battery cable.

End Of Sie

4WD CONTROL MODURE INSPECTIONA6E632227100212

Note

•4WD CM terminal voltage can vary depending on measuring conditions and vehicle aging, resulting in

misdiagnosis. Therefore, it is necessary to perform an overall inspection of the input/output systems and

4WD CM to determine which part is malfunctioning.

•With the 4WD CM connector connected, measure voltage by connecting the voltmeter negative (-) lead to

the body ground and positive (+) lead to each 4WD CM terminal.

1. Measure voltage or resistance at each 4WD CM terminal using a voltmeter and an ohmmeter.

•If not as specified, replace the 4WD CM.

Terminal Voltage List (Reference)

A

B

A6J63222103

Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

ADifferential oil

temperature

sensor signalInputDifferential oil

temperature

sensorVoltageIgnition

key

ONDifferential oil

temperature

20°C {68°F}3.0•Inspect

differential oil

temperature

sensor

•Inspect related

harness Differential oil

temperature

60°C {140°F}1.4

B——— ——— — —

CDifferential oil

temperature

sensor GND—Differential oil

temperature

sensorContinuity Any condition Yes•Inspect related

harness

D——— ——— — —

E——— ——— — —

F——— ——— — —

GCAN-HInput/

output—Perform measurement during DTC inspection.—

HCAN-LInput/

output—Perform measurement during DTC inspection.—

A

B C

D E

F G

H I

J K

L M

N O

P

A6J63222104

Page 697 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–67

M

End Of Sie

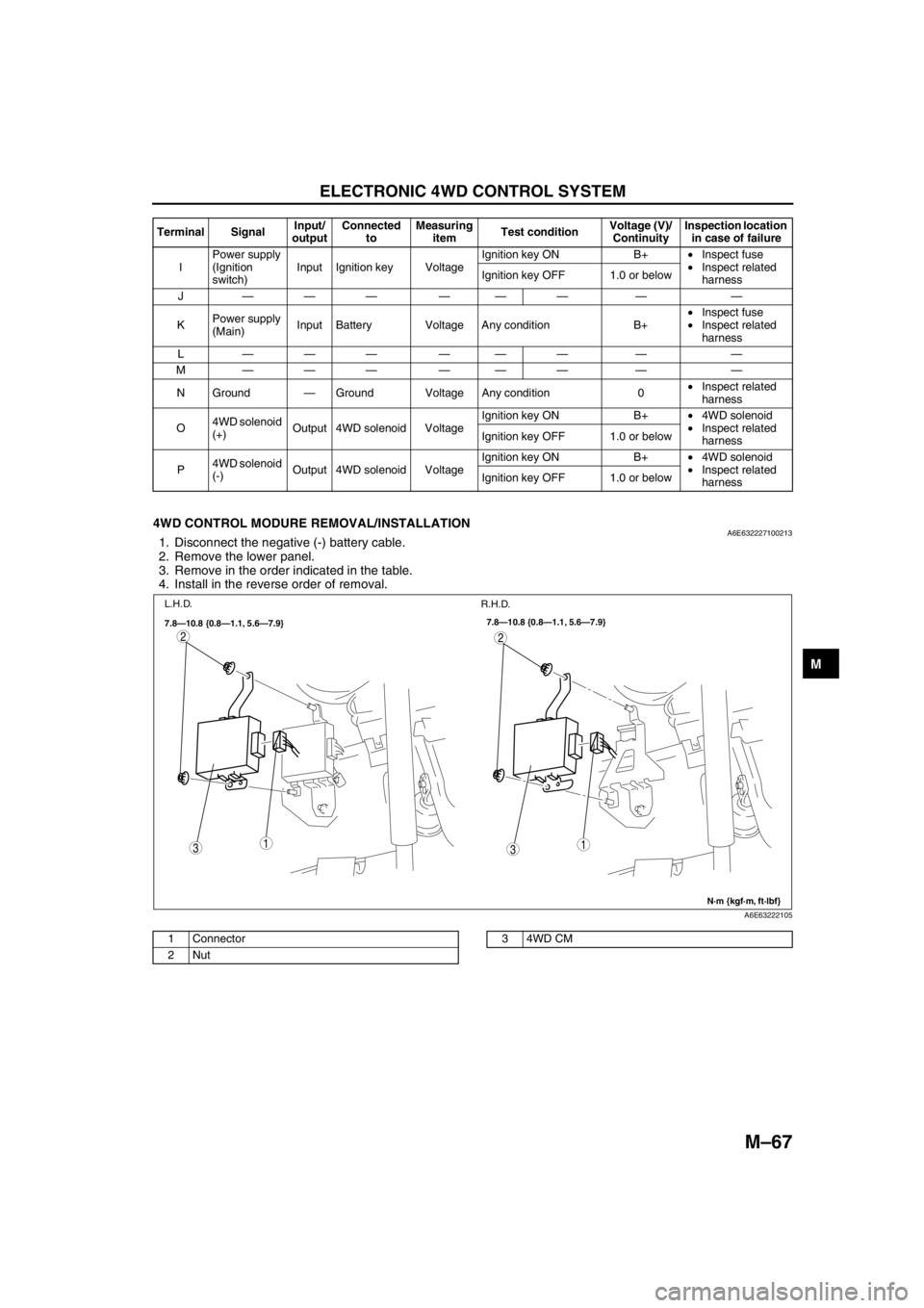

4WD CONTROL MODURE REMOVAL/INSTALLATIONA6E6322271002131. Disconnect the negative (-) battery cable.

2. Remove the lower panel.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

IPower supply

(Ignition

switch)Input Ignition key VoltageIgnition key ON B+•Inspect fuse

•Inspect related

harness Ignition key OFF 1.0 or below

J——— ——— — —

KPower supply

(Main)Input Battery Voltage Any condition B+•Inspect fuse

•Inspect related

harness

L——— ——— — —

M——— ——— — —

N Ground—Ground Voltage Any condition 0•Inspect related

harness

O4WD solenoid

(+)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below

P4WD solenoid

(-)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

31

2

31

2

7.8—10.8 {0.8—1.1, 5.6—7.9}

N·m {kgf·m, ft·lbf} 7.8—10.8 {0.8—1.1, 5.6—7.9}

L.H.D.

R.H.D.

A6E63222105

1 Connector

2Nut34WD CM

Page 705 of 909

ON-BOARD DIAGNOSTIC

M–75

M

WIRING DIAGRAMA6E637027100201

End Of Sie

ON-BOARD DIAGNOSTIC

IGNITION SWITCH

BATTERY

DIFFERENTIAL OIL

TEMPERATURE

SENSOR4WD CM4WD SOLENOID ELECTRONIC CONTROL

COUPLING

CAN DRIVERINSTRUMENT CLUSTER

CAN-H

CAN-LPCM DSC HU/CM KO

P I

A

C

NH G

TCM

A6E63702002

Page 706 of 909

M–76

ON-BOARD DIAGNOSTIC

ELECTRONIC 4WD CONTROL SYSTEM ON-BOARD DIAGNOSISA6E637027100202Reading DTCs Procedure

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Retrieve DTC by WDS or equivalent.

•If a DTC is displayed, proceed with inspection

steps for that DTC.

3. After repair, clear DTCs stored in the 4WD CM by

referring to the Clearing DTCs Procedure.

Clearing DTCs Procedures

1. Connect WDS or equivalent to the vehicle DLC-2

16-pin connector.

2. Clear DTCs by WDS or equivalent.

3. Turn the ignition key to OFF.

4. Perform the DTC inspection again, and verify that

no DTC appears.

5. Disconnect the WDS or equivalent.

DTC Table

End Of Sie

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DLC-2

DLC-2

L.H.D.

R.H.D.

A6E63702005

DTC

Diagnosis system component Page

WDS or equivalent

P1887 System wiring (See M–77 DTC P1887)

P1888 Differential oil temperature sensor (See M–79 DTC P1888)

U0100 PCM communication (See M–80 DTC U0100)

U0101 TCM communication (See M–80 DTC U0101)

U0121 ABS/DSC communication (See M–80 DTC U0121)